Professional Documents

Culture Documents

Field Alignment Kit: Hardware Manual

Uploaded by

Anonymous dPyHoLOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Field Alignment Kit: Hardware Manual

Uploaded by

Anonymous dPyHoLCopyright:

Available Formats

Part Number 140185-01

Revision C, July 2001

Field Alignment Kit

Hardware Manual

Field Alignment Kit Hardware Manual

Copyright 2001 Bently Nevada Corporation

All Rights Reserved.

The information contained in this document is subject to change without notice.

The following are trademarks of Bently Nevada Corporation in the United States and

Other Countries:

Actionable Information SM, Actionable Information to the Right People at the Right

TimeSM, ADRE, Bently ALIGN, Bently BALANCE, Bently DOCUVIEW ,

Bently LUBE, Bently Nevada, Bently PERFORMANCE, CableLoc,

ClickLoc, Data Manager, Decision SupportSM, DemoNet, Dynamic Data

Manager, Dynamic Transmitor, Engineer Assist, FieldMonitor, FluidLoc,

flexiTIM, flexiTAM, Helping You Protect and Manage All Your Machinery,

HydroVU, Key , Keyphasor, Machine Condition Manager 2000,

MachineLibrary, Machine Manager, MicroPROX, Move Data, Not People,

Move Information, Not Data, NSV, Preformalign, PROXPAC, Proximitor,

REBAM, SE, Seismoprobe, ServoFluid, Smart Monitor, Snapshot,

System 1, System Extender, TDXnet, TDIXconnX, Tecknowledgy,

TipLoc, TorXimitor, Transient Data Manager, Trendmaster, TrimLoc,

VAM, Velomitor, XLerometer

The Bently Nevada Corporation Orbit Design, Bently Balance and Design, System 1

Enabled and Design, and M-Squared and Design are all trademarks or registered

marks of Bently Nevada Corporation in the United States and other countries.

Disposal Statement

Customer or any third party that is in control of product at the end of its life or at the

end of its use is solely responsible for proper disposal of product. No person, firm,

corporation, association or agency that is in control of product shall dispose of it in a

manner that is in violation of United States federal or state laws or any applicable

international law. Bently Nevada Corporation is not responsible for disposal of

product at the end of its life or at the end of its use.

The following ways of contacting Bently Nevada Corporation are provided for those

times when you cannot contact your local Bently Nevada representative:

Mailing Address

1631 Bently Parkway South

Minden, NV 89423

USA

1 775 782 3611

1 800 227 5514

1 775 782 9259

www.bently.com

Telephone

Fax

Internet

ii

Laser Product Warning Labels

The Bently Field Alignment Kit complies with 21 CFR 1040.10 and 1040.11.

Please note the content and location of warning labels.

Figure I - Detector Heads, Front

Figure II - Detector Heads, Rear

iii

Field Alignment Kit Hardware Manual

Contents

Note:

This manual shows how to install, verify, and

maintain the Field Alignment Kit. Document

142399-01, which is attached at the end of this

manual, contains the specifications and

ordering information for the module.

Chapter 1 Getting Started ............................................................... 5

Overview............................................................................................................................................ 5

Field Alignment Kit Components ...................................................................................................... 5

Chapter 2 Hardware Usage ............................................................. 7

Hardware Setup.................................................................................................................................. 7

Chapter 3 Care and Maintenance ................................................. 11

iv

Chapter 1 Getting Started

Chapter 1 Getting Started

Overview

The Bently Field Alignment Kit provides accurate shaft-to-shaft alignment

measurements. It uses what is commonly known as the reverse dial indication

method of performing shaft alignment. To accomplish this, laser/detector heads

are mounted on the shaft ends facing each other. The laser from one head is

incident on the detector of the other, and vice-versa. When the shafts are rotated

together through 360, the lasers will migrate on the detectors. Measuring this

movement, and knowing some other geometry, the machinery misalignment is

calculated. The instrument can also calculate misalignment with only 90 of

shaft rotation. Each laser/detector head is equipped with its own inclinometer so

that shaft alignment can be performed on machines that are not coupled together.

