Professional Documents

Culture Documents

RO-EP-DMSS-STD-046-01-E Standardization of The Explosion-Proof Protection For Low Voltage Electrical Motors

RO-EP-DMSS-STD-046-01-E Standardization of The Explosion-Proof Protection For Low Voltage Electrical Motors

Uploaded by

agaricusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RO-EP-DMSS-STD-046-01-E Standardization of The Explosion-Proof Protection For Low Voltage Electrical Motors

RO-EP-DMSS-STD-046-01-E Standardization of The Explosion-Proof Protection For Low Voltage Electrical Motors

Uploaded by

agaricusCopyright:

Available Formats

OMV Petrom EP Demand Management

Standard

PETROM

Membru OMV Grup

Title:

STANDARDIZATION

PROTECTION FOR

MOTORS

OF THE EXPLOSION-PROOF

LOW VOLTAGE ELECTRICAL

Objec

tive:

To assure the optimal explosion-proof protection type for low

voltage electrical motors, depending on the operational area

Elaborated by: P-EP-DA DM-SS

Cristian Preda

Checked by:

Nicolae Jugravu

P-EP-PE FE

-EP-DA-DM-SS

Approved by:

Atif Sheikh

P-EP-PE-FE

loan Manea

P-EP-DA-DM

Ion Anyhel

P-EP-DA

Gabriel Selischi

Organizatia

Nume

r

ss.~ile~

jr

/

91. ,&&~

-

In the interest of simplicity and readability, the language of this document is

as far as possible gender neutral. Where applicable, the masculine

incorporates the feminine.

Petrom EP Standard RO-EP-DMSS-STD-046-O1-E

Management system of EP

I

I Valid from: 29.02.2012

documents

Page lfrom9

Edition: 02

STANDARDIZATION OF THE EXPLOSION-PROOF PROTECTION FOR LOW VOLTAGE

ELECTRICAL MOTORS

Notes for users:

A controlled copy of this version is on Intranet Petrom EP. Prior to make reference to

this document, the user must ensure that any other copy is the last reviewed one. For

further information, contact the issuer of the document.

This document belongs to EP Petrom department. It cannot be disclosed to other

persons, either partially or integrally, cannot be multiplied, stored or sent by any

method (electronically, mechanically), cannot be recorded, graphically or in other way

reproduced, without the owners agreement.

The users are encouraged to participate in a continuous enrichment of this document

by sending a constructive feedback to the author of document.

Petrom EP Standard RO-EP-DMSS-STD-048-O 1-R

Management system of El

Page 2 from 9

Valid from:

documents

Edition: 01

OMV Petrom EP Demand Management

L~

PETROM

Standard

Membru OMV Grup

1. Scope

This standard is applicable for the low voltage electrical motors designed for potentially

explosive areas. It determines the type of explosion-proof protection for motors that

must be used in hazardous environment.

2. Introduction

Explosion prevention and protection are of a crucial importance as explosions

endanger peoples life and health as a result of the uncontrollable effects of flame and

blast (hot radiations, flames, pressure waves, projected particles, propelled debris), of

the chemical toxic reactive substances and of oxygen depletion from air. Furthermore,

damages caused by an explosion might be particularly significant in terms of

equipment and plant damage and can affect long term production loss and business

reputation.

Oil&Gas Industry operates at high level of risk in regard with the potential explosive

areas.

Relative to the electrical motor applications, more than 40% from operations take place

in classified areas. Formerly, the explosion-proof motors were prominent because they

seemed robust, could be used in Area 1 and had the best rated turnover in the market.

Another reason for the prevailing utilization of explosion-proof motors was also the

limits imposed by that time regulations. As the result of the standard modifications in

the nineties, non-incendiary protection type has been built, especially for Area 2, and

the Exe-increased safety type, has been accepted for Area 1. Based on some

commercial and financial reasons, Exe-increased (non-incendiary) motors should be

purchased against explosion-proof motors, which are much more expensive Its a pity

that some users, for some reasons (including the ignorance), keep on ordering

explosion-proof motors which are much more expensive than the Exe-increased safety

(non-incendiary) motors.

Furthermore, although the explosion-proof motors seem to be safe, most of them

actually lose their ex-proof characteristics after the first intervention.

As a consequence of the above mentioned, standardization of the protection types for

low voltage electrical motors designed for potential explosive areas has been decided

as being necessary.

3. Definitions

Zones : Hazardous areas are classified per zones, depending on the frequence and

duration of a gaseous explosive atmosphere, as follows:

Zone 0: An aria where a gaseous explosive atmosphere persists or lasts for a

long period of time.

