Professional Documents

Culture Documents

Tyfo SW-1 Epoxy

Uploaded by

Jeje AjrCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tyfo SW-1 Epoxy

Uploaded by

Jeje AjrCopyright:

Available Formats

Tyfo SW-1 Epoxy

Underwater Epoxy

DESCRIPTION

Tyfo SW-1 is a two part, 100% solids epoxy

formulation consisting of epoxy resins,

hardeners and inert fillers specifically designed

for underwater applications on steel, concrete

and mansory surfaces. Tyfo SW-1 is used

in fiber wrap applications, with or without an

aggregate, as a protective coating or repair

mortar to protect against damage and erosion

in splash zone areas.

USES

Tyfo SW-1 is formulated for use as the patching

material, primer and adhesive in fiber wrap

applications. Tyfo SW-1 can also be used

to coat or repair concrete and steel materials

in underwater and splash zone applications

providing protection against corrosion, erosion

and deterioration from salt or fresh water.

Colors

The standard color of Tyfo SW-1 is gray. Special

colors are available subject to minimum order

quantities.

CERTIFICATE OF COMPLIANCE

Will be supplied upon request, complete

with state and federal packaging laws with

copy of labels used.

Material safety data sheets will be supplied

upon request.

Possesses 0% V.O.C. level.

HOW TO USE

THE TYFO SW-1 EPOXY

SURFACE PREPARATION

Surface must be structurally sound, clean, free

of loose or deteriorated concrete or coatings,

marine growth or any other material which would

impair adhesion. Sand blasting or high pressure

water blasting are preferred methods of surface

preparation. Application of Tyfo SW-1 should

begin promptly after surface preparation to

reduce possibility of surface contamination.

Tyfo SW-1 should be mixed above water and

then transported below water. Premix Part A

(base) and Part B (hardener) individually. Then

combine Part A and Part B in a clean container

and mix thoroughly with a slow speed motor

and Jiffy type mixer. Scrape the side of the

container at least once during mixing.

Order in 4-gallon pre-measured units in 5-gallon

containers.

MIX RATIO

100.0 parts of component A to 74.0 parts

of component B by volume. ( 1 0 0 p a r t s o f

component A to 56.0 parts of component B

by weight.)

SHELF LIFE

Two years in original, unopened and properly

stored containers.

STORAGE CONDITIONS

Store epoxy at 40o to 90o F (4o to 32o C). Avoid

freezing. Store rolls flat, not on ends, at

temperatures below 100 o F (38 o C). Avoid

moisture and water contamination.

5/15 Tyfo SW-1

Coverage

Tyfo SW-1 coverage rates are approximate and

will vary with temperature, surface porosity and

texture. Following is the approximate coverage

on a smooth surface:

sq. ft./gal. thickness

50 30 mils (1/32")

25.5 62 mils (1/16")

12.8 125 mils (1/18")

One gallon of Tyfo SW-1 mixed with one gallon

of dry aggregate will yield approximately 1.6

gallons of mortar.

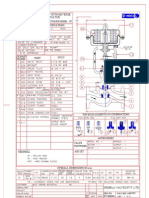

Typical Material Properties at 75 F.

MoRTAr Grout

PACKAGING

Apply Tyfo SW-1 at water and surface temperatures of 40 F or higher. Mix the Tyfo

SW-1 above water and transport underwater

after mixing. Prime the surface by scrubbing

the surface with neat Tyfo SW-1. Apply by

pressing the Tyfo SW-1, mixed with or without

aggregate, onto the surface with gloved hand

or trowel. Work the Tyfo SW-1 firmly into the

surface to displace water. Build up the material

to the desired thickness. The mortar grout (1:1

by volume) should be used for deep patching

and the repair should be made in lifts of no

more than 1.0 inch at a time. Allow each lift to

achieve initial set prior to applying the next lift.

Please refer to the NSF Listing for the NSF-61

Listed Application.

Tyfo SW-1

or mortar

MIXING

A mortar grout can be made by mixing clean,

dry silica sand with an equal volume of Tyfo

SW-1.

APPLICATION

Mixing ratio, by wt.

