Professional Documents

Culture Documents

Lesson 10 - 13 PDF

Uploaded by

crysOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lesson 10 - 13 PDF

Uploaded by

crysCopyright:

Available Formats

Lesson 10 - Reliability of Welding Filler Metals

1 dari 1

Lesson 1

The Basics of Arc

Welding

http://www.esabna.com/euweb/AWTC/Lesson10_15.htm

LESSON X

10.9.3

Coating Moisture Test - The coating moisture test is conducted by removing a

small amount of the coating from the middle portions of three electrodes, all from the same

Lesson 2

Common Electric

Arc Welding

Processes

can or package. A small measured amount (4 grams) of this coating sample is tested in

sophisticated laboratory apparatus. The method of moisture testing satisfies AWS A5.5-96

and AWS D1.1 Specifications and is sensitive only to water. It is the most accurate and

reliable method of moisture determination currently in use.

Lesson 3

Covered Electrodes

for Welding

Mild Steels

Lesson 4

Covered Electrodes

for Welding Low

Alloy Steels

Current

Chapter

Table of

Contents

Go To Test

10.9.4

Guided Bend Tests -

10.9.4.1

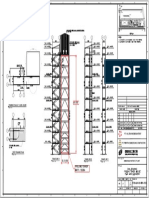

Transverse Face Bend, Root Bend and Side Bend Tests. The specifications for

some filler metals require that guided bend tests be made to evaluate the ductility and

soundness of a welded joint. The test plate is welded in the flat position and is made long

enough to produce the necessary number of specimens. See Figure 5.

10.9.4.1.1

Glossary

The specimens are cut from the test plate, and the backing strip and weld

reinforcement machined flush with the face and root surfaces. If the test plate is greater

Lesson 5

Welding Filler Metals

for Stainless Steels

than 3/8" thick, it must be machined to 3/8" thickness, removing the metal from the root

surface for face bends, and from the face surface for root bends. In face bends, the face

of the weld is on the outside or convex surface of the specimen, and in root bends, the root

of the weld is on the outside or convex surface of the bend. The specimen is bent in a

Lesson 6

Carbon & Low Alloy

Steel Filler Metals GMAW,GTAW,SAW

guided bend test jig, the design of which is described in the specification, over a justified

radius (usually a 3/4" radius) through an angle of 180. When removed from the jig, the

Search

Chapter

(Faster

Download)

Lesson 7

Flux Cored Arc

Electrodes Carbon

Low Alloy Steels

FACE OR ROOT BEND TEST

Search

Document

(Slower

Download)

SIDE BEND TEST PLATE

Lesson 8

Hardsurfacing

Electrodes

Lesson 9

Estimating &

Comparing Weld

Metal Costs

Turn Pages

FACE BEND

ROOT BEND

SIDE BEND

TRANSVERSE GUIDED BEND TESTS

Lesson 10

Reliability of Welding

Filler Metals

FIGURE 5

COPYRIGHT 2000 THE ESAB GROUP, INC.

09/12/2013 14:41

You might also like

- Farm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape MetalFrom EverandFarm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape MetalRating: 4.5 out of 5 stars4.5/5 (3)

- Learn More About Charpy Impact TestingDocument25 pagesLearn More About Charpy Impact TestingGodwin A.udo-akanNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Pipelines Welding HandbookDocument64 pagesPipelines Welding HandbookSixto GerardoNo ratings yet

- 1.07 TIG Welding Part-2Document79 pages1.07 TIG Welding Part-2rohit mathanker100% (1)

- Welding NotesDocument39 pagesWelding NotesSabir JadejaNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- ESAB - PipelinesDocument65 pagesESAB - PipelinesLigia114100% (2)

- Pneumatic TestDocument10 pagesPneumatic TestcrysNo ratings yet

- Sae J419-1983 Methods of Measuring Decarburization PDFDocument8 pagesSae J419-1983 Methods of Measuring Decarburization PDFTanveer Singh GumtalaNo ratings yet

- Welders Training Program ManualDocument140 pagesWelders Training Program ManualAlmario Sagun100% (1)

- GRADE 12 SMAW MODULE 4A 1st QuarterDocument20 pagesGRADE 12 SMAW MODULE 4A 1st QuarterClare GarcesNo ratings yet

- Design of Steel Structures: Materials, Connections, and ComponentsFrom EverandDesign of Steel Structures: Materials, Connections, and ComponentsNo ratings yet

- Basic Welding GuideDocument71 pagesBasic Welding GuideIsac Newton100% (1)

- Welding Lecture and OrientationDocument57 pagesWelding Lecture and OrientationHenry SyNo ratings yet

- Assembling Flanged Joints Procedure1 PDFDocument34 pagesAssembling Flanged Joints Procedure1 PDFcrysNo ratings yet

- ITP Installation of Boiler - R1Document14 pagesITP Installation of Boiler - R1crys100% (4)

