Professional Documents

Culture Documents

Manhole

Manhole

Uploaded by

barouniamine0 ratings0% found this document useful (0 votes)

8 views4 pagesmanhole

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentmanhole

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views4 pagesManhole

Manhole

Uploaded by

barouniaminemanhole

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

SHAIRCO gig 2

ForTrading Industry @Contracting FIBERGLAGS 2 sjlally delinally 8 Lait!

asm

Pica seer nbrecdereia

“Siuboiteatd Connections Upon requests

‘priming, and using resin fiber-r ceniicel iadioun

in the fabrication of the fiberglass manhole,

8.2 MANUFACTURE: Manhole cylinders, mal

reinforced polyester resin using a combination of ch

Interior Access :All manholes shall be designed so that

manhole.

‘Manway Reducer ; Manway reducers will be concentric with respect to the larger portion of the manho!

through 60 inches. Larger manholes may have concentric or eccentric manway reducer openings,

Cover and Ring Support: The manhole shall provide an area from which a grade ring or brick can be installed to

accept a typical metal ring and cover and have the strength to support a traffic load without damage to the man-

hole. The grade ring should be extended past the perimeter of the manhole at least 1" in order to transfer as much

load as practical to the exterior wall of the manhole.

‘AB REQUIREMENTS:

Exterior Surface : The exterior surface shall be relatively smooth with no sharp projections. Hand: work finish is

acceptable if enough resin is present to eliminate fiber show. The exterior surface shall be free of blisters larger than

5 inch in diameter, delamination or fber show.

Interior Surface :The interior surface shall be resin rich with no exposed fibers. The surface shall be free age

delamination, blisters larger than 0.5 inch in diameter and wrinkles of 0.125 inch or greater in depth. Voids that

cannot be broken with finger pressure and that are entirely below the resin surface shall be permitted if they are

less than 0.5 inch in diameter and less than 0.0625 inch thick.

Repairs : Any manhole repair is subject to meet all requirements of this specification.

Manhole Length : Manhole lengths shall be in 6 inch increments +/- 2 inches.

Diameter Tolerance : Tolerance of inside diameter shall be +/- 1% of required manhole diameter.

Load Rating :The complete manhole shall have a minimum dynamic-load rating of 16,000 Ibs. when tested in accor-

dance with AS.T.M. 3753 84 (note 1). To establish this rating the complete manhole shall not leak, crack, or suffer

other damage when load tested to 40,000 Ibs. and shall not deflect vertically downward more than 0.25 inch at the

point of load! application when loaded to 24,000 Ibs.

Stiffness : The manhole cylinder shall have the minimum pipe-stiffness values shown in the table below when

tested in accordance with A.S.1.M. 3753 8.5 (note 1).

aa coesmneconetie may be used to form bench area and invert, Also concrete may be used on top of

i flotation ring and around the reducer section as required for buoyancy.

“Concrete Bottom : Lower manhole into wet concrete until it rests at the proper elevation, with a minimum of 4

"inches of fiberglass manhole inserted into the wet concrete below flow line, then move manhole to plumb. The:

“concrete shall extend a minimum of one foot from the outside wall of the manhole and a minimum of 6 inches

_ above incoming lines. On the inside concrete shall form the bench and invert area and rise a minimum of 4 inches

"above incoming lines. if required by engineer concrete may be used around reducer section for buoyancy.

_A.8 BACKFILL:

Backfill Material : Unless shown otherwise on drawings and approved by the engineer, sand, crushed stone, or pea

‘gravel shall be used for backfill around the manhole for a minimum distance of one foot from the outside surface

and extending from the bottom of the excavation to the top of the reducer section. Suitable material chosen from

the excavation may be used for the remainder of the backfill. The material chosen shall be free of large lumps or

clods, which will not readily break down under compaction. This material will be subject to approval by the engi-

neer

Backfill Procedure :Backiill shall be placed in layers of not more than 12 loose measure inches and mechanically

tamped to 95% Standard Proctor Density, unless otherwise approved by the engineer, Flooding will not be permit-

ted, Backfill shall be placed in such a manner as to prevent any wedging action against the fiberglass manhole

structure,

A.9 MARKING and IDENTIFICATION : Each manhole shall be marked on the inside and outside with the following

information.

1, Manufacturer's name or trademark

2. Manufacturer's factory location

3, Manufacturer's serial number

4 Total length

GRP MANHOLE

P.O.Box 9301 , Jeddah 21413 , Kigdom of Saudi Arabia

Tel: + 966 2 6637666 (10 Lines) Fax:+ 966 2 6659424

E-mail : sales@ shairco.com Website :www.shairco.com

Wega ace SMe Cn ee bed ST e esl pee tr cereal)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Sismotectonique TunisieDocument1 pageSismotectonique TunisiebarouniamineNo ratings yet

- Soutenement v7-5Document12 pagesSoutenement v7-5barouniamineNo ratings yet

- Pca Notes On Aci 318 05Document2 pagesPca Notes On Aci 318 05khajarasool786No ratings yet

- VSL Construction SystemsDocument26 pagesVSL Construction SystemsbarouniamineNo ratings yet

- VSL Construction SystemsDocument29 pagesVSL Construction SystemsbarouniamineNo ratings yet

- 6 e 91 D 330Document32 pages6 e 91 D 330barouniamineNo ratings yet

- ASCE 7-05 Table 15-4-2Document1 pageASCE 7-05 Table 15-4-2barouniamineNo ratings yet

- Col 713824Document16 pagesCol 713824barouniamineNo ratings yet

- Amiantit Polyolefin Piping Systems Co.: Product Guide Hdpe Pipe SystemsDocument2 pagesAmiantit Polyolefin Piping Systems Co.: Product Guide Hdpe Pipe SystemsbarouniamineNo ratings yet

- Abandonment of Sewer MainsDocument5 pagesAbandonment of Sewer MainsbarouniamineNo ratings yet

- APPSCoDocument36 pagesAPPSCoshafeeqm3086No ratings yet

- Guard Post Installation For: CertifiedDocument1 pageGuard Post Installation For: CertifiedbarouniamineNo ratings yet

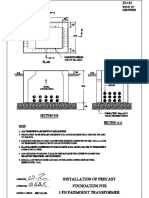

- Installation of Precast Foundation For 1 PH Padmount TransformerDocument1 pageInstallation of Precast Foundation For 1 PH Padmount TransformerbarouniamineNo ratings yet

- Prefabricated Manhole Detail: CertifiedDocument1 pagePrefabricated Manhole Detail: CertifiedbarouniamineNo ratings yet

- Ada 240629Document75 pagesAda 240629barouniamineNo ratings yet