Professional Documents

Culture Documents

AWS b2.1-1-022-94 - Standard Welding Procedure

AWS b2.1-1-022-94 - Standard Welding Procedure

Uploaded by

Walter Trajada100%(3)100% found this document useful (3 votes)

706 views17 pagesWPS, pre qualified WPS, Standard

Welding Procedure

Original Title

AWS b2.1-1-022-94 - Standard welding procedure

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWPS, pre qualified WPS, Standard

Welding Procedure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(3)100% found this document useful (3 votes)

706 views17 pagesAWS b2.1-1-022-94 - Standard Welding Procedure

AWS b2.1-1-022-94 - Standard Welding Procedure

Uploaded by

Walter TrajadaWPS, pre qualified WPS, Standard

Welding Procedure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 17

mm 0784265 OSO4dSy Lou mm

Standard

Welding Procedure

Specification (WPS) for

Shielded Metal Arc Welding of

Carbon Steel (M-1/P-1/S-1, Group 1 or 2),

1/8 through 1-1/2 inch Thick,

E6010 (Vertical Uphill)

Followed by E7018,

As-Welded or PWHT

Condition

PUT ea a

mm 0784265 0504095 O40 mm

Key Words — welding Procedure Specification, ANSI/AWS B2.1-1-022-94

base met allowable on cesigas ‘An American National Standard

filler metal, carbon steel, manual

shielded metal are welding

Approved by

American National Standards Institute

April 15, 1993

Standard Welding Procedure

Specification (WPS)

Shielded Metal Arc Welding of Carbon Steel

(M-1/P-1/S-1, Group 1 or 2)

1/8 through 1-1/2 inch Thick,

E6010 (Vertical Uphill) Followed by E7018

As-Welded or PWHT Condition

Prepared by

AWS Committee on Welding Qualification

Under the Direction of the

AWS Technical Activities Commitee

Approved by

AWS Board of Directors

Abstract

This standard contains the essential welding variables for carbon stel inthe thickness range of 1/8 through 1-1/2 inch,

using manual shielded metal are welding, It cites the base metals and operating conditions necessary to make the

woldment, the filler metal specifications, and the allowable joint designs for fillet and groove welds, This WPS was

developed primarily for plate and structural applications.

American Welding Society

550 N.W. LeJeune Road, Miami, Florida 33126

Cops by the Amaian Melig Society

‘Satu 05 142548 1857

mm 0784265 0504056 187 mm

‘Statement on Use of AWS Standards

[All standards (codes, specifications, recommended practices, methods, classifications, and guides) of the American

‘Welding Society ate voluntary consensus standards that have been developed in accordance with the rules of the

‘American National Standards Institute. When AWS standards are either incorporated in, or made part of, documents that

are included in federal or state laws and regulations, or the regulations of other governmental bodies, their provisions

‘carry the full legal authority ofthe statute, In such cases, any changes in those AWS standards must be approved by the

governmental body having statutory jurisdiction before they can become a part of those laws and regulations. In all

‘eases, these standards carry the full legal authority of the contract or other document that invokes the AWS standards.

‘Where this contractual relationship exists, changes in or deviations from requirements of an AWS standard must be by

agreement between the contracting parties.

International Standard Book Number: 0-87171-431-0

“American Welding Society, $50 N.W. LeJeune Road, Miami, Florida 33126

‘© 1994 by American Welding Society. All rights reserved

Printed in the United States of America

Note: The primary purpose of AWS isto serve and benefit its members. To this end, AWS provides a forum for the

‘posal that are relevant to the welding industry and the

ding such a forum, AWS does not assume any duties to

‘which a user ofthese standards may be required to adhere. By publishing this standard, the American Welding Society

400s not insure anyone using the information it contains against any lability arising from that use. Publication of a

standard by the American Welding Society doesnot cary with it any right to make, use, or sell any patented items.

‘Uses ofthe information inthis standard should make an independent, substantiating investigation of the validity of that

information for their particular use and the patent status of any item referred to herein

With regard to technical inquiries made concerning AWS standards, oral opinions on AWS standards may be rendered.

