Professional Documents

Culture Documents

Introduction To CNC Machine PDF

Introduction To CNC Machine PDF

Uploaded by

Patricio ArrobaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Introduction To CNC Machine PDF

Introduction To CNC Machine PDF

Uploaded by

Patricio ArrobaCopyright:

Available Formats

What is CNC?

Introduction to CNC

CNC means Computer Numerical Control.

A form of programmable automation.

Typical program containing coded alphanumeric data, such as

G01 X120 Y200

Dr. J. M. Zhou

The data represent relative positions between a cutting tool and a

workpiece

spindle

Slide

movement

Drive motor

Avdelningen fr mekanisk teknologi och verktygsmaskiner

Lund Tekniska Hgskola

Feedback

device

Drive motor signal

MCU

Feedback signal

NC part program

Why CNC machining?

Improved automation

Improve the quality and accuracy of manufactured parts

Flexibility to manufacture complex or otherwise

impossible jobs

2D and 3D contours

Stabilize manufacturing costs

Drives of CNC machine tool

Typical CNC machine

Major component:

- Drivers unit

- Sliding system

- Machine control unit (MCU)

Ball-bearing leadscrew

Hydraulic actuator

- high power machine tool

Stepping motor

- small machine due to limited power and torque

DC motor

- excellent speed regulation, high torque,

most widely used

Nut

Nut

Ball-bearing leadscrew

Friction behavior versus velocity

(a) Sliding friction, conventional screw

(b) Rolling friction, ball-bearing screw

Control of CNC Machine Tool

Interpret a CNC program

Produce coordinated pulses for multiple axes of motion

Activate the series of commands in sequential order

Two Basic Types of Control in CNC

Open loop system

Operates without verifying that the actual position is equal to

the specified position

Usually a stepping motor

Closed loop control system

Uses feedback measurement to verify that the actual position is

equal to the specified location

Servo motor with a feedback loop

Schematic illustration of the major components of

a numerical control machine tool.

Measurement of linear displacement

Encoder operating principles

Direct measurement

A measuring scale secured to the slide or machining table and

measuring value resolver (encoder) pick up information optically

from measuring scale and converts this into electrical signal.

LED light passes through a moving disc to

produce an electronic output from a

photodiode cell

Encoders

- Incremental encoder

- Absolute encoder

Indirect measurement

The slide traverse is represented by rotation and a resolver

records the rotational movement of a pulse disc. The control

system calculates the slide traverse movement from rotation

pulse.

(a) Direct measurement of the linear displacement of a machine-tool worktable. (b)

and (c) Indirect measurement methods.

Touch Probes

Incremental vs. absolute encoders

Incremental encoders

The most common incremental provide a digital pulse for each

resolvable position to be counted and referenced to a home position.

These digital pulses are then fed into a high-speed counter module

located in a drive or controller interface.

Absolute encoders

Every position of an absolute device is unique, and these devices do

not lose position when power is removed.

Workpiece

coordinate system

Z

X

G54

Y

Machine

coordinate system

Touch probes used in machining

centers for determining workpiece and

tool positions and surfaces relative to

the machine table or column. (a)

Touch probe determining the X-Y

(horizontal) position of a workpiece,

(b) determining the height of a

horizontal surface, (c) determining the

planar position of the surface of a

cutter (for instance, for cutter-diameter

compensation), and (d) determining

the length of a tool for tool-length

offset. Source: Hitachi Seiki Co., Ltd.

Motion control - point to point control

B

Motion control - continuous path (CP)

Continuous simultaneous control of more than one axis, thus

controlling path followed by tool relative to part

Workpiece is moved to a programmed

location with no regard for path taken

to get to that location

Controls both the displacement and the velocity.

Use linear and circular interpolators.

Once the move is completed, some

processing action is accomplished by

the cutting tool

Examples: drilling or punching a hole

A

Workpiece

Interpolator: Digital differential analyzers (DDA).

Moving at maximum rate from point to

point.

Accuracy of the destination is important

but not the path

B

Linear interpolation

NC machine rating

Circular interpolation

NC Part Programming Techniques

Accuracy

Repeatability

Spindle and axis motor horsepower

Number of controlled axes

1. Manual part programming

2. Computer-assisted part programming

3. CAD/CAM- assisted part programming

Common features:

Dimension of workspace

Features of the machine and the controller.

