Professional Documents

Culture Documents

Abovegroundhydrants Dropdownpillar 84-25-27 P7 PDF

Uploaded by

Limhot SitanggangOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abovegroundhydrants Dropdownpillar 84-25-27 P7 PDF

Uploaded by

Limhot SitanggangCopyright:

Available Formats

INSTALLATION AND MAINTENANCE INSTRUCTIONS

AVK ABOVE GROUND HYDRANTS

SERIES 84/25-27 Model P7

1. FIELDS OF APPLICATION

APPLICATIO AND PROPER USE

Installed in the water supplying pipe system the hydrant can be used for fire

fighting, operations of water supplying

ing companies and other applications as

water supply for construction work or road cleaning. Furthermore the hydrant

must not be operated with more than 16 bar at a maximum operating temperatemper

ture of 40 C. Every other use exceeding these limits is considered to be an

improper use. The hydrant producer is not liable for damages resulting from an

improper use. The risk is on the user only.

NG

2. PRODUCT MARKING

Label:

AVK-Logo

Manufacturer

Description

Internal production number

DVGW registration number

CE registration number

Standards

AVK reference number (see Table 1) with bar code

Date of production

Casting:

AVK-Logo

Model

DVGW marking

Standards

Nominal size

Nominal pressure PN 16

Material

COPYRIGHTAVK GROUP A/S 2014 - AVK Mittelmann Armaturen GmbH, Schillerstr. 50, 42489 Wlfrath - www.avkmittelmann.com

598425AB

INSTALLATION AND MAINTENANCE INSTRUCTIONS

AVK ABOVE GROUND HYDRANTS

SERIES 84/25-27 Model P7

3. WORK SAFETY

The hydrant has a state-of-the-art technology and is safe in operation. However, this valve can imply risks, when operated by

untrained staff or when applied for improper use.

In order to guarantee proper use observe the installation and maintenance instructions. Unauthorized re-engineering and adaption, that have influence on safe and proper operation of the hydrant, are prohibited.

4. INSTALLATION

Before installation, make sure the hydrant is clean. Otherwise the hydrant has to be cleaned or disinfected. Before placing the

hydrant on the pipe remove the protection cap. Installation onto the pipe has to be done without causing any tension. The

tightening torque should be between 80 Nm and 150 Nm. If using a socket connection it must be protected against shearing. A

proper hydrant drainage has to be guaranteed by commercially available drain stones or packaging (e.g. AVK Flexdrain). After

assembly the hydrant requires thorough rinsing.

The installation guidelines according DVGW worksheet W 331 section 5 must be observed.

5. OPERATION

The hydrant is a shut-off valve and must not be used in intermediate position! In frost the fire hydrant is to be closed immediately after every withdrawal and the outlet armature is to be opened thus preventing the hydrant from freezing. If the hydrant

does not empty, it is to be pumped out immediately. An endangerment of traffic by black ice must be avoided.

Open:

At first remove one or more caps. Then connect couplings with valves or hoses with valves and open these valves. According

to EN 14384 the maximum operating torque is 125 Nm (range 2). Open the hydrant with the recommended key (DIN 3223 type

A or B) by slowly turning the operation nut counter-clockwise until it is fully open. The end position is clearly perceivable. Use

the outlet armatures to control the volume, not the hydrant main valve.

Close:

Close the outlet armatures and remove all connected hoses. Slightly open one outlet valve to prevent overpressure in the hydrant body. Close the hydrant main valve fully by evenly turning the operation nut clockwise. The end position is clearly perceivable. The hydrant is equipped with a radially working piston seal. Therefore the closing force has no influence on the tightness.

Remove the remaining outlet valves and couplings and check the automatic drainage. Finally the caps have to be screwed on.

Despite the caps the drainage continues because of the venting valve.

6. MAINTENANCE

Hydrants of the P7 series are virtually maintenance free. However, they should be checked yearly. Therefore it is sufficient to

open and close the hydrant main valve once (function control). Proceed as described under 5. Otherwise look at DVGW code of

practise W392. For operation and maintenance follow the DVGW code of practice W 331.

