Professional Documents

Culture Documents

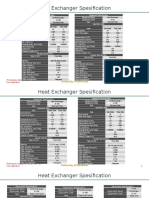

Design, Material, and Construction (Continued) : API 661 Air-Cooled Heat Exchanger - Specification Sheet

Uploaded by

tataircOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design, Material, and Construction (Continued) : API 661 Air-Cooled Heat Exchanger - Specification Sheet

Uploaded by

tataircCopyright:

Available Formats

API 661 Air-Cooled Heat Exchanger - Specification Sheet

Job No.

Item No.

Page

Page 2

Date

2/9/2011

Proposal No.

P1011SR3163

Inquiry No.

FIN FAN COOLER

By

PRP

Revision

Contract No.

Order No.

Design, Material, and Construction (continued)

Header (continued)

144

No./Bundle

Slope

N.A.

Length

(mm)

Plug material

SA 105

Pitch

(mm)

Gasket material

SOLID METAL

Layout

Nozzle

No.

Size, (mm)

Rating/Facing

8500.

60.000

Triangular

Fin

Inlet

50 DN

300# WNRF

Type

Plain round (G TYPE)

Outlet

50 DN

300# WNRF

Material

Aluminum 1060 - H14

Vent

25 DN

300# WNRF

Thickness

(mm)

0.400

Drain

25 DN

300# WNRF

Selection temp.

(C)

(mm)

51.000

(fin/meter)

433.1

Chemical Cleaning

Outside diameter

Min. Wall Thk.

Fin density

Tube

ASME Code, Sec. VIII, Div. 1

SA 179

Material

Tube outside diameter

(mm)

25.000

Average wall thickness

(mm)

2.413

Customer Specifications

Mechanical Equipment

Fan

COFIMCO/EQ

Manufacturer

No./Bay

RPM

LATER

(Revs/min.)

(mm)

Diameter

3353.

No. of blades

Angle

(degrees)

Pitch adjustment

Hub material

1440

Service factor

Enclosure

IP 55

Voltage

415 V

Phase

LATER

Cycle

LATER

Fan noise level

MANUAL

Speed Reducer

FRP

ALUMINIUM

Blade material

RPM

50 HTZ

(dB)

85 @ 1M

Type

VEE BELT (HTD)

Manufacturer

FENNER/EQ

BKW @design temp 41 C

16.00

No./Bay

BKW @min. ambient temp 5 C

18.07

Service factor

1.8

Tip speed

LATER

Driver

Speed ratio

LATER

Support

Type

INCREASE SAFETY EX e

Manufacturer

KIRLOSKER/ABB/CGL/BB/SEIMENS/EQ

No./Bay

FROM MAIN STRUCTURE

Vib. switch

YES

Enclosure

IP 55

Driver

30 HP X 4 P

Controls - Air Side

Air recirculation

NO

Louvers

Degree control of outlet process temp.

NO

Positioner

(Max. Cooling),+/-

Signal air pressure (kgf/cm2A)

Action on control signal failure

Fan pitch

Louvers

From

To

From

To

Supply air pressure (kgf/cm2A)

Actuator air supply

From

To

Fan

From

To

Shipping

Plot area (WxL)

(mm)

Bundle weight

(kg)

Bay

(kg)

4412. x 8500.

~4700

Total

(kg)

Shipping

(kg)

Note: 1) Reported duty and flow rates include a user-specified

multiplier of 1.10

2) ** All structure parts of plunum chamber, motor suspension assembly, shaft housing, gratings for stairs and platform, all guard

etc. shall be hot dip galvanized. Bolting shall be electro galvanized.

3) Pressure drop is in Kg/cm^2 A unit.

4) No of unit - 1, Duty - 879409 Kcal/hr, Instalation type - Horizontal Tube bundle and fan arrangment, Air flow - Vertical

5) MOCD:\EST\ESSAR\P1011SR3163

: Tube - SA 179, Fan Blade - FRP, Header

- SA 516

GR 60, Fan Hub

- Aluminium

(FIN FAN

COOLER)\FIN

FAN

COOLER HFO OIL REV FOR DENSITY.htri

6) Tune to tube sheet joint is Expanded and Strength Weld.