However, such opinions represent only the personal opinions of the particular individuals giving them. These

individuals do not speak on bebalf of AWS, nor do these oral opinions constitute official or unofficial opinions of

interpretations of AWS. In addition, oral opinions are informal and should not be used as a substitute for an official

interpretation.

‘This standard is subject (o revision at any time by the AWS Welding Qualification Commitee. It must be reviewed

every five years and if not revised, it must be either reapproved or withdrawn. Comments (recommendations, additions,

of deletions) and any pertinent data that may be of use in improving this standard aze requested and should be addressed

to AWS Headquarters. Such comments will recaive careful consideration by the AWS Welding Qualification Commit-

tee and the author ofthe comments will be informed of the Committee’s response to the comments. Guests are invited

toattend all meetings of the AWS Welding Qualification Committee to express their comments verbally. Procedures for

appeal of an adverse decision concerning all such comments are provided in the Rules of Operation of the Technical

Activities Committee. A copy of these Rules can be obtained from the American Welding Society, 550 N.W. LeJeune

Road, Miami, Florida 33126,

Cops by the Amaian Melig Society

‘Satu 05 142548 1857 "

Cops by the Amaian Melig Society

‘Satu 05 142548 1857

mm 0784265 0504057 913 mm

Personnel

AWS Committee on Welding Qualification

T.J. Anderson, Chairman Bechtel Group, Incorporated

D.L. Sprow, Vice Chairman McDermott, Incorporated

MJ. Houle, Vice Chairman Welding Engineering Services

D.R. Papenfuss, Vice Chairman The Boeing Company

LP. Connor, Secretary American Welding Society

W.L-Ballis Columbis Gas Distribution Companies

H.B. Cary Mobart Brothers Company

JL. Cooley Mortison-Kaudsen Corporation

P.B.Dickerson*® Aluminum Company of America

W.D. Doty Doty and Associates

J.J.Falco* Army Materials and Mechanics Research Center

J.J. Fluekiger —_Babock and Wilcox, Idaho, Inc.

E.H.Gray U.S. Nuclear Regulatory Commission

JE. Hinkel Lincoln Electric Company

R.W.Jackson Consultant

JLW.MeGrew —Babock and Wilcox

C.L.Null® Naval Sea Systems Command

A.S. Olivares ‘The Hartford Steam Boiler Inspection and

Insurance Company

Welding Research Council

Canadian Welding Bureau

J.J.Sekely Dick Enterprises, Inc.

A.W. Sindel — CENatoo

W.R Smith Sr.*** Bechtel Group, Incorporated

CE. Spueder Lehigh University

VW. Suter American Welding Institute

G.M, Wisbrock Jr. Loral Vought Systems Corporation

mm 0784265 0504098 8ST mm

Foreword

(This Foreword is not a part of the ANSVAWS B2.1-1-022-94, Standard Welding Procedure Specification, but is

included for information purposes only.)

The American Welding Society and the Welding Research Council have joined in a cooperative effort to generate

standard welding procedures for industry. The nced for pretested welding procedures that are supported by adequate test

data and that satisfy the technical requirements forthe commonly used construction coges and specification has been

‘expressed by many individuals and organizations. The purpose of a welding procedure qualification is to provide test

data for assessing the properties of a weld joint

This Welding Procedure Specification is an outgrowth of the coordinated work of the Welding Procedures

Committee of WRC and the Committee on Welding Qualification ofthe AWS. The Welding Procedures Committe has

provided the test data documented on Procedure Qualification Records, which are available from the Welding Research

Council

“The welding terms used inthis specification shall be interpreted in accordance with the definitions given inthe latest

edition of ANSUAWS A3., Standard Welding Terms and Definitions. Welding symbols shall be those shown in the

lates: edition of ANSVAWS A2.4, Standard Symbols for Welding, Brazing, and Nondestructive Examination

The AWS Committee on Welding Qualification was formed in 1979 to provide welding standards concerning the

subject of qualification. The primary document developed by this committee is AWS B2.1, Standard for Welding

Procedure and Performance Qualification. This document established the foundation and framework for Standard

‘Welding Procedure Specifications.

