Professional Documents

Culture Documents

Maxon EC6 1.2watt

Uploaded by

ElectromateOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maxon EC6 1.2watt

Uploaded by

ElectromateCopyright:

Available Formats

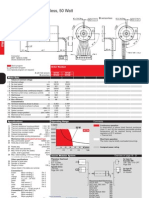

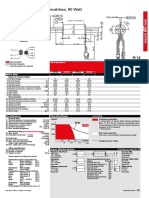

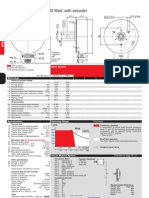

EC 6 Æ6 mm, brushless, 1.

2 Watt

maxon EC motor

M 2.5:1

Stock program

Standard program Order Number

Special program (on request)

310599 250101

Motor Data

Values at nominal voltage

1 Nominal voltage V 6.0 12.0

2 No load speed rpm 45100 34400

3 No load current mA 53.1 19

4 Nominal speed rpm 22400 11200

5 Nominal torque (max. continuous torque) mNm 0.251 0.26

6 Nominal current (max. continuous current) A 0.265 0.105

7 Stall torque mNm 0.542 0.427

8 Starting current A 0.480 0.147

9 Max. efficiency % 45 41

Characteristics

10 Terminal resistance phase to phase W 12.5 81.5

11 Terminal inductance phase to phase mH 0.0911 0.602

12 Torque constant mNm / A 1.13 2.9

13 Speed constant rpm / V 8470 3290

14 Speed / torque gradient rpm / mNm 93800 92500

15 Mechanical time constant ms 4.91 4.84

16 Rotor inertia gcm2 0.00500 0.00500

Specifications Operating Range Comments

Thermal data n [rpm]

17 Thermal resistance housing-ambient 75 K / W Continuous operation

18 Thermal resistance winding-housing 5.0 K / W In observation of above listed thermal resistance

19 Thermal time constant winding 0.467 s (lines 17 and 18) the maximum permissible winding

310599 temperature will be reached during continuous

20 Thermal time constant motor 80.2 s

operation at 25°C ambient.

21 Ambient temperature -20 ... +100°C

= Thermal limit.

22 Max. permissible winding temperature +125°C

Mechanical data (preloaded ball bearings) Short term operation

23 Max. permissible speed 100000 rpm The motor may be briefly overloaded (recurring).

24 Axial play at axial load < 0.15 N 0 mm

> 0.15 N max. 0.06 mm

25 Radial play 0.01 mm Assigned power rating

26 Max. axial load (dynamic) 0.1 N

27 Max. force for press fits (static) 10 N

28 Max. radial loading, 2 mm from flange 8N

maxon Modular System Overview on page 16 - 21

Other specifications

29 Number of pole pairs 1 Planetary Gearhead Encoder MILE

30 Number of phases 3 Æ6 mm 64 CPT,

31 Weight of motor 2.8 g 0.002 - 0.03 Nm 3 channels

Page 203 Page 256

Values listed in the table are nominal. Micro Harmonic Drive®

Connection Æ8 mm

0.006 - 0.016 Nm

Pin 1 Motor winding 3 Page 204

Pin 2 Motor winding 2

Pin 3 Hall sensor 3

Pin 4 VHall 4.5 ... 12 VDC

Pin 5 GND

Pin 6 Hall sensor 1 Recommended Electronics:

Pin 7 Hall sensor 2 DEC 24/1 Page 288

Pin 8 Motor winding 1 DEC Module 24/2 289

Connector for Flexprint, MOLEX 52745-0896, EPOS 24/1 302

EPOS2 Module 36/2 302

FPC, 8 pole, pitch 0.5 mm, top contact style. EPOS 24/1 for MILE on request

Wiring diagram for Hall sensors see page 27 Notes 20

Sold & Serviced By:

Option

Sterilisable version ELECTROMATE

INDUSTRIAL SALES LIMITED

PRECISION TECHNOLOGY & QUALITY

Toll Free Phone (877) SERVO98

142 Toll Free Fax (877) SERVO99 May 2009 edition / subject to change

sales@electromate.com

www.electromate.com

You might also like

- Maxon EC-Powermax30 200wattDocument1 pageMaxon EC-Powermax30 200wattElectromateNo ratings yet