Programmed position

Repeatability

Points, lines, and surfaces of the workpart must be

defined relative to NC axis system

Movement of the cutting tool must be defined

relative to these part features

Avg. error

Test result

NC Words

A G-code program consists the following words:

N, G, X, Y, Z, I, J, K, F, H, D, S, T, R, M

N - Sequence number (Used for line identification)

G - Preparatory function

X - X axis designation

Y - Y axis designation

Z - Z axis designation

R - Radius designation

F - Feedrate designation

S - Spindle speed designation

H - Tool length offset designation

D - Tool radius offset designation

T - Tool Designation

M - Miscellaneous function (See below)

NC Words G codes

Preparatory functions: preparing MCU to perform a specific mode of operation

Use G codes followed by two digits

Interpolation is used, linear and circular

Canned cycles

Example

N10 MSG(This is my first

NC program)

N20 F200 S900 T1 D2 M3

N30 G0 X100 Y100

N40 G1 X150

N50 G2 X150 Y120

I=AC(45) J=AC(35)

N60 X100

N70 Y100

N80 G0 X0 Y0

N90 M30

NC Words M Codes

NC Words

Spindle control words

S word is used to specify the spindle speed

M03: turn spindle on in clockwise

M04 turns spindle on in counter clockwise

M05 turn spindle off

Dimensional words

X, Y, Z for primary motion direction in X, Y, Z

Feed words

F Code. feed speed. mm/min (mmpm), or mmpr.

Automatic tool change

T word is used to tell the machine which tool station is to

placed in the spindle.

Manual Part Programming: Example

M0

M01

M02

M03

M04

M05

M06

M07

M08

M09

M17

M30

Program stop

Optional stop

End of main program

Spindle CW

Spindle CCW

Spindle stop

Tool change

Flood coolant on

Mist coolant on

Coolant off

End of subprogram

End of program

Example

N10 MSG(This is my first

NC program)

N20 T1 D2 M06

N25 F200 S900 M3 M07

N30 G0 X100 Y100

N40 G1 X150

N50 Y120

N60 X100

N70 Y100

N80 G0 X0 Y0 M05

N90 M30

Summary

Example block command for milling operation:

N10 MSG(This is my first NC program) Y

N15 G54

N20 F200 S900 T1 D2 M3

120

N30 G41 G0 X100 Y100

N40 G1 X150

N50 Y120

N60 X100

100

N70 Y100

N80 G40 G0 X0 Y0

100

N90 M30

M Code. miscellaneous word.

Concept of CNC machine

Basic components of CNC machine

CNC control

CNC programming

150

Complete part program consists of a sequence of

such block commands

You might also like

- Corduroy 110411155214 Phpapp01Document29 pagesCorduroy 110411155214 Phpapp01Trung Quoc LeNo ratings yet

- Osd Stds ST FurnitureDocument18 pagesOsd Stds ST FurnitureTrung Quoc LeNo ratings yet

- Moo Baa PDFDocument7 pagesMoo Baa PDFTrung Quoc LeNo ratings yet

- Us 20030110749Document9 pagesUs 20030110749Trung Quoc LeNo ratings yet

- NCT 201 L Operator's Manual 130131Document100 pagesNCT 201 L Operator's Manual 130131Trung Quoc LeNo ratings yet

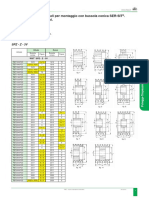

- Pulegge A Gole Trapezoidali Per Montaggio Con Bussola Conica SER-SIT - Nuovi Standard CostruttiviDocument6 pagesPulegge A Gole Trapezoidali Per Montaggio Con Bussola Conica SER-SIT - Nuovi Standard CostruttiviTrung Quoc LeNo ratings yet

- Value of Own Tool Sharpening: European Dealer MeetingDocument29 pagesValue of Own Tool Sharpening: European Dealer MeetingTrung Quoc LeNo ratings yet

- Sheet Metal Forming ProcessesDocument51 pagesSheet Metal Forming ProcessesTrung Quoc LeNo ratings yet

- Fqmmtyd2r3isinmsklkg Signature Poli 150402133420 Conversion Gate01Document495 pagesFqmmtyd2r3isinmsklkg Signature Poli 150402133420 Conversion Gate01Trung Quoc LeNo ratings yet

- Metal Craft ChennaiDocument25 pagesMetal Craft ChennaiTrung Quoc LeNo ratings yet

- Edu Cat en Fms Fi v5r19 ToprintDocument219 pagesEdu Cat en Fms Fi v5r19 ToprintTrung Quoc LeNo ratings yet

- LAADP 3D Profile Panels 08 2011 BDocument20 pagesLAADP 3D Profile Panels 08 2011 BTrung Quoc LeNo ratings yet

- Ultrasonic-Machining ProcessDocument16 pagesUltrasonic-Machining ProcessTrung Quoc LeNo ratings yet

- Mill DetailsDocument18 pagesMill DetailsTrung Quoc LeNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Conduits and Wiring DiagramsDocument19 pagesConduits and Wiring DiagramsSaunok100% (1)

