Professional Documents

Culture Documents

Mitsubishi 4N13, 4N14 Engines PDF

Mitsubishi 4N13, 4N14 Engines PDF

Uploaded by

Ra AranzasoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mitsubishi 4N13, 4N14 Engines PDF

Mitsubishi 4N13, 4N14 Engines PDF

Uploaded by

Ra AranzasoCopyright:

Available Formats

MITSUBISHI 4N13, 4N14 ENGINES

COMMON RAIL SYSTEM (CRS)

Issued : November 2010

Applicable Vehicle :

Vehicle Manufacturer

Vehicle Name

LANCER

MITSUBISHI

ASX

OUTLANDER

50000023E

2010 DENSO CORPORATION

All rights reserved. This material may not be reproduced

or copied, in whole or in part, without the written

permission of DENSO Corporation.

Table of Contents

Operation Section

1. PRODUCT APPLICATION INFORMATION

1.1

Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2

Applicable Vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3

System Component Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. SUPPLY PUMP

2.1

Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2.2

Suction Control Valve (SCV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2.3

Fuel Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3. RAIL

3.1

Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3.2

Rail Pressure Sensor (Pc Sensor). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3.3

Pressure Limiter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4. INJECTOR

4.1

Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

5. OPERATION OF CONTROL SYSTEM COMPONENTS

5.1

Engine Control System Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

5.2

Engine Electronic Control Unit (ECU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

5.3

Sensor Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

6. FUEL INJECTION CONTROL

6.1

Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

6.2

Fuel Injection Quantity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

6.3

Other Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

7. OTHER SYSTEMS

7.1

Diesel Particulate Filter (DPF) System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

7.2

Fuel Filter with Filter Clog Switch, In-Tank Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

8. DIAGNOSTIC TROUBLE CODES (DTC)

8.1

Codes Shown in the Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

8.2

DTC Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

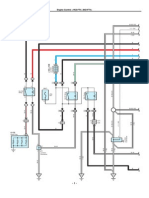

9. CONTROL SYSTEM COMPONENTS

9.1

Engine ECU External Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

9.2

ECU Connector Terminal Layouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Operation Section

1 1

1. PRODUCT APPLICATION INFORMATION

1.1 Outline

This section describes the Common Rail System (CRS) newly introduced for the 4N13 engine equipped in

the MITSUBISHI ASX and LANCER (from March 2010), as well as the CRS newly introduced for the 4N14

engine equipped in the MITSUBISHI OUTLANDER (from July 2010). The 4N13 and 4N14 engines conform

to the European emission standards stipulated in the "EURO 5" regulations.

For CRS basics, refer to "COMMON RAIL SYSTEM SERVICE MANUAL - OPERATION (Doc ID:

00400534EA)."

Features

Maximum injection pressure increased to 200 MPa.

Equipped with G3 type injectors.

Equipped with fuel filter with filter clog switch (made by DENSO), and an in-tank pump (made by another

company.)

1.2 Applicable Vehicles

Vehicle Manufacturer

Vehicle Name

Engine Model

LANCER

4N13

ASX

MITSUBISHI

Destination

OUTLANDER

Europe

Line Off Period

March 2010

4N14

July 2010

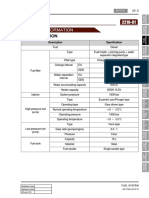

1.3 System Component Part Numbers

4N13 Engine (LANCER, ASX)