‘Comments on this publication are most welcome. They should be addressed to: Secretary, AWS Committee on

‘Welding Qualification, American Welding Society, $50 N.W. LeTeune Road, Miami, Florida 33126,

Cops by the Amaian Melig Society

‘Satu 05 142548 1857

mm 0784265 0504099 796 mm

ANSI/AWS B2.1-1-022-94

Page 1 of 12

Standard Welding Procedure Specification (WPS)

Shielded Metal Arc Welding of Carbon Steel (M-1/P-1/S-1, Group 1 or 2),

1/8 through 1-1/2 inch Thick, E6010 (Vertical Uphill) Followed by E7018,

As-Welded or PWHT Condition

Welding Research Council'—Supporting PQR Numbers:

001001, 001009, 001021, 001022, 001028, 003016, 003017, 008001, 103004,

106004, 106005, 106006, 107020, 107021, 107022, 200018, 200108, 200109,

200110, 200111, 200112, 200113, 200114, 200115, 200116, 200117, 200118,

200119, 200120, 200121, 200122, 200123, 200124, 200125, 200126, 200142,

200143, 200144, 200145, 200514, 200516, 200517, 200518, 200519, 200611,

200614, 200615, 200617, 200618, 200619, 200620, 200702, 200703, 500001,

500002, 500006, 500007, 500008, 500021, 500023, 500024, 500028, 500029,

500119, 001A, 002A, 197A, 198A, 1994

Requirements for Application

of Standard WPSs

‘Scope. The data to support this Standard Welding

Procedure Specification (WPS) have been derived

from the above listed Procedure Qualification Records

(PQRs) which were reviewed and validated under

the auspices of the Welding Research Council. This

Standard WPS is not valid using conditions and

variables outside the ranges listed, The American

‘Welding Society considers that this Standard WPS

presents information for producing an acceptable

‘weld using the conditions and variables listed. The

user needs a significant knowledge of welding and

‘accepls full responsibilty for the performance of the

weld and for providing the engineering capability,

qualified personnel, and proper equipment to imple-

ment this Standard Welding Procedure Specification.

Application. This Standard WPS is to be used only

1s permitted by the applicable fabrication document

[such as code, specification, or contract docu-

Tentt(s)]. The fabrication document should specify

the engineering requirements such as design, need

for neat treatment, fabricating tolerances, quality

‘control, and examination and tests applicable to the

‘end product.

User's Responsibility. A Standard WPS does not

replace or substitute for fabrication codes, specifica-

41, Welding Research Council, 245 East 47th Street, New

York, NY 10017.

Cops by the Amaian Melig Society

‘Satu 05 142548 1857

tions, contract requirements, or capability and judg-

‘ment on the part of the user. A Standard WPS is to

bbe used only as permitted by the applicable fabrica-

tion code, specication, or contract deoument.

The ability to produce production welds having

properties suitable forthe application depends upon

supplementing the Standard WPS with appropriate

performance qualification tests and sound engineer-

lng judgement. The usor is responsible for the qual-

ity and performance of the final productin accordance

with the provisions ofthe fabrication document.

‘Supplementary Instructions. To adapt this Stan-

dard WPS to a specific application, a user may

Issue supplementary instructions. Such instructions,

may consist of tighter fit-up tolerances, higher

‘minimum preheat temperature or any other instruc

‘ons necessary to produce a weldment that meets

the requirements ofthe fabrication document. These

instructions shall not be iess restrictive than pro-

vided in the Standard WPS.

Safety. Safoty precautions shall conform to the latest

edition of ANSYASC 248.1, Safety in Welding and

‘Cutting, published by the American Welding Society

‘This specification may involve hazardous mate-

tials, operations, and equipment. The specification

does not purport to address all of the safety prob-

Jems associated with its uso. itis the responsiblity of

the user to establish appropriate safety and health

practices. The user should determine the applica-

bility of any regulatory limitations prior to use.

m 0784265 0504100 238 mm

ANSIAWS B2.1-1-022-94

Page 2 of 12

Standard Welding Procedure Specification (WPS)

LIMITATIONS

This procedure is not qualified for Notch Toughness applications.

