Professional Documents

Culture Documents

31-30!00!002 - External Source

Uploaded by

cicungcimongCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

31-30!00!002 - External Source

Uploaded by

cicungcimongCopyright:

Available Formats

ABS submersible drainage pump J 84

Specification

Electric submersible pump.

Maximum submergence: 65 ft. Protection class IP 68.

Max temperature of pumped medium at max power input and

continuous duty 104F.

Max medium density 0.0397 Lbs/inch3.

pH of the pumped medium 5-8.

Strainer hole 5/16 x 7/8. Max number of starts 30/hour.

US 60 Hz

ft

200

HD

180

160

140

120

J 84 ND Medium head, 3-phase.

J 84 HD High head, 3-phase.

J 84 LD High flow, 3-phase.

100

ND

80

60

Electric Motor

3-phase squirrel-cage induction motor, 60 Hz.

Service factor 1.1. Class F insulation.

Dual voltage stator 230/460 V (single voltage contactor coil)

Motor rating P2: 15.0 Hp. Speed: 3400 rpm

LD

40

20

0

208

230/460

575

Nominal current, A

37

34.0/17.0

13.5

200

400

600

Starting method

D.O.L. start with built-in contactor.

D.O.L. start with built-in SoftDrive (400-460V).

When used with VFD, pump must be equipped with terminal block

instead of contactor.

113/8

ND/HD: 145/16 LD: 1515/16

Motor Protection

Built-in thermal switches in the stator windings (284F, 5),

connected to built-in contactor

Bearings

Upper bearing: Single-row deep groove ball bearing.

Lower bearing: Double angular contact ball bearing.

1000 gpm

ND/HD: 29

LD: 30

Power Cable

Heavy duty power cable for submersible pump applications

65 ft AWG 8/4 W (UL, MSHA), 208, 230, 460 V

65 ft AWG 10/4 SOOW (UL, CSA, MSHA), 460 V

65 ft AWG 12/4 SOOW (UL, CSA, MSHA), 575 V

Shaft Seal

Double mechanical seal in oil bath.

Primary seal: Silicon carbide on silicon carbide.

Secondary seal: Stainless steel on antimony treated carbon.

800

J 84 LD

Weight (without cable)

154 lb

Options and Accessories

Zinc anodes Surface protection coating

Diffuser in polyurethane (ND+HD) Electronic motor supervision

Series connection Starter and control units

Automatic level control unit Floatation system Repair kit

Discharge connection accessories and hose

Discharge Connections

3, 4, 6 hose connections.

3(standard HD), 4(standard ND), 6(standard LD)

NPT threaded connections.

Materials

ASTM

Castings

Aluminium

ASTM AlSi10mg

Casing / Handle / Fasteners

Stainless steel

AISI 304

Shaft

Stainless steel

AISI 420

Impeller LD

Hardened chrome steel

AISI 420

Impeller ND, HD

High chrome alloy

ASTM A 532: Alloy III A

Wear parts / O-rings

Nitrile rubber

2009-03-31 | We reserve the rights to alter specifications due to technical developments.

Voltage, V

You might also like

- PLN Item Number: 11 Item Name: Spring & Gasket Manufacturer: - Manufacturer Part Number: S100-1 Remarks: For Pressure Safety ValveDocument1 pagePLN Item Number: 11 Item Name: Spring & Gasket Manufacturer: - Manufacturer Part Number: S100-1 Remarks: For Pressure Safety ValvecicungcimongNo ratings yet

- Torn in Between PDFDocument211 pagesTorn in Between PDFcicungcimongNo ratings yet

- Time Sheet Pradhita Audi NovemberDocument1 pageTime Sheet Pradhita Audi NovembercicungcimongNo ratings yet

- Career Change CV Template UseDocument2 pagesCareer Change CV Template UseSyed Ghazanfar AliNo ratings yet

- 440 1300 077Document1 page440 1300 077cicungcimongNo ratings yet

- Delicioats Menu April 2016Document6 pagesDelicioats Menu April 2016cicungcimongNo ratings yet

- 31-30!00!001 - External SourceDocument1 page31-30!00!001 - External SourcecicungcimongNo ratings yet

- Visa Application Form 2012Document2 pagesVisa Application Form 2012Honey OliverosNo ratings yet

- Introduction Fort ADocument3 pagesIntroduction Fort AcicungcimongNo ratings yet

- Ploadedfile 130353684033553132Document1 pagePloadedfile 130353684033553132cicungcimongNo ratings yet

- App Letter TemplateDocument1 pageApp Letter TemplatecicungcimongNo ratings yet

- Ploadedfile 130353684033553132Document1 pagePloadedfile 130353684033553132cicungcimongNo ratings yet

- Curriculum Vitae: Personal InformationDocument1 pageCurriculum Vitae: Personal InformationcicungcimongNo ratings yet

- Essay TugasDocument2 pagesEssay TugascicungcimongNo ratings yet

- Tugas MetnumDocument9 pagesTugas MetnumcicungcimongNo ratings yet

- F (X) e x-5X 2: Metode GrafikDocument9 pagesF (X) e x-5X 2: Metode GrafikcicungcimongNo ratings yet

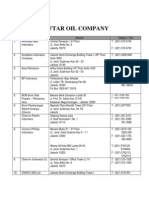

- Daftar Dan Alamat Oil CompanyDocument16 pagesDaftar Dan Alamat Oil Companysetia wirawan100% (7)

- Gas To BGPDocument5 pagesGas To BGPcicungcimongNo ratings yet

- BGPDocument4 pagesBGPcicungcimongNo ratings yet

- Parts of Speech TableDocument3 pagesParts of Speech TablecicungcimongNo ratings yet

- Tugas Baca & Kerjakan Soalnya KBRDocument21 pagesTugas Baca & Kerjakan Soalnya KBRcicungcimongNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)