Professional Documents

Culture Documents

How I Make Reamer

How I Make Reamer

Uploaded by

DastnCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How I Make Reamer

How I Make Reamer

Uploaded by

DastnCopyright:

Available Formats

How I make chamber reamers

Page 1 of 1

How I make chamber reamers

There really isnt any magic to this. Any well-educated American with a couple of brain cells to rub

together should be able to figure this out heck, I did! But caution is advised. Machining tolerances

must be exact or dangerous situations will be produced. Excellent quality chamber reamers are available

through multiple commercial sources (e.g. Clymer, PTG, Manson) at very reasonable prices, especially

given the time involved in making your own. Despite these caveats Ive enjoyed spending more time

than I should developing the method described. Ive pulled information from various sources, especially

Paul Rodgers (http://www.saubier.com/paulrodgers/reamer.html), so nothing here has been invented.

The method described is what I have personally used I guarantee there are better ways and I hope that

suggestions will be shared. If you engage in this activity, do so at your own risk. If you really need a

reamer you should buy one commercially if youre like me your initial efforts will fail!

Step 1: Cut a piece of 01 steel seven inches long. The cheap bandsaw is one of my favorite tools.

Page 2.htm

http://personal.geeksnet.com/soderstrom/ReamerMaking/HowImakechamberreamers.htm

8/4/2004

Step 2:

Page 1 of 2

Step 2: Face and drill one end of the reamer blank. I use a 3, four-jaw chuck in my mini-lathe

Set-up

Face

Drill for live center

http://personal.geeksnet.com/soderstrom/ReamerMaking/Page%202.htm

8/4/2004

Step 2:

Page 2 of 2

Page 3.htm

http://personal.geeksnet.com/soderstrom/ReamerMaking/Page%202.htm

8/4/2004

Step 3:

Page 1 of 5

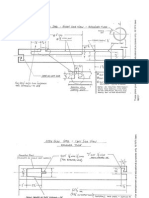

Step 3: Turn the reamer blank

Set-up in four-jaw chuck and live center

Take a cut (to 0.48 0.49)

Cut to neck diameter. This blank is for an 8 x 57 AI. Neck diameter = 0.357. The cross slide is set to

40* for the shoulder.

http://personal.geeksnet.com/soderstrom/ReamerMaking/Page%203.htm

8/9/2004

Step 3:

Page 2 of 5

Measure the neck

Turn the pilot

http://personal.geeksnet.com/soderstrom/ReamerMaking/Page%203.htm

8/9/2004

Step 3:

Page 3 of 5

Now its time to set the taper. This was difficult at first and took some practice but is no big deal now. I

set the taper by offsetting the mini-lathe tailstock.

Mark the shoulder-to-base dimension

http://personal.geeksnet.com/soderstrom/ReamerMaking/Page%203.htm

8/9/2004

Step 3:

Page 4 of 5

Use feeler gauges to measure the taper. For the 8 x 57 AI the shoulder is 0.455 and the base is 0.470,

a difference of 0.015. This difference is in-terms of the diameter of the reamer at these points. The

feeler guage measurements reflect differences between the radius of these points. Because the radii are

the diameters, we are looking for a 0.0075 difference between shoulder and base. The limit of my

feeler gauge precision is 0.001 and so I round down to 0.007. I can set this using a 0.010 gauge at the

shoulder and a 0.017 gauge at the base.

0.010 at the shoulder

0.017 at the base

http://personal.geeksnet.com/soderstrom/ReamerMaking/Page%203.htm

8/9/2004

Step 3:

Page 5 of 5

And cut the taper. Go slow. This is the tricky part. The base diameter is determined by the web of the

brass and cannot vary. Make your first cuts light and keep checking. Approach the base diameter

slowly. If your taper is correct, when the base diameter is reached the shoulder will be right-on. Focus

on hitting the base.

OK, now the taper is cut and its time to polish with 400 grit.

Page 4.htm

http://personal.geeksnet.com/soderstrom/ReamerMaking/Page%203.htm

8/9/2004

Step 4: Cutting the flutes

Page 1 of 3

Step 4: Cutting the flutes

Cut a piece of masking tape exactly long enough to fit around the unturned end of the reamer blank.

Ive found that I can fit a total of five flutes around reamers of this size. Measure the piece of tape

(which is the blank circumference) and divide by five. Mark the tape and return around the reamer.

Mark the reamer. These marks will guide flute placement. Masking tape is cheaper than a dividing

head.