WELDING PROCESSES

Welding Processes: 'SMAW (Shielded Metal Arc Welding)

Method of Application: Manual

BASE METALS

Base Metal:* Carbon Steel, M-1, P-t, or S-1, Group 1 or 2to Met, Pat, or S-1,

Group 1 or 2

Thickness Range: 1/8 in. through 1-1/2 in. for groove welds,

118 in. minimum for filet welds

Diameter: Groove Welds: 1 in. minimum

Fillet Welds: all diameters

FILLER METALS

Filler Metal Specification: ANSVAWS AS.1 or ASME SFA 5.1

‘ANumber 1, F Number 3 for E6010, and F Number 4 for E7018

Classification: E6010 end E7018

Deposit Thickness Range: 1-1/2 in. maximum plus reinforcement for groove welds; the maximum

deposit thickness for E6010 electrode is limited to 9/8 in, (nominal)

1-1/2 in filet weld size for filet welds; the maximum filet deposit size for

E6010 electrode is limited to 9/8 in. (nominal)

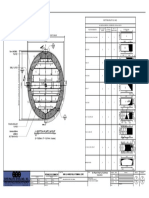

JOINT DESIGNS

Joint Designs: See Figure 1

Backing: Not required

Backing Material:* Carbon steel, M-1, P-1, or S-1, Group 1, 2, oF 3 or carbon steel weld metal

Nonmetallic or nonfusing metal retainers are not permitted

POSITIONS

Permitted Positions: All

Vertical Progression: Uphit

PREHEAT AND INTERPASS TEMPERATURES,

Preheat Temperature:* 50°F Minimum; 150°F Minimum for £6010 on base metal thickness over

‘3/4 in. thick

Interpass Temperature:* 50°F Minimum, 500°F Maximum

Preheat Maintenance: Continuous or special heating not required

2. M,P, and 8 numbers for base metal and F ang A numbers for filer metal and weld metal respectively, are as detalled

In ANS 82.1 or ASME Boiler and Pressure Vessel Code, Section IX.

4, Prehoet and intorpass temperatures must be sufficient to prevent crack formation. Temperatures above the minimum

‘showin may be required for base metals wth a specified carbon content greatar than 0.25%, for highly restrained welds,

(oF to meet the requirsments ofthe fabrication document(s).

Cops by the Amaian Melig Society

‘Satu 05 142548 1857

Mm 0784265 OSO4102 174 mm

ANSI/AWS B2.1-1-022-94

Page 3 of 12

Standard Welding Procedure Specification (WPS)

POSTWELD HEAT TREATMENT

Postweld Heat Treatment: Welds may either be as-welded or postweld heat treated at 1100 to 1200°F. If

heat treated, the heat treatment time shall be 1 hour per inch of thickness

(15 minutes minimum) unless otherwise noted in the fabrication document.

ELECTRICAL CHARACTERISTICS

Electrode’ Current

| Classification Dia?in, Amperes Polarity

E6010 arae 40-80 DCEP (Reverse)

E6010 118 75-125 DCEP (Reverse)

E6010 5/32 110-170 DCEP (Reverse)

Electrode! Current

Classification Diatin, Amperes Polarity

E7018 9/92 70-110 CEP (Reverse)

E7018 18 90-150 DCEP (Reverse)

E7018 5/32 120-190 DCEP (Reverse)

E7018 316 170-280 DCEP (Reverse)

1, The care and storage of electrodes shall be as recommended by the electrode

manufacturer.

2. 3116 in, electrodes shall not be used for tack or root pass welding nor for welding

in the vertical or evarhaad positions.

Pulsing Current Not permitted

‘TECHNIQUE

Weave or Stringer Bead: Either

Peenin; Not required f used, proceed as directed by the fabrication document

Initial Cleaning: ‘Chemical or mechanical; joint shall be dry prior to welding

Interpass Cleanin Mechanical only

Backgouging: Mechanical or thermal when required by Figure 1

Gouging: Mechanical or thermal

Single or Multiple Passes: Either

Maximum Bead Thickness: 1/4 in

COMPANY NAME

Inthe name of the Company stated above, | accept full responsibilty forthe application ofthis Standard WPS.

for use with

Dated

Fabrication Document(s): such as Gode, Spectication or Contract Document

DATE APPROVED BY Te

Cops by the Amaian Melig Society

‘Satu 05 142548 1857

mm 0784265 0504302 O00 mm

ANSV/AWS B2.1-1-022-94

Page 4 of 12

Standard Welding Procedure Specification (WPS)

FILLET WELDS: All Joints

GROOVE WELDS: See Joints 1 through 17. Joints having prequalified joint details permitted by

the latest edition of ANSVAWS D1.1, Structural Welding Code—Stee! are also permitted.

