Professional Documents

Culture Documents

Mems

Mems

Uploaded by

Amalina Syahirah Amir Kusin0 ratings0% found this document useful (0 votes)

8 views2 pagesMicro-Electro-Mechanical Systems (MEMS) Technology

Original Title

mems

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMicro-Electro-Mechanical Systems (MEMS) Technology

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesMems

Mems

Uploaded by

Amalina Syahirah Amir KusinMicro-Electro-Mechanical Systems (MEMS) Technology

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

1.2.

4 Micro-Electro-Mechanical Systems (MEMS) Technology: The Fourth

Technology Wave

Imagine a machine so small that it is imperceptible to the human eye.

Imagine working machines with gears no bigger than a grain of sand. Imagine

these machines being batch fabricated, tens of thousands at a time, at a cost of

only a few pennies each.

Imagine a realm where the world of design is turned upside down and the

seemingly impossible

suddenly becomes easy.

Welcome to the microdomaina world occupied by an explosive new technology

known as MEMS. MEMS are the next logical step in the silicon revolution.

We believe that the next step in the silicon revolution will be different and more

important than simply packaging more transistors onto the silicon.

To the scientist or technologist, MEMS is like a dream come true.

There is something magical about flicking on the electron microscope, zooming

in and wandering through a micro-mechanical landscape that you conceived,

created and understood, a world where the laws of nature dont behave as the

layman expects.

The micro-machinists building site is the size of a grain of rice, the architecture

the size of a human hair, the building elements smaller than a red blood cell, but

our lithographic backhoes are the size of a city, so we can construct a thousand

sites at once.

We have mastered the art of building the impossible, from gyroscopes, micromotors, gear trains and transmissions, to fluid pumps, x-y tables and entire selfassembling optical bench erector sets. Enamored by this wondrous new frontier

and its parallels with microelectronics, we technologists have declared MEMS as

the fourth technology wave and the second semiconductor revolution.

We have claimed unconditional applicability of Moores Law and economic

hockey stick curves, and many of us believe that MEMS will soon become as

pervasive in all aspects of every day life as microprocessors are today. Two

factors drive Moores Law in microelectronics: smaller is better and the

building blocks are universal across applications.

However, neither of these is particularly valid for MEMS.

The second factor, about universal building blocks, is especially problematic. At

the highest level of abstraction, the real power of microelectronics is not even its

massively parallel fabrication paradigm.

It is the existence of a generic element, called a transistor, which allows us to

build extremely diverse functionality simply by implementing appropriate

interconnection patterns within large collections of the generic elements.

This is what makes semiconductor economics so vastly different from anything

seen before in history.

The impact of pushing the generic components along Moores curve is therefore

universal across all imaginable application areas, which in turn justifies massive

spending aimed at pushing even further along the curve.

The gain factor in the financial feedback loop is greater than one because of the

generic element paradigm.

In contrast, MEMS, by its very nature, does not have a set of generic elements.

There is no MEMS transistor. MEMS touches and participates in the physical

world of the mixed bag of applications and therefore needs to be much more

application specific and less generic in every aspect of design, modeling,

manufacturing, packaging, etc.

Thus, it is much more challenging to keep the gain factor that drives Moores Law

greater than one. This is where many of the economic parallels with

microelectronics break down, and economics is evidently what makes the

difference between a possible future and a likely future for a technology. Figure

1.8 illustrates an example of MEMS.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Century IservicemanualDocument25 pagesCentury IservicemanualJessica Stanton Aahcc0% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Connections On Breadboard: The Diagram Shows How The Breadboard Holes Are ConnectedDocument3 pagesConnections On Breadboard: The Diagram Shows How The Breadboard Holes Are ConnectedyoungmoonNo ratings yet

- Henzler - 2010 - Time-To-Digital Converters PDFDocument132 pagesHenzler - 2010 - Time-To-Digital Converters PDFmimitech mimitechNo ratings yet

- Mainboard+FY16+2K+GN2S QW+&+QT+Segments+Easy+Repair+Guide (GN2S)Document28 pagesMainboard+FY16+2K+GN2S QW+&+QT+Segments+Easy+Repair+Guide (GN2S)oscarmdNo ratings yet

