Professional Documents

Culture Documents

Circular Anchor Bolt Pattern Calculation

Uploaded by

Krishna Varun DuvvuruOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Circular Anchor Bolt Pattern Calculation

Uploaded by

Krishna Varun DuvvuruCopyright:

Available Formats

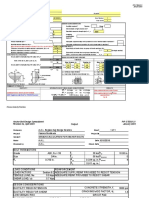

Circular Anchor Bolt Pattern Calculations

Analysis Method Taken From:

Tubular Steel Structures - Theory and Design, by M.S. Troitsky

Design Loads

Design Axial Force, P

Design Moment, M

Anchor Layout

Bolt Circle Diameter, D

Bolt Circle Radius, r

Nominal Anchor Bolt Size, db

Anchor Bolt Stess Area, Ab

Number of Anchor Bolts, N

Total Steel Area, As

Job:

CSP0000562

Date:

10/26/2016

Designer: DCB

Neutral

Axis

36.0 k

988 k-ft

C

2

180.00 in

90.00 in

zD

r = D/2

jD

1 in

0.61 in

8

4.85 in

As = AbN

Equivalent Steel Thickness, ts

0.01 in

ts = As/(2r)

Bearing Plate Width, tc

9.00 in

T

Anchor Bolt

Equivalent

Steel Area

Material Properties

Concrete Compressive Strength, f'c

4,000 psi

Steel Modulus of Elasticity, Es

29,000 ksi

Concrete Modulus of Elasticity, Ec

3,605 ksi

Ec = 57,000[f'c]

Modular Ratio, n

8.044

n = Es/Ec

Calculations

Neutral Axis Depth, D

Neutral Axis Factor,

9.73 in

0.054

= D/D

Angle to Neutral Axis,

Tension Constant, CT

.469 rad

`

`

c

o

c

o

`

`

c

co

o

`

`

c

o

c

o

tc

c

o

c

o

`

`

c

oc

o

ts

`

`

c

o

c

o

c

o

c

o

c

o

`

`

c

o

Anchor Bolts

Equation 5.45

2.998

= cos-1(1-2)

CT = 2[sin-(-)cosa]/(1+cos)

Tension Force Distance from Neutral Axis, 1

129.08 in

1 = [(-)cos2+3/2sincos+1/2(-)]r / [sin+(-)cos]

Equation 5.49

Compression Constant, CP

0.623

CP = 2[cos-sin]/[cos-1]

Table 5.2

Compression Force Distance from Neutral Axis, 2

7.77 in

2 = [cos2-3/2sincos+1/2]r/[sin-cos]

Equation 5.52

Internal Moment Arm Factor, j

0.760

j = (1+2)/D

Table 5.2

Compression Distance from Centroid Factor, z

Maximum Steel Stress, fs

0.489

z = (2+rcos)/D

Table 5.2

27.44 ksi

fs = 2(M-PzD)/(AsCTjD)

Equation 5.53

Maximum Concrete Stress, fc

0.20 ksi

fc = (P+rtsCTfs)/(tcCPr+rtsCPn)

Equation 5.55

Maximum Bolt Tension, Tb

16.6 k

Tb = fsAb

Calculated Neutral Axis Factor,

Difference Between Estimated and Calculated

0.054

0.00

= 1/[1+fs/(nfc)]

Table 5.2

Equation5.44

You might also like

- Circular Anchor Bolt Pattern ExampleDocument1 pageCircular Anchor Bolt Pattern ExampleSisu Stefan100% (1)

- Skid Lifitng Lug CalculationsDocument5 pagesSkid Lifitng Lug CalculationsinnovativekarthiNo ratings yet

- Bolt Connection Design Based On AISC 360-10/16: Input Data & Design SummaryDocument1 pageBolt Connection Design Based On AISC 360-10/16: Input Data & Design SummaryKaren Esther Acuña VelasquezNo ratings yet

- Anchorage Design, With Circular Base Plate, Based On ACI 318-14 & AISC 360-10/16Document2 pagesAnchorage Design, With Circular Base Plate, Based On ACI 318-14 & AISC 360-10/16JuanAlfaroRodríguezNo ratings yet

- Lifting LugDocument4 pagesLifting LugUmmer BavaNo ratings yet

- Anchor BoltsDocument10 pagesAnchor BoltsLex LiwNo ratings yet

- Wind PDFDocument24 pagesWind PDFnagarajhebbarNo ratings yet

- Shear Check for 530UB82.0 Beam ProjectDocument1 pageShear Check for 530UB82.0 Beam ProjectArjun RajaNo ratings yet