DENSO

Manufacturer

Part Name

Part Name

Supply Pump

294000-099#

1460A043

Injector

295050-012#

1465A323

Rail

095440-142#

1465A304

275700-080#

1860B624

275700-081#

1860A625

275700-082#

1860A626

275800-972#

1860B179

079800-929#

1865A156

Mass Air Flow (MAF) Meter

197400-5200

1525A021

Diesel Throttle

197920-008#

1450A139

Part Name

Engine ECU

Manifold Absolute Pressure

(MAP) Sensor

Remarks

For the LANCER

For the ASX

For the ASX

Operation Section

1 2

DENSO

Manufacturer

Part Name

Part Name

265600-233#

1587A038

265600-234#

1587A039

265600-235#

1587A040

104990-170#

1865A184

139700-106#

8657A091

Fuel Filter with Filter Clog Switch

186320-003#

1770A179

Air Cleaner

014140-241#

1500A271

Inter-Cooler

127100-371#

1530A093

DENSO

Manufacturer

Part Name

Part Name

Supply Pump

294000-099#

1460A043

Injector

295050-034#

1465A353

Rail

095440-142#

1465A304

Engine ECU

275800-972#

1860B179

079800-929#

1865A156

Mass Air Flow (MAF) Meter

197400-5200

1525A021

Diesel Throttle

197920-008#

1450A139

Differential Pressure Sensor

104990-170#

1865A184

139700-106#

8657A091

Fuel Filter with Filter Clog Switch

186320-003#

1770A179

Air Cleaner

014140-241#

1500A271

Part Name

Exhaust Gas Temperature

Sensor

Differential Pressure Sensor

Electric-Vacuum Regulating

Valve (E-VRV)

Remarks

For the LANCER

For the LANCER

4N14 Engine (OUTLANDER)

Part Name

Manifold Absolute Pressure

(MAP) Sensor

Electric-Vacuum Regulating

Valve (E-VRV)

Remarks

Operation Section

1 3

2. SUPPLY PUMP

2.1 Outline

The supply pump equipped with the 4N13 and 4N14 engines is compliant with pressures up to 200 MPa.

The supply pump uses an SV3 type Suction Control Valve (SCV.)

1 4

Operation Section

2.2 Suction Control Valve (SCV)

When the solenoid in the SCV is not energized, the return spring pushes against the needle valve,

completely opening the fuel passage and supplying fuel to the plungers. (Total quantity suctioned

Total

quantity discharged)

When the solenoid in the SCV is energized, the armature pushes the needle valve, compressing the return

spring and closing the fuel passage.

The solenoid is actuated ON and OFF by duty ratio control. Fuel is supplied in an amount corresponding to

the open surface area of the passage in response to the duty ratio. The fuel is then discharged by the

plungers.

(1) Duty ratio control

The engine ECU outputs sawtooth wave signals with a constant frequency. The current value is the

effective (average) value of these signals. As the effective value increases, the valve opening decreases.

Conversely, as the effective value decreases, the valve opening increases.

Operation Section

1 5

(2) When the SCV energization duration (duty ON time) is short

When the SCV energization time is short, the average current flowing through the solenoid is small. As a

result, the needle valve is returned by spring force, creating a large valve opening. Subsequently, the fuel

suction quantity increases.

(3) When the SCV energization duration (duty ON time) is long

When the energization time is long, the average current flowing to the solenoid is large. As a result, the

needle valve is pressed out (in the compact SCV, the needle valve is pulled), creating a small valve

opening. Subsequently, the fuel suction quantity decreases.

1 6

Operation Section

2.3 Fuel Temperature Sensor

The fuel temperature sensor detects the fuel temperature, and sends a corresponding signal to the engine

ECU. Based on this information, the engine ECU calculates the injection volume correction that is

appropriate for the fuel temperature.

Operation Section

1 7

3. RAIL

3.1 Outline

The rail used in the CRS equipped with the 4N13 and 4N14 engines has a system pressure of 200 MPa.

As such, a rail pressure sensor and pressure limiter are used that comply with the system pressure.

3.2 Rail Pressure Sensor (Pc Sensor)

The rail pressure sensor (Pc sensor) detects the fuel pressure of the rail, and sends a signal to the engine

ECU. The sensor is made from a semiconductor that uses the Piezo resistive effect to detect changes in

electrical resistance based on the pressure applied to the elemental silicon. In comparison to the old model,

this sensor is compatible with high pressure.

