Professional Documents

Culture Documents

Section 4: Specification Classification

Uploaded by

Rudi SyamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 4: Specification Classification

Uploaded by

Rudi SyamCopyright:

Available Formats

SECTION

MANUFACTURERS OF A DIVERSE RANGE OF

ADVANCED WELDING CONSUMABLES

WI-0304 DS23 RD-718 Rev. 3, Date 01.07.2013

RD-718

DATA SHEET

NO.

LOW HYDROGEN - IRON POWDER ELECTRODE

WITH OPTIMUM WELDABILITY FOR WORKSHOP

AND SITE FABRICATIONAL WORK

SPECIFICATION

AWS A5.1

23

BS EN ISO 2560-B

JIS Z 3212

CLASSIFICATION

E7018

E4918

D5016

The design emphasis of the chemically basic flux is engineered to ensure the

optimum weld metal properties demanded by the specification are fully met.

PRODUCT

DESCRIPTION

The basic flux containing the appropriate alloying elements with a controlled

balanced addition of iron powder, is extruded onto a high purity ferritic core wire

with a blend of silicates that ensures both coating strength and a coating

resistant to subsequent moisture absorption.

WELDING

FEATURES

OF THE

ELECTRODE

APPLICATIONS

AND

MATERIALS

TO BE WELDED

WELD METAL

ANALYSIS

COMPOSITION

% BY Wt.

The chemical nature of the flux together with a significant proportion of iron

powder ensures maximum deposition efficiency without detracting from its ability

to be used in all positions except vertical down.

Overall the arc is very stable, slag detachability is good and metal recovery is

some 120% with respect to the core wire.

Medium and high tensile carbon-manganese steels with UTS of up to 510 N/mm2

max. Typical grades :

BS 1449 plate and sheet BS 4360 grades 43A and 43C Lloyds A & D ship steel

BS 4360 grade 50B, Lloyds grades AH and DH BS 3059 and BS 3601 grade

320-410

API 5L A-B and X42,

BS 4360-50B-50C-50D, BS 1501-151 430-490, BS 3602-410-460.

Such steels are used in ship construction, bridge building and pressure vessel

work as well as general construction work.

C

Mn

Si

S

P

Cr

Ni

Mo

V

Fe

MIN

MAX

0.15

1.6

0.75

0.035

0.035

0.2

0.3

0.3

0.08

TYPICAL

0.1

1.0

0.35

0.01

0.01

0.1

0.01

0.02

0.02

PROPERTY

WELD METAL

PROPERTIES

(ALL WELD METAL)

UNITS

MINIMUM

TYPICAL

Tensile strength

N/mm2

490

600

0.2% Proof stress

N/mm

400

550

Elongation on 4d

22

28

70

27

80

Reduction of Area (RA)

o

Impact energy -30 C

WELDING

AMPERAGE

AC or DC+

OTHER DATA

APPROVED BY

(mm)

2.6

3.2

4.0

5.0

MIN

50

90

130

170

MAX

100

140

180

220

OTHERS

Electrodes that have become damp should be re-dried at 150 C for 1 hour

LR; ABS; GL Grade 3Y

Bal.

You might also like

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Duplex Stainless Steels: Properties and Welding TechniquesDocument25 pagesDuplex Stainless Steels: Properties and Welding Techniqueskdsenipah6667No ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerNo ratings yet

- Arc Welding ElectrodesDocument6 pagesArc Welding ElectrodeswaleedyossefNo ratings yet

- Essar Oil Limited Vadinar Refinery Expansion: 1O1O1O (O1Document17 pagesEssar Oil Limited Vadinar Refinery Expansion: 1O1O1O (O1ashish_rocksNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Welding Consumables For The Offshore IndustryDocument24 pagesWelding Consumables For The Offshore IndustryLuis DuarteNo ratings yet

- Welding Technology Steelconstr - EngDocument32 pagesWelding Technology Steelconstr - EngLukman Tarigan SumatraNo ratings yet

- 11KV TRANSMISSION LINES SpecificationDocument16 pages11KV TRANSMISSION LINES SpecificationIwan Tristiawan0% (1)

- Accumulator PartsDocument98 pagesAccumulator PartsRudi Syam100% (1)

- Welding Consumables For Hydro Power StationsDocument16 pagesWelding Consumables For Hydro Power StationsMohamed FaragNo ratings yet

- SHS Welding GuideDocument44 pagesSHS Welding Guideamarkhamhgnl100% (1)

- 10 TMSS 05 R1Document11 pages10 TMSS 05 R1Omar HijaziNo ratings yet

- Ruukki Hot Rolled Steels Processing of Material WeldingDocument11 pagesRuukki Hot Rolled Steels Processing of Material Weldingprince5621No ratings yet

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- Outokumpu Duplex DatasheetDocument12 pagesOutokumpu Duplex DatasheetzosternatNo ratings yet

- ST 12 - Echivalenta DC01Document12 pagesST 12 - Echivalenta DC01mariussinhoNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptionFery FebryantoNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Mild Steel 490mpa High Tensile Strength SteelDocument38 pagesMild Steel 490mpa High Tensile Strength SteelCarlos PadillaNo ratings yet

- RD 360R3Document1 pageRD 360R3Rachmad Budi WNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanNo ratings yet

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- Stick electrodes for welding steels and stainless steelsDocument46 pagesStick electrodes for welding steels and stainless steelsAdeKusumahNo ratings yet