- AISC 9th Edition Prying Action Analysis ProgramDocument8 pagesAISC 9th Edition Prying Action Analysis ProgramjoseherreramogollonNo ratings yet

- Design Base Plate for Platform 1 ColumnDocument93 pagesDesign Base Plate for Platform 1 ColumnAnand.5No ratings yet

- Wind Load AS1170 2Document15 pagesWind Load AS1170 2Divesh rahulNo ratings yet

- SPREADSHEET - ANALYSIS OF BLOCK TYPE MACHINE FOUNDATION PROJECTDocument5 pagesSPREADSHEET - ANALYSIS OF BLOCK TYPE MACHINE FOUNDATION PROJECTrajasekhar.cheruvu8635No ratings yet

- AISC 13th Slip Critical Bolt Capacity ASDDocument1 pageAISC 13th Slip Critical Bolt Capacity ASDdantevariasNo ratings yet

- Base Plate DesignDocument118 pagesBase Plate Designsanjay singhNo ratings yet

- Moment Connection DETAIL 2Document5 pagesMoment Connection DETAIL 2way2vaseemNo ratings yet

- 0Kl#888Km5 (.+&' (. Ÿ 2. E.' Ÿ N ' (4 - &oÿ J./) + Ÿ: 5 2pno@Document1 page0Kl#888Km5 (.+&' (. Ÿ 2. E.' Ÿ N ' (4 - &oÿ J./) + Ÿ: 5 2pno@Pop JiNo ratings yet

- Short Circular Steel StacksDocument12 pagesShort Circular Steel Stackskselvan_1No ratings yet

- Baseplate MonorailDocument31 pagesBaseplate Monorailmohamad chandraNo ratings yet

- Mathcad - Angle Bracing Connected To A Gusset Plate On BeamDocument14 pagesMathcad - Angle Bracing Connected To A Gusset Plate On BeamValentinNo ratings yet

- Seismic analysis and design of reinforced concrete moment frameDocument16 pagesSeismic analysis and design of reinforced concrete moment frameKalpanaNo ratings yet

- Connection ScheduleDocument192 pagesConnection ScheduleNikitaBhattaraiAcharyaNo ratings yet

- 498 Plate Girder ShearDocument1 page498 Plate Girder ShearAssem ElhajjNo ratings yet

- Vertical Vessel Circular Pattern Anchor Bolt Design - ACI 318-14Document4 pagesVertical Vessel Circular Pattern Anchor Bolt Design - ACI 318-14dovi01No ratings yet

- Splice ConnectionUC 254X254X73Document1 pageSplice ConnectionUC 254X254X73PavanGuptaNo ratings yet

- Princess Noura Bint Abdulrahman University For Women Project Joint Venture El Seif/CCCDocument9 pagesPrincess Noura Bint Abdulrahman University For Women Project Joint Venture El Seif/CCCНемања КараклајићNo ratings yet

- Design of Base Plate & Anchor Bolt (Crusher House)Document5 pagesDesign of Base Plate & Anchor Bolt (Crusher House)titir bagchiNo ratings yet

- Mathcad - Angle Bracing Connected To Gusset Plate On ColumnDocument13 pagesMathcad - Angle Bracing Connected To Gusset Plate On ColumnValentinNo ratings yet

- Calculation For Base Plate ConnectionDocument85 pagesCalculation For Base Plate ConnectionpriantomoNo ratings yet

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearDocument4 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearVenu GopalNo ratings yet

- Larsen & Toubro Limited: ECC Division - EDRCDocument5 pagesLarsen & Toubro Limited: ECC Division - EDRCK Divakara RaoNo ratings yet

- Checks For CompactnessDocument15 pagesChecks For CompactnessjologscresenciaNo ratings yet

- Column Base Plate DesignDocument1 pageColumn Base Plate DesignBunkun15No ratings yet

- Crane Beam Web Splice DesignDocument7 pagesCrane Beam Web Splice DesignCrystal JaneNo ratings yet

- Body Flange .PVDB FlangeDocument1 pageBody Flange .PVDB FlangeAnonymous aBg51lbe18No ratings yet

- Insert Plate Design - LugsDocument8 pagesInsert Plate Design - Lugsnavneet3bawaNo ratings yet

