Professional Documents

Culture Documents

Chapter 2 - Speed Converter and Gear Ratios

Uploaded by

Gaurav Agarwal0 ratings0% found this document useful (0 votes)

5 views4 pagesgd

Original Title

Chapter 2_ Speed Converter and Gear Ratios

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentgd

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views4 pagesChapter 2 - Speed Converter and Gear Ratios

Uploaded by

Gaurav Agarwalgd

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF or read online from Scribd

You are on page 1of 4

4.2. Speed Converter for Moving Off

Internal combustion engines have a minimum rotational speed. The speed difference be-

tween the lowest engine operating speed and the stationary transmission input shaft has to

be bridged by a speed converter. Frictional engaged clutches are always used as moving.

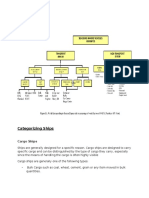

off elements. Figure 4.3 shows a systematic classification of master clutches [4.1]. The

main moving-off elements to have established themselves in motor vehicles are:

O the dry clutch where is = 1.0 is standard for manual transmissions,

© the torque converter where is 2 1.0 is standard for conventional fully automatic

transmissions.

Less common is the magnetic powder clutch in which a magnetisable powder transmits

the power by frictional engagement, Magnetic powder clutches, and also wet multi-dise

clutches, are used as automatic clutches in continuously variable transmissions, for exam.

ple.

In dry clutches the pressure force is produced by a spring. A distinction is made be-

{ween coil spring clutches and membrane spring clutches depending on the type of spring

used. A distinction is also made between clutches activated by pulling and by pushing,

Shiftable, master controlled,

frictionally engaged

Frictiona || Hydro: Hydro || Electro: | Electro Magnetic

dynamic static dynamic | static

See

1

Magnetic

powder

foo

Clutch [converter

| Dy Wet

Figure 4.3. Systematic classification of master clutches on the basis oftheir characteristics

‘The characteristic features of a speed converter are (Figure 4.4)

(O the output torque 73 is equal to the input torque T} h=N

© the output speed ny is tess than or equal to the input speed my: nem

(© the input power P) is reduced by the power loss Py: Pre Pi

oD SPEED => Pe=Pi-Py

CONVERTER:

17> -> b="

Pe Pee

Figure 4.4, Speed converter input and output va

Figure 4.5 shows an idealised clutch operation sequence when moving off. The input

‘output speeds converge in the course of the clutch operation sequence, Some of the in

power is converted into waste heat during the continuous slip phase. The efficiency of

clutch 7c is given by Equations 4.2 and 4.3 and is.

Py_T2an,

Ba ee ve. as

R T2anm “ve

Ty vice, a= 1, then

hn

ove asi

ny

Reduction of

Engine speed _engine speed

Speed of

gearbox

input shaft

Disengaged | Engagingphase | Engaged Time t

Figure 4.5. Idealised moving-off sequence with a friction clutch

43, Total Ratio and Overall Gear Ratio 81

The slip 5 is defined as the ratio of the difference between the input and output speeds to

the input speed

nan:

46)

Equations 4.5 and 4.6 give the following relationship between efficiency, slip and speed

ratio

s

Yes an

The master clutch must be so designed that it both transmits the maximum output torque

with sufficient reliability, and tolerates the thermal stress arising in repetitive “stop end

20” use [4.2].

4.3 Total Ratio and Overall Gear Ratio

‘The power train has to offer ratios between engine speed and road wheel speed enabling

the vehicle to:

O move off under difficult conditions,

Q reach the required maximum speed, and

© operate in the fuel-efficient ranges of the engine performance map.

The maximum ratio required ia, max is fixed by the first condition. The second condition

ives the maximum road speed ratio ia(Uimx,s)- The smallest power-train ratio tn, min is

given by the third condition. Figure 4.6 shows the speed spread of a transmission in

diagram of velocity against engine speed. The engine speed range (primary side) is

(Spread” by the transmission to the speed range of the secondary side. The operating

range extends between the ratio boundaries,

Gearbox

speed spread

(secondary side)

Velocity v

Engine speed n

|+——— Engine speed spread ———»|

(primary side)

max

Fieure 4.6, Velocity/onaine-cpeed dingram, overall gear ratio

ncreasing legal constraints and traffic density are reducing the importance of maximum

Peeds of passenger cars. By the same token, acceleration performance is gaining in

portance,

A wide overall gear ratio is particularly important for heavy passenger cars with powerful

engines and a low drag coefficients [4.3]. They need:

Q ahigh stall torque ratio is, max for moving off and accelerating,

© a low minimum ratio ia, min for low engine speeds at high road speeds to reduce

fuel consumption

4.3.1 Overall Gear Ratio

‘The overall gear ratio of the transmission, often referred to as the range of ratios, is the

ratio between the largest and smallest ratio.

ig. max _ ft

with the gears

fcr Lup toz (48)

fc.min fe

‘The overall gear ratio depends on:

Q the specific power output of the vehicle (Prax / (me + Mpaytead) in KW/),

Q the overall gear ratio of the engine, (see Section 3,3.2), and.

O the intended use.