- En 21 250Document1 pageEn 21 250compimagmaticNo ratings yet

- Maxon EC60 400wattDocument1 pageMaxon EC60 400wattElectromateNo ratings yet

- Maxon EC-Max16 5wattDocument1 pageMaxon EC-Max16 5wattElectromateNo ratings yet

- Maxon EC-Max40 70wattDocument1 pageMaxon EC-Max40 70wattElectromateNo ratings yet

- Maxon EC-Max30 40wattDocument1 pageMaxon EC-Max30 40wattElectromateNo ratings yet

- 12 156 enDocument1 page12 156 enLuka MadridNo ratings yet

- EC 20 MOTOR SPECSDocument1 pageEC 20 MOTOR SPECSivanlawms6745No ratings yet

- Maxon EC22 50wattDocument1 pageMaxon EC22 50wattElectromateNo ratings yet

- Maxon EC90 Flat 90wattDocument1 pageMaxon EC90 Flat 90wattElectromateNo ratings yet

- 90mm EC Brushless MotorDocument1 page90mm EC Brushless MotorLucas SuplinoNo ratings yet

- En 21 251Document1 pageEn 21 251Froylan OchoaNo ratings yet

- EC 90 Flat: 90 MM, Brushless, 600 WattDocument1 pageEC 90 Flat: 90 MM, Brushless, 600 WattDiy DoeNo ratings yet

- Maxon EC20 Flat 3wattDocument1 pageMaxon EC20 Flat 3wattElectromateNo ratings yet

- Maxon EC22 20watt Integrated ElectronicsDocument2 pagesMaxon EC22 20watt Integrated ElectronicsElectromateNo ratings yet

- EC 40 40 MM, Brushless, 170 Watt: Part NumbersDocument1 pageEC 40 40 MM, Brushless, 170 Watt: Part NumbersfurkanfurkanfurkanNo ratings yet

- Maxon RE30 Graphite Brushes 60wattDocument1 pageMaxon RE30 Graphite Brushes 60wattElectromateNo ratings yet

- Motor Maxon 323772Document1 pageMotor Maxon 323772Henry Daniel VerdugoNo ratings yet

- Maxon Ec45 136210Document1 pageMaxon Ec45 136210compimagmaticNo ratings yet

- Maxon EC45 Flat 30wattDocument1 pageMaxon EC45 Flat 30wattElectromateNo ratings yet

- Maxon EC-Max22 25wattDocument1 pageMaxon EC-Max22 25wattElectromateNo ratings yet

- 30 MM, Graphite Brushes, 60 Watt: Order NumberDocument1 page30 MM, Graphite Brushes, 60 Watt: Order NumberRatanieriNo ratings yet

- Graphite Brushes, 60 Watt Maxon DC MotorDocument1 pageGraphite Brushes, 60 Watt Maxon DC MotorRatanieriNo ratings yet

- EC-max 30 ∅30 mm, brushless, 60 Watt motor specsDocument1 pageEC-max 30 ∅30 mm, brushless, 60 Watt motor specsfurkanfurkanfurkanNo ratings yet

- Maxon EC20 Flat 5wattDocument1 pageMaxon EC20 Flat 5wattElectromateNo ratings yet

- Maxon EC22 50watt SterilisableDocument1 pageMaxon EC22 50watt SterilisableElectromateNo ratings yet

- EC 22 22 MM, Brushless, 50 Watt: Part NumbersDocument1 pageEC 22 22 MM, Brushless, 50 Watt: Part NumbersfurkanfurkanfurkanNo ratings yet

- 12 171 enDocument1 page12 171 enLuka MadridNo ratings yet

- 17 en 170 Lstage DatasheetDocument1 page17 en 170 Lstage DatasheetSana SyedNo ratings yet

- Maxon Re40 DC Motor 148866 Datasheet PDFDocument1 pageMaxon Re40 DC Motor 148866 Datasheet PDFtoony reyesNo ratings yet