Mount the turned blank in V-blocks. Move the end mill down to touch one of the unturned ends.

Measure. Because the stock I use is 0.498, if I go down 0.249 Ill be at the midline. Machine shop

handbooks indicate that reamer flutes are usually at 95*. To simulate this extra 5* without too much

drama I just go down an additional 0.005. It seems to work.

http://personal.geeksnet.com/soderstrom/ReamerMaking/Page%204.htm

8/4/2004

Step 4: Cutting the flutes

Page 2 of 3

Cut the first flute

Rotate the reamer until the next mark is TDC and cut the second flute. Repeat until five are cut. Dont

cut too deep youll run out of room and and destroy the edge of neighboring flutes.

http://personal.geeksnet.com/soderstrom/ReamerMaking/Page%204.htm

8/4/2004

Step 4: Cutting the flutes

Page 3 of 3

Page 5.htm

http://personal.geeksnet.com/soderstrom/ReamerMaking/Page%204.htm

8/4/2004

Step Five: Heat treating

Page 1 of 3

Step Five: Heat treating

I use an oxyacetylene torch to heat until non-magnetic, followed by a used motor oil quench.

Mounting the reamer in a drill press may help even heating and reduce warpage I havent had a

problem yet (knock-knock).

Cut-off unturned end proximal to the pilot (how did I live without a band saw?)

Stamp the cartridge information and grind flats for a 7/16 wrench

Mount in a drill press and get everything ready for heat-treat and quenching. Thats used motor oil in

http://personal.geeksnet.com/soderstrom/ReamerMaking/Page%205.htm

8/4/2004

Step Five: Heat treating

Page 2 of 3

the pasta sauce jar, although the sauce would probably get the job done. It might smell better too (but

maybe not).

While turning, heat to non-magnetic

http://personal.geeksnet.com/soderstrom/ReamerMaking/Page%205.htm

8/4/2004

Step Five: Heat treating

Page 3 of 3

Quickly (and safely) extinguish the torch, and in one smooth movement raise the motor oil to cover the

rotating, red-hot reamer and move the press table to support the jar. Stinky! Let the reamer cool in the

oil

Page 6.htm

http://personal.geeksnet.com/soderstrom/ReamerMaking/Page%205.htm

8/4/2004

Step 6: Relieving and sharpening

Page 1 of 1

Step 6: Relieving and sharpening

Stone off the burrs from the cutting edges. Careful! Just take the burr off. Any more will dull the

reamer.

I use a Dremel with a grinding wheel to relieve the cutting edges. You only need/want about 1/8-1/16

of a land behind each cutting edge. Much more and the flute wont cut well. Carefully grind to about

this width.

Page 7.htm

http://personal.geeksnet.com/soderstrom/ReamerMaking/Page%206.htm

8/4/2004

Step 7: Trying it out

Page 1 of 2

Step 7: Trying it out!

Chuck-up a shot-out Mauser barrel

Ream!

http://personal.geeksnet.com/soderstrom/ReamerMaking/Page%207.htm

8/4/2004

Step 7: Trying it out

Page 2 of 2

There are some nice chips!

Ive got this barrel mounted to an action and have fire-formed five nice pieces of 8 x 57 AI brass. Stay

tuned for the next episode where I chamber a Mauser take-off in good condition and work-up loads!

http://personal.geeksnet.com/soderstrom/ReamerMaking/Page%207.htm

8/4/2004

You might also like

- DIY GUNS: Recoil Magazine's Guide to Homebuilt Suppressors, 80 Percent Lowers, Rifle Mods and More!From EverandDIY GUNS: Recoil Magazine's Guide to Homebuilt Suppressors, 80 Percent Lowers, Rifle Mods and More!Rating: 4 out of 5 stars4/5 (4)

- Building a Home Defense Remington 870 ShotgunFrom EverandBuilding a Home Defense Remington 870 ShotgunRating: 3.5 out of 5 stars3.5/5 (5)

- Metalworking for Home Machinists: 53 Practical Projects to Build YourselfFrom EverandMetalworking for Home Machinists: 53 Practical Projects to Build YourselfNo ratings yet

- Build Bolt ActionDocument101 pagesBuild Bolt Actionknkl99% (68)

- Semiplans Sten MK2Document4 pagesSemiplans Sten MK2Mike Nichlos69% (13)