-

Petrom EP Standard RQ-EP-VMSS-STD-046-O1-E

Management system of EP

I

IValid from: 29.02.2012

documents

Page 3 from 9

Edition: 02

STANDARDIZATION OF THE EXPLOSION-PROOF PROTECTION FOR LOW VOLTAGE

ELECTRICAL MOTORS

-

Zone 1: An aria where a gaseous explosive atmosphere is probable under normal

operational conditions.

Zone 2: An aria where a gaseous explosive atmosphere is not probable under

normal operational conditions; even if it occurs, it will be seldom and for a short

period of time.

Protection types used in this standard:

Increased safety e : protection type comprising some additional characteristics for

an increased safety in case of an overheating, flame arc and sparks, under the

conditions of a normal operation or under specified abnormal conditions.

Relative to this protection type, there are also defined the following:

Non-incendiary ,,n: protection type applied to the electrical apparatus to prevent

ignition of a surrounding explosive atmosphere under normal work conditions or under

some specified abnormal conditions.

Explosion-proof encapsulation d: protection type where the potential flammable

parts of apparatus are placed into an encapsulation reliable for the pressure developed

by an internal explosion and able to prevent the explosion propagation to the external

explosive atmosphere.

Explosion prevention and protection is based on two principles considering the

simultaneous conditions of an explosive atmosphere and an efficent ignition source

and considering, at the same time, the foreseen effects of an explosion. These two

priciples are:

a) Prevention:

To avoid an explosive atmospheres. This objective is mainly achievable by

modification of either the flammable substance concentration to a value

out of the ignition range or the oxygen concentration to a value under the

limit of oxygen concentration (LOG);

To avoid all the actual/potential ignition sources;

b) Protection:

To limit the effects of an explosion to an acceptable limit through

constructive protection actions. Unlike the actions described above, the

probability of an explosion has been considered here.

Risk elimination or mitigation can be achieved either by applying one of the aforesaid

prevention/protection principle or by a combination of these priciples.

Protection types can be classified by three categories, depending on the lighting

source and the potential explosive atmosphere, as follows:

1. Protection type allowing a direct contact between the ignition source and hazardous

atmosphere (explosion-proof encapsulation ,,d, intrinsic safety ,,i, non-incendiary

nC).

Petrom EP Standard RO-EP-DMSS-STD-046-O1-R

Management system of EP

Valid from:

Page 4from9

Edition: 01

documents

OMV Petrom EP Demand Management

Standard

LW

PETROM

Membru OMV Grup

2. Protection type disallowing a direct contact between the ignition source and

hazardous atmosphere (oil immersion ,,o, pressurized encapsulation p. sand

embedment ,,q).

3. Protection type tending (by its own construction) to eliminate the ignition source

under specified conditions (increased safety ,,e, non-incendiary ,,nA).

Equipment Protection Level

EPL (Equipment Protection Level), in accordance with the series of standards IEC /

EN 60079-xx.

Definition:

Protection level assigned to equipment, based on the risk of becoming an ignition

source, categorized per gaseous explosive atmospheres, dust explosive

environments and potential explosive environments in coal mines.

Ratio between zones, Atex categories and EPL:

Zone classification

Explosive

concentration

Equipment category/level

Risk

Explosion

group

ATEX

category

IEC EPL

Often/long

periods

High, safe with 2

defects

II

1G

Ga

Occasional

High, safe with

defect

II

2G(1G)

Gb(Ga)

II

3G(1G/2G)

Gc(GalGb)

Seldom/almost

never

Normal

For some cases, it was established that the protection type can be divided in

different protection levels matching to each zone. A better risk assesment shall

consider all factors. Use of the risk assessment instead of an inflexible approach, like

formerly, correlation to the zones with equipment under potential risk of ignition is

obviously more profitable, irrespective of the protection type. Since 2007, IEC

technical standards from series IEC 60079 and, especially IEC 60079 part 14, have

determined that, for some special situations, protection against ignition sources

must be increased over the normal levels. This concept can take into consideration

the risk (i.e., explosion consequences), unlike the simple probability of a flammable

atmosphere a conventional selection criterium between the protection types and

zone of use.

Petrom EP Standard RO-EP-DMSS-STD-046-O1-E

Management system of EP

Page 5 from 9

I Valid from: 29.02.2012

documents

Edition: 02

STANDARDIZATION OF THE EXPLOSION-PROOF PROTECTION FOR LOW VOLTAGE

ELECTRICAL MOTORS

Under normal circumstances, EPLs effect will be a normal maintenance of the ratio

zone/protection equipment. When, despite of all these, risk is deemed more

critical, the required EPL for zone can be increased. Similarly, when the risk is

deemed particularly low or neglectable, EPL can be decreased.