Field Alignment Kit Components

Part Number

Description

Qty.

139752-01

Stationary Head

139753-01

Moveable Head

02200338

10 Serial Cable

139772-01

Chain Assembly

139774-01

V-block Assembly

139770-01

3 Slide Rod

139770-02

6 Slide Rod

04100307

Carrying Case

140185-01

Hardware Manual

02200340

PC Card

04470305

5/16 Wrench

141281-01

Post Holder

141308-01

Quick Ref. Card

04490701

10 Tape Measure

Field Alignment Kit Hardware Manual

Chapter 2 The Alignment Process

Chapter 2 Hardware Usage

Using the Field Alignment Kit is a two step process: 1) Setting up the hardware,

and 2) Running the software. This manual simply describes the use of the

hardware. Refer to the software manual for a detailed description of the software

operation.

Hardware Setup

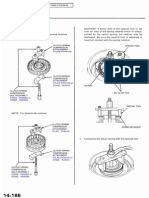

1. Mount the v-blocks to the shafts using the chain clamps (see Figure 1). If

needed, use the three foot extension chain. By sight, try to clamp the vblocks so that they are in the same rotational position relative to each other.

Figure 1

2. Thread the slide rods into the v-blocks (Figure 2). Use any combination of

three and six inch slide rods as needed. The slide rods fasten to the v-block

or to each other. Use the 5/16 open end wrench to secure all slide rods.

Figure 2

Field Alignment Kit Hardware Manual

3. Slide the detector heads onto the slide rods and secure them with the locking

thumb screws (Figure 3). Make sure the detector head labeled

MOVEABLE is fastened to the machine that will be moved, and the

STATIONARY head is fastened to the machine that will remain

stationary. Also, the detector heads must be oriented so they are facing one

another, and that the labels would be upright when placed in the 12:00

Oclock position.

Figure 3

4. Plug the pc card into the pc card slot in your laptop computer.

Figure 4

Chapter 2 The Alignment Process

5. Attach the cables between the 9-pin connectors on the heads and the 9-pin

connectors on the pc card. It does not matter which port is connected to

which head.

Figure 5

Note: If a dim secondary laser beam appears near the main laser beam during the

aiming of the lasers, slightly adjust the laser by turning the thumbscrews until the

secondary beam is not visible. Failure to remove the secondary beam will not

prevent accurate alignment but may necessitate an extra iteration of moves on

grossly misaligned machines.

Field Alignment Kit Hardware Manual

10

Chapter 3 Care and Maintenance

Chapter 3 Care and Maintenance

There is very little maintenance to be performed on the Field Alignment Kit.

The detector heads are sealed for protection against the elements present in the

industrial environment.

Use a cotton (not paper) cloth and mild soap to clean the components of the

system. Do not use soap on the detector surface. It can be cleaned with alcohol

if required.

Do not attempt to open the detector heads. There are no field serviceable parts

inside.

11

Field Alignment Kit Hardware Manual

12

You might also like

- Low Frequency Velocity Sensor: Operation ManualDocument15 pagesLow Frequency Velocity Sensor: Operation ManualRabah AmidiNo ratings yet

- Vibxpert CatalogDocument78 pagesVibxpert Catalogrichard mvulaNo ratings yet

- VA Report - BPCL Bangalore - 16.8.22Document43 pagesVA Report - BPCL Bangalore - 16.8.22keshava RNo ratings yet

- Forbes Monec 8964 ManualDocument48 pagesForbes Monec 8964 Manualrajanarsu12No ratings yet

- NEST UsersGuideDocument225 pagesNEST UsersGuidesebinjose87No ratings yet

- VibGraph Users GuideDocument123 pagesVibGraph Users GuidesubbusaravanakumarNo ratings yet

- Model 601A02 Low-Cost Industrial ICP® Accelerometer Installation and Operating ManualDocument19 pagesModel 601A02 Low-Cost Industrial ICP® Accelerometer Installation and Operating ManualQ Llanos HenryNo ratings yet