- Professional Gunsmithing - A Textbook on the Repair and Alteration of Firearms - With Detailed Notes and Suggestions Relative to the Equipment and Operation of a Commercial Gun ShopFrom EverandProfessional Gunsmithing - A Textbook on the Repair and Alteration of Firearms - With Detailed Notes and Suggestions Relative to the Equipment and Operation of a Commercial Gun ShopRating: 5 out of 5 stars5/5 (3)

- Advanced Gunsmithing: A Manual of Instruction in the Manufacture, Alteration, and Repair of Firearms (75th Anniversary Edition)From EverandAdvanced Gunsmithing: A Manual of Instruction in the Manufacture, Alteration, and Repair of Firearms (75th Anniversary Edition)Rating: 3.5 out of 5 stars3.5/5 (2)

- MAC-11 9mm Construction Conversion Iron Wulf PublishingDocument86 pagesMAC-11 9mm Construction Conversion Iron Wulf PublishingJordan Voller100% (6)

- Full Auto Conversion For Tokarev TT, TT-33 and Similar Design of PistolsDocument18 pagesFull Auto Conversion For Tokarev TT, TT-33 and Similar Design of PistolsGhazali Zuberi88% (8)

- Weaponeer Forums - STEN MK II BuildDocument221 pagesWeaponeer Forums - STEN MK II Buildcrbspoa93% (15)

- Firearms - Blueprint - Sten MK III Sub Machine Gun Receiver BondDocument1 pageFirearms - Blueprint - Sten MK III Sub Machine Gun Receiver Bondanjan971% (14)

- Blueprint - Sten MK II, MP-40, Yugo 56, Submachine GunsDocument8 pagesBlueprint - Sten MK II, MP-40, Yugo 56, Submachine GunsNorm80% (10)

- Gunsmithing Modern Firearms: A Gun Guy's Guide to Making Good Guns Even BetterFrom EverandGunsmithing Modern Firearms: A Gun Guy's Guide to Making Good Guns Even BetterRating: 5 out of 5 stars5/5 (1)

- Building Firearms - HoffmanDocument81 pagesBuilding Firearms - HoffmanWilliam Owers100% (3)

- Gunsmithing Made Easy: Projects for the Home GunsmithFrom EverandGunsmithing Made Easy: Projects for the Home GunsmithRating: 3 out of 5 stars3/5 (2)

- Building The SGN-22 (Single-Shot Rifle Build)Document25 pagesBuilding The SGN-22 (Single-Shot Rifle Build)blowmeasshole191167% (6)

- The Welrod SuppressorDocument60 pagesThe Welrod Suppressorblowmeasshole1911100% (14)

- Thermo King Parts Manual MAGNUM (51745-4-PM Rev 2) PDFDocument99 pagesThermo King Parts Manual MAGNUM (51745-4-PM Rev 2) PDFSerhiiNo ratings yet

- SI Unit Conversion TableDocument4 pagesSI Unit Conversion TableGhazali ZuberiNo ratings yet

- PPSH41 Complete Machine Plan / BlueprintsDocument31 pagesPPSH41 Complete Machine Plan / BlueprintsGhazali Zuberi92% (87)

- Union e PDFDocument33 pagesUnion e PDFGuillermo RamirezNo ratings yet

- SGN22 1 PDFDocument3 pagesSGN22 1 PDFgalak12001100% (4)

- Practical Guide to the Operational Use of the PPS-43 Submachine GunFrom EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunNo ratings yet

- Thompson SMG PlansDocument52 pagesThompson SMG PlansNicholas Jumikis100% (22)

- Blowback Bolt WeightsDocument4 pagesBlowback Bolt Weightsorions_hammer100% (2)

- Handloader's Manual - A Treatise on Modern Cartridge Components and Their Assembly by the Individual Shooter Into Accurate Ammunition to Best Suit his Various PurposesFrom EverandHandloader's Manual - A Treatise on Modern Cartridge Components and Their Assembly by the Individual Shooter Into Accurate Ammunition to Best Suit his Various PurposesNo ratings yet

- ExtrasDocument32 pagesExtrasS84S100% (5)

- The Gunsmith's Manual: Practical Guide to All Branches of the TradeFrom EverandThe Gunsmith's Manual: Practical Guide to All Branches of the TradeNo ratings yet

- Holmes 50Document65 pagesHolmes 50The_Desolator100% (15)

- 1911 Frame TutorialDocument22 pages1911 Frame Tutorialblackta6100% (6)