~18500

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- AS4041 PresurecontainmentDocument5 pagesAS4041 PresurecontainmentJOHNKNo ratings yet

- Design Calculations For Pressure VesselsDocument32 pagesDesign Calculations For Pressure VesselsGeorge Georgian100% (3)

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsVinoth Rajendra100% (3)

- Design Calculations For Pressure VesselsDocument24 pagesDesign Calculations For Pressure VesselsMichael Lageman93% (15)

- Insulation ThicknessDocument29 pagesInsulation Thicknessrajachem100% (2)

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- NCR - SampleDocument7 pagesNCR - SamplecamycaxNo ratings yet

- MP Steam Boiler Package Familiarisation - Attachment 1Document12 pagesMP Steam Boiler Package Familiarisation - Attachment 1simba8661100% (2)

- Above Ground Piping Wall Thickness CalculationsDocument7 pagesAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- Design Calculations For Pressure VesselsDocument73 pagesDesign Calculations For Pressure Vesselsshani5573No ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Selection and Use of Engineering MaterialsFrom EverandSelection and Use of Engineering MaterialsRating: 3.5 out of 5 stars3.5/5 (3)

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsPeña Eepesa100% (2)

- PA Fan Sizing Calculation Formula UsedDocument1 pagePA Fan Sizing Calculation Formula UsedtataircNo ratings yet

- Hot Tapping CalculationsDocument17 pagesHot Tapping CalculationsVikash Tiwari100% (3)

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Ceramic Cutting Tools: Materials, Development and PerformanceFrom EverandCeramic Cutting Tools: Materials, Development and PerformanceRating: 3.5 out of 5 stars3.5/5 (3)

- Flare Boom vs. Vent BoomDocument18 pagesFlare Boom vs. Vent BoomUmdpmg Ursa100% (3)

- Flare Boom vs. Vent BoomDocument18 pagesFlare Boom vs. Vent BoomUmdpmg Ursa100% (3)

- LP ValveDocument72 pagesLP ValvetataircNo ratings yet

- HeatExchanger ReportDocument5 pagesHeatExchanger ReportNur Izzati KamrulnizamNo ratings yet

- Anderson Separator: Fuel Gas Skid General Arrangment - 250 PsigDocument2 pagesAnderson Separator: Fuel Gas Skid General Arrangment - 250 PsigJhonny Rincones100% (1)

- Flame Arrestor DatasheetDocument2 pagesFlame Arrestor DatasheetAmit Pandey67% (6)

- Air Cooler 45 Case1 PDFDocument2 pagesAir Cooler 45 Case1 PDFHeny MarthaNo ratings yet

- GI - Thermowell CatalogueDocument18 pagesGI - Thermowell CatalogueMahdy MazinyNo ratings yet

- 80MX1Document1 page80MX1Sanjay BiswasNo ratings yet

- Picture Model 302-06 3-V 54Document2 pagesPicture Model 302-06 3-V 54Nilesh MistryNo ratings yet

- 02 - AC Equipment ScheduleDocument8 pages02 - AC Equipment ScheduleductienssjNo ratings yet

- AHU DetailsDocument2 pagesAHU DetailsamitbslpawarNo ratings yet

- Pipe Design Thikness For PipingDocument1 pagePipe Design Thikness For PipingKanit ChobNo ratings yet

- Flanged Safety Relief Valves - Spring Loaded: Type 447 PTFE-lined Packed Lever H4 Closed Bonnet Bellows DesignDocument9 pagesFlanged Safety Relief Valves - Spring Loaded: Type 447 PTFE-lined Packed Lever H4 Closed Bonnet Bellows DesignSaleh EttehadiNo ratings yet

- CCK VNT Tank Cal DataDocument1 pageCCK VNT Tank Cal Datachompink6900No ratings yet