Vehicles with a low specific power output, such as commercial vehicles, need a larger

overall gear ratio. The same applies for vehicles with diesel engines, which have a small

‘engine speed spread. Reference values for overall gear ratios of Various vehicles are

shown in Figure 4.7.

Truck> 16t

fi 1) Truck < 16

i ] Bus, long-distance

|

Pass. car: ace. & consumpt. opt. Fut? 1

[_ 1] Pass. car, diesel engine; transporter

(| Passenger car, spark ignition engine

GS Passenger car: automatic

[EGEF Bus, urban: automatic

0 2 4 6 8 0 12 4 16 18

Ratio spread ig op

Figure 4.7. Reference values for overall gear ratios for various types of vehicle. In the

cease of automatic transmissions, the conversion of the torque converter (Lmax = 2-3) has

tobe added

For passenger cars in particular itis necessary to consider that:

O However great the overall gear ratio is, the transmission can only move the

‘operating point on the demand power hyperbola (see also Figure 3.17). The most

fuel-efficient range cannot be exploited by a passenger car with a powerful en-

gine travelling on the level at moderate speeds since there is “insufficient power |

required”. The engine and all power-train components have to fit together: |

power-train matching, see Chapter 5 |

Q Overdrive gears (ic <'1.0) result in reduced gear efficiency. |

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Case Study Analysis Re Building A GlobalDocument5 pagesCase Study Analysis Re Building A GlobalGaurav AgarwalNo ratings yet

- Financial Statements 2019 of BMW AG PDFDocument48 pagesFinancial Statements 2019 of BMW AG PDFGate Bennet4No ratings yet

- Propulsion of ShipsDocument8 pagesPropulsion of ShipsGaurav AgarwalNo ratings yet

- Reading Mankiw-Taylor Chapter 3Document21 pagesReading Mankiw-Taylor Chapter 3Gaurav AgarwalNo ratings yet

- TerminologyDocument20 pagesTerminologyGaurav AgarwalNo ratings yet

- PaintDocument24 pagesPaintGaurav AgarwalNo ratings yet

- Chapter 3 Solved ProblemsDocument16 pagesChapter 3 Solved ProblemsGaurav AgarwalNo ratings yet

- Categorizing Ships NotesDocument11 pagesCategorizing Ships NotesGaurav AgarwalNo ratings yet

- Ships SystemsDocument10 pagesShips SystemsGaurav AgarwalNo ratings yet

- Drive LineDocument1 pageDrive LineGaurav AgarwalNo ratings yet

- Ship GlosaryDocument39 pagesShip GlosaryHskumarReddy KarriNo ratings yet

- Mooring: Mooring Equipment MOORING: A Vessel Is Said To Be Moored When It Is Fastened To ADocument7 pagesMooring: Mooring Equipment MOORING: A Vessel Is Said To Be Moored When It Is Fastened To AGaurav AgarwalNo ratings yet

- SYSYTEM OF LIMITS, FITS, TOLERANCES AND GAUGINGDocument17 pagesSYSYTEM OF LIMITS, FITS, TOLERANCES AND GAUGINGGaurav AgarwalNo ratings yet

- CH 05Document22 pagesCH 05Gaurav AgarwalNo ratings yet

- ClutshesDocument15 pagesClutshesAmr Abd ElrahmanNo ratings yet

- Vehicle DynamicsDocument24 pagesVehicle Dynamicssviggnesh_hpNo ratings yet

- MATLAB Tutorial of Fundamental ProgrammingDocument34 pagesMATLAB Tutorial of Fundamental Programmingsprynter19No ratings yet

- SYSYTEM OF LIMITS, FITS, TOLERANCES AND GAUGINGDocument17 pagesSYSYTEM OF LIMITS, FITS, TOLERANCES AND GAUGINGGaurav AgarwalNo ratings yet

- ME389 Automotive TransmissionsDocument2 pagesME389 Automotive TransmissionsGaurav AgarwalNo ratings yet

- Problemsopencycle&closecyclegasturbines 2Document7 pagesProblemsopencycle&closecyclegasturbines 2Gaurav AgarwalNo ratings yet

- Chapter 1 NotesDocument15 pagesChapter 1 NotesGaurav AgarwalNo ratings yet

- Answering Machine at The Mental Hospital..Document1 pageAnswering Machine at The Mental Hospital..Gaurav AgarwalNo ratings yet

- Common Faults For GearDocument3 pagesCommon Faults For GearGaurav AgarwalNo ratings yet

- Definition of SexDocument1 pageDefinition of SexAhmad Shahril KhushairiNo ratings yet

- Common Wealth GamesDocument9 pagesCommon Wealth GamesGaurav AgarwalNo ratings yet

- Chapter 1Document5 pagesChapter 1Gaurav AgarwalNo ratings yet

- 100 Weird Facts About The Human Body (CuPpY) PDFDocument11 pages100 Weird Facts About The Human Body (CuPpY) PDFZahid QamarNo ratings yet

- Amazingly True and HilariousDocument3 pagesAmazingly True and HilariousGaurav AgarwalNo ratings yet

- BoltzmannDocument31 pagesBoltzmannGaurav AgarwalNo ratings yet