During maintenance the built-in ball shut-off serves as a shut-off valve.

In case of a knock-over, normally no damages are caused to the hydrant and the pipe system. The patented break-away point

with titanium bushes separates the upper from the lower barrel. The operating pipe is loosely plugged together and uncouples

at the same time.

For repair, the upper barrel is to be placed onto the lower barrel. The broken titanium bushes and probably bent screws have

to be replaced and tightened as follows:

Tighten the four screws at the two clamp halves evenly with approx. 5 Nm (then the upper barrel sits firmly on the lower barrel

without inclination to one side). Then all four screws have to be tightened with an intermediate torque of approx. 20 Nm in

order to reach an even clamp force, before being tightened with the final torque of 405 Nm. Afterwards the hydrant has to be

tested for function and tightness.

INSTALLATION AND MAINTENANCE INSTRUCTIONS

AVK ABOVE GROUND HYDRANTS

SERIES 84/25-27 Model P7

If the main valve disc is damaged, e.g. by contamination or foreign bodies, the lower operating pipe including the main valve

disc has to be replaced as follows:

1. Dismantle the upper barrel by loosening the four screws at the break-away point.

Remove the blocking ring and the o-ring shown in Fig. 1.

Fig. 1

2. Fix the safety stirrup with screws and segments as shown in Fig. 2.

3. Loosen the stem guide by turning the stem counter-clockwise. Rotate the stem

guide by 90 (Fig. 3). Make sure that there is a distance of 10-20 mm between the

plate of the safety stirrup and the stem.

4. Lift the stem up by turning counter-clockwise (Fig. 3). Turn up also simultaneously

the plate, keeping the distance. Rotate the stem guide again by 90 to place it on

the two protrusions at the top of the lower barrel (see Fig. 4).

5. Turning the stem clockwise, the main valve disc is pulled out of its seat.

Fig. 2

Important note:

To ensure the personal safety of the mounting staff working on a pressurized hydrant, the safety stirrup (see points 4 and 5) must not be removed, until it has been

checked that the ball has shut off successfully.

6. Remove the safety stirrup and take the lower operating pipe with the disc away

from the lower barrel. Unscrew the stem assembly.

7. Screw the stem assembly into the new operating pipe and put it back into the

lower barrel. The stem nut carrier has two noses with different width. During assembly the noses must be inserted in their corresponding grooves (broad nose

towards drain nipple).

Fig. 3

8. Remount the safety stirrup, screw the threaded bolt down to push the main valve

disc into the seat. Rotate the stem guide by 90 to lock it. To prevent a slide out

of the valve rod turn the stem guide 90under the above stop.

9. Remove the safety stirrup; insert the blocking ring and o-ring, check the position

of the O-ring. Remount the upper barrel and reassemble the complete hydrant.

Check function and tightness.

Fig. 4

7. GENERAL NOTES

For damages resulting from a disregard of this operation manual, we do not take any liability. The design and specifications

shown in this operation manual are subject to change without notice due to our continuing program of product development.

The copyright of this manual remains with AVK Mittelmann Armaturen GmbH. This manual includes technical regulations and

drawings that must not be copied, distributed or used unauthorized for competitive ends or other influence in third parties,

neither completely, nor partly.

INSTALLATION AND MAINTENANCE INSTRUCTIONS

AVK ABOVE GROUND HYDRANTS

SERIES 84/25-27 Model P7

8. TECHNICAL DATA

Above ground hydrant according to DIN EN 14384-C DN 80/100 PN 16.

Ductile cast iron GJS, in break-away design with additional ball shut-off and

automatic drain.

Max. operating pressure (PFA):

Max. operating temperature:

16 bar

40 C

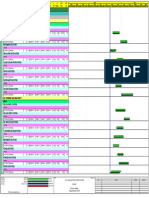

Table 1

DIMENSIONS AND WEIGHTS

AVK Reference No.