- @ptitude AnalysistDocument295 pages@ptitude AnalysistHần Phạm VănNo ratings yet

- Compliant Mechanism - Gear Box ApplicationDocument90 pagesCompliant Mechanism - Gear Box ApplicationGenerator RexNo ratings yet

- Idoc - Pub MCDocument227 pagesIdoc - Pub MCLuis pulgarNo ratings yet

- Commissioning and Maintenance Manual for HXL300 Cooling UnitDocument56 pagesCommissioning and Maintenance Manual for HXL300 Cooling UnitTanuTiganuNo ratings yet

- Modal Testing Theory and PracticeDocument166 pagesModal Testing Theory and PracticeGianluca FacchiniNo ratings yet

- Vib - AccelerometerDocument16 pagesVib - AccelerometerMahmoud SobhyNo ratings yet

- Report SI-08010025 - SPRO1Document42 pagesReport SI-08010025 - SPRO1Rashyd RidhaNo ratings yet

- GearboxDocument20 pagesGearboxViknesh VikneshNo ratings yet

- Oil WhirlDocument10 pagesOil WhirlAftabNo ratings yet

- System 1: Optimization and Diagnostics SoftwareDocument14 pagesSystem 1: Optimization and Diagnostics SoftwareAndy Kong KingNo ratings yet

- Lubricantes 495HRDocument4 pagesLubricantes 495HRMiguel Angel RodriguezNo ratings yet

- Boschrexroth 74200EN 01-03Document16 pagesBoschrexroth 74200EN 01-03ibnuharyNo ratings yet

- Artisan: DefinitiveDocument23 pagesArtisan: DefinitiveTrie WahyudiNo ratings yet

- High Vibration On Centrifugal Compressor Offshore Platform 1633664873Document19 pagesHigh Vibration On Centrifugal Compressor Offshore Platform 1633664873alraffarNo ratings yet

- OceanEng ResumesDocument84 pagesOceanEng ResumesChristoper NavaNo ratings yet

- SMSR PHGM Catalog RefDocument20 pagesSMSR PHGM Catalog Refprashant mishraNo ratings yet

- Development of A Vibration Haptic Simulator For Shoulder ArthroplastyDocument14 pagesDevelopment of A Vibration Haptic Simulator For Shoulder ArthroplastyAkbar HidayatullahNo ratings yet

- Dm200 CatalogDocument6 pagesDm200 CatalogAS_865025438No ratings yet

- FINAL Revised USFD Manual 2012Document135 pagesFINAL Revised USFD Manual 2012Mitesh KumarNo ratings yet

- Romaco DB Macofar Micromaxx-EnDocument2 pagesRomaco DB Macofar Micromaxx-EnmangthuyNo ratings yet

- MFS Presentation PDFDocument61 pagesMFS Presentation PDFSaid RoukbiNo ratings yet

- Test Equipment Buyers GuideDocument29 pagesTest Equipment Buyers GuideMojoshe MonasheNo ratings yet

- YCM GT SeriesDocument30 pagesYCM GT SeriesCNC SYSTEMSNo ratings yet

- J Turbomachinery 1986 Vol 108 N1Document162 pagesJ Turbomachinery 1986 Vol 108 N1Deepa PrakashNo ratings yet

- Instruction ManualDocument276 pagesInstruction ManualSET SolucionesNo ratings yet

- TN 7 VibxpertDocument1 pageTN 7 VibxpertBahtiar YudhistiraNo ratings yet

- Carter EpDocument1 pageCarter EpNguyễn Quang HưngNo ratings yet

- SteelsDocument72 pagesSteelsLLNo ratings yet

- VIBDI skriptaEN PDFDocument114 pagesVIBDI skriptaEN PDFЖивко ОрешковNo ratings yet

- WorkBee Screw Assembly Manual 2019Document40 pagesWorkBee Screw Assembly Manual 2019CsíkJúliusNo ratings yet

