Professional Documents

Culture Documents

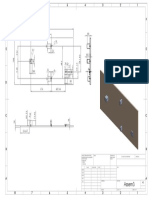

Sučeljni Zavar

Uploaded by

Kerouac AnyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sučeljni Zavar

Uploaded by

Kerouac AnyaCopyright:

Available Formats

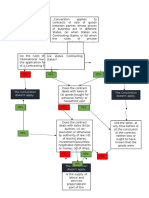

Kutni spoj moe biti izveden zavarivanjem samo s jedne strane ili s obje strane, a predstavlja

prikladno rjeenje i za zavarivanje relativno debljih dijelova. Izvedba kutnog spoja mogua je bez

skoavanja stranice ruba zavarivanog elementa, a isto tako s jednostranim ili dvostranim skoenjem.

Kutni spoj s jednostranim skoenjem obino se koristi kod spajanja limova debljine do 12 mm, kada

se zavarivanje izvodi samo s jedne strane, dok su kutni spojevi s dvostranim skoenjem primjereni

za debljine do 40 mm, pa i vie. Butt welds are welds where two pieces of metal are to be joined are

in the same plane.[1] These types of welds require only some preparation and are used with thin sheet

metals that can be welded with a single pass.[2] Common issues that can weaken a butt weld are the

entrapment of slag, excessive porosity, or cracking. For strong welds, the goal is to use the least

amount of welding material possible. Butt welds are prevalent in automated welding processes, such

as submerged-arc welding, due to their relative ease of preparation. [3] When metals are welded

without human guidance, there is no operator to make adjustments for non-ideal joint preparation.

Because of this necessity, butt welds can be utilized for their simplistic design to be fed through

automated welding machines efficiently.

You might also like

- Program Sufi Nan Sir Anja Zap o 2017Document11 pagesProgram Sufi Nan Sir Anja Zap o 2017Kerouac AnyaNo ratings yet

- Assem3 PDFDocument1 pageAssem3 PDFKerouac AnyaNo ratings yet

- Assem3 PDFDocument1 pageAssem3 PDFKerouac AnyaNo ratings yet

- Assem3 PDFDocument1 pageAssem3 PDFKerouac AnyaNo ratings yet

- FREELETICDocument10 pagesFREELETICKerouac AnyaNo ratings yet

- BikeDocument1 pageBikeKerouac AnyaNo ratings yet

- 56 Business English Phrases Fo PDFDocument7 pages56 Business English Phrases Fo PDFRebecca TohNo ratings yet

- Bam 02032017Document1 pageBam 02032017Kerouac AnyaNo ratings yet

- The Convention Doesn't Apply. The Convention Doesn't ApplyDocument4 pagesThe Convention Doesn't Apply. The Convention Doesn't ApplyKerouac AnyaNo ratings yet

- The Convention Doesn't Apply. The Convention Doesn't ApplyDocument4 pagesThe Convention Doesn't Apply. The Convention Doesn't ApplyKerouac AnyaNo ratings yet

- Daily Schedule Template 07Document1 pageDaily Schedule Template 07Kerouac AnyaNo ratings yet

- Ukupno: 296 27,25 32,2 5,4Document2 pagesUkupno: 296 27,25 32,2 5,4Kerouac AnyaNo ratings yet

- Lazar Angelov'S: Fitness FactsDocument15 pagesLazar Angelov'S: Fitness FactsOriel Boldrini Valdivia100% (1)

- Felga - TutorijalDocument8 pagesFelga - TutorijalKerouac AnyaNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Beachbody Insanity Custom Chart - Version 1.0 PDFDocument1 pageBeachbody Insanity Custom Chart - Version 1.0 PDFDavid BerissoNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)