DN

PN

Bury

m

84-100-26-2110XX

84-100-26-3110XX

84-100-26-4110XX

84-100-25-2110XX

84-100-25-3110XX

84-100-25-4110XX

100

100

100

100

100

100

16

16

16

16

16

16

1,00

1,25

1,50

1,00

1,25

1,50

L1 L2 L3 L4 L5 L6 L7 SW D1 Weight

mm mm mm mm mm mm mm mm mm

kg

2117

2367

2617

2117

2367

2617

265

265

265

265

265

265

725 1232

975 1232

1225 1232

725 1232

975 1232

1225 1232

958

958

958

958

958

958

155 70 360

155 70 360

155 70 360

155 355 70 360

155 355 70 360

155 355 70 360

92

98

103

93

99

104

0620

AVK Mittelmann Armaturen GmbH, 42489 Wlfrath

14

0620-CPR-6122

Standards and und further regulations:

DIN EN 14384, Pillar fire hydrants

DIN EN 1074-6, Valves for water supply Part 6: Hydrants

DIN 14318, Solid coupling type B with metallic sealing area and cover;

PN 16

DIN 14319, Solid coupling type A with metallic sealing area and cover;

PN 16

DVGW inspection code of practice VP 325, Hydrants for drinking water

supply

DVGW code of practice W 331, Selection, installation and operation of

hydrants

DIN 3223, Handling keys for valves

EN 14384

Above ground hydrant, ductile cast iron, DN 100, PN 16

Closing direction ................ clockwise

Number of turns to open:

(ineffective and total) .......... 3 and 14

Torque (MOT, mST)............ 125 Nm, 250 Nm (Range 2)

Inlet ..................................... EN 1092-2 DN 100

Outlet .................................. DIN 14318 B, DIN 14319 A

Typ C ..................................

Kv for 1x DN 65 ................. 149 m/h

Kv for 2x DN 65 ................. 209 m/h

Kv for 1x DN 100 ............... 270 m/h

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Manual Zetkama Fig.215 - 216Document8 pagesManual Zetkama Fig.215 - 216George_Wabag_2014No ratings yet

- p177 02 PDFDocument4 pagesp177 02 PDFJuan ZamoraNo ratings yet

- Vane Presiune DN40 - DN250Document28 pagesVane Presiune DN40 - DN250iza66bellNo ratings yet

- Ball Valves and Rotary Actors GuideDocument12 pagesBall Valves and Rotary Actors GuideAdvokat HadziTonicNo ratings yet

- Control Valve Norriseal - Series2200 O&MDocument16 pagesControl Valve Norriseal - Series2200 O&MJairo AlonsoNo ratings yet

- Pre-Setting Manual Balancing Valves CIM 788: Technical InformationDocument7 pagesPre-Setting Manual Balancing Valves CIM 788: Technical InformationblindjaxxNo ratings yet

- Installation and Service Instructions Solar Divicon, Solar Circuit Pump LineDocument16 pagesInstallation and Service Instructions Solar Divicon, Solar Circuit Pump LineIonut SomneaNo ratings yet

- Es Acv M115F M1115FDocument4 pagesEs Acv M115F M1115FWattsNo ratings yet

- SB388CDocument13 pagesSB388CBenjamin LeedsNo ratings yet

- PVR-108-2 Fueling Model SheetDocument2 pagesPVR-108-2 Fueling Model SheetLetycia RosalesNo ratings yet

- Worcester Controls 10, 15, 20 ACCESS I and 10-40 ACCESS M 39 Actuators Intrinsically SafeDocument16 pagesWorcester Controls 10, 15, 20 ACCESS I and 10-40 ACCESS M 39 Actuators Intrinsically SafeMijin28No ratings yet

- Atmospheric Relief Valve ManualDocument12 pagesAtmospheric Relief Valve ManualTarun ChandraNo ratings yet

- HDPH436vikingheavypump (German)Document17 pagesHDPH436vikingheavypump (German)Hector_Cornejo_5673No ratings yet

- 25F-PRCServ PDFDocument38 pages25F-PRCServ PDFsindelu60No ratings yet

- Maintenance and Operation Manual Hydraulic Choke and Control ConsoleDocument42 pagesMaintenance and Operation Manual Hydraulic Choke and Control ConsoleMehdi Hajd KacemNo ratings yet