- Kairos Application Note Web InterfaceDocument35 pagesKairos Application Note Web InterfaceEric BartholomewNo ratings yet

- 100-00119 Rev A Q1200-Series FluidScan User's GuideDocument137 pages100-00119 Rev A Q1200-Series FluidScan User's GuideJuan José BarrigaNo ratings yet

- ReportTemplate PracticalTask or ProjectDocument27 pagesReportTemplate PracticalTask or ProjectDony Beast (DurraniFared)No ratings yet

- Brookfield Process CatalogDocument24 pagesBrookfield Process CatalogenzopandolfiNo ratings yet

- Result Vibration Analysis: Picture MachineDocument2 pagesResult Vibration Analysis: Picture Machinefelix haryokoNo ratings yet

- AS 4171-1994 Rolling Bearings - Static Load Ratings PDFDocument5 pagesAS 4171-1994 Rolling Bearings - Static Load Ratings PDFSAI Global - APACNo ratings yet

- UntitledDocument24 pagesUntitledEdward Erney Salas ValenzuelaNo ratings yet

- Bently Nevada Services Support Fact SheetDocument2 pagesBently Nevada Services Support Fact SheetFaruk IbisevicNo ratings yet

- Principle of Acceleration SensorsDocument7 pagesPrinciple of Acceleration SensorsEr Vijay MamoriaNo ratings yet

- Electric Circuit Analysis - CompleteDocument175 pagesElectric Circuit Analysis - Completemary mutunga100% (1)

- Model 3741E1210G DC Response Accelerometer Installation and Operating ManualDocument16 pagesModel 3741E1210G DC Response Accelerometer Installation and Operating ManualfazzlieNo ratings yet

- User Manual2016.4Document67 pagesUser Manual2016.4Adderly De La Cruz MezaNo ratings yet

- Graphtec CE6000Document179 pagesGraphtec CE6000Christian ZepedaNo ratings yet

- DP3CL Open Bus Step Driver ManualDocument54 pagesDP3CL Open Bus Step Driver ManualNguyen QuanNo ratings yet

- Cirkan ZsDocument1 pageCirkan ZsbilalNo ratings yet

- Anti Rodent TestDocument5 pagesAnti Rodent TestVô Cảm100% (1)

- Electrical Diagnostic Check ListDocument1 pageElectrical Diagnostic Check ListSergiSerranoNo ratings yet

- Programming For Lathe: Doosan Infracore EZ Guide-IDocument108 pagesProgramming For Lathe: Doosan Infracore EZ Guide-ILuis Angel Oaxaca GarciaNo ratings yet

- Chase Testing PresentationDocument18 pagesChase Testing PresentationDiego Chavez0% (1)

- Nara Bassinet Maintenance ManualDocument46 pagesNara Bassinet Maintenance ManualAnonymous KiraNo ratings yet

- Iscan Installation Guide (v3, Mar 2020)Document129 pagesIscan Installation Guide (v3, Mar 2020)Yosep Gunawan100% (1)

- Vibration Transducer Interface Manual 128132 Rev CDocument53 pagesVibration Transducer Interface Manual 128132 Rev CHamid HannitNo ratings yet

- 50mm de Expansion Transducer 131029-01 Rev BDocument30 pages50mm de Expansion Transducer 131029-01 Rev BHamid HannitNo ratings yet

- Welcome To Guitar Lessons: MALT©2007 Smartlesson Music / Guitar ChordsDocument13 pagesWelcome To Guitar Lessons: MALT©2007 Smartlesson Music / Guitar ChordsAnonymous dPyHoLNo ratings yet

- Discover CandaDocument129 pagesDiscover CandaDeathAyrusNo ratings yet

- National Anthem eDocument1 pageNational Anthem eAnonymous dPyHoLNo ratings yet

- Discover CanadaDocument68 pagesDiscover CanadaqatharyNo ratings yet

- Guitar I and Guitar II Class 10 Spring 06 Rev BDocument82 pagesGuitar I and Guitar II Class 10 Spring 06 Rev BArvind Kumar AgrahariNo ratings yet

