Professional Documents

Culture Documents

Solar Energy For Water Purification - A Historical Perspective!

Uploaded by

Deepak Sahu0 ratings0% found this document useful (0 votes)

17 views6 pagesdeepak

Original Title

13639. deeepak sahu.29.01.2015

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdeepak

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views6 pagesSolar Energy For Water Purification - A Historical Perspective!

Uploaded by

Deepak Sahudeepak

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 6

Solar Energy for Water Purification A Historical Perspective!

Greek navigators used to boil sea water and condense the vapours on

Sponges to produce fresh water

Arab alchemists practiced solar distillation using polished Damascus

concave

Mirrors 1551

Della Porte used wide earthen pots exposed to the most intense heat of

the

Solar rays to evaporate water and collect the condensate drop by drop into

vases placed underneath

Lavoisier used large glass lenses to concentrate solar energy on to the

contents

Of distillation flasks

Charles Wilson, 1872, has designed and erected the first conventional

solar

Distillation apparatus near Las Salinars in Northern Chile to supply fresh

Water to the workers and animals of the nearby nitrate mine. Brackish water

was

Used as feed and interestingly the plant was in operation for 4o years

Subsequently several attempts from all over the world have been

reported

Where in solar energy, a cost free energy source, is used for the process of

Desalination

Process Developed for Desalination of water

A simple, highly reproducible, economical desalination process, where in

the

Unique potential of the solar energy as well as the adsorption capacity of

granular

Activated carbon have been effectively used, has been developed.

Salient Features of the Process:

i. Unique combination of solar energy and the adsorption ability of inexpensive

Activated carbon

ii. Both the solar energy and activated carbon are economically viable options

For producing pure and clean drinking water

iii. After several cycles of desalination process the activated carbon bed

Covered with salt can be washed and the adsorbent can be reused.

iv. In addition, during regeneration of the sorbent, the salts recovered from

Activated carbon serve as a byproduct of several chemicals.

v. The test solution used for desalination experiments (1 M Brine solution,

58 wt. % salinity) is twice as saline as sea water (38 wt. % salinity). Thus the

Process developed will be much more effective for sea water and still more

Efficient for ground water that contains traces of contaminants or impurities.

vi. The apparatus (reactor) is so designed that it is portable, light in weight, easy

to fabricate, handle, carry and operate with simple know-how.

vii. The device designed can be deployed in remote rural areas, sea coasts (for

sea water desalination) and also in disaster relief camps and will be helpful in

situations demanding clean drinking water.

viii.

ix.

Simplicity in operation as no moving parts are involved, modest costs of

installation and operation, use of low temperature and abundantly

available and renewable solar energy for the evaporation of saline water

makes the process and device appealing.

Unlike other distillation based processes, the current process works at

Atmospheric pressure.

x. Can cater effectively to the local decentralized needs of drinking water. Suits

well to Indian climatic conditions.

Description of the Experimental Set up

The experimental set up comprises of a rectangular shaped

Base made of aluminum with a length of 12 and breath of 10.

The metal wall is raised to a height of 4.5 at one end of the

Base (towards the breath direction) and in the exactly opposite

Direction the metal wall is raised to a height of 2.

The door made of glass is fixed on top of the based at a

Height of 4.5 at one end and at a height of 2 at the other

End making an angle of 18 towards the opening end of the

Door.

The two opening ends on the length direction of the base

Are then raised forming a closed reaction vessel made of

Aluminum metal and comprising of glass door.

The reactor (reaction) vessel is made in to two chambers

(Top chamber and bottom chamber) placing a partition at

About 2 length towards the opening end of the reactor.

The top chamber is filled with granular activated carbon and

The bottom chamber is meant for collection of purified water

Obtained by the process of evaporation followed by condensation.

1 M NaCl solution is continuously fed into the reactor at a

Specified flow rate from a brian solution reservoir (500 ml

Polyethylene wash bottle).

The test solution reservoir is connected to the inlet of the

Reactor through rubber tube of suitable diameter and the

Reservoir is placed at a sufficient height allowing free flow of

1 M NaCl solution into the reaction chamber loaded with

activated carbon.

The photographs of the solar energy powered reactor packed

With granular activated carbon are shown.