- DTan625 Operating Instructions For The DN40 PN25 ValvesDocument15 pagesDTan625 Operating Instructions For The DN40 PN25 ValvesGeorgeKKonsolasNo ratings yet

- 7.06 EC 10M SINGLE BOP manDocument20 pages7.06 EC 10M SINGLE BOP manRafael BolivarNo ratings yet

- Apv Delta Sv1Document20 pagesApv Delta Sv1VLASTARNo ratings yet

- Tomoe General CatalogDocument508 pagesTomoe General CatalogArianto SutarnioNo ratings yet

- Proinert® Cylinder Completer Kit - Ig-541Document2 pagesProinert® Cylinder Completer Kit - Ig-541Марко НакићNo ratings yet

- Orbinox VG08 Knife Gate ValveDocument8 pagesOrbinox VG08 Knife Gate ValveYorkistNo ratings yet

- Air Dryer - Maint - Manual - Rev - 1 PDFDocument34 pagesAir Dryer - Maint - Manual - Rev - 1 PDFCristiTancuNo ratings yet

- Installation and maintenance manual for Type A knife gate valveDocument10 pagesInstallation and maintenance manual for Type A knife gate valveAntonio Luque CruzNo ratings yet

- Manual SSW10Document31 pagesManual SSW10Victor RodriguezNo ratings yet

- Avk Underground Hydrants Underground Hydrants: SERIES 35-72 - Model Model GOSTDocument4 pagesAvk Underground Hydrants Underground Hydrants: SERIES 35-72 - Model Model GOSTDavid Luna MolinaNo ratings yet

- Engine Component Inspection GuideDocument248 pagesEngine Component Inspection GuideLolok Tiviyanto100% (3)

- Choke Maintnance PDFDocument42 pagesChoke Maintnance PDFbtrasla9023No ratings yet

- Operating Instructions & Service Manual Blue Max Ii Hydrostatic Test PumpDocument10 pagesOperating Instructions & Service Manual Blue Max Ii Hydrostatic Test PumpdocrafiNo ratings yet

- Bomba Primaria e CombustibleDocument8 pagesBomba Primaria e CombustibleoscarNo ratings yet

- 2, 5 Inch Side Door Stripper PDFDocument16 pages2, 5 Inch Side Door Stripper PDFOvRrj AhmedNo ratings yet

- CEDASPE® VP VP150 InstructionsDocument2 pagesCEDASPE® VP VP150 InstructionssvismaelNo ratings yet

- Viking 4324A Oandm TSM6303 PDFDocument11 pagesViking 4324A Oandm TSM6303 PDFQOBITNo ratings yet

- Series 808Y Installation InstructionsDocument4 pagesSeries 808Y Installation InstructionsFEBCONo ratings yet

- Typical Module Maintenance Schedule - Turbine MeteredDocument1 pageTypical Module Maintenance Schedule - Turbine MeteredRindu Putra AmbaritaNo ratings yet

- CFS PRV IOM Single PageDocument2 pagesCFS PRV IOM Single PageMazenNo ratings yet

- Topworx Position SwitchDocument60 pagesTopworx Position SwitchsarkaftNo ratings yet

- 760 Series Installation and Operation Instruction: Electrohydraulic ServovalveDocument4 pages760 Series Installation and Operation Instruction: Electrohydraulic ServovalveeferviNo ratings yet

- MODEL 5500 HYDRAULIC TUBING TONG OPERATIONS AND SERVICE MANUALDocument37 pagesMODEL 5500 HYDRAULIC TUBING TONG OPERATIONS AND SERVICE MANUALLucas Lewis0% (3)

- Standard Gate Valves ManualDocument8 pagesStandard Gate Valves ManualmechanikyNo ratings yet

- Sauter B6R Three-Way Valve With Female Thread, PN 16Document4 pagesSauter B6R Three-Way Valve With Female Thread, PN 16pitanje1991No ratings yet

- Hydro6 Operation Manual PDFDocument12 pagesHydro6 Operation Manual PDFCastro Dios En Ti ConfioNo ratings yet

