Professional Documents

Culture Documents

Regen Seives Economically PDF

Uploaded by

killemall19882859Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Regen Seives Economically PDF

Uploaded by

killemall19882859Copyright:

Available Formats

ESL-IE-84-04-145

PROPER DESIGN SAVES ENERGY FOR

MOLECULAR SIEVE DEHYDRATION SYSTEMS

John Barrow

Ray Veldman

Coastal Chemical Company

The molecular sieve system is a signif

icant energy user in the cryogenic gas

plant. Designing and operating the

system properly can save thousands of

dollars in fuel each year. A poorly

designed energy saving system can

result in poor plant operation, freeze

ups, and lost plant production.

HEAT

PRODUCT

e>-<l

FIGURE 1

TURbO EXPANDER PLA1~T

The molecular sieve system is a batch

process. One tower dehydrates while

the other tower is being regenerated by

heating. Energy can be conserved in

several ways.

REGENERA TION CONFIGURATIONS

Res idu e

Molecular sieve is the desiccant usu

ally chosen to remove water vapor ahead

of the natural gas processing cryogenic

plant. The molecular sieves are needed

to dry the gas to less than 0.1 ppmv.

Concentrations of water higher than 0.1

ppmv can cause ice to form and plug

lines in the cryogenic plant. These

plants typically operate from -100 to

-lBOF.

.,:Lo

...-::-;c"-----,--,,,O-'-.rL-'..-'-'O-=-"-''-'-------..,

PI,lnl

FIGURE 2

liASE CASE FOR OPTIHUAnON STUDY

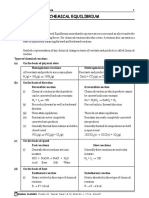

TABLE I

The molecular sieve .system is a signif

icant energy user in the plant. One

bed is adsorbing while the other bed is

heated then cooled. At the end of the

cycle the beds are switched. The bed

which was adsorbing is switched into

heating to remove the water or regen

erate the bed. To effectively remove

the water from the sieve requires

heating the bed higher than 450F (nor

mally 550F) with a slip stream of gas

taken from somewhere in the plant. A

slip stream of dry effluent from the

bed in adsorption is one source of re

generation gas, while residue gas is

another choice. In either case the

INLET CONDITIONS

FLOw

TEMPERATURE . ..........

PRESSURE .... _ ...... _. _ .

"'ATER CONTENT

50 HHSCPD

100'P

615 psla

90 Ib "zO/mmsc f

DEHYOKATOR VESSE1.S

HUMBER

of

8E1>S ............

DIAMETER (I. D. ) ......

8EO HEIGHT

.

5.S. HEIGHT

_._ ...

PRESSURE DROP ...........

CYCLES

------':DSOR8 ..............

HEAr . ..................

COOL. .

2

5.5 ft

12.0 ft.

14. a ft

3,0 psi

8 hr.

5 hr.

3 hr.

REGENERATION CAS

FLOW

PRESSURE .... _... _

_.

HOT GAS INLET ............

MAX IHUH OUTLET . ...........

HOLECUl.AR SI EVE

TyPE

SiZE

.

_

WE IGHT I DEHYDRATOR

.

.

itA molecular sieve

1/8"

13,ISO lbs

833

Proceedings from the Sixth Annual Industrial Energy Technology Conference Volume II, Houston, TX, April 15-18, 1984

ESL-IE-84-04-145

l~st

comp nies design for 8 hour

cycles. When waste heat is not use. 8

hours may not be the best time chos n.

Fig 3 shows he correct cycle time

(proportion 1 to pounds required) a a

function f operating co t and capi al

inv stment. Larger beds require m ie

sieve and a higher cap' tal investment,

but save energy through fewer regenJ

erations.

simple quick look t tile

probl m, show' that the slight inCrjaSe

in capit 1 inv stment (Larger beds) is

a good en rgy s ving ide and that

e

optimum is 10-12 hour cycles. The n

gineering hous and project engine

should spend the time to decide on he

most en rgy efficient system to bui d.

slipstream is heated, then used to heat

the sieve bed.

From the bed, the gas

is cooled and water is condensed at the

regeneration gas scrubber.