Granular Activated Carbon used for Desalination Process

You might also like

- Dishwasher Engineering ReportDocument27 pagesDishwasher Engineering ReporttiarnamNo ratings yet

- Solar Water Distillation For Drinking Purposes.: Presented By-: SULAKSHYA GAUR (121684)Document18 pagesSolar Water Distillation For Drinking Purposes.: Presented By-: SULAKSHYA GAUR (121684)Sulakshya GaurNo ratings yet

- Literature ReviewDocument3 pagesLiterature ReviewShravan KumarNo ratings yet

- Y Yy Y Yyyyy Y YyyyyDocument62 pagesY Yy Y Yyyyy Y YyyyyAnkush ChoudharyNo ratings yet

- Non-Conventional Solar Stills With Charcoal Particles As Absorber MediumDocument10 pagesNon-Conventional Solar Stills With Charcoal Particles As Absorber MediumGreen Action Sustainable Technology GroupNo ratings yet

- 2002 A Solar Desalination Plant For Domestic Water Needs in Arid Areas of South AlgeriaDocument5 pages2002 A Solar Desalination Plant For Domestic Water Needs in Arid Areas of South AlgeriaRahul TripathiNo ratings yet

- RRLDocument19 pagesRRLJBSNo ratings yet

- Presentation # 1 Membrane Desalination PDFDocument70 pagesPresentation # 1 Membrane Desalination PDFMahad QaziNo ratings yet

- Water DesalinationDocument19 pagesWater Desalinationravi_patidar_6No ratings yet

- Layout of The StructureDocument5 pagesLayout of The StructureAnonymous Y9dgyXhANo ratings yet

- C14 - The Earth's ResourcesDocument7 pagesC14 - The Earth's ResourcesSahasra BhongirwarNo ratings yet

- Heat Processes For High-Quality DesalinationDocument9 pagesHeat Processes For High-Quality DesalinationIvanaPeranNo ratings yet

- Solar Water Purifier 1Document40 pagesSolar Water Purifier 1Srini0% (1)

- Solar Water Distillation 490A Final ReportDocument45 pagesSolar Water Distillation 490A Final ReportRahul TripathiNo ratings yet

- My Final MathafodiDocument51 pagesMy Final Mathafodiyatharth sharmaNo ratings yet

- Solar Water Purification System: Presented by Rohit Sen (Me)Document17 pagesSolar Water Purification System: Presented by Rohit Sen (Me)Santoshi AgrawalNo ratings yet

- Advances in Seawater Desalination TechnologiesDocument23 pagesAdvances in Seawater Desalination TechnologiesFrank FanNo ratings yet

- Kualitas Air Tawar Yang Dihasilkan Dengan Menggunakan Energi MatahariDocument6 pagesKualitas Air Tawar Yang Dihasilkan Dengan Menggunakan Energi MataharifarahsadaNo ratings yet

- Water Supply Engineering ProjectDocument18 pagesWater Supply Engineering Projectnikita kaliyerNo ratings yet

- Wahlgren 1993 AtmosphericDocument3 pagesWahlgren 1993 Atmosphericzeeshan arifNo ratings yet

- Minor Project PPT SolarDocument21 pagesMinor Project PPT Solarganesh ambiyaNo ratings yet

- Extraction of Freshwater and Energy From AtmosphereDocument14 pagesExtraction of Freshwater and Energy From AtmosphereKate VentilacionNo ratings yet

- Ocean Power: Ed Lemery, Brooke Scatchard, Nate TrachimowiczDocument19 pagesOcean Power: Ed Lemery, Brooke Scatchard, Nate TrachimowiczGanesh Kumar100% (1)

- Solar DesalinationDocument41 pagesSolar DesalinationRahul TripathiNo ratings yet

- 0 AbsDocument2 pages0 AbsSilvers RayleighNo ratings yet

- Centrifugal Sprinkler PDFDocument14 pagesCentrifugal Sprinkler PDFVignesh PanneerselvamNo ratings yet

- Topic 4a - MSF-Process-Jan 2021Document32 pagesTopic 4a - MSF-Process-Jan 2021Bilal AhmedNo ratings yet

- Fabrication of Sea Water DesalinatorDocument44 pagesFabrication of Sea Water DesalinatorvinothNo ratings yet

- The Rajokri Water Body Revitalisation ProjectDocument4 pagesThe Rajokri Water Body Revitalisation ProjectAayush MishraNo ratings yet

- Fabricaton of Solar Water Desalination by Using Photovoltaic MethodDocument43 pagesFabricaton of Solar Water Desalination by Using Photovoltaic MethodvinothNo ratings yet

- Water Requirement in Chemical Process IndustriesDocument145 pagesWater Requirement in Chemical Process IndustriesKAUSTAV ROYNo ratings yet