100:56

Specific Gravity

1.6

Viscosity A & B mixed, cps

14,000 - 18,000

Gel Time, 65 F, hours

2.5 - 3.5

ASTM D695, 7 day

compressive strength, psi

7,000 - 8,000

ASTM D695, 7 day

compressive strength, mortar, psi

(gel/uw:sand 1:1 by volume)

ASTM D2240

Shore D hardness

8,000 - 9,000

80 - 85

FIRST AID

CAUTION!

Do not thin or dilute Tyfo SW-1. Do not mix

or apply below 40F. Use only clean, oven

dry aggregate to produce mortar. Tyfo SW-1

is not designed to resist hydrostatic pressure

from the negative side. Agitation of the product

once under water should be minimized. When

applying in a splash zone, protection should be

provided from wave action under the product

has reached initial cure (8-10 hours). Due to the

many variables which can exist in underwater

applications, a test application under job site

conditions is recommended prior to the start

of every project to evaluate both application

techniques and adhesion properties.

In case of skin contact, wash immediately and

thoroughly with soap and water. For eye contact,

flush immediately with water for 15 minutes and

consult a physician. For respiratory problems,

remove person immediately to fresh air.

CLEANUP

Clean tools and application equipment

immediately after use with xylene or a similar

approved solvent. Clean spills and drips

while wet with approved solvent.Collect with

absorbent material. Dispose of in accordance

with current local, state and federal regulations.

Read material safety data sheet before using.

Uncured material can be removed with approved

solvent. Cured materials can only be removed

mechanically.

Packaging: 4 gallon pre-measured kits

Storage: 40-90F

Shelf life: 2 years in protected storage

Freight Class: Class 60

SHIPPING LABELS CONTAIN

State specification number with modifications,

if applicable

Component designation

Type, if applicable

Manufacturers name

Date of manufacture

Batch name

State lot number, if applicable

Directions for use

Warnings or precautions required by law

SHIPPING

Freight Class 60

KEEP CONTAINER TIGHTLY CLOSED.

NOT FOR INTERNAL CONSUMPTION.

CONSULT MATERIAL SAFETY DATA SHEET

(MSDS) FOR MORE INFORMATION.

KEEP OUT OF REACH OF CHILDREN.

FOR INDUSTRIAL USE ONLY.

COMPONENT A - Irritant:

Component A contains epoxy resin. Vapors can

cause respiratory irritation. Contact may cause

skin or eye irritation. Can cause sensitization

after prolonged or repeated exposure. Use safety

goggles and chemical resistant gloves. Use only

with adequate ventilation.

COMPONENT B - Irritant:

Component B is corrosive and contains amines.

Contact with skin may cause severe burns.

Avoid eye contact. Product is a strong

sensitizer. Use of safety goggles and chemical

resistant gloves recommended. Remove

contaminated clothing. Avoid breathing vapors.

Use adequate ventilation. Use of an organic

vapor respirator recommended.

Fyfe Co. LLC

Tyfo Fibrwrap Systems

3940 Ruffin Road, Suite C, San Diego, CA 92123

Tel: 858.642.0694 Fax: 858.444.2982

E-mail: info@fyfeco.com www.fyfeco.com

Statement of Responsibility: The technical information and application advice in this publication is based on the present state of our best scientific and practical knowledge.

As the nature of the information herein is general, no assumption can be made as to the products suitability for a particular use or application, and no warranty as to its

accuracy, reliability or completeness, either expressed or implied, is given other than those required by State legislation. The owner, his representative or the contractor is

responsible for checking the suitability of products for their intended use. Field service, where provided, does not constitute supervisory responsibility. Suggestions made

by the Fyfe Co., either verbally or in writing, may be followed, modified or rejected by the owner, engineer or contractor since they, and not the Fyfe Co., are responsible

for carrying out procedure appropriate to a specific application.