- Butterfly Valves Series U: Cat: 16UCATR08-E Rev: 08 - 08/2009Document22 pagesButterfly Valves Series U: Cat: 16UCATR08-E Rev: 08 - 08/2009starlaysNo ratings yet

- Warning: L1200 Superseded by LS200. For L1100 & DVU, See New InfoDocument6 pagesWarning: L1200 Superseded by LS200. For L1100 & DVU, See New InfoRiky AyalaNo ratings yet

- 45Kg Cylinder & Valve AssemblyDocument4 pages45Kg Cylinder & Valve AssemblyRaju Saha100% (1)

- Ecodan Indoor EHPT20X-VM2HB ServiceDocument92 pagesEcodan Indoor EHPT20X-VM2HB ServiceEbi ZamaniNo ratings yet

- AVK HydrantDocument16 pagesAVK HydrantNarendra Reddy BhumaNo ratings yet

- Service Guide: Armstrong Inverted Bucket Steam TrapsDocument36 pagesService Guide: Armstrong Inverted Bucket Steam Trapsaacp271165No ratings yet

- Methven Nefa Pressure Reducing Valves ReferenceDocument36 pagesMethven Nefa Pressure Reducing Valves ReferenceLen Salisbury100% (1)

- 390 InstructionsDocument48 pages390 InstructionsemaanazeemNo ratings yet

- Differential Pressure Valve: Model 4143ADocument7 pagesDifferential Pressure Valve: Model 4143Ashahrol effendy rodziNo ratings yet

- Es Acv 1116FMDocument4 pagesEs Acv 1116FMWattsNo ratings yet

- RTHC Svn02c enDocument16 pagesRTHC Svn02c enRicardo100% (1)

- FVCPDocument14 pagesFVCPmichaelxiaoNo ratings yet

- PETRO FILL-RITE 900 Series Meter Owner ManualDocument4 pagesPETRO FILL-RITE 900 Series Meter Owner Manualpaulm3565No ratings yet

- Samson PRV Mounting and Operating InstructionDocument20 pagesSamson PRV Mounting and Operating InstructionRick CalaguiNo ratings yet

- Febco DCD and DC 850 856 870 and 876Document12 pagesFebco DCD and DC 850 856 870 and 876Brandon TrocNo ratings yet

- Actuador de Válvula FlowserveDocument8 pagesActuador de Válvula FlowserveemanuellesanchezNo ratings yet

- Etabs PDFDocument12 pagesEtabs PDFLimhot SitanggangNo ratings yet

- Hercule Design 2D Pipe Fittings Library - Installation InstructionsDocument1 pageHercule Design 2D Pipe Fittings Library - Installation InstructionsLimhot SitanggangNo ratings yet

- Datasheet PDFDocument1 pageDatasheet PDFLimhot SitanggangNo ratings yet

- Datasheet2 PDFDocument1 pageDatasheet2 PDFLimhot SitanggangNo ratings yet

- MS Project Tutorial for Software Project ManagementDocument36 pagesMS Project Tutorial for Software Project ManagementBilal Ahmed Barbhuiya100% (3)

- Epmp1000SectorAntennaFINAL 1-20-2013Document4 pagesEpmp1000SectorAntennaFINAL 1-20-2013Limhot SitanggangNo ratings yet

- Epmp1000SectorAntennaFINAL 1-20-2013Document4 pagesEpmp1000SectorAntennaFINAL 1-20-2013Limhot SitanggangNo ratings yet

- Document 1Document1 pageDocument 1Limhot SitanggangNo ratings yet

- 13 X 18 Cm. Cutout PrintsDocument1 page13 X 18 Cm. Cutout PrintsLimhot SitanggangNo ratings yet

- Konversi Satuan, Sipil, Analisis Satuan, Mpa Ke kg/cm2Document1 pageKonversi Satuan, Sipil, Analisis Satuan, Mpa Ke kg/cm2Muhammad Reza Umari75% (4)

- 10 X 15 Cm. Album PrintsDocument1 page10 X 15 Cm. Album PrintsLimhot SitanggangNo ratings yet