1 8

Operation Section

3.3 Pressure Limiter

The pressure limiter releases pressure when the internal rail pressure becomes abnormally high. The

pressure limiter opens when internal pressure reaches 241 MPa (2458 kg/cm2), and closes when rail

pressure reaches a given set value. Fuel released from the pressure limiter is returned to the fuel tank.

Operation Section

1 9

4. INJECTOR

4.1 Outline

G3 injectors are used in the CRS equipped with the 4N13 and 4N14 engines. G3 injectors comply with a

system pressure of 200 MPa, and were designed to show improved responsiveness, as well as to increase

resistance against foreign material adherence to the nozzle.

1 10

Operation Section

(1) Correction points using QR codes

295050-012#

295050-034#

Operation Section

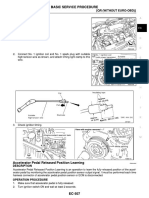

5. OPERATION OF CONTROL SYSTEM COMPONENTS

5.1 Engine Control System Diagram

1 11

1 12

Operation Section

5.2 Engine Electronic Control Unit (ECU)

The engine ECU is the command center that controls the fuel injection system and overall engine operation.

Operation Section

1 13

5.3 Sensor Operation

(1) Mass Air Flow (MAF) meter

The MAF meter used in the CRS equipped with the 4N13 and 4N14 engines is a plug-in type, and is

constructed so that a portion of the intake air flows through detector of the meter. Directly measuring the

quantity and flow volume of the intake air improves detection accuracy, and decreases intake air

resistance.

The MAF meter is built into the intake air temperature sensor.

(2) Manifold Absolute Pressure (MAP) sensor

The MAP sensor is a semiconductor pressure sensor that utilizes changes in electrical resistance that

occur when the pressure applied to a silicon crystal changes. The MAP sensor uses a VSV to alternate

between atmospheric pressure and manifold absolute pressure so that a single sensor can perform both

pressure measurements.

1 14

Operation Section

(3) Diesel throttle

Outline

The diesel throttle is interlocked with the key switch to reduce vibration when the engine is stopped by

blocking the intake of air.

Operation

Operation Section

1 15

6. FUEL INJECTION CONTROL

6.1 Outline

The following explains the types of fuel injection control used in MITSUBISHI vehicle systems. For details

on each type of control, refer to "General Edition Manual: Common Rail System (Doc ID: 00400076E)."

Fuel injection rate control function

The fuel injection rate control function regulates the amount of fuel discharged from the injector orifice per

unit of time.

Fuel injection quantity control function

The fuel injection quantity control function replaces the conventional governor function. Fuel injection

quantity control adjusts the fuel injection to the optimal injection quantity based on the engine speed and

accelerator position signals.

Fuel injection timing control function

The fuel injection timing control function replaces the conventional timer function, and controls the

injection to an optimal timing based on the engine rotational speed and the injection quantity.

Fuel injection pressure control function (rail pressure control function)

The fuel injection pressure control function (rail pressure control function) controls the discharge volume

of the pump by measuring the fuel pressure at the rail pressure sensor and feeding a signal back to the

ECU. Pressure feedback control is performed so that the discharge volume matches the optimal

(command) value set in accordance with the engine rotational speed and the injection quantity.

6.2 Fuel Injection Quantity Control

The following explains controls unique to MITSUBISHI vehicles. For other types of basic fuel injection

quantity control, refer to "General Edition Manual: Common Rail System (Doc ID: 00400076E)."

(1) Maximum injection quantity

The basic maximum injection quantity is determined by the engine rotational speed, the added

corrections for intake air pressure, and gear position.

1 16

Operation Section

(2) Idle speed control (ISC) system

The ISC system controls the idle speed by regulating the injection quantity so that the actual speed

matches the target speed calculated by the engine ECU.

The target speed varies depending on whether the A/C is on or off, and the coolant temperature.

Operation Section

1 17

6.3 Other Controls

The following explains microinjection quantity learning control.