From the

regeneration as scrubber the gas is

returned to the molecular sieve inlet

(for dry effluent regeneration) or to

Lhe sales gas line (for residue regen

eration) .

(Figs. 1 & 2)

Regeneration requires about 7,200 BTU's

p r pound of water removed. This ex

pense can be eliminated or greatly re

duced in several different ways. Re

ducing the amount of water removed via

molecular sieve, utilizing waste heat

recovery, and operating the system in

an energy efficient manner are, all

way that less energy can be used to

operate a mole ular sieve system.

A glycol unit is an economical way 0

dehydrate natural gas but will only

dehydrate to a lev 1 of 1 to 7 poun s

of water per mmscf. A glycol unit ses

less energy because the he t of ab

sorption of water into glycol is no as

high as the heat of absorption of ,ter

onto molecular sieve. Putting a glycol

unit an a molecular siev system i

series will allow removal of wat r

0

less than 0.1 ppmv and use less ene gy.

The economics, how ver, are disap

pointing (Table II) as th extra

capital investment takes 5-7 year

0

payout. H wever, a retr fit of a I

cryogenic pL 1 t to an exist'ng older

plant which already has a glycol un t

may utilize the old glycol unit eco

nomically.

The compressors whichrepressure the

gas after the cryogenic plant are usu

ally driven by gas turbines or gas

engines. Heat from the xhaust can be

r cov red a d used to heat the regen

eration gas stream. There are many gas

to gas exchangers which can be used in

this service. Utilizing compressor

waste heat essentially eliminates the

energy xpense. However, it can also

present th op rator with some dif

ficult problems.

Some plant operators

have been reluctant to build a gas to

as exchanger because a leak would

certainly m an a fire when the high

pressur regener tion gas would be

m'xed with an exhaust gas containing

oxy en. One solution to this p~ublem

is 0 heat a salt bath with compres

sor exh ust then heat the regeneration

gas with the salt.

Internall insulating the molecular

sieve b ds will s ve 20- 0% of the

required energy. The economics sho a

f th

2 to 3 year pay b ck peria.

refractory lining is correctly in

stalled this idea will w rk we l . f

the insulation is installed incor

rectly, wet gas will channel down t e

walls and f eeze ups will be a consfant

problem.

The reg neration system which u es r

sidue gas regener tion can be driv I by

dropping the entire residue gas str am

pressure across a control valve

and forcing a slip stream of gas

thraug the rege eration loop.

New r

plants are using a small com ressor to

pump the lips ream and save horesp?wer

in the re ompressors.

This idea may be

suitable for retrofit to existing

plants.

Waste heat recovery has resulted in

operating probl ms for some plants when

they run at redu ed rates.

If the

waste heat units were designed so that

all compressor exhausts were needed to

maintain both the volume and the tem

perature of the required regeneration

s ream, and one compressor is down due

to low throughput, the operator has the

rollowing choices. He can accept a

ege ration stream flowing at the cor

r ct rate and

lower temperature, or

he can c oose

rate lower than design

at the carre t tempera ure. Since most

sie e syst ms are designed at minimum

t mperature and minimum regeneration

gas rate, either choice results in poor

r gen rati ns and freeze-ups.

An aux

illary burner in the gas to gas ex

changer could solve this problem.

Another energy savings idea is he

addition of a third be

This woul

allow the regener tion gas to be pre

heated as the bed DaIs, saVing n rgy.

A brief review f the e onomi~s shows

hat the energy sa ed pays for the in

vestment i. 5 to 7 year.

We tested the economics for the fol

lowing ideas using a 50 rnmscfd system

described by Table I.

834

Proceedings from the Sixth Annual Industrial Energy Technology Conference Volume II, Houston, TX, April 15-18, 1984

ESL-IE-84-04-145

The single largest waste of energy

results froQ operating with cycles

times which are too short. We fre

quently find plants which are operating

on 8 hour cycles (which is design) but

now process significantly less gas, or

gas which has been dehydrated in the

field.

The only way to operate at the

maximum possible cycle time is to run

frequent breakthrough tests.

These

tests are simply made, the operators

put the bed switching mechanism on

manual and switch the bed when the

plant I:1oisture monitor shows an in

crease in the water content of the gas

leaving the bed.