- Elementary Gunsmithing: A Manual of Instruction for Amateurs in the Alteration and Repair of FirearmsFrom EverandElementary Gunsmithing: A Manual of Instruction for Amateurs in the Alteration and Repair of FirearmsNo ratings yet

- Building A Button Rifling Machine by Harold HoffmanDocument15 pagesBuilding A Button Rifling Machine by Harold HoffmanNorm100% (19)

- 50 Cal PlansDocument24 pages50 Cal PlansClint Muldoon100% (10)

- SuppressorsFrom EverandSuppressorsEditors of RECOIL MagazineNo ratings yet

- Berdan II (M1870) Rifle Complete BlueprintsDocument49 pagesBerdan II (M1870) Rifle Complete BlueprintsGhazali Zuberi95% (57)

- Barrel Shank DimensionsDocument29 pagesBarrel Shank DimensionsNO2NWO100% (4)

- 1F7BZ MR Singleshot's Book of Rifle Plans Part5Document12 pages1F7BZ MR Singleshot's Book of Rifle Plans Part5angelines123100% (7)

- Custom Gunsmithing for Self-Defense FirearmsFrom EverandCustom Gunsmithing for Self-Defense FirearmsRating: 5 out of 5 stars5/5 (3)

- How To Use A Milling MachineDocument44 pagesHow To Use A Milling MachineGhazali ZuberiNo ratings yet

- How To Use A Milling MachineDocument44 pagesHow To Use A Milling MachineGhazali ZuberiNo ratings yet

- Soviet AKM 47 Assault Rifle Manual Kalashnikov 1970Document86 pagesSoviet AKM 47 Assault Rifle Manual Kalashnikov 1970Ghazali Zuberi100% (4)

- Power Inverter 12VDC To 230VAC 3000WDocument19 pagesPower Inverter 12VDC To 230VAC 3000WGhazali Zuberi100% (4)

- Building or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsFrom EverandBuilding or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsNo ratings yet

- Practical Guide to the Use of the SEMI-AUTO PPS-43C Pistol/SBRFrom EverandPractical Guide to the Use of the SEMI-AUTO PPS-43C Pistol/SBRNo ratings yet

- The Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsFrom EverandThe Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsRating: 5 out of 5 stars5/5 (3)

- Barrel Fitting by Harold HoffmanDocument114 pagesBarrel Fitting by Harold HoffmanNorm100% (7)

- Darcy Falling Block Study PlansDocument12 pagesDarcy Falling Block Study Plansangelines123100% (19)

- US660725 Hamilton Rifling MachineDocument3 pagesUS660725 Hamilton Rifling MachineDavid Corbett100% (2)

- IWI Carmel Brochure 2021 ENDocument4 pagesIWI Carmel Brochure 2021 ENพีร์พีร์0% (2)

- Barrel Drilling and ReamingDocument9 pagesBarrel Drilling and Reamingbigsmoke31100% (2)

- D66C5 MR Singleshot's Book of Rifle Plans Part1 PDFDocument18 pagesD66C5 MR Singleshot's Book of Rifle Plans Part1 PDFMainAvel100% (7)

- Material Grade Comparison TableDocument6 pagesMaterial Grade Comparison TableGhazali Zuberi100% (3)

- Antique Firearms Assembly/Disassembly: The comprehensive guide to pistols, rifles & shotgunsFrom EverandAntique Firearms Assembly/Disassembly: The comprehensive guide to pistols, rifles & shotgunsRating: 4.5 out of 5 stars4.5/5 (2)

- D-Bit Chambering Reamer MakingDocument5 pagesD-Bit Chambering Reamer MakingEadNo ratings yet

- How To Drill A Rifle BarrelDocument6 pagesHow To Drill A Rifle BarrelMaria Donoghue50% (2)

- Making Chamber ReamersDocument3 pagesMaking Chamber Reamersfmchuck100% (7)

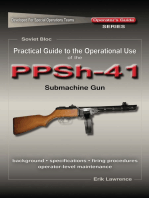

- Practical Guide to the Operational Use of the PPSh-41 Submachine GunFrom EverandPractical Guide to the Operational Use of the PPSh-41 Submachine GunRating: 5 out of 5 stars5/5 (2)

- Rifling by Flow FormingDocument6 pagesRifling by Flow FormingOzkar Pirata100% (2)

- Heat Shrink Cable End Caps 3M SKE15 40 15 32mm CablesDocument2 pagesHeat Shrink Cable End Caps 3M SKE15 40 15 32mm CablesGhazali ZuberiNo ratings yet