- Owner'S Manual: U6DR31E0.book Page 1 Tuesday, May 14, 2013 8:46 AMDocument108 pagesOwner'S Manual: U6DR31E0.book Page 1 Tuesday, May 14, 2013 8:46 AMAlex VdbusscheNo ratings yet

- Honda CVTDocument6 pagesHonda CVTAbo FatmaNo ratings yet

- Manual de Instrucciones - Cabina de Bioseguridad Thermo - Fisher - Scientific 1375 Serie 1300Document70 pagesManual de Instrucciones - Cabina de Bioseguridad Thermo - Fisher - Scientific 1375 Serie 1300MARIA ALEJANDRA SIERRA GILNo ratings yet

- Blanchard Model (Situational Leadership Model)Document5 pagesBlanchard Model (Situational Leadership Model)yeldez arraNo ratings yet

- FLS Minerals Brochure PDFDocument8 pagesFLS Minerals Brochure PDFmonam ellghorbeliNo ratings yet

- Plan Electrique Ascenseur 11085289Document39 pagesPlan Electrique Ascenseur 11085289Mohamed AbdolahNo ratings yet

- DOKA Formwork For BridgesDocument80 pagesDOKA Formwork For BridgesTamaduianu Ioan100% (1)

- lpd8806 EnglishDocument6 pageslpd8806 EnglishpeterpetNo ratings yet

- KodakDocument10 pagesKodakEmerson Fonte Dos Santos FreireNo ratings yet

- Study Files CountsDocument68 pagesStudy Files CountsForbes LendingNo ratings yet

- Beneficiation of Low Grade Graphite Ore of Eastern India by Two-Stage Grinding and Flotation N. Vasumathi, T.V. Vijaya Kumar, B. Nayak, S. Subba Rao, S. Prabhakar, G. Bhaskar RajuDocument9 pagesBeneficiation of Low Grade Graphite Ore of Eastern India by Two-Stage Grinding and Flotation N. Vasumathi, T.V. Vijaya Kumar, B. Nayak, S. Subba Rao, S. Prabhakar, G. Bhaskar RajusanjibkrjanaNo ratings yet

- Calculate Battery Voltage Using Pic ADC - Electrical Engineering Stack ExchangeDocument5 pagesCalculate Battery Voltage Using Pic ADC - Electrical Engineering Stack ExchangeJaiParkashNo ratings yet

- Vapour Absorption Chiller (VAM) - Working Principle in DetailDocument14 pagesVapour Absorption Chiller (VAM) - Working Principle in DetailSantosh BaladhyeNo ratings yet

- Lead Auditors Training CourseDocument94 pagesLead Auditors Training CourseCherryRoseSaguinsin100% (5)

- Steel Design Guide 14 - Staggered Truss Framing Systems PDFDocument45 pagesSteel Design Guide 14 - Staggered Truss Framing Systems PDFAndré Luiz Nogueira100% (1)

- Ie655 Assignments 4revaDocument6 pagesIe655 Assignments 4revaapi-375920197No ratings yet

- Strahlenfolter Stalking - TI - Human Experimentation - Psychotronics Warfare - Part 2 - Electromagnetic Murders - GeeldonDocument65 pagesStrahlenfolter Stalking - TI - Human Experimentation - Psychotronics Warfare - Part 2 - Electromagnetic Murders - GeeldonHermann-SchwanneckeNo ratings yet

- Artikel SkripsiDocument7 pagesArtikel SkripsiWuri AstiwiNo ratings yet

- FNU Employee Confidentiality Agreement EditableDocument2 pagesFNU Employee Confidentiality Agreement EditableManishaNo ratings yet

- 79114Document36 pages79114Esraa AliNo ratings yet

- Allplan 2006 Engineering Tutorial PDFDocument374 pagesAllplan 2006 Engineering Tutorial PDFEvelin EsthefaniaNo ratings yet

- JAMCO GF Fittings SubmittalDocument24 pagesJAMCO GF Fittings SubmittalMohammad Rashad BarakatNo ratings yet

- Omr 120 Questions PDFDocument1 pageOmr 120 Questions PDFabhinav100% (1)

- Company Profile PT. Fajar Mas MurniDocument39 pagesCompany Profile PT. Fajar Mas MurniAndi CampusNo ratings yet

- DQ542MADocument5 pagesDQ542MADima RedkinNo ratings yet

- 3-1 DMM1 (Nov 2009 Regular)Document9 pages3-1 DMM1 (Nov 2009 Regular)micmechNo ratings yet

- Difference Between A Leader Vs ManagerDocument5 pagesDifference Between A Leader Vs ManagerFrank Guy100% (6)

- Order & Ranking Practice QuesDocument15 pagesOrder & Ranking Practice QuesShubham Verma100% (1)