5/15 Tyfo SW-1

Patented in U.S.A., Canada, and other countries. Copyright 2015 Fyfe Co. LLC 31-15

You might also like

- Tyfo SEH 51A CompositeDocument2 pagesTyfo SEH 51A CompositeThanongsak ImjaiNo ratings yet

- Tyfo SCH AnchorsDocument2 pagesTyfo SCH AnchorsLindy KhoNo ratings yet

- Fiber WrapDocument2 pagesFiber WrapStephen WilberNo ratings yet

- Tyfo SCH-41 Composite: Using Tyfo S EpoxyDocument2 pagesTyfo SCH-41 Composite: Using Tyfo S EpoxyPE EngNo ratings yet

- 025 - Guard Zinc Phosphate Epoxy PrimerDocument3 pages025 - Guard Zinc Phosphate Epoxy PrimerBalgo BalgobinNo ratings yet

- Tyfo SEH-51ADocument2 pagesTyfo SEH-51AgammankNo ratings yet

- Quick guide to choosing the right flooring gratingDocument32 pagesQuick guide to choosing the right flooring gratingFaris MahmoodNo ratings yet

- Fyfe Corporate BrochureDocument16 pagesFyfe Corporate BrochuresaikiranNo ratings yet

- ISO 9001, ISO 14001 & OHSAS 18001 Certified Product Data SheetDocument3 pagesISO 9001, ISO 14001 & OHSAS 18001 Certified Product Data SheetHendri Dwi cahyonoNo ratings yet

- AV GasketsDocument2 pagesAV GasketsAliNo ratings yet

- Catalogue 2014 en HDDocument58 pagesCatalogue 2014 en HDBrad BarnesNo ratings yet

- Comment Response Sheet of Surface Preparation and Painting ProcedureDocument22 pagesComment Response Sheet of Surface Preparation and Painting ProcedureAgung PrasetyooNo ratings yet

- Sea-Struct Groutbag PDFDocument2 pagesSea-Struct Groutbag PDFErica MartinNo ratings yet

- General Information G-0002: Description On Material JIS-ASTMDocument4 pagesGeneral Information G-0002: Description On Material JIS-ASTMEko Indra SaputraNo ratings yet

- Raychem WPCT Heat Shrink SleevesDocument4 pagesRaychem WPCT Heat Shrink SleevesmngNo ratings yet

- Foster Adhesive: Technical Data SheetDocument2 pagesFoster Adhesive: Technical Data SheetMounir BoutaghaneNo ratings yet

- FRP Repair of Corrosion-Damaged Concrete BeamsDocument13 pagesFRP Repair of Corrosion-Damaged Concrete BeamsahmadlieNo ratings yet

- Technical Manual - 2000 USG Horizontal Lined Acid TankDocument20 pagesTechnical Manual - 2000 USG Horizontal Lined Acid TankGade JyNo ratings yet

- Prorox WM 960 Sa PDFDocument1 pageProrox WM 960 Sa PDFr afriantoNo ratings yet

- Conceptual Design of Plem Structure Labuhan DeliDocument4 pagesConceptual Design of Plem Structure Labuhan DeliFandy SipataNo ratings yet

- Storage and HandlingDocument6 pagesStorage and HandlingalagurmNo ratings yet

- Water Soluble Penetrant Test ProcedureDocument7 pagesWater Soluble Penetrant Test ProcedureTahseen Ahmed100% (1)

- Catalog Intipratama Global TeknikDocument34 pagesCatalog Intipratama Global TeknikToto SusantoNo ratings yet

- DVS 2207-3Document12 pagesDVS 2207-3gura9054No ratings yet

- BTE Dome Brochure Jun 10Document2 pagesBTE Dome Brochure Jun 10م.ذكى فضل ذكىNo ratings yet

- FRP Installation GuideDocument8 pagesFRP Installation GuideDouglas HillNo ratings yet

- PVC CPVC Physical Properties and Astm Specifications For Piping PDFDocument1 pagePVC CPVC Physical Properties and Astm Specifications For Piping PDFShahfaraz AhmadNo ratings yet

- Mcnichols GratingsCat09Document21 pagesMcnichols GratingsCat09jasonvigilNo ratings yet

- Witness Joint ChecklistDocument1 pageWitness Joint ChecklistAustin J AlfredNo ratings yet

- High HDT Superior Vinyl Ester Resin - Crest731Document3 pagesHigh HDT Superior Vinyl Ester Resin - Crest731GautamNo ratings yet

- Polyken Pipeline #1027,: Primers #1019Document3 pagesPolyken Pipeline #1027,: Primers #1019Azmi SyariefNo ratings yet

- Renderoc TGDocument2 pagesRenderoc TGMansoor Ali50% (2)