- How To Make SpringsDocument62 pagesHow To Make Springsrudey18No ratings yet

- CNC Turning Center ProgrammingDocument29 pagesCNC Turning Center ProgrammingSrinivas Yadav100% (1)

- Virgo Virgo: Installation Installation Operation & Operation & Maintenance Maintenance Manual ManualDocument17 pagesVirgo Virgo: Installation Installation Operation & Operation & Maintenance Maintenance Manual ManualRio WitcandraNo ratings yet

- ON/OFF Switches (Actuators) ON/OFF Switches (Bodies) : Series L2 Series L2Document7 pagesON/OFF Switches (Actuators) ON/OFF Switches (Bodies) : Series L2 Series L2Ilija ShatanovskiNo ratings yet

- PP 4 Word of WarningDocument1 pagePP 4 Word of Warningvictor SanmiguelNo ratings yet

- Weihrauch 07 CatalogueDocument8 pagesWeihrauch 07 Cataloguegraham4877100% (1)

- Laporan Kalibrasi Alkes RSKHDocument5 pagesLaporan Kalibrasi Alkes RSKHIsmaika HamidiaNo ratings yet

- CTS Turner UpdateDocument19 pagesCTS Turner Updateswami061009No ratings yet

- Internal Threads - Class 2BDocument13 pagesInternal Threads - Class 2BCraig SwensonNo ratings yet

- Unit 2 Me1203Document20 pagesUnit 2 Me1203Muthuvel MNo ratings yet

- Canvass Materials Company Name: Pouri Marketing Enterprises IncDocument1 pageCanvass Materials Company Name: Pouri Marketing Enterprises IncTeddy AcedoNo ratings yet

- Pliers and Types PDFDocument13 pagesPliers and Types PDFFred GervacioNo ratings yet

- Tool:-Single Point Cutting Tool 25Document10 pagesTool:-Single Point Cutting Tool 25HITESH SONAWANENo ratings yet

- 011 SanipackDocument2 pages011 SanipackmhdjassimNo ratings yet

- AHP-450 S3 E-Diagrams EU 380VDocument13 pagesAHP-450 S3 E-Diagrams EU 380Vyoyyo7805No ratings yet

- Sibre Data Sheet Drum Coupling ABC VDocument18 pagesSibre Data Sheet Drum Coupling ABC VGabriel MoreiraNo ratings yet

- Polea Guia, Podadora, Z355EDocument5 pagesPolea Guia, Podadora, Z355ECESARNo ratings yet

- SM Uniform - Catalog Vol 24 With CoverDocument190 pagesSM Uniform - Catalog Vol 24 With CoverNote SuwansomphongNo ratings yet

- Amcp 706-253 Feb1979 PDFDocument251 pagesAmcp 706-253 Feb1979 PDFtsegayNo ratings yet

- Catalogo HiossenDocument140 pagesCatalogo HiossenItzel MarquezNo ratings yet

- Excel Lengkap Pabrik DMEDocument24 pagesExcel Lengkap Pabrik DMEwinaNo ratings yet

- CPVC - Price List - 7th Oct 2022Document16 pagesCPVC - Price List - 7th Oct 2022Vijay SharmaNo ratings yet

- Series Consig 8040: Control Device SystemDocument22 pagesSeries Consig 8040: Control Device SystemsilvioNo ratings yet

- Drager Neonate Flow Sensor - Google SearchDocument1 pageDrager Neonate Flow Sensor - Google Searchmohammad shmasnaNo ratings yet

- Principal Properties of Commercial Pipe (Metric Data) : Table E2.1MDocument8 pagesPrincipal Properties of Commercial Pipe (Metric Data) : Table E2.1MVicky GautamNo ratings yet

- A5 Autosampler Service Manual - V1Document30 pagesA5 Autosampler Service Manual - V1Rogger RuffiniNo ratings yet

- T-Class: Commercial Split Systems Up To 20-Ton TSA/TPA ModelsDocument6 pagesT-Class: Commercial Split Systems Up To 20-Ton TSA/TPA ModelsOscar ArrésteguiNo ratings yet

- Group 3 Pilot Circuit: RCV Pedal Remote Control Valve (LH Lever) Remote Control Valve (RH Lever)Document8 pagesGroup 3 Pilot Circuit: RCV Pedal Remote Control Valve (LH Lever) Remote Control Valve (RH Lever)Dado OgameNo ratings yet