Professional Documents

Culture Documents

Book 1 W

Uploaded by

Andre YunusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Book 1 W

Uploaded by

Andre YunusCopyright:

Available Formats

No

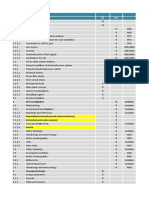

Clause/Part/Book

Content in document

The piping systems shall conform to the codes

and standards as specified in general in part

4.5.1.1.2.1, Book III 4.3A.5 "Code and Standards" and as indicated in

the various Clauses of this specification

C25 For all concrete work in contact with sea

water and jetty

2

4.4.2.5 Book III

4.4.2.5 Concrete,

Formwork and

Reinforcement

Cement type I shall be used for above grade

work, cement type II for sub structure and

cement type V for all structure directs contact

with sea water including wharf.

3

All handrails shall be shop prime and field finish

painted

4 4.4.2.9.8

Jetty structure will be supported by pre-coring

steel piping, or other type of pile subject for

Owner's approval.

5 4.4.1.1.10 Book III

Two unit continuous, ship unloader, travelling

clamshell bucket unloader type, which is capable

of independent simultaneous 24 hours operation

with average digging rate capacity around 250

tons/hr (free digging rate capacity, 500 tons/hr).

6 4.5.18.2 Book III

7 4.5.4.4.1 Book III

This system shall consist of intake tower and sea

bed intake pipe

Deviation from DEC

Employer's Response

Chinese Standard "DL/T 5054-2016

Code for Design of Thermal Power

Plant Steam/ Water Piping" was

applied. Chinese material for steam

pipe was applied in DEC's proposal.

According to Chinese standard "JTS

153-2015 Standard for Durability

Design of Port and Waterway

Engineering Structure" we use cap

and higher grade concrete for

reinforced concrete structure in

contact with sea

Cement type I shall be used for above

grade work, Cement type V for sub

structure and all structure directs

contact with sea water including

wharf. (Because cement type II has

been little produced and used at

present.)

A small portion of handrails could be

fabricated at site and the primer shall

be painted in accordance with the

requirements of factory.

According to the geologist

investigation data in land area, We

use cast-in-situ bored pile as the

jetty's foundation at this phase.

We use two fixed single boom cranes

with rated lifting capacity of 16t and

maximum outreach of 37m whose

working range can cover all hatches of

12,000t barges with digging rate

capacity around 250 tons/hr (free

digging rate capacity, 500 tons/hr).

we used open intake channel instead

of most of intake pipe

Please provide the geologist investigation

data in land area

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Euclid Contest: The Centre For Education in Mathematics and Computing Cemc - Uwaterloo.caDocument6 pagesEuclid Contest: The Centre For Education in Mathematics and Computing Cemc - Uwaterloo.caAndre YunusNo ratings yet

- Chapter 12 - Wave Forces On Slender CylinderDocument78 pagesChapter 12 - Wave Forces On Slender CylinderJuan Carlos GonzálezNo ratings yet

- IB Physics Review-WavesDocument21 pagesIB Physics Review-WavesTheEinsteinofTomorrow100% (1)

- Further Mathematics 9231Document2 pagesFurther Mathematics 9231Andre YunusNo ratings yet

- Cambridge International AS & A Level: Further Mathematics 9231/11Document20 pagesCambridge International AS & A Level: Further Mathematics 9231/11Andre YunusNo ratings yet

- (Template) Chapter 13 Lesson 3Document3 pages(Template) Chapter 13 Lesson 3Andre YunusNo ratings yet

- Uniform Circular MotionDocument10 pagesUniform Circular MotionAndre YunusNo ratings yet

- S2P CVL DWG 629 A3 MergedDocument3 pagesS2P CVL DWG 629 A3 MergedAndre YunusNo ratings yet

- 5-7 Sum ProductDocument4 pages5-7 Sum ProductAndre YunusNo ratings yet

- (Mai 1.2-1.3) Exponents - Systems of Linear EquationsDocument8 pages(Mai 1.2-1.3) Exponents - Systems of Linear EquationsJuhi KastiyaNo ratings yet

- Tutorial 2 Home Work 1 TrystnDocument5 pagesTutorial 2 Home Work 1 TrystnAndre YunusNo ratings yet

- Graded Quiz#2 On Integration: X DX XDocument2 pagesGraded Quiz#2 On Integration: X DX XAndre YunusNo ratings yet

- Continous Random Variable AnsDocument9 pagesContinous Random Variable AnsAndre YunusNo ratings yet

- Arlan Zelenky - Algebra II - HW #41 - 300 PtsDocument4 pagesArlan Zelenky - Algebra II - HW #41 - 300 PtsArlan ZelenkyNo ratings yet

- Uniform Circular MotionDocument10 pagesUniform Circular MotionAndre YunusNo ratings yet

- Syllabus: Cambridge International AS & A Level Further Mathematics 9231Document52 pagesSyllabus: Cambridge International AS & A Level Further Mathematics 9231Andre YunusNo ratings yet

- 2020 2022 Syllabus PDFDocument51 pages2020 2022 Syllabus PDFmengleeNo ratings yet

- Functions11 Sec1 7Document10 pagesFunctions11 Sec1 7Andre YunusNo ratings yet

- 0c. Toc Ugc Itf Wte SunterDocument5 pages0c. Toc Ugc Itf Wte SunterAndre YunusNo ratings yet

- Stuktur Kurikulum S2 Teknik SipilDocument33 pagesStuktur Kurikulum S2 Teknik SipildikiNo ratings yet

- 1Document9 pages1Andre YunusNo ratings yet

- ENCV 800108 - 3 WAVE HYDRODYNAMICS-DTS-S2-UI-2014 (Compatibility Mode) PDFDocument37 pagesENCV 800108 - 3 WAVE HYDRODYNAMICS-DTS-S2-UI-2014 (Compatibility Mode) PDFAndre YunusNo ratings yet

- Is There Any Correlation Between Grade and Calorie Intake in A Day?Document23 pagesIs There Any Correlation Between Grade and Calorie Intake in A Day?Andre YunusNo ratings yet

- 1998-03 Pages 38-41 PDFDocument4 pages1998-03 Pages 38-41 PDFMu Hardi100% (1)

- Toc TocDocument3 pagesToc TocAndre YunusNo ratings yet

- List PerakDocument1 pageList PerakAndre YunusNo ratings yet

- Mathematical Methods Paper 1 SL PDFDocument16 pagesMathematical Methods Paper 1 SL PDFAndre YunusNo ratings yet

- Iutssoal 1Document1 pageIutssoal 1Andre YunusNo ratings yet

- 4 CDocument2 pages4 CAndre YunusNo ratings yet