- Electrically Dissipating Mortar for Tiling and Brick LiningsDocument2 pagesElectrically Dissipating Mortar for Tiling and Brick Liningsshankarkl100% (1)

- PT Bhaita Wire Rope Inspection ProcedureDocument4 pagesPT Bhaita Wire Rope Inspection ProcedureSugianto TanNo ratings yet

- Bollard Catalogue PDFDocument16 pagesBollard Catalogue PDFHaris PrasetiyoNo ratings yet

- Class Flanges Bolt Torque LoadsDocument2 pagesClass Flanges Bolt Torque LoadsAulia RahmanNo ratings yet

- Roundness Shell #1 - 1-Tank -012 BEFORE WELDDocument2 pagesRoundness Shell #1 - 1-Tank -012 BEFORE WELDyuwantoniNo ratings yet

- 6 MM TCDocument1 page6 MM TCpranesh kadamNo ratings yet

- Fepa P Paper Micron μm Fepa F Grain Micron μm JIS R6001 Japan 1973 Micron μmDocument4 pagesFepa P Paper Micron μm Fepa F Grain Micron μm JIS R6001 Japan 1973 Micron μmapi-19654224No ratings yet

- Enron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsDocument2 pagesEnron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsLorenaNo ratings yet

- MS For Fabrication of Above-Ground Storage TankDocument8 pagesMS For Fabrication of Above-Ground Storage Tankdadz mingiNo ratings yet

- Holiday Detector Voltage SettingsDocument1 pageHoliday Detector Voltage Settingsrizviabbas2012No ratings yet

- MATERIAL TRACKING LISTDocument2 pagesMATERIAL TRACKING LISTgopaltryNo ratings yet

- HEMPINOL 10220 Bituminous CoatingDocument2 pagesHEMPINOL 10220 Bituminous CoatingeternalkhutNo ratings yet

- Material Safety Data Sheet: Poly Cell AdhesiveDocument8 pagesMaterial Safety Data Sheet: Poly Cell AdhesiveMinh BảoNo ratings yet

- SDLINC NDT Level II Certification CourseDocument8 pagesSDLINC NDT Level II Certification CourseNkwor AndersonNo ratings yet

- Wca-27 - Heien Larssen - Fire Alarm and Extinguisher SystemDocument97 pagesWca-27 - Heien Larssen - Fire Alarm and Extinguisher SystemANo ratings yet

- Nominal Pipe Size ChartDocument1 pageNominal Pipe Size ChartvijayachiduNo ratings yet

- Wavistrong Installation ManualDocument63 pagesWavistrong Installation ManualRenganathan Prabunath0% (1)

- Hand Lever Cage ClampDocument2 pagesHand Lever Cage ClampSMSUMINISTROS SRL.No ratings yet

- st44 2 PDFDocument1 pagest44 2 PDFAraby Gamal GamalNo ratings yet

- A223 6 44 0074Document15 pagesA223 6 44 0074mishtinilNo ratings yet

- Seoul, Korea: Estimation SheetDocument6 pagesSeoul, Korea: Estimation SheetHRK65No ratings yet

- Core-Loc Armour For Offshore Breakwater: Costa Azul LNG ProjectDocument1 pageCore-Loc Armour For Offshore Breakwater: Costa Azul LNG ProjectRaed Naim KhammashNo ratings yet

- S1239 Epoxy Primer: DescriptionDocument2 pagesS1239 Epoxy Primer: DescriptionELEJONDO Pablo - VCNo ratings yet

- Approved Itp-Dss - 28 Sep 2016Document4 pagesApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNo ratings yet

- Eco-friendly protective coatingDocument2 pagesEco-friendly protective coatingRaed Naim KhammashNo ratings yet

- Technical Data Sheet for Phenolic/Novolac Epoxy Tank CoatingDocument5 pagesTechnical Data Sheet for Phenolic/Novolac Epoxy Tank CoatingHermanNo ratings yet

- WeldOn Low 810 PB Sep08Document3 pagesWeldOn Low 810 PB Sep08geverett2765No ratings yet

- Water Damage Restoration and Clean Up ChecklistFrom EverandWater Damage Restoration and Clean Up ChecklistRating: 1 out of 5 stars1/5 (1)