(1) Microinjection quantity learning control

Outline

Microinjection quantity learning control is used in every vehicle engine (injector) to preserve the accuracy

of the quantity (specifically, the pilot injection quantity.)

This type of control is first performed when shipped from the factory (L/O), and later is automatically

performed every time the vehicle runs a set distance (for details, see item "(A) below). Microinjection

quantity learning control not only preserves the accuracy of each injector initially, but also as deterioration

in injection occurs over time. Microinjection quantity learning also records the correction values to the

ECU. During normal driving operations, these correction values are used to make modifications to

injection commands, resulting in accurate microinjection.

Learning operations

Microinjection quantity learning control takes place for every two no-load, idle instability conditions

established (see chart "(A)" below). This control can also be performed manually as a diagnostic tool.

1 18

Operation Section

Operational outline

Learning control sends ISC (target speed correction quantity) and FCCB (cylinder-to-cylinder correction

quantity) feedback based on engine speed to apply injection control. Corrections are applied to each

cylinder based on ISC and FCCB correction information, and the corrected injection quantities are

calculated. Under microinjection quantity learning control, injection is divided into five injections.

Therefore, the "learning value" is calculated as the corrected injection quantities for ISC and FCCB,

divided by five injections.

Operation Section

1 19

7. OTHER SYSTEMS

7.1 Diesel Particulate Filter (DPF) System

Outline

For details on basic DPF construction and operation, refer to "General Edition Manual: Common Rail

System (Doc ID: 00400076E)". The differential pressure sensors and exhaust gas temperature sensors in

the systems for the applicable vehicles are DENSO products.

Differential pressure sensor

The construction and operation of the current differential pressure sensor is identical to that of the

conventional differential pressure sensor. The differential pressure sensor detects the difference in exhaust

gas pressure across the DPF.

Exhaust gas temperature sensors

The construction and operation of the current exhaust gas temperature sensors is identical to that of the

conventional differential pressure sensor. The exhaust gas temperature sensors detect the temperature of

the exhaust gas both before and after the DPF.

1 20

Operation Section

7.2 Fuel Filter with Filter Clog Switch, In-Tank Pump

Fuel filter with filter clog switch

The filter clog switch detects filter clogs using the pressure difference between the fuel filter inlet and outlet.

When a filter clog is detected, a diagnostic signal is outputted. (The fuel filter with filter clog switch is made

by DENSO.)

In-tank pump

The CRS equipped with the 4N13 and 4N14 engines uses an in-tank pump. The in-tank pump sends fuel

from inside the fuel tank to the supply pump, thereby assisting the pump in suctioning fuel to stabilize the

feed pressure. (The in-tank pump is made by another company.)

Operation Section

1 21

8. DIAGNOSTIC TROUBLE CODES (DTC)

8.1 Codes Shown in the Table

The "SAE" DTC column below indicates codes that are output through the use of the STT (MUT-III).

(SAE: Society of Automotive Engineers)

8.2 DTC Details

Applicable Engine

DTC

P0003

P0004

P0016

Detection Item

Suction Control Valve (SCV) actuation line

abnormality

SCV +B short circuit

Crankshaft position sensor, cylinder recognition

sensor phase gap malfunction

4N13

4N14

Detection

MIL

Detection

MIL

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

P0047

Turbo PWM output (low side)

YES

YES

YES

YES

P0048

Turbo PWM output (high side)

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

P0072

P0073

Intake air temperature sensor abnormality (low

side)

Intake air temperature sensor abnormality (high

side)

P0088

Abnormally high rail pressure

YES

YES

YES

YES

P0089

SCV stuck

YES

YES

YES

YES

P0093

Fuel leak

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

P0102

P0103

P0106

Mass Air Flow (MAF) meter abnormality (low

side)

MAF meter abnormality (high side)

Abnormal Manifold Absolute Pressure (MAP)

sensor characteristics

P0107

MAP sensor abnormality (low side)