Table below shows EPL for each protection type.

Codification

Description

EPL

Ex ia

Intrinsic safety ia

Ga

Ex ib

Intrinsic safety ib

Gb

Ex ic

Intrinsic safety ic

Gc

Ex d

Ex-proof encapsulation

Gb

Ex p

Pressurized

Gb

Ex px

Gb

Ex py

Gb

Ex pz

Gc

Ex e

Increased safety

Gb

Ex m

Encapsulation

Gb

Ex ma

Encapsulation

Ga

Ex mb

Encapsulation

Gb

Ex o

Oil immersion

Gb

Ex q

Sand embedment

Gb

Ex n

Non-incendiary

Gc

Selection depending on the gas and vapour flash point

Electrical motor type must be selected so that the maximum surface temperature

shall not achieve the flash point of all potential gases or vapours in operating

environment. Temperature class shall be marked on the electrical equipment

according to the below table.

Ratio between the temperature class, surface temperature and flash point

Temperature class

Maximum surface

temperature

Gas or vapour flash point

Ti

450C

>450C

T2

300C

>300C

Petrom EP Standard RO-EP-LYMSS-STD-046-O7-R

Management system of EP

Page 6 from 9

Valid from:

documents

Edition: 01

OMV Petrom EP Demand Management

Standard

LW

PETROM

embru OMV Grup

T3

200C

>200C

T4

135C

>135C

T5

100C

>100C

T6

85C

>85C

4. Standardization of the explosion-proof protection for low voltage motors

It must be specified that an important percentage of electrical motors, more than 95%

from the motors working in classified zones, are placed in Zone 2. Nevertheless, most

of the existing motors are Exd type which is more than necessary. For different

reasons, not the subject of this standard, the Exd motors are requested and used

inclusively for unclassified zones, like PUs with polished rod. For Zone 1 and 2 related

motors, the following protection types shall be used under the current regulatory

conditions:

-

Exe with EPL Gb for Zone 1; additional protections, required by SR EN 60079

relative to use of protection e in Zone 1, shall be applied in parallel;

Exn with EPLGcforZone2.

Exd protected motors shall not be purchased.

In order to not impede the technological evolution, some new explosion-proof

protections that could be manufactured, (like s type, for an attractive price), will be

timely considered.

5. Additional requirements for the variable frequency driven ex-proof low voltage

motors

Motors intended to be driven through the frequency converters shall be marked in

addition with the following information:

-

For Converter Supply;

Speed range or frequency range over which the machine is intended to be

operated;

Minimum switching frequency;

Type of torque application, e.g., variable torque, constant torque, constant

power; or alternatively the operational torque limits;

If applicable

Type identification of specific converter intended.

Petrom EP Standard RO-EP-DMSS-STV-046-O1-E

Management system of EP

Page 7from ~

I Valid from: 29.02.2012

documents

Edition: 02

STANDARDIZATION OF THE EXPLOSION-PROOF PROTECTION FOR LOW VOLTAGE

ELECTRICAL MOTORS

In addition, irrespective of the zone (1 or 2), the below mentioned requirements shall

be observed for the following motor types:

-

Exe with EPL Gb or EPL Gc,

observance of the heat protection conditions;

motor and converter shall be compulsory tested together, as an assembly.

Exd with EPL Gb or EPL Go,

observance of the heat protection conditions;

provided with temperature sensors included in windings, for a direct

control of temperature;

motor and converter test as an assembly is not compulsory.

Ex nA with EPL Gc,

Type test of the motor together with the specified converter, in accordance

with CEI 60079-15:2010.

Note: The aforesaid conditions for Exd motors have been presented as additional

information and they do not infrige on decision from section 4 above.

6. Standardization of the ex-proof low voltage motors depending on the temperature

class

Pursuant to the analysis bulletins for gas and crude conveyed/processed in E&P, as well

as to the data sheets for substance safety (MSDS) related to Ex equipment falling in

temperature classes, T3 class (200 DEG C, test gas-Hexane) is deemed satisfactory for

E&P crude and gas installations.

7. Standardization principles for the ex-proof low voltage motors depending on the

explosion-proof type

-

Economic;

Technical (for converter supply).

8. Advantages and risks

-

Advantages:

Purchasing prices significantly decreased; almost 20% decrease of capital

expenses is expected;

Cheaper prices related to maintenance;

Purchasing prices reduced by attenuation of the types number and by

decrease of the equipment weight.