- An VCHNDocument14 pagesAn VCHNEko KiswoyoNo ratings yet

- Picture Model: 529-065Document2 pagesPicture Model: 529-065Nilesh MistryNo ratings yet

- TBF 0102 AD10 050D - F610036egDocument1 pageTBF 0102 AD10 050D - F610036egdannymay95No ratings yet

- Astava 329Document2 pagesAstava 329Nilesh MistryNo ratings yet

- Picture Model: 113-06 SDocument2 pagesPicture Model: 113-06 SNilesh MistryNo ratings yet

- Valve Data Sheet: BCXS302TDocument1 pageValve Data Sheet: BCXS302TRoo FaNo ratings yet

- PT9141Document2 pagesPT9141mohammed8051No ratings yet

- CS PipingDocument15 pagesCS PipingJavierSeimanNo ratings yet

- Tech Sheet - UXN-B1DS2 - Prasana HQDocument1 pageTech Sheet - UXN-B1DS2 - Prasana HQJeghi100% (2)

- Item 6 Ebro Feed Valve Z011-A-150Document4 pagesItem 6 Ebro Feed Valve Z011-A-150ehngieNo ratings yet

- Heat Exchanger Thermal Design Shell&Tube V7.3.1 CP1Page 1: Basic GeometryDocument8 pagesHeat Exchanger Thermal Design Shell&Tube V7.3.1 CP1Page 1: Basic GeometryaminNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- 10QH - 10CL501 - Deaerator Magnetic LevelDocument1 page10QH - 10CL501 - Deaerator Magnetic LevelPablo HerreroNo ratings yet

- Ed 1 DF 66 DDocument5 pagesEd 1 DF 66 DSurangaG100% (1)

- Astava 102Document2 pagesAstava 102Nilesh MistryNo ratings yet

- Ejemplo Tubesheet Asme UHXDocument14 pagesEjemplo Tubesheet Asme UHXPedro Montes MarinNo ratings yet

- B 84567 SB MM1 SPC ST 00 0301 - 1 - AOC - Seal Gas Mercury Guard BedDocument7 pagesB 84567 SB MM1 SPC ST 00 0301 - 1 - AOC - Seal Gas Mercury Guard BedpragatheeskNo ratings yet

- Assg 3 He Valve PnidDocument7 pagesAssg 3 He Valve PnidpangiastikaNo ratings yet

- 2020 KRT 200 330Document10 pages2020 KRT 200 330Ramón OvalleNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- 1015 5e PDFDocument1 page1015 5e PDFmomtazaliNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Picture Model 290-06 2-VDocument2 pagesPicture Model 290-06 2-VNilesh MistryNo ratings yet

- Pressure Indicator Data SheetDocument2 pagesPressure Indicator Data SheetnwabukingzNo ratings yet

- Quot 4973Document4 pagesQuot 4973Mudasir ATNo ratings yet

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- CW Pipe Thickness CalculationDocument1 pageCW Pipe Thickness CalculationtataircNo ratings yet

- STG Terminal Point DetailsDocument10 pagesSTG Terminal Point DetailstataircNo ratings yet

- PSV TRV - Priority 6 Nos.Document2 pagesPSV TRV - Priority 6 Nos.tataircNo ratings yet

- KKS Numbering ProcedureDocument1 pageKKS Numbering ProceduretataircNo ratings yet

- Aux CT - Tower Tech - Weights and Dimension PDFDocument1 pageAux CT - Tower Tech - Weights and Dimension PDFtataircNo ratings yet

- Weights and Dimension PDFDocument1 pageWeights and Dimension PDFtataircNo ratings yet

- Model TTXL-081937 Downloads: Cooling Tower Sizing Calculation SelectionDocument1 pageModel TTXL-081937 Downloads: Cooling Tower Sizing Calculation SelectiontataircNo ratings yet

- 4.10 Water Balance Diagram Rev-1 08.03.13Document1 page4.10 Water Balance Diagram Rev-1 08.03.13tataircNo ratings yet