- Music TheoryDocument8 pagesMusic TheoryAnonymous dPyHoLNo ratings yet

- 2011-01-20 235608 Debra J Macchioni mt425 01 Unit 10 FinalDocument17 pages2011-01-20 235608 Debra J Macchioni mt425 01 Unit 10 FinalAnonymous dPyHoLNo ratings yet

- Music Theory 101 - BDocument20 pagesMusic Theory 101 - BPaulo DantasNo ratings yet

- Music Theory 101 - BDocument20 pagesMusic Theory 101 - BPaulo DantasNo ratings yet

- How To Give FE Exam Strategies PDFDocument38 pagesHow To Give FE Exam Strategies PDFMuhammad BilalNo ratings yet

- Tropical Sun Blended Department Unit Reconciliation: Cost of Equivalent Unit CalculationDocument2 pagesTropical Sun Blended Department Unit Reconciliation: Cost of Equivalent Unit CalculationAnonymous dPyHoLNo ratings yet

- Chemistry FE ExamDocument35 pagesChemistry FE ExamRobby RenzNo ratings yet

- 1137B1 PDFDocument173 pages1137B1 PDFAnonymous dPyHoLNo ratings yet

- ACCT 346 Week 4 Midterm 2Document13 pagesACCT 346 Week 4 Midterm 2Anonymous dPyHoLNo ratings yet

- 1138B1 PDFDocument173 pages1138B1 PDFAnonymous dPyHoLNo ratings yet

- 1135C1 PDFDocument184 pages1135C1 PDFAnonymous dPyHoLNo ratings yet

- 0773D1 PDFDocument2 pages0773D1 PDFAnonymous dPyHoLNo ratings yet

- TDI Offline Setup GuideDocument19 pagesTDI Offline Setup GuideAnonymous dPyHoLNo ratings yet

- 1121e1 PDFDocument46 pages1121e1 PDFAnonymous dPyHoLNo ratings yet

- 1078K1 PDFDocument92 pages1078K1 PDFAnonymous dPyHoLNo ratings yet

- 1136C1 PDFDocument184 pages1136C1 PDFAnonymous dPyHoLNo ratings yet

- 0747B1 PDFDocument22 pages0747B1 PDFAnonymous dPyHoLNo ratings yet

- 0875J1 PDFDocument149 pages0875J1 PDFAnonymous dPyHoL100% (1)

- 0748e1 PDFDocument94 pages0748e1 PDFAnonymous dPyHoLNo ratings yet

- 0432G1 PDFDocument588 pages0432G1 PDFAnonymous dPyHoLNo ratings yet

- 0867F1 PDFDocument20 pages0867F1 PDFAnonymous dPyHoLNo ratings yet

- 1029C1 PDFDocument29 pages1029C1 PDFAnonymous dPyHoLNo ratings yet

- 0585H1 PDFDocument17 pages0585H1 PDFAnonymous dPyHoLNo ratings yet

- 0482J1 PDFDocument19 pages0482J1 PDFAnonymous dPyHoLNo ratings yet

- 0337B1 PDFDocument12 pages0337B1 PDFAnonymous dPyHoLNo ratings yet

- Dish22 Change Advice 03apr14 IATADocument3 pagesDish22 Change Advice 03apr14 IATARoberto PruebaNo ratings yet

- MSC-FAL.1-Circ.3 (Maritime Cyber Risk Management)Document5 pagesMSC-FAL.1-Circ.3 (Maritime Cyber Risk Management)claudio.jc.limaNo ratings yet

- Food Safety Management System Implementation Guide: GloballyDocument36 pagesFood Safety Management System Implementation Guide: GloballyGen100% (1)

- BOSaNOVA Secure Manual - 01 - 2015 PDFDocument85 pagesBOSaNOVA Secure Manual - 01 - 2015 PDFCybercom SacNo ratings yet

- In Touch Tag ViewerDocument28 pagesIn Touch Tag ViewerGalang Pandu SatyaNo ratings yet