- F2140 Eng DatasheetDocument4 pagesF2140 Eng Datasheettngyew leeNo ratings yet

- Maxon Re40Document1 pageMaxon Re40compimagmaticNo ratings yet

- 16 275 enDocument1 page16 275 enmawadNo ratings yet

- Maxon RE65 Graphite Brushes 250wattDocument1 pageMaxon RE65 Graphite Brushes 250wattElectromateNo ratings yet

- Maxon RE25 Precious Metal Brushes 10wattDocument1 pageMaxon RE25 Precious Metal Brushes 10wattElectromateNo ratings yet

- Maxon EC90 Flat 90watt With EncoderDocument1 pageMaxon EC90 Flat 90watt With EncoderElectromateNo ratings yet

- MAXON Brushed Motor A-Max 26, 4.5 WDocument1 pageMAXON Brushed Motor A-Max 26, 4.5 WRadu BabauNo ratings yet

- 12 149 enDocument1 page12 149 enLuka MadridNo ratings yet

- Maxon RE50 Graphite Brushes 200wattDocument1 pageMaxon RE50 Graphite Brushes 200wattElectromateNo ratings yet

- RE 50 50mm Graphite Brushes 200W MotorDocument1 pageRE 50 50mm Graphite Brushes 200W MotorJorge Alejandro Barrutia BorbollaNo ratings yet

- RE50Document1 pageRE50Yhony Gamarra VargasNo ratings yet

- Motor 30 WattDocument1 pageMotor 30 WattPRED4T0R85No ratings yet

- Motores Maxon 2017Document1 pageMotores Maxon 2017--No ratings yet

- Maxon RE-Max17 Graphite Brushes 4.5wattDocument2 pagesMaxon RE-Max17 Graphite Brushes 4.5wattElectromateNo ratings yet

- EC 60mm 400W Brushless MotorDocument1 pageEC 60mm 400W Brushless MotorZoltán SoósNo ratings yet

- Maxon RE40 Graphite Brushes 150wattDocument1 pageMaxon RE40 Graphite Brushes 150wattElectromateNo ratings yet

- RE 25 25 MM, Precious Metal Brushes CLL, 10 Watt: Part NumbersDocument1 pageRE 25 25 MM, Precious Metal Brushes CLL, 10 Watt: Part NumbersWALTER ANDRES CORDOBA CACERENo ratings yet

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsFrom EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNo ratings yet

- Electrical and Electronic Principles: Volume 2From EverandElectrical and Electronic Principles: Volume 2Rating: 4 out of 5 stars4/5 (5)

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsFrom EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsRating: 3 out of 5 stars3/5 (5)

- Galil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesDocument1 pageGalil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesElectromateNo ratings yet

- Introducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionDocument1 pageIntroducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionElectromateNo ratings yet

- Electromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseDocument1 pageElectromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseElectromateNo ratings yet

- Electromate Elated With Win at The 2022 Business Achievement AwardsDocument2 pagesElectromate Elated With Win at The 2022 Business Achievement AwardsElectromateNo ratings yet

- Electromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaDocument1 pageElectromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaElectromateNo ratings yet

- New LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsDocument1 pageNew LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsElectromateNo ratings yet

- Kollmorgen Debuts EKM Series Servo MotorsDocument1 pageKollmorgen Debuts EKM Series Servo MotorsElectromateNo ratings yet

- Exor X5 Wireless Press ReleaseDocument1 pageExor X5 Wireless Press ReleaseElectromateNo ratings yet

- Mecademic Robotics Releases New Firmware For Its Meca500 RobotDocument2 pagesMecademic Robotics Releases New Firmware For Its Meca500 RobotElectromateNo ratings yet

- Electromate Recertified As A Great Place To Work' Press ReleaseDocument1 pageElectromate Recertified As A Great Place To Work' Press ReleaseElectromateNo ratings yet

- AMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMDocument2 pagesAMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMElectromateNo ratings yet

- New 100 Amps Peak FlexPro Servo Drives Available From AMCDocument1 pageNew 100 Amps Peak FlexPro Servo Drives Available From AMCElectromateNo ratings yet