For tubular products, see Joints 1, 2, 6 and 7. In addition, joints having groove designs resulting

from end preparations conforming with the latest edition of ANSYASME 816.25, Butt Welding

Ends, are also allowable for application with this WPS.

(pes

= orTIONAL

t —| jek

WITH BACKING. ;THOUT BACKING.

a= 45° MIN, = 60° MIN

Re tit in, +14-4716 R= YBin, 116-106

=F fe t/8 in MAX.

sows

WITH BACKING WITHOUT BACKING

a= 45° MIN, a= 60" MIN,

Fe tiein, 118-196 Re iein, 16-16

1-R2 P= 16 in WAX,

soit 2

Figure 1—Allowable Joint Designs

Cops by the Amaian Melig Society

‘Satu 05 142548 1857

mm 0784265 OS04L03 TH? mm

ANSI/AWS B2.1-1-022-94

Page 5 of 12

Standard Welding Procedure Specification (WPS)

a

xcKcoune &

a ——

yy {

Fe

a=60" MIN,

R= V8ie, 16470

= NOT LIMITED

d

A

vow 3

Figure 1 (continued) —Allowable Joint Designs

Cops by the Amaian Melig Society

‘Satu 05 142548 1857

ANSI/AWS B2.1-1-022-94

Page 6 of 12

Mm 0784265 0504204 953 mm

Standard Welding Procedure Specification (WPS)

BACKGOUGE

| BACK WELD.

ae

BAND ~ 60°

som s

A,

1}

\

\—

oy

MIN

Re tin, Hee

T LIMITED

St = NOT UMITED.

82 = NOT LIMITED.

A

JOINT 6

atl

wm gaciaNa \wirsour sacks

aoe treo MN

Retin, 4-46 Roane seme

fee Poe nse

Figure 1 (continued) Allowable Joint Designs

Cops by the Amaian Melig Society

‘Satu 05 142548 1857

mm 0784265 0504105 417 mm

ANSI/AWS B2.1-1-022-94

Page 7 of 12

Standard Welding Procedure Specification (WPS)

fe &

WITH BACKING WITHOUT BACKING

a= 45" MIN. a= 60" MIN.

Retin, 1/448 Re Bin, e616

tne Te 178 in MAK.

sont

Cy

Uke

|

BACKGOUGE

aR ES NED

a= 45" MIN.

Fe 8 i 136-18

+ Nor LitarED

somnr a

Figure 1 (continued) —Allowable Joint Designs

Cops by the Amaian Melig Society

‘Satu 05 142548 1857

Wm 0784265 0504105 756 mm

ANSI/AWS B2.1-1-022-94

Page 8 of 12

Standard Welding Procedure Specification (WPS)

BackGOUGE

a

BACKGOUGE

ABACK WELD

(OT LIMITED

sons

BACKGOUGE

e—A

+

a= 45" MIN,

>

Max.

Re iBin, e1ne-Wi6

t= NOT UTED

SOT 10

Figure 1 (continued) —1

ljowable Joint Designs

Cops by the Amaian Melig Society

‘Satu 05 142548 1857

mm 0784265 OSO4107 692 mm

ANSI/AWS B2.1-1-022-94

Page 9 of 12

Standard Welding Procedure Specification (WPS)

wy, - am _

poe x £

=e

1

st

| “Ea

Se LES

ja

la

a= 45" Min,

R= Vein, 416-108

f= NoT UTED

81 = NOT UMITED

82 NOTLUMITED

vor 1

mi

in, 116-128

‘Nor UMiTED

=n, 180

sown 12

Figure 1 (continued) —Allowable Joint Designs

Cops by the Amaian Melig Society

‘Satu 05 142548 1857

Mm 0764265 0504108 S29 mm

ANSI/AWS B2.1-1-022-94

Page 10 of 12

Standard Welding Procedure Specification (WPS)

BACKGOUGE

'