- Gantry Girder DesignDocument6 pagesGantry Girder DesignpandianNo ratings yet

- Raw Water Tank-DataDocument1 pageRaw Water Tank-DataSivaArabiNo ratings yet

- Anchor BoltDocument7 pagesAnchor BoltChris OngNo ratings yet

- Design Lifting Hook Plate LiftingDocument3 pagesDesign Lifting Hook Plate LiftingSaravan KumarNo ratings yet

- 150 VV 1010 Davit CalculationDocument3 pages150 VV 1010 Davit Calculationdraj1875977No ratings yet

- SKID LIFTING LUG CALCULATIONSDocument5 pagesSKID LIFTING LUG CALCULATIONSinnovativekarthiNo ratings yet

- Analysis of Self-Supported Steel Chimney With The Effects of Geometrical ParametersDocument6 pagesAnalysis of Self-Supported Steel Chimney With The Effects of Geometrical Parametersvikram413No ratings yet

- NozzleDocument11 pagesNozzleharyfadlyNo ratings yet

- End Plate Moment ConnectionDocument4 pagesEnd Plate Moment Connectionteguh andriantoNo ratings yet

- LIFTING PADEYE STRESS ANALYSISDocument16 pagesLIFTING PADEYE STRESS ANALYSISCHENo ratings yet

- Calculation For Beam Connection AISC 14th Edition 2011: LRFD Method Material and Load PropertiesDocument7 pagesCalculation For Beam Connection AISC 14th Edition 2011: LRFD Method Material and Load PropertiesYunizar Putra MahardikaNo ratings yet

- Calculation of bearing plate dimensionsDocument3 pagesCalculation of bearing plate dimensionsk.m.ariful islamNo ratings yet

- Column Beam Seismic ConnectionDocument8 pagesColumn Beam Seismic ConnectionPrakash Singh RawalNo ratings yet

- Calculation of Beam/Column Splice: HB-300x300x10x15Document5 pagesCalculation of Beam/Column Splice: HB-300x300x10x15amachmouchiNo ratings yet

- Web Flange WeldDocument1 pageWeb Flange Weldakgupta733779No ratings yet

- Bolt capacity and bending checks as per BS EN-1993-1-8Document2 pagesBolt capacity and bending checks as per BS EN-1993-1-8waweng22No ratings yet

- Designing Foundations for Pumps and CompressorsDocument38 pagesDesigning Foundations for Pumps and CompressorsAmrut BhattNo ratings yet

- Double Angle CleatsDocument6 pagesDouble Angle CleatsKaushal KishoreNo ratings yet

- Lifting Lug Analysis (Asd) : ASME Notation AISC Preferred Geometry AISC Alternate GeometryDocument2 pagesLifting Lug Analysis (Asd) : ASME Notation AISC Preferred Geometry AISC Alternate GeometryJohn PacelloNo ratings yet

- Base Plate Connection DesignDocument4 pagesBase Plate Connection DesignAnonymous 1HFV185Sl4No ratings yet

- Cdo CalcDocument3 pagesCdo CalcJeric FarinNo ratings yet

- Calculation of Base Shear (Ubc-1997) Location: Rancakusumba SubstationDocument2 pagesCalculation of Base Shear (Ubc-1997) Location: Rancakusumba SubstationDS IchaqueNo ratings yet

- Calculation For SpliceDocument15 pagesCalculation For SpliceSandeep Singh0% (1)

- Bolt Head - Portland BoltDocument1 pageBolt Head - Portland BoltKrishna Varun DuvvuruNo ratings yet

- Hi Lite XL Transmission Insulators: SectionDocument36 pagesHi Lite XL Transmission Insulators: Sectionfarhan khanNo ratings yet

- Technical Manual 1Document118 pagesTechnical Manual 1Homero Silva100% (14)

- Technical Manual 1Document118 pagesTechnical Manual 1Homero Silva100% (14)

- Mechanical Properties of SCCDocument5 pagesMechanical Properties of SCCKrishna Varun DuvvuruNo ratings yet

- The Effect of Addition of Limestone Powder On The Properties of Self-Compacting ConcreteDocument8 pagesThe Effect of Addition of Limestone Powder On The Properties of Self-Compacting ConcreteKrishna Varun DuvvuruNo ratings yet

- Intelligent BuldingsDocument20 pagesIntelligent BuldingsKrishna Varun DuvvuruNo ratings yet

- Curing of HPC Using Light Weight AggregatesDocument15 pagesCuring of HPC Using Light Weight AggregatesKrishna Varun DuvvuruNo ratings yet

- Soil PollutionDocument20 pagesSoil PollutionKrishna Varun DuvvuruNo ratings yet