Risks:

No risk identified.

Petrom EP Standard RO-EP-DMSS-STD-046-O1-R

I Valid from:

Management system of EP

Page 8from9

Edition: 01

documents

OMV Petrom EP Demand Management

Standard

PETROM

Mombru OMV Grup

9. Actions to be undertaken

-

Blocking in the system of SAP codes representing motors with Exd protection

type (77 codes);

Blocking in the system of SAP codes representing motors with ExnA protection

type and T4 temperature class (97 codes);

Creation in the system of SAP codes for all the motors with ExnA protection type

and T3 temperature class, in balance with the blocked ones but with T4 class (97

new codes).

10.Applicable standards

SR EN 60079 series of Explosive atmospheres

standards

-

NP 099-04

Regulations for designing, manufacturing, verification

and operation of the electrical installations in areas with

explosion hazard.

Petrom EP Standard RO-EP-DM$S-STD-046-O1-E

Management system of EP

documents

Page 9 from 9

I Valid from: 29.02.2012

Edition: 02

You might also like

- 202 Procedure 0-Project Execution PlanDocument8 pages202 Procedure 0-Project Execution PlanagaricusNo ratings yet

- Eg 21 019Document155 pagesEg 21 019agaricusNo ratings yet

- 318 Procedure 0-Electronic Document ManagementDocument11 pages318 Procedure 0-Electronic Document ManagementagaricusNo ratings yet

- Es 16 417Document8 pagesEs 16 417agaricusNo ratings yet

- 316 - Procedure - 0-Record Filing, Maintenance, Retrieval, and RetentionDocument6 pages316 - Procedure - 0-Record Filing, Maintenance, Retrieval, and RetentionagaricusNo ratings yet

- 317 - Procedure - 0-Document Control and DistributionDocument8 pages317 - Procedure - 0-Document Control and DistributionagaricusNo ratings yet

- 211 - Procedure - 0-Project Definition Rating Index (Pdri)Document5 pages211 - Procedure - 0-Project Definition Rating Index (Pdri)agaricus100% (1)

- To-HQ-02-026-00 Philosophy Communications Security Systems OnshoreDocument28 pagesTo-HQ-02-026-00 Philosophy Communications Security Systems Onshoreagaricus100% (1)

- 213 - Procedure - 0-Project Multi-Office Engineering Execution PlanDocument9 pages213 - Procedure - 0-Project Multi-Office Engineering Execution PlanagaricusNo ratings yet

- To HQ 02 027 00 PhilosophyforFlowMeteringSystems OnshoreDocument12 pagesTo HQ 02 027 00 PhilosophyforFlowMeteringSystems OnshoreagaricusNo ratings yet

- 200 Procedure 0-Project InitiationDocument9 pages200 Procedure 0-Project InitiationagaricusNo ratings yet

- 600 Procedure 0-Project CloseoutDocument5 pages600 Procedure 0-Project CloseoutagaricusNo ratings yet

- 202 Procedure 0-Project Execution PlanDocument8 pages202 Procedure 0-Project Execution PlanagaricusNo ratings yet

- Annex To Engineering 003-Civil Structural Design Criteria On ShoreDocument84 pagesAnnex To Engineering 003-Civil Structural Design Criteria On ShoreagaricusNo ratings yet

- E-C.2.4-HQ-PRO-001 Process and Mechanical Valving and Isolation PhilosophyDocument16 pagesE-C.2.4-HQ-PRO-001 Process and Mechanical Valving and Isolation Philosophyagaricus100% (2)

- 201 - Procedure - 0-Scope of Work DocumentDocument7 pages201 - Procedure - 0-Scope of Work DocumentagaricusNo ratings yet

- PE D HA PRO 001 01 E - ATEX Procedure For ProjectsDocument29 pagesPE D HA PRO 001 01 E - ATEX Procedure For ProjectsagaricusNo ratings yet

- HSEQ-RO-06!04!00 Management of Technical IntegrityDocument13 pagesHSEQ-RO-06!04!00 Management of Technical IntegrityagaricusNo ratings yet

- HSEQ-HQ-06!16!00 Hydrogen Sulphide in Operations StandardDocument19 pagesHSEQ-HQ-06!16!00 Hydrogen Sulphide in Operations StandardagaricusNo ratings yet

- Engineering 0016 General Process Design RequirementsDocument51 pagesEngineering 0016 General Process Design RequirementsagaricusNo ratings yet

- EP FF 02 PH Philosophy Passive Fire FightingDocument18 pagesEP FF 02 PH Philosophy Passive Fire FightingagaricusNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- RAX711-L (A) Quick Installation Guide (Rel - 03)Document7 pagesRAX711-L (A) Quick Installation Guide (Rel - 03)Rachid TahiriNo ratings yet