Fe tain, A616

sow +3

a

vA

NS a

BACKGOUGE te a

ec

a= 45° MN,

Re tin, 16-18

= NOT LiMiTED

Fe 2iB in, 1/1616

vom 14

Figure 1 (continued)—Allowable Joint Designs

Cops by the Amaian Melig Society

‘Satu 05 142548 1857

mm 0784265 0504309 465 mm

ANSI/AWS B2,1-1-022-94

Page 11 of 12

Standard Welding Procedure Specification (WPS)

BAcKGOUGE

ABACK WELD

a= 45 MIN

8 in, 146-18,

t= NOT UTED

Fe 3B in, +1716-106

Jot 15

si

a= 45° Min,

Retin, +1618

in, ANB

(OT LIMITED

81 AND 82 = NOT LIMITED

JOINT 16

Figure 1 (continued) —Allowable Joint Designs

Cops by the Amaian Melig Society

‘Satu 05 142548 1857

Wm 0784265 0504130 187 a

ANSV/AWS B2.1-1-022-94

Page 12 of 12

Standard Welding Procedure Specification (WPS)

‘BACKGOUGE,

a= 45" MIN.

Re tin, H/16-18

F298, S166

1 = NOT LIMITED

owt 17

Figure 1 (continued) —Allowable Joint Designs

Cops by the Amaian Melig Society

‘Satu 05 142548 1857

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TSWR Sling Inspection ReportDocument1 pageTSWR Sling Inspection ReportWalter TrajadaNo ratings yet

- ASME B31.3 2014 NDT AcceptanceDocument9 pagesASME B31.3 2014 NDT AcceptanceWalter Trajada83% (6)

- Rulefinder Version 9.21 (January 2014) - Lloyd's Register Rules and Regulations - Section 2Document9 pagesRulefinder Version 9.21 (January 2014) - Lloyd's Register Rules and Regulations - Section 2Walter TrajadaNo ratings yet

- Hardness Test Procedure PDFDocument8 pagesHardness Test Procedure PDFTim Joseph Alvaro83% (6)

- PT Q&a Newest Version PDFDocument33 pagesPT Q&a Newest Version PDFWalter Trajada100% (1)

- Niton XL3t GOLDD+ Spec Sheet 2011jan26 PDFDocument2 pagesNiton XL3t GOLDD+ Spec Sheet 2011jan26 PDFWalter TrajadaNo ratings yet

- Berthold PDFDocument1 pageBerthold PDFWalter TrajadaNo ratings yet

- World Safety Organization: Basic Occupational Safety & Health Course (40 Hours)Document4 pagesWorld Safety Organization: Basic Occupational Safety & Health Course (40 Hours)Walter TrajadaNo ratings yet

- For Mpi Test: Elence Marine & Industrial CorpDocument1 pageFor Mpi Test: Elence Marine & Industrial CorpWalter TrajadaNo ratings yet

- Borescope Sample Report PDFDocument14 pagesBorescope Sample Report PDFWalter TrajadaNo ratings yet

- ASTM Compass G ListDocument6 pagesASTM Compass G ListWalter Trajada100% (1)

- Borescope Sample Report PDFDocument14 pagesBorescope Sample Report PDFWalter TrajadaNo ratings yet

- PAUTDocument7 pagesPAUTDeepakNo ratings yet

- Verify Structural Concrete Base: Bottom Plate LayoutDocument1 pageVerify Structural Concrete Base: Bottom Plate LayoutWalter TrajadaNo ratings yet

- Borescope Inpection - Turbine Inspection Report 2Document14 pagesBorescope Inpection - Turbine Inspection Report 2Walter TrajadaNo ratings yet

- Borescope Sample Report PDFDocument14 pagesBorescope Sample Report PDFWalter TrajadaNo ratings yet

- ASTM E164-13 Standard Practice For Contact Ultrasonic Testing of WeldmentsDocument24 pagesASTM E164-13 Standard Practice For Contact Ultrasonic Testing of WeldmentsFernandoi100% (1)

- 2 VSTDocument1 page2 VSTWalter TrajadaNo ratings yet

- E527-12 Standard Practice For Numbering Metals and Alloys in The Unified Numbering System (UNS)Document7 pagesE527-12 Standard Practice For Numbering Metals and Alloys in The Unified Numbering System (UNS)Walter TrajadaNo ratings yet