- 19G412-1180-E2 Parts ListDocument31 pages19G412-1180-E2 Parts ListNeilNo ratings yet

- Dembla Control ValvesDocument30 pagesDembla Control ValvesMixmikmic' KrittananNo ratings yet

- Case Study On Structure Collapse: Jacklin Mary - J 121901040Document12 pagesCase Study On Structure Collapse: Jacklin Mary - J 121901040Crazy MechonsNo ratings yet

- Bolts - SlidesDocument133 pagesBolts - SlidesImran BabarNo ratings yet

- PIP STE05121 - Anchor Bolt Design GuideDocument55 pagesPIP STE05121 - Anchor Bolt Design Guidenistiana100% (4)

- Tube StructureDocument27 pagesTube StructureI Gede Arta RismawanNo ratings yet

- Iwaki Diafragma 1.25 inDocument4 pagesIwaki Diafragma 1.25 inRaul ArizagaNo ratings yet

- Dire-Dawa University Institute of Technology: Construction Technology and Management Chair Course Code: byDocument34 pagesDire-Dawa University Institute of Technology: Construction Technology and Management Chair Course Code: bySemNo ratings yet

- Detail Ground TankDocument1 pageDetail Ground TankRully SaputraNo ratings yet

- 15.1 Isa20 50 Control ValveDocument2 pages15.1 Isa20 50 Control Valvepastyl100% (1)

- Manual Partes 6135JDocument1,012 pagesManual Partes 6135JEsther Roncal MoscolNo ratings yet

- High Temperature Tensile Strength TestingDocument4 pagesHigh Temperature Tensile Strength TestingWalter RuedaNo ratings yet

- Cold-Formed Steel Shear Wall DesignDocument8 pagesCold-Formed Steel Shear Wall DesignjmiguelmenaNo ratings yet

- Spare Parts For. Schwing Concrete Pumps. Section 2Document16 pagesSpare Parts For. Schwing Concrete Pumps. Section 2CosminNo ratings yet

- Is 13935Document26 pagesIs 13935Ashaprava MohantaNo ratings yet

- Liebherr Fridge ManualDocument18 pagesLiebherr Fridge ManualJames RavensdaleNo ratings yet

- Mill Certification: Other Test ResultsDocument1 pageMill Certification: Other Test ResultsAlonso FraireNo ratings yet

- Lts-Cvg-P01-16-0005-A4 Daar PDFDocument32 pagesLts-Cvg-P01-16-0005-A4 Daar PDFSanjoy SanyalNo ratings yet

- Waterman SS-250 SlideGates Booklet 2019Document24 pagesWaterman SS-250 SlideGates Booklet 2019Kamarrada Markeyev A Rangelov GNo ratings yet

- Civil Engineering Industrial Training Presentation (Piling Site)Document25 pagesCivil Engineering Industrial Training Presentation (Piling Site)Bshfirnaudz50% (2)

- 4190 HPRVDocument12 pages4190 HPRVvadivel415No ratings yet

- Shehata2000 PDFDocument10 pagesShehata2000 PDFMoe GyiNo ratings yet

- IC WBS With Gantt ChartDocument1 pageIC WBS With Gantt ChartWarren DiwaNo ratings yet

- WMS For Pipe Supports ErectionDocument17 pagesWMS For Pipe Supports ErectionRamaraju RNo ratings yet

- Batangas State University Civil Engineering Department Proposed Public Market and Parking Facility Design ReportDocument9 pagesBatangas State University Civil Engineering Department Proposed Public Market and Parking Facility Design ReportJanissaries NivercaNo ratings yet

- Service Manual Goodman GPH16MDocument63 pagesService Manual Goodman GPH16MMitchell BaileyNo ratings yet

- Design and Optimization of Aircraft Assembling Based On Comprehensive Simulation of Manufacturing Processes - A. Rozhdestvensky, O. SamsonovDocument10 pagesDesign and Optimization of Aircraft Assembling Based On Comprehensive Simulation of Manufacturing Processes - A. Rozhdestvensky, O. SamsonovSamuel JiménezNo ratings yet

- Pump CalculationDocument3 pagesPump CalculationSaeid Rahimi Mofrad100% (1)

- 02-04 Chap GereDocument12 pages02-04 Chap GereSri DNo ratings yet