- Water Pumping and Filtration Design ProjectDocument23 pagesWater Pumping and Filtration Design ProjectShepherd ChoeniNo ratings yet

- The Seabin Sips and Sucks in Water and Rubbish, Which Gets Caught in A Catch Bag FilterDocument3 pagesThe Seabin Sips and Sucks in Water and Rubbish, Which Gets Caught in A Catch Bag FilterMika AyranNo ratings yet

- Design of Multistage Evaporators For Integrating With Scheffler Solar Concentrators For Food Processing ApplicationsDocument6 pagesDesign of Multistage Evaporators For Integrating With Scheffler Solar Concentrators For Food Processing ApplicationsDinakar KrishnaNo ratings yet

- Trends in The Development of Desalination Plants For Use in Ship Energy Installations 2016-2022Document7 pagesTrends in The Development of Desalination Plants For Use in Ship Energy Installations 2016-2022SargeSarioNo ratings yet

- Solar Water Distillation 490A Final Report PDFDocument45 pagesSolar Water Distillation 490A Final Report PDFHamza Heb75% (4)

- Renewable EnergyDocument7 pagesRenewable EnergyGauravGuptaNo ratings yet

- Water Sources by Rey John C. BorjeDocument11 pagesWater Sources by Rey John C. BorjeRey John BorjeNo ratings yet

- SubhDocument10 pagesSubhsunilsubhranshu28No ratings yet

- ABC of DesalinationDocument52 pagesABC of DesalinationMAS98No ratings yet

- 21 Century Phosphoric Acid Plant Designs (Bigger Is Better) : Page 1 of 8Document14 pages21 Century Phosphoric Acid Plant Designs (Bigger Is Better) : Page 1 of 8kaldjdsjkaNo ratings yet

- S.pool Seminar 16.06.14low1Document194 pagesS.pool Seminar 16.06.14low1Miguel Angel100% (1)

- 10 1016@j Renene 2019 01 114Document26 pages10 1016@j Renene 2019 01 114martha veraNo ratings yet

- Building ServicesDocument21 pagesBuilding ServicesdorgbetorkcNo ratings yet

- Thermal Distillation Technology For Management of Produced Water and Frac Flowback WaterDocument12 pagesThermal Distillation Technology For Management of Produced Water and Frac Flowback WaterSebastián Arboleda PalaciosNo ratings yet

- Recrystallization Process For The Upgrading of Rock-And Solar SaltsDocument17 pagesRecrystallization Process For The Upgrading of Rock-And Solar SaltsVirgil CenariuNo ratings yet

- 05 PublicationDocument21 pages05 Publicationrpr013279No ratings yet

- International Journal of Applied Research & Studies ISSN 2278 - 9480Document7 pagesInternational Journal of Applied Research & Studies ISSN 2278 - 9480Kuna KunavathiNo ratings yet

- Solar Water HeaterDocument58 pagesSolar Water HeaterRishav DevkotaNo ratings yet

- Efficiency Analysis of Modified Double Basin Pyramid ShapedDocument4 pagesEfficiency Analysis of Modified Double Basin Pyramid ShapedNancy SoniNo ratings yet

- AJAYDocument26 pagesAJAYNavin Reuben DawsonNo ratings yet

- Ocean Thermal Energy Conversion Tide Current and Tide RangeDocument56 pagesOcean Thermal Energy Conversion Tide Current and Tide RangeSiddharth PatelNo ratings yet

- Abdessemed 2019Document19 pagesAbdessemed 2019adnan bin sultanNo ratings yet

- Evaporation Pond PresentationDocument30 pagesEvaporation Pond PresentationNAHASALI11100% (1)

- Notore grp3Document44 pagesNotore grp3GildaZoe IghorayeNo ratings yet

- The System - Calcium Oxalate - Sulphuric AcidDocument43 pagesThe System - Calcium Oxalate - Sulphuric AcidSebastian MoraNo ratings yet

- Birzeit University Department of Civil Engineering ENCE 411: Seminar in Civil EngineeringDocument9 pagesBirzeit University Department of Civil Engineering ENCE 411: Seminar in Civil EngineeringMahmoudSehweilNo ratings yet

- Local Media8708183453467574327Document4 pagesLocal Media8708183453467574327Alfred Cedrix BornelNo ratings yet

- Fertilizer CalculationDocument8 pagesFertilizer CalculationAmir MohammedNo ratings yet

- Abstraction: Amount of Rainfall That Doesn't Turn Into RunoffDocument8 pagesAbstraction: Amount of Rainfall That Doesn't Turn Into RunoffyomifNo ratings yet