- Single 'V' Butt Joint Carbon Steel: Pt. Alphacon ValfindoDocument20 pagesSingle 'V' Butt Joint Carbon Steel: Pt. Alphacon Valfindocrys0% (1)

- Welding Questions and AnswersDocument6 pagesWelding Questions and Answersengrzia76No ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Lesson X 10.9.3 Coating Moisture Test - The Coating Moisture Test Is Conducted by Removing ADocument1 pageLesson X 10.9.3 Coating Moisture Test - The Coating Moisture Test Is Conducted by Removing AcrysNo ratings yet

- 10.9.4guided Bend Tests - 10.9.4.1transverse Face Bend, Root Bend and Side Bend Tests. The Specifications ForsomeDocument1 page10.9.4guided Bend Tests - 10.9.4.1transverse Face Bend, Root Bend and Side Bend Tests. The Specifications ForsomeHandri YantoNo ratings yet

- Course Name: NAME 301 Shipbuilding Technology-I: Md. Omar FarukDocument56 pagesCourse Name: NAME 301 Shipbuilding Technology-I: Md. Omar FarukMd. Omar FarukNo ratings yet

- Bend TestDocument2 pagesBend TestFsNo ratings yet

- Section 5. Welding and BrazingDocument27 pagesSection 5. Welding and BrazingrobinyNo ratings yet

- Bend Test SummaryDocument4 pagesBend Test SummaryManish MNo ratings yet

- A Demonstration of Heat Affected Zone From WeldingDocument9 pagesA Demonstration of Heat Affected Zone From WeldingMduduzi Magiva MahlanguNo ratings yet

- Mechanical Testing: Notched Bar or Impact Testing. Part IIDocument4 pagesMechanical Testing: Notched Bar or Impact Testing. Part IIMehmet Soysal100% (1)

- Friction Stir Welding Thesis PDFDocument8 pagesFriction Stir Welding Thesis PDFcarolinalewiswashington100% (2)

- Bend Testing: Job Knowledge 73Document3 pagesBend Testing: Job Knowledge 73kevin herryNo ratings yet

- The Use of Serrated Metallic Gaskets On Air CoolersDocument12 pagesThe Use of Serrated Metallic Gaskets On Air Coolerssammar_10No ratings yet

- AAR TC 128 GR B Weld Failure Analysis - EdittedDocument3 pagesAAR TC 128 GR B Weld Failure Analysis - Edittedamir ghabraeiNo ratings yet

- Lesson X 10.9.1 Chemical Composition Analysis Test - A Weld Pad For Determining The ChemiDocument1 pageLesson X 10.9.1 Chemical Composition Analysis Test - A Weld Pad For Determining The ChemicrysNo ratings yet

- Question 1Document27 pagesQuestion 1Rammer PakpahanNo ratings yet

- Welding Procedure & Welder Qualification: Pak-Arab Refinery LimitedDocument70 pagesWelding Procedure & Welder Qualification: Pak-Arab Refinery LimitedRizwan BangashNo ratings yet

- Weld-FAQ-A (Page A) : and The Correct AnswersDocument22 pagesWeld-FAQ-A (Page A) : and The Correct AnswerssanthakumarNo ratings yet

- Flexural Behaviour of Trapezoidal Corrugation Beam by Varying Aspect RatioDocument5 pagesFlexural Behaviour of Trapezoidal Corrugation Beam by Varying Aspect RatioijsretNo ratings yet

- Shielded Metal Arc Welding: Mild Steel III (E6011)Document33 pagesShielded Metal Arc Welding: Mild Steel III (E6011)greatsteelNo ratings yet

- Experiment No. 8 DoneDocument25 pagesExperiment No. 8 DoneshahNo ratings yet

- Experimental Investigation of Resistance Spot Welding of Duplex Stainless SteelDocument5 pagesExperimental Investigation of Resistance Spot Welding of Duplex Stainless SteelM.SoundarrajanNo ratings yet

- Welding Procedure & Welder QualificationDocument71 pagesWelding Procedure & Welder QualificationRizwan BangashNo ratings yet

- Eddy Current MeasurementsDocument4 pagesEddy Current MeasurementsBassam AbdelazeemNo ratings yet

- Mechanical Testing - Notched Bar or Impact TestingDocument7 pagesMechanical Testing - Notched Bar or Impact TestingFsNo ratings yet

- Algunas Preguntas de AWS D1Document8 pagesAlgunas Preguntas de AWS D1cordobaluisfNo ratings yet

- Welding Facts (Summary of Welding Notes) : EML2322L - Design & Manufacturing LaboratoryDocument2 pagesWelding Facts (Summary of Welding Notes) : EML2322L - Design & Manufacturing LaboratoryDiego AlonsoNo ratings yet

- WLD 290 Submerged Arc WeldingDocument52 pagesWLD 290 Submerged Arc WeldingDanem HalasNo ratings yet