- Electromate® Made It Onto The 2021 List of Best Workplaces™ in Professional ServicesDocument2 pagesElectromate® Made It Onto The 2021 List of Best Workplaces™ in Professional ServicesElectromateNo ratings yet

- New High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesDocument2 pagesNew High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesElectromateNo ratings yet

- ADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesDocument2 pagesADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesElectromateNo ratings yet

- Meet The World's Most Precise Six-Axis RobotDocument1 pageMeet The World's Most Precise Six-Axis RobotElectromateNo ratings yet

- Electromate Recertified For The 2021 Canada's Most Admired Corporate Cultures AwardDocument2 pagesElectromate Recertified For The 2021 Canada's Most Admired Corporate Cultures AwardElectromateNo ratings yet

- POSITAL Kit Encoders Certified For Compliance With BiSS Interface StandardsDocument1 pagePOSITAL Kit Encoders Certified For Compliance With BiSS Interface StandardsElectromateNo ratings yet

- New Robotic Cycloidal Gearbox From GAM - New Product Press ReleaseDocument1 pageNew Robotic Cycloidal Gearbox From GAM - New Product Press ReleaseElectromateNo ratings yet

- Electromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseDocument2 pagesElectromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseElectromateNo ratings yet

- New LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsDocument1 pageNew LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsElectromateNo ratings yet

- Excellence Canada Announces Electromate Is A Recipient of The 2021 Canadian Business Excellence Awards For Private BusinessesDocument2 pagesExcellence Canada Announces Electromate Is A Recipient of The 2021 Canadian Business Excellence Awards For Private BusinessesElectromateNo ratings yet

- New Integrated Spindle Drives Available From JVLDocument1 pageNew Integrated Spindle Drives Available From JVLElectromateNo ratings yet

- Electromate Extends Its Product Portfolio To Include Robots From MecademicDocument1 pageElectromate Extends Its Product Portfolio To Include Robots From MecademicElectromateNo ratings yet

- Electromate Recognized With 2021 AHTD Foundation AwardDocument1 pageElectromate Recognized With 2021 AHTD Foundation AwardElectromateNo ratings yet

- Netzer Introduce VLP-60 Two-Plate Ring Absolute Encoder For Harsh EnvironmentsDocument1 pageNetzer Introduce VLP-60 Two-Plate Ring Absolute Encoder For Harsh EnvironmentsElectromateNo ratings yet

- Electromate Inc. Recognized As Canadas Most Admired Corporate Cultures For 2020Document2 pagesElectromate Inc. Recognized As Canadas Most Admired Corporate Cultures For 2020ElectromateNo ratings yet

- Maxon's New IDX Integrated Motor - Power at The Press of A ButtonDocument1 pageMaxon's New IDX Integrated Motor - Power at The Press of A ButtonElectromateNo ratings yet

- Electromate Extends Its Product Portfolio To Include Collaborative Robots Manufactured by Universal RobotsDocument2 pagesElectromate Extends Its Product Portfolio To Include Collaborative Robots Manufactured by Universal RobotsElectromateNo ratings yet

- ADVANCED Motion Controls Releases The FM060-25-CMDocument1 pageADVANCED Motion Controls Releases The FM060-25-CMElectromateNo ratings yet

- Eaton 9SX Datasheet A4 Rev B LOW PDFDocument2 pagesEaton 9SX Datasheet A4 Rev B LOW PDFElfy PalmaNo ratings yet

- SGS Technical Note 150 - 40 Industrial Application IdeasDocument32 pagesSGS Technical Note 150 - 40 Industrial Application IdeasPeterNo ratings yet

- Modelling of DG SetsDocument7 pagesModelling of DG SetsAshish MishraNo ratings yet

- Microcontrollers: Digitally Addressable Lighting Interface (DALI) Unit Using The MC68HC908KX8Document162 pagesMicrocontrollers: Digitally Addressable Lighting Interface (DALI) Unit Using The MC68HC908KX8alexwongks6118No ratings yet