- Nikko - Problem Steel E-309-16Document1 pageNikko - Problem Steel E-309-16TbayuNo ratings yet

- Ga-24 Aws E7024Document1 pageGa-24 Aws E7024Bang OchimNo ratings yet

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16No ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptionRudi SyamNo ratings yet

- Welding Wires & Rods: MIG/MAG - Low Alloyed Steels: ClassificationDocument6 pagesWelding Wires & Rods: MIG/MAG - Low Alloyed Steels: ClassificationTaufikWibowoNo ratings yet

- Atmospheric Corrosion Resisting SteelDocument10 pagesAtmospheric Corrosion Resisting SteelCarlos PadillaNo ratings yet

- RD 360 1post File 2019 12 10 161048Document1 pageRD 360 1post File 2019 12 10 161048Adityo Bambang WNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptiontamharNo ratings yet

- SYABAS' SPEC FOR DUCTILE IRON FERROUS SADDLESDocument12 pagesSYABAS' SPEC FOR DUCTILE IRON FERROUS SADDLESWr ArNo ratings yet

- Inception Report Air SelangorDocument3 pagesInception Report Air SelangorNurul IzzatiNo ratings yet

- Euro 410 Ni MoDocument1 pageEuro 410 Ni MoMustafa OğuzhanNo ratings yet

- Mild Steel Welding Electrodes: Salient FeaturesDocument16 pagesMild Steel Welding Electrodes: Salient FeaturesHandrea Hadi SaputraNo ratings yet

- Astm B633 19Document4 pagesAstm B633 19Satish JadhavNo ratings yet

- Heat Treat 2Document5 pagesHeat Treat 2gawaNo ratings yet

- ASMe Sec2 PartcDocument53 pagesASMe Sec2 PartcSARSAN NDTNo ratings yet

- Presentation1 (1)Document35 pagesPresentation1 (1)S RNo ratings yet

- B-62 2507 Rev 06Document5 pagesB-62 2507 Rev 06Shaik ShahNo ratings yet

- Dual Shield 7000a1Document1 pageDual Shield 7000a1Gokul RajanNo ratings yet

- NSB 316LR0 PDFDocument1 pageNSB 316LR0 PDFDika AnggaraNo ratings yet

- Sea Water Corrosion Resisting SteelDocument8 pagesSea Water Corrosion Resisting SteelCarlos PadillaNo ratings yet

- Section 6: Specification ClassificationDocument1 pageSection 6: Specification ClassificationDimas Wisnu WardanaNo ratings yet

- Recom. de Soldadura XARDocument4 pagesRecom. de Soldadura XARelias667No ratings yet

- S31803Document2 pagesS31803Elliott RussellNo ratings yet

- 22%Cr DUPLEX STAINLESS STEEL WELDING CONSUMABLESDocument7 pages22%Cr DUPLEX STAINLESS STEEL WELDING CONSUMABLESNguyen Anh TuanNo ratings yet

- Diamondspark 46 MC: Seamless Metal-Cored WireDocument2 pagesDiamondspark 46 MC: Seamless Metal-Cored WireDavid RodriguesNo ratings yet

- Technical Specifications for MS PipelineDocument107 pagesTechnical Specifications for MS PipelinePC Snehal Construction Pvt. Ltd. JhalawarNo ratings yet

- Manufacturers of advanced welding consumables data sheet for cobalt alloy NS-ECo-6Document1 pageManufacturers of advanced welding consumables data sheet for cobalt alloy NS-ECo-6yadi_baeNo ratings yet

- Mild Steel Filler Metal GuideDocument1 pageMild Steel Filler Metal GuideNenad NedeljkovicNo ratings yet

- FOX CN 23-12 Mo-ADocument1 pageFOX CN 23-12 Mo-AVIRPOPNo ratings yet

- Argonaut Bogie Spare Parts Listing PAGE 7Document1 pageArgonaut Bogie Spare Parts Listing PAGE 7Rudi SyamNo ratings yet

- Dalle BesarDocument7 pagesDalle BesarRudi SyamNo ratings yet

- Argonaut Bogie Spare Parts Listing Page 8Document1 pageArgonaut Bogie Spare Parts Listing Page 8Rudi SyamNo ratings yet

- Service Manual: TF SeriesDocument52 pagesService Manual: TF SeriesRudi SyamNo ratings yet

- Vendor Registration FormDocument7 pagesVendor Registration FormRudi SyamNo ratings yet

- IrwinDocument8 pagesIrwinRudi SyamNo ratings yet

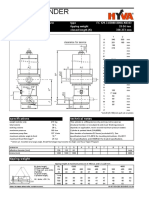

- HyvaDocument2 pagesHyvaRudi SyamNo ratings yet

- Alfagoma 6j511Document1 pageAlfagoma 6j511Rudi SyamNo ratings yet

- HPF Catalog OpenAndCloseDocument68 pagesHPF Catalog OpenAndCloseRudi SyamNo ratings yet

- Raychem JBS100Document3 pagesRaychem JBS100Rudi SyamNo ratings yet

- Drawing3 ModelDocument1 pageDrawing3 ModelRudi SyamNo ratings yet

- Aringo ComputerDocument1 pageAringo ComputerRudi SyamNo ratings yet

- En RaychemE100LAendseal IM H59141 Tcm432 51607Document8 pagesEn RaychemE100LAendseal IM H59141 Tcm432 51607Rudi SyamNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptionRudi SyamNo ratings yet

- Coverall NomexDocument60 pagesCoverall NomexRudi SyamNo ratings yet