- RESULT WeldingDocument4 pagesRESULT WeldingAiman ShahNo ratings yet

- Lecture 2 - Test For SteelDocument55 pagesLecture 2 - Test For SteelKier Lorenz FernandezNo ratings yet

- Design and Analysis of Connecting Rod For Reduction of Weight and Cost ReportDocument52 pagesDesign and Analysis of Connecting Rod For Reduction of Weight and Cost Reporthemtheboss100% (1)

- 2nd ProjectDocument72 pages2nd ProjectrohanNo ratings yet

- Mig Welding Literature ReviewDocument8 pagesMig Welding Literature Reviewklbndecnd100% (1)

- ESW - Strip Cladding + LBW Long.Document8 pagesESW - Strip Cladding + LBW Long.Ricardo MouraNo ratings yet

- Twi Impact TestingDocument17 pagesTwi Impact TestingchungndtNo ratings yet

- Laboratory Experiment 1.3Document6 pagesLaboratory Experiment 1.3Wes FerrerNo ratings yet

- Aluminium Alloy Specimens With High Edge RetentionDocument4 pagesAluminium Alloy Specimens With High Edge RetentionfotickNo ratings yet

- KEM.545.182Document7 pagesKEM.545.182katfyNo ratings yet

- 19 Ijmperdapr201719Document10 pages19 Ijmperdapr201719TJPRC PublicationsNo ratings yet

- 2062: Hot Rolled Medium and High Tensile Structural Steel - SpecificationsDocument9 pages2062: Hot Rolled Medium and High Tensile Structural Steel - SpecificationsKapa SandeepNo ratings yet

- Outokumpu Corrosion Management News Acom 1and2 Edition 2002Document24 pagesOutokumpu Corrosion Management News Acom 1and2 Edition 2002turboconchNo ratings yet

- Pt. Intan Anugrah PersadaDocument1 pagePt. Intan Anugrah PersadacrysNo ratings yet

- Pt. Intan Anugrah PersadaDocument1 pagePt. Intan Anugrah PersadacrysNo ratings yet

- Cipta Sukses, PT.: Pt. Intan Anugrah PersadaDocument1 pageCipta Sukses, PT.: Pt. Intan Anugrah PersadacrysNo ratings yet

- Pt. Intan Anugrah PersadaDocument1 pagePt. Intan Anugrah PersadacrysNo ratings yet

- Sdb-Atap Tower A Db-Fire Atap Tower A Pp-Lift.2A Pp-Lift.1A: Pt. Intan Anugrah PersadaDocument1 pageSdb-Atap Tower A Db-Fire Atap Tower A Pp-Lift.2A Pp-Lift.1A: Pt. Intan Anugrah PersadacrysNo ratings yet

- Pt. Intan Anugrah Persada: Void VoidDocument1 pagePt. Intan Anugrah Persada: Void VoidcrysNo ratings yet

- Pt. Intan Anugrah PersadaDocument1 pagePt. Intan Anugrah PersadacrysNo ratings yet

- 328 PDFDocument1 page328 PDFcrysNo ratings yet

- Cipta Sukses, PT.: Pt. Intan Anugrah PersadaDocument1 pageCipta Sukses, PT.: Pt. Intan Anugrah PersadacrysNo ratings yet

- Vac 105 PDFDocument1 pageVac 105 PDFcrysNo ratings yet

- Vac 113 PDFDocument1 pageVac 113 PDFcrysNo ratings yet

- Vac 112 PDFDocument1 pageVac 112 PDFcrysNo ratings yet

- Vac 110 PDFDocument1 pageVac 110 PDFcrysNo ratings yet

- RFCC-T-PJ-GS-0900 Project Quality Plan (B) PDFDocument23 pagesRFCC-T-PJ-GS-0900 Project Quality Plan (B) PDFcrysNo ratings yet

- Indonesia LNGDocument22 pagesIndonesia LNGcrys100% (1)

- Equipment PhotoDocument6 pagesEquipment PhotocrysNo ratings yet

- Instalation Genset CSTS 36 Unit 23-1-2019Document1 pageInstalation Genset CSTS 36 Unit 23-1-2019crysNo ratings yet

- PASCAL Check Valves CatalogueDocument19 pagesPASCAL Check Valves Cataloguecrys100% (1)

- Piping Color CodesDocument12 pagesPiping Color CodescrysNo ratings yet

- List Equipment JC Periode 2018Document1 pageList Equipment JC Periode 2018crysNo ratings yet

- Master Document Register ListDocument10 pagesMaster Document Register ListcrysNo ratings yet

- Supplier Deliverable Register (SDR) : - Document TitleDocument11 pagesSupplier Deliverable Register (SDR) : - Document TitlecrysNo ratings yet

- Prilling TowerDocument1 pagePrilling TowercrysNo ratings yet

- Overall Heat Transfer CoefficientDocument22 pagesOverall Heat Transfer CoefficientcrysNo ratings yet