- Peavey Black WidowDocument8 pagesPeavey Black Widowgjm126No ratings yet

- Lnk302/304-306 Linkswitch-Tn Family: Lowest Component Count, Energy-Efficient Off-Line Switcher IcDocument19 pagesLnk302/304-306 Linkswitch-Tn Family: Lowest Component Count, Energy-Efficient Off-Line Switcher IcFrancisReis100% (1)

- STK4181 AF Power Amplifier (Split Power Supply) (45W + 45W Min, THD 0.08%)Document8 pagesSTK4181 AF Power Amplifier (Split Power Supply) (45W + 45W Min, THD 0.08%)João Carlos EspindolaNo ratings yet

- First Time User Guide To Moscap : Network For Computational Nanotechnology (NCN)Document15 pagesFirst Time User Guide To Moscap : Network For Computational Nanotechnology (NCN)alfredkirubarajNo ratings yet

- Overview: Brushless DC Motor Driver Circuit Using 555 ICDocument4 pagesOverview: Brushless DC Motor Driver Circuit Using 555 ICJanet Walde100% (1)

- DM00035129 - STM32F41xxxDocument156 pagesDM00035129 - STM32F41xxxKhánh Lê QuangNo ratings yet

- Mediatek Confidential: Mt7688 DatasheetDocument52 pagesMediatek Confidential: Mt7688 DatasheetSimas ŽalaNo ratings yet

- Plessey Radar and Radio Communications IC Handbook 1980Document445 pagesPlessey Radar and Radio Communications IC Handbook 1980Roberto BernerNo ratings yet

- Teletext in Digital TelevisionDocument8 pagesTeletext in Digital Televisionj_ayala_duranNo ratings yet

- NI Tutorial 6994 enDocument1 pageNI Tutorial 6994 enasutoshpatNo ratings yet

- Low Power Quad Operational Amplifiers Az324Document13 pagesLow Power Quad Operational Amplifiers Az324AbdoNo ratings yet

- 294 2886 PRV Audio 3df750 5000 Crossover Board Spec SheetDocument1 page294 2886 PRV Audio 3df750 5000 Crossover Board Spec SheetChrisNo ratings yet

- Adc 12 DJ 3200Document155 pagesAdc 12 DJ 3200The Game CaveNo ratings yet

- Slu - Lloren, Anjelo Michael - Power TransformerDocument8 pagesSlu - Lloren, Anjelo Michael - Power TransformerGyver AquinoNo ratings yet

- EPIC Ultra High Impedance ECG Sensor Advance Information: FeaturesDocument7 pagesEPIC Ultra High Impedance ECG Sensor Advance Information: FeaturesKarthik Raj VNo ratings yet

- Produk Konten ReceiverDocument2 pagesProduk Konten ReceiverSumber ParabolaNo ratings yet

- Basic ElectronicsDocument3 pagesBasic Electronicsvinay10356No ratings yet

- STA543SA DatasheetDocument23 pagesSTA543SA DatasheetforumrajchaNo ratings yet

- Data Communication Unit1 As Per Pune UniversityDocument22 pagesData Communication Unit1 As Per Pune UniversityDr. Hitesh MohapatraNo ratings yet

- Di/dt Noise in CMOS Integrated Circuits: Patrik LarssonDocument2 pagesDi/dt Noise in CMOS Integrated Circuits: Patrik LarssonmadhuriNo ratings yet

- R.M.D Engineering College (An Autonomous Institution) Ec8391 - Control System Engineering Question BankDocument6 pagesR.M.D Engineering College (An Autonomous Institution) Ec8391 - Control System Engineering Question Bankaarthir88No ratings yet

- Product Specification: CosmoDocument3 pagesProduct Specification: CosmoMike MinNo ratings yet

- AD594Document8 pagesAD594Oscar TorresNo ratings yet

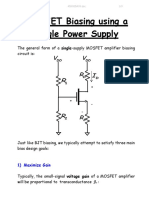

- MOSFET Biasing Using A Single Power SupplyDocument9 pagesMOSFET Biasing Using A Single Power SupplySabaJavedNo ratings yet

- Incremental Encoders: End Shaft Ø8 To Ø14 MM Resolution 50 1024 PulsesDocument4 pagesIncremental Encoders: End Shaft Ø8 To Ø14 MM Resolution 50 1024 PulsesMiguel Nallar SaucedoNo ratings yet

- Voltage Regulation SystemDocument4 pagesVoltage Regulation SystemSnehil RastogiNo ratings yet