- Pyrometalllurgy ModuleDocument66 pagesPyrometalllurgy ModuleFelix TinasheNo ratings yet

- 1111 - Microbiological Examination of Nonsterile Products - Acceptance Criteria For Pharmaceutical Preparations and Substances For Pharmaceutical UseDocument2 pages1111 - Microbiological Examination of Nonsterile Products - Acceptance Criteria For Pharmaceutical Preparations and Substances For Pharmaceutical UseCarolina MontoyaNo ratings yet

- Sts Study Guide Hatag Nyag Answer UgmaDocument18 pagesSts Study Guide Hatag Nyag Answer UgmaTribunalo, Aliana R.No ratings yet

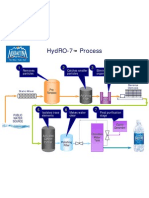

- Aqua Fin A Purification DiagramDocument1 pageAqua Fin A Purification DiagramPEPITOPULNo ratings yet

- Euroklav 29 S: User Manual For The AutoclaveDocument47 pagesEuroklav 29 S: User Manual For The AutoclaveGheorghe OtocNo ratings yet

- General Education Reviewer (PRC)Document44 pagesGeneral Education Reviewer (PRC)Ara HerreraNo ratings yet

- Chapter 1 (Final)Document12 pagesChapter 1 (Final)Nahzel Mae DulayNo ratings yet

- Boiler Log DailyDocument2 pagesBoiler Log DailyAdi Riyanto100% (2)

- Week 1 - Modules 1-3: Earth As The Only Habitable PlanetDocument25 pagesWeek 1 - Modules 1-3: Earth As The Only Habitable PlanetDon't mind meNo ratings yet

- MKL 3 ReportDocument9 pagesMKL 3 ReportMatthew NelsonNo ratings yet

- Hoja de Seguridad 242Document6 pagesHoja de Seguridad 242Gabo TellezNo ratings yet

- G CLIMATE OF PAKISTAN Key PointsDocument11 pagesG CLIMATE OF PAKISTAN Key PointsTalha AfzalNo ratings yet

- Lysergic Acid DiethylamideDocument12 pagesLysergic Acid DiethylamideKyle Ryan100% (1)

- Andritz Separation Fluid Bed Dryer en DataDocument16 pagesAndritz Separation Fluid Bed Dryer en DataElias AyanaNo ratings yet

- CLM Series Steam & Water BoilersDocument4 pagesCLM Series Steam & Water BoilersAlexánder Muñoz FerrerNo ratings yet

- Brief Note & Present Condition of KalangiDocument11 pagesBrief Note & Present Condition of KalangiVenkata KishoreNo ratings yet

- Aquaculture Week1 Module2Document33 pagesAquaculture Week1 Module2Gerald LauglaugNo ratings yet

- Pds Luxathane 5000 VocDocument2 pagesPds Luxathane 5000 Vocmuthukumar100% (1)

- Boiler CommissioningDocument35 pagesBoiler CommissioningNikhil MalhotraNo ratings yet

- Damage Control Column - Stress Corrosion Cracking (SCC) DetectionDocument26 pagesDamage Control Column - Stress Corrosion Cracking (SCC) Detectionjonnie myersNo ratings yet

- Guide To Hot Water Systems Tmvs in Commercial BuildingsDocument2 pagesGuide To Hot Water Systems Tmvs in Commercial BuildingsSteven KeyesNo ratings yet

- Steam Tables - SuperheatedDocument6 pagesSteam Tables - SuperheatedFarouk BassaNo ratings yet

- Ethyl Chloride c2h5cl Safety Data Sheet Sds p4597 PDFDocument9 pagesEthyl Chloride c2h5cl Safety Data Sheet Sds p4597 PDFIstiqomah Asmawati ShafiyahNo ratings yet

- Hydraulic Energy Dissipaters A ReviewDocument3 pagesHydraulic Energy Dissipaters A ReviewPinjis PliersNo ratings yet

- 5 - Paes Part 2 SummaryDocument3 pages5 - Paes Part 2 SummaryCherry Mae Arado CervantesNo ratings yet

- Global WASH KAP Questionnaire 2020Document17 pagesGlobal WASH KAP Questionnaire 2020Younas WisalNo ratings yet

- SM Advocates For Water Security and Conservation Through Sustainable InitiativesDocument2 pagesSM Advocates For Water Security and Conservation Through Sustainable InitiativesANGELA MAE ABADNo ratings yet