Installing a new

probe before the test assures that

breakthrough will be easily observed

and that the plant will not freeze up.

Sellers of molecular sieves sometimes

do these tests for free.

If a break

through test shows that 24 hours on

adsorption is possible and you oper

ate on only 8 hour cycles, the excess

energy bill can be very high.

UTILIZE WASTE HEAT

TABLE I I

USES COfIPRESSOR EXHAUST AS

A HEAT SOURCE

REQUIRES THE INSTALLATION OF

AN AUXILLARY BURNER

WITHOUT

PROBLEMS OCCUR WITH

TURNDOWN (MULTIPLE

RECOMPRESSORS)

REGENERATION GAS VELOCITY

OR TEMPERATURE NUST DROP

WITH THE SHUT DOWN

OF 1 ENGINE

This paper has presented a brief over

view on how to save energy in a cryo

genic plant.

If your next cryogenic

plant cannot use waste heat for the

regeneration gas, the ideas presented

should be evaluated.

If waste heat is

used, be sure that the design is

flexible enough to allow good oper

ations at processing rates well below

design.

OPTUIUl'1 CYCLE TUIE

GRAPHICAL SOL~TION

Il

1Z

10

PRESENT

VALUE ~ '"

INCREMENTAL

o

o

CAPITAL

COST b 0

\0

\2.

I~

\(,

2.0

FIGURE J

CYCLE TIME PRUPORTIONAL

TO SIEVE QUANTITY

835

Proceedings from the Sixth Annual Industrial Energy Technology Conference Volume II, Houston, TX, April 15-18, 1984

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- New NoteDocument1 pageNew Notekillemall19882859No ratings yet

- Ancient Egyptians, Grand Canyon - Ancient Egyptians in America, DiscoveriesDocument11 pagesAncient Egyptians, Grand Canyon - Ancient Egyptians in America, Discoverieskillemall19882859100% (5)

- Mark Twain QuotesDocument1 pageMark Twain QuotesBen ChongNo ratings yet

- Rotary Conflict of Interest PolicyDocument3 pagesRotary Conflict of Interest Policykillemall19882859No ratings yet

- The Starrett Combo SquareDocument2 pagesThe Starrett Combo Squarekillemall19882859No ratings yet

- Chem Profile of Sugarcane SpiritsDocument6 pagesChem Profile of Sugarcane Spiritskillemall19882859No ratings yet

- EthyleneDocument145 pagesEthyleneAnimesh TiwariNo ratings yet

- Turmeric-Postharvest FAO PDFDocument21 pagesTurmeric-Postharvest FAO PDFAila YumekoNo ratings yet

- Permit To Work FormDocument12 pagesPermit To Work Formkillemall19882859No ratings yet

- The Alcohol-Textbook PDFDocument449 pagesThe Alcohol-Textbook PDFkillemall19882859100% (3)

- Ancient Egyptians in America, DiscoveriesDocument2 pagesAncient Egyptians in America, Discoverieskillemall19882859No ratings yet

- 2013 Fiji ConstitutionDocument98 pages2013 Fiji ConstitutionThe BFDNo ratings yet

- Best Marinara Sauce Yet Recipe - AllrecipesDocument1 pageBest Marinara Sauce Yet Recipe - Allrecipeskillemall19882859No ratings yet

- The Unofficial Glock Armorer's ManualDocument31 pagesThe Unofficial Glock Armorer's Manualkillemall19882859100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Entropy, Free Gibbs Energy: Use The Table Below To Answer The Questions That FollowDocument6 pagesEntropy, Free Gibbs Energy: Use The Table Below To Answer The Questions That FollowHUY NGUYỄN PHƯƠNG PHÚCNo ratings yet

- CH03 & CH04 Technical DataDocument32 pagesCH03 & CH04 Technical DataKSNo ratings yet

- Hkum Termo 1 Sistem Terbuka PDFDocument75 pagesHkum Termo 1 Sistem Terbuka PDFrizky andrianNo ratings yet

- (Total 1 Mark) : IB Questionbank Physics 1Document5 pages(Total 1 Mark) : IB Questionbank Physics 1Irwansyah RamadhaniNo ratings yet