- Oel ExperimentDocument15 pagesOel ExperimentDianah NajeebNo ratings yet

- ISO27k ISMS Implementation and Certification Process 4v1 PDFDocument1 pageISO27k ISMS Implementation and Certification Process 4v1 PDFJMNAYAGAMNo ratings yet

- TV and Broadcast 2013Document478 pagesTV and Broadcast 2013jeckofNo ratings yet

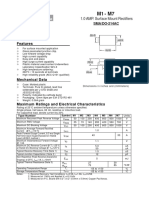

- M7 1N4007 - DatasheetDocument2 pagesM7 1N4007 - DatasheetsongdashengNo ratings yet

- HCIA-Data Center Facility V1.0 Training MaterialDocument422 pagesHCIA-Data Center Facility V1.0 Training MaterialShamsuzzaman FaridNo ratings yet

- Flash Point Stanhope-SetaDocument6 pagesFlash Point Stanhope-SetarabeaNo ratings yet

- Xerox AltaLink C8000 Specifications PDFDocument14 pagesXerox AltaLink C8000 Specifications PDFMarco Delsalto100% (1)

- Operating Instructions For Fuses and RelaysDocument20 pagesOperating Instructions For Fuses and RelaysAlex TefovNo ratings yet

- A Daybook For Nurse Educators - K. Parkieser-Reed (STI Int'l., 2011) WWDocument191 pagesA Daybook For Nurse Educators - K. Parkieser-Reed (STI Int'l., 2011) WWRadu ȘopuNo ratings yet

- mf6500 Series-PcDocument70 pagesmf6500 Series-PcsashkovichNo ratings yet

- Generating Django CRUD Scaffolding With Cookiecutter - WildfishDocument3 pagesGenerating Django CRUD Scaffolding With Cookiecutter - Wildfishms6675No ratings yet

- Openmp For JavaDocument94 pagesOpenmp For Javabogdan.oancea3651No ratings yet

- Effects of The Industrial RevolutionDocument24 pagesEffects of The Industrial RevolutionGae NastasiNo ratings yet

- Maya Evaluating InterfacesDocument6 pagesMaya Evaluating InterfacesChristopher WalkerNo ratings yet

- Format of DissertationDocument3 pagesFormat of Dissertationameyaiba100% (1)

- Uttarakhand Technical University, Dehradun: II Year (IV Semester)Document5 pagesUttarakhand Technical University, Dehradun: II Year (IV Semester)shubhamNo ratings yet

- Design Calculation of 2 KL Lin Storage Manf Si. No.: Vs/Asme/03 DOC NO.: PVL/VAL/2021 REV. NO.: 0 DATE: 24 SEPTEMBER, 2021Document1 pageDesign Calculation of 2 KL Lin Storage Manf Si. No.: Vs/Asme/03 DOC NO.: PVL/VAL/2021 REV. NO.: 0 DATE: 24 SEPTEMBER, 2021pratyaNo ratings yet

- Snow ITIL Implementation GuideDocument35 pagesSnow ITIL Implementation Guidegunalprasadg100% (1)

- Tidal EnergyDocument8 pagesTidal EnergyNayakhannanNo ratings yet

- MATLAB Crash CourseDocument11 pagesMATLAB Crash CourseMohsen salimyNo ratings yet

- Caterpillar - Class of Insulation and Temprature Rise - Online CommunityDocument3 pagesCaterpillar - Class of Insulation and Temprature Rise - Online Communitylbk50No ratings yet

- TYBA GeographyDocument35 pagesTYBA Geographysameersay20007No ratings yet

- Aramco Hot Tap Welding Procedure Rev 1Document3 pagesAramco Hot Tap Welding Procedure Rev 1BWQNo ratings yet

- H.R.P. at Different LevelsDocument3 pagesH.R.P. at Different LevelsShalini Swaroop0% (1)

- Qlight Total Catalogue (En)Document446 pagesQlight Total Catalogue (En)Anonymous MDkp0hnb3lNo ratings yet

- Ussd Money TransferDocument4 pagesUssd Money TransfermadrasNo ratings yet

- Intel GFXDocument8 pagesIntel GFXnikhilrk13janNo ratings yet

- DCR Nit NagpurDocument158 pagesDCR Nit NagpurVirendra Kumar GajbhiyeNo ratings yet

- Bta Brochure 10-15 CompleteDocument8 pagesBta Brochure 10-15 CompletePop IonNo ratings yet