- 1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part3Document200 pages1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part3CandieApple100% (1)

- SQL Interview Questions in 40 CharactersDocument10 pagesSQL Interview Questions in 40 CharactersSowmiya SowmiNo ratings yet

- Bluetooth HandoutDocument26 pagesBluetooth HandoutsaafinlandNo ratings yet

- Organisational Strategic Choice - ToyotaDocument13 pagesOrganisational Strategic Choice - ToyotaSajedul Islam Chy100% (2)

- Wilkerson CompanyDocument26 pagesWilkerson CompanyChris Vincent50% (2)

- Iso 15614-13Document24 pagesIso 15614-13Marija IvanovskaNo ratings yet

- Escalator PlanningDocument24 pagesEscalator Planningdcf67myNo ratings yet

- LLOYDS REGISTER Type MGD Approval Certificate SHF1 SHF2 MUD COPPER DATA CABLESDocument4 pagesLLOYDS REGISTER Type MGD Approval Certificate SHF1 SHF2 MUD COPPER DATA CABLESPritam MitraNo ratings yet

- 3G Network Benchmarking Report: NairobiDocument57 pages3G Network Benchmarking Report: NairobiAmit GurungNo ratings yet

- 7vk61 Catalog Sip E6Document18 pages7vk61 Catalog Sip E6Ganesh KCNo ratings yet

- Datasheet of DS-9600NI-I8 - V3.3.2 - 20150629Document2 pagesDatasheet of DS-9600NI-I8 - V3.3.2 - 20150629mhguuNo ratings yet

- Emmet Cheat Sheet for HTML and CSS ShortcutsDocument2 pagesEmmet Cheat Sheet for HTML and CSS ShortcutsStudyanteNo ratings yet

- ITIL 4 Specialist - HVIT in 1000 Words - DIGITAL PDFDocument5 pagesITIL 4 Specialist - HVIT in 1000 Words - DIGITAL PDFĐoàn Đức ĐềNo ratings yet

- (Jquery & PHP) Ajax Login Validation System in PHP Using JqueryDocument3 pages(Jquery & PHP) Ajax Login Validation System in PHP Using JqueryRizki Agung ANo ratings yet

- NAS Drive User ManualDocument59 pagesNAS Drive User ManualCristian ScarlatNo ratings yet

- KISTLER Torque Sensor Type 4503ADocument6 pagesKISTLER Torque Sensor Type 4503ASantiago MolinaNo ratings yet

- CloudSpan CloudConnect GatewayDocument2 pagesCloudSpan CloudConnect GatewayLayer7TechNo ratings yet

- Mplement Ontent Iltering: Lay Minh (Makito)Document27 pagesMplement Ontent Iltering: Lay Minh (Makito)NaingWinOoNo ratings yet

- DIGI 001 Requerimientos de ComputadoraDocument2 pagesDIGI 001 Requerimientos de Computadoradit_marzioNo ratings yet

- General Specification For Concrete EG - C - 401E 1/17: Engineering Standardization System - SPEDocument17 pagesGeneral Specification For Concrete EG - C - 401E 1/17: Engineering Standardization System - SPEOpencae EngenhariaNo ratings yet

- Mtcospro SfsDocument2 pagesMtcospro SfsJulio Chinchilla ValenzuelaNo ratings yet

- SG800GDocument26 pagesSG800GRodrigo CorintoNo ratings yet

- SC 2014 13 Introduction of Xenon 3.0L DICOR BS-III 4X4Document17 pagesSC 2014 13 Introduction of Xenon 3.0L DICOR BS-III 4X4NitinNo ratings yet

- ZTE UMTS UR15 NodeB Uplink Interference Cancellation Feature GuideDocument34 pagesZTE UMTS UR15 NodeB Uplink Interference Cancellation Feature GuideNiraj Ram ShresthaNo ratings yet

- Td01508002e Swich Board Seismic DesignDocument2 pagesTd01508002e Swich Board Seismic DesignthorenNo ratings yet