- Aquaplus Cha-K 182-P÷604-P CLB 61.7Document36 pagesAquaplus Cha-K 182-P÷604-P CLB 61.7Valentin MalihinNo ratings yet

- Chemical EquilibriumDocument68 pagesChemical Equilibriumhappy100% (1)

- Evaporative Cooling Equations 1589983721 PDFDocument10 pagesEvaporative Cooling Equations 1589983721 PDFAbdulhamit KAYYALINo ratings yet

- Carta Psicrometrica PDFDocument1 pageCarta Psicrometrica PDFFederico Ferreira LopezNo ratings yet

- RAC Tutorial Sheet 4Document3 pagesRAC Tutorial Sheet 4Ankur SachdevaNo ratings yet

- Problem SetDocument65 pagesProblem Setu1468813mvrhtnetNo ratings yet

- TTCI Heat TransferDocument14 pagesTTCI Heat TransferRerrysta YolandaNo ratings yet

- Chapter 7Document5 pagesChapter 7Earl averzosaNo ratings yet

- E 01 Mean Activity FinalDocument9 pagesE 01 Mean Activity FinalReine GNo ratings yet

- HVAC TH Week 3-4Document32 pagesHVAC TH Week 3-4M WaleedNo ratings yet

- Data GRS PLTP Gunung Salak #3 PDFDocument28 pagesData GRS PLTP Gunung Salak #3 PDFfirmantuakiaNo ratings yet

- Refrigeration Systems Are Common in The Natural Gas Processing Industry and Processes Related To The Petroleum RefiningDocument15 pagesRefrigeration Systems Are Common in The Natural Gas Processing Industry and Processes Related To The Petroleum RefiningMahmoud ElarabyNo ratings yet

- DR SureshDocument22 pagesDR SureshSubramaniyan MadhavakrishnanNo ratings yet

- AA283 Aircraft and Rocket Propulsion Table of Contents BJ CantwellDocument5 pagesAA283 Aircraft and Rocket Propulsion Table of Contents BJ CantwellSsheshan PugazhendhiNo ratings yet

- Theoritical Calculation For EDTA LDO ConsumptionDocument6 pagesTheoritical Calculation For EDTA LDO ConsumptionRupesh SinhaNo ratings yet

- Heat Transfer Chapter One and TwoDocument74 pagesHeat Transfer Chapter One and TwoTariku Negash100% (2)

- Time Am Four Reg Fours emDocument3 pagesTime Am Four Reg Fours emArun KumarNo ratings yet

- Thermodynamic of InterfacesDocument33 pagesThermodynamic of InterfacesTeka KamNo ratings yet

- Planck Discovers The Quantum of Action file:///home/igor/Public/webstrodjel/dokumenti/Plan..Document3 pagesPlanck Discovers The Quantum of Action file:///home/igor/Public/webstrodjel/dokumenti/Plan..Victor VizcarraNo ratings yet

- Enthalpy of An Ideal Gas Is A Function Only of A. Entropy B. Internal Energy C. Temperature D. PressureDocument150 pagesEnthalpy of An Ideal Gas Is A Function Only of A. Entropy B. Internal Energy C. Temperature D. PressureTed Mana-ayNo ratings yet

- Use of Table Salt As An Additive To The Alternative Air CoolerDocument44 pagesUse of Table Salt As An Additive To The Alternative Air CoolerYvonne Bridget AriojaNo ratings yet

- Calculation and Analysis of Dissipation Heat Loss in Large-Scale Circulating Fluidized Bed BoilersDocument6 pagesCalculation and Analysis of Dissipation Heat Loss in Large-Scale Circulating Fluidized Bed BoilersYuliyan StoyanovNo ratings yet

- KdasdklaDocument3 pagesKdasdklaJuan Jose Martinez PadillaNo ratings yet

- Thermoelectric PropertiesDocument4 pagesThermoelectric PropertiesM ZarakNo ratings yet

- Effective Thermal Conductivity Porous MediaDocument6 pagesEffective Thermal Conductivity Porous Media曾帅No ratings yet

- Specific Heat Capacity and Latent Heat: AS Level Physics Notes OnDocument44 pagesSpecific Heat Capacity and Latent Heat: AS Level Physics Notes OnChrise RajNo ratings yet