- Plumbing CalculationDocument12 pagesPlumbing Calculationmkchy12100% (9)

- CH 9Document6 pagesCH 9Virah Sammy ChandraNo ratings yet

- Bandhara, Percolation TankDocument52 pagesBandhara, Percolation TankAppaso B. Sonalkar55% (11)

- Water Sizing Chart With FORMULA 8.15.11Document10 pagesWater Sizing Chart With FORMULA 8.15.11dheerajdorlikarNo ratings yet

- Lay Up ProcedureDocument21 pagesLay Up ProcedureAmir100% (1)

- Home Water Supply SystemDocument49 pagesHome Water Supply Systemragani ramadasNo ratings yet

- Progress Master Schedule of Construction: Piping Power BlockDocument7 pagesProgress Master Schedule of Construction: Piping Power BlockSamuelTrinandoNo ratings yet

- SJMVertical Mixed Flow Pumps en E10016 6 2008Document8 pagesSJMVertical Mixed Flow Pumps en E10016 6 2008Paijo TejoNo ratings yet

- Kayakal ChecklistDocument38 pagesKayakal Checklistgeologistlakhan100% (1)

- Water, Sanitation, Hygiene and Habitat in PrisonsDocument147 pagesWater, Sanitation, Hygiene and Habitat in PrisonsInternational Committee of the Red Cross100% (2)

- Phu Dong Premier ApartmentDocument146 pagesPhu Dong Premier ApartmentMan EbookNo ratings yet

- Vertical Pump Ranges: Sulzer PumpsDocument4 pagesVertical Pump Ranges: Sulzer Pumpsjhonny_restrepo001No ratings yet

- Water PollutionDocument38 pagesWater PollutionJes GarciaNo ratings yet

- Lecture 10 Stream GaugingDocument49 pagesLecture 10 Stream Gaugingengineeringhydrologyfa23No ratings yet

- Piping Site Visit Report-02Document8 pagesPiping Site Visit Report-02Sundravadivel PalanisamyNo ratings yet

- Kirloskar 2 HP - 1.5 KW 3 Phase Self Priming Monoblock Pump (SP-1HM-3PH)Document2 pagesKirloskar 2 HP - 1.5 KW 3 Phase Self Priming Monoblock Pump (SP-1HM-3PH)Goutham MohanNo ratings yet

- Septic TankDocument19 pagesSeptic TankDevendra Sharma100% (1)

- 2019 IWA WDCE SriLanka Programme-Book Website PDFDocument75 pages2019 IWA WDCE SriLanka Programme-Book Website PDFPradeep KumaraNo ratings yet

- Water Requirements of LivestockDocument2 pagesWater Requirements of LivestockEdsonJAmbaneNo ratings yet

- State of Art of Compacted CFRDDocument9 pagesState of Art of Compacted CFRDjnfNo ratings yet

- SABIAN BWS Filter IntroductionDocument3 pagesSABIAN BWS Filter Introductionrohl55No ratings yet

- Nairobi City Water & Sewerage Company LTDDocument1 pageNairobi City Water & Sewerage Company LTDSophy70% (10)

- Seawater DesalinationDocument12 pagesSeawater DesalinationJames Bradford100% (2)

- Challenges of Urban Water Management in Nigeria THDocument11 pagesChallenges of Urban Water Management in Nigeria THOlusegun TolulopeNo ratings yet

- SGLGB Form 1 - Barangay ProfileDocument3 pagesSGLGB Form 1 - Barangay ProfileDonavel Nodora Jojuico67% (3)

- Protect downstream equipment with a resin trapDocument2 pagesProtect downstream equipment with a resin trapdeyprasenNo ratings yet

- Eps12 PDFDocument3 pagesEps12 PDFFuadChiwaNo ratings yet

- Flow Over WeirsDocument3 pagesFlow Over WeirsNurshazwani syuhada bt al- badri0% (1)

- Water Resources Engineering Case StudyDocument13 pagesWater Resources Engineering Case StudyCris Alron Dizon ChatoNo ratings yet