- XJ700N NC 1985Document64 pagesXJ700N NC 1985jcgiovatto1No ratings yet

- X1 2020 Disinfection Dental Chair/Dental Unit: Instrument Tray With Metal Base Dismountable Metal BackrestDocument31 pagesX1 2020 Disinfection Dental Chair/Dental Unit: Instrument Tray With Metal Base Dismountable Metal BackrestAbdiNo ratings yet

- Wiring Diagram: Convertible Packaged Air Conditioner 208/230 Volt Single Phase 60HzDocument1 pageWiring Diagram: Convertible Packaged Air Conditioner 208/230 Volt Single Phase 60HzGouse Ahmed ShaikNo ratings yet

- 07 - ValvesDocument31 pages07 - ValvesArdanNo ratings yet

- BS-STANDARDS-ELECTRICAL-CABLEDocument3 pagesBS-STANDARDS-ELECTRICAL-CABLEAruna Prasanna DewasurendraNo ratings yet

- Feed Mixing Mill Type MGP/2140-O + Electric Plant For Feeding Section of Textile Line 1C1519Document7 pagesFeed Mixing Mill Type MGP/2140-O + Electric Plant For Feeding Section of Textile Line 1C1519Asep SomantriNo ratings yet

- 2002 f350 Wiring DiagramDocument454 pages2002 f350 Wiring Diagramharveg83% (30)

- Friction Clutches Transmit Rotary Motion Between ShaftsDocument23 pagesFriction Clutches Transmit Rotary Motion Between ShaftsAnup M UpadhyayaNo ratings yet

- CONTROLS A4 en Load Bearing Buyer's Guide April 2021 REV2Document19 pagesCONTROLS A4 en Load Bearing Buyer's Guide April 2021 REV2carlos riveraNo ratings yet

- Fisker Ocean Trim Comparison USDocument1 pageFisker Ocean Trim Comparison USMaria MeranoNo ratings yet

- Elimination of Transformer Inrush Currents by Controlled Switching PDFDocument11 pagesElimination of Transformer Inrush Currents by Controlled Switching PDFAshroof AbdoNo ratings yet

- Harmonics Presentation: Causes and EffectsDocument21 pagesHarmonics Presentation: Causes and EffectsArpit PatelNo ratings yet

- PC lbp2410Document58 pagesPC lbp24102nd-levelNo ratings yet

- Goulds Pumps DisassemblyDocument19 pagesGoulds Pumps Disassemblyobaidur_rehman_3No ratings yet

- Tramp Metal Detector MODEL 1230 Installation & Operation ManualDocument32 pagesTramp Metal Detector MODEL 1230 Installation & Operation ManualmiguelperuperuNo ratings yet

- Samsung SyncMaster 400PXn, 400PX, 460PXn, 460PX User ManualDocument41 pagesSamsung SyncMaster 400PXn, 400PX, 460PXn, 460PX User Manualjeremiashee asheNo ratings yet

- MPMC IV UnitDocument33 pagesMPMC IV UnitVenkatasamy EEENo ratings yet

- Titanic ShipDocument35 pagesTitanic ShipМаксим ШульгаNo ratings yet

- 1.4.1 CPU Architecture (MT) PDFDocument6 pages1.4.1 CPU Architecture (MT) PDFezzeddinezahra_55049No ratings yet

- Do-It-Auto ADS-OBD Interface ReviewDocument5 pagesDo-It-Auto ADS-OBD Interface Reviewloncuvaca100% (1)

- VMC1 Leaflet 0807Document2 pagesVMC1 Leaflet 0807lerim75No ratings yet

- Yole RF Filters Pass Antenna Switches ReportDocument16 pagesYole RF Filters Pass Antenna Switches Reportvikas251632No ratings yet

- Radiator Guide: Quick ReferenceDocument130 pagesRadiator Guide: Quick ReferenceOcta IrawanNo ratings yet

- Simple Spur Gear Calculator SpreadSheetDocument2 pagesSimple Spur Gear Calculator SpreadSheetRandyWilsonNo ratings yet

- Manual de Servicio SONY KDL-55HX857Document53 pagesManual de Servicio SONY KDL-55HX857paelocom8550100% (1)

- ONCCY Electrical Introduction PPT 230709Document74 pagesONCCY Electrical Introduction PPT 230709satthubattuongNo ratings yet