YES

YES

YES

YES

P0108

MAP sensor abnormality (high side)

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

P0112

P0113

P0117

P0118

Intake manifold intake air temperature sensor

abnormality (low side)

Intake manifold intake air temperature sensor

abnormality (high side)

Coolant temperature sensor abnormality (low

side)

Coolant temperature sensor abnormality (high

side)

Operation Section

1 22

Applicable Engine

DTC

Detection Item

4N13

4N14

Detection

MIL

Detection

MIL

P0122

Intake valve sensor low

YES

YES

YES

YES

P0123

Intake valve sensor high

YES

YES

YES

YES

P0130

A/F sensor element abnormality

YES

YES

P0134

A/F sensor activation abnormality

YES

YES

P0135

A/F sensor heater abnormality

YES

YES

P0182

Fuel temperature sensor abnormality (low side)

YES

YES

YES

YES

P0183

Fuel temperature sensor abnormality (high side)

YES

YES

YES

YES

P0191

Abnormal rail pressure sensor characteristics

YES

YES

YES

YES

P0192

Rail pressure sensor (time) abnormality (low side)

YES

YES

YES

YES

YES

YES

YES

YES

P0193

Rail pressure sensor (time) abnormality (high

side)

P0201

TWV 1 (cylinder 1) actuation line open circuit

YES

YES

YES

YES

P0202

TWV 4 (cylinder 4) actuation line open circuit

YES

YES

YES

YES

P0203

TWV 2 (cylinder 2) actuation line open circuit

YES

YES

YES

YES

P0204

TWV 3 (cylinder 3) actuation line open circuit

YES

YES

YES

YES

P0219

Engine overrun abnormality

YES

P0234

High boost abnormality

P0299

Low boost abnormality

YES

YES

YES

YES

P0301

Injector function (non-injection) 1

YES

YES

YES

YES

P0302

Injector function (non-injection) 2

YES

YES

YES

YES

P0303

Injector function (non-injection) 3

YES

YES

YES

YES

P0304

Injector function (non-injection) 4

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

P0335

P0336

P0340

P0341

YES

YES

No crankshaft position sensor (NE sensor) pulse

input

Abnormal number of crankshaft position sensor

pulses

No cylinder recognition sensor pulse input

Abnormal number of cylinder recognition sensor

pulses

YES

P0381

Glow plug open/short circuit abnormality

YES

YES

YES

YES

P0401

Exhaust Gas Recirculation (EGR) insufficient flow

YES

YES

YES

YES

P0403

EGR DC motor status abnormality

YES

YES

YES

YES

YES

YES

YES

YES

P0420

No

temperature

increase

during

regeneration

DOC

P0427

Exhaust gas temperature sensor 2 low

YES

YES

YES

YES

P0428

Exhaust gas temperature sensor 2 high

YES

YES

YES

YES

P0489

EGR lift sensor low

YES

YES

YES

YES

Operation Section

1 23

Applicable Engine

DTC

Detection Item

4N13

4N14

Detection

MIL

Detection

MIL

P0490

EGR lift sensor high

YES

YES

YES

YES

P0500

Vehicle speed abnormality (low)

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

P0545

P0546

Exhaust gas temperature sensor 1 abnormality

(low side)

Exhaust gas temperature sensor 1 abnormality

(high side)

P0602

EOL not programmed

YES

YES

YES

YES

P0604

RAM abnormality

YES

YES

YES

YES

P0605

ECU flash-ROM abnormality

YES

YES

YES

YES

P0606

ECU CPU abnormality (main IC abnormality)

YES

YES

YES

YES

YES

YES

YES

YES

P0607

ECU

CPU

abnormality

(monitoring

IC

abnormality)

P062F

EEPROM diagnosis

YES

YES

YES

YES

P0630

VIN not programmed

YES

YES

YES

YES

P0638

Intake valve stuck

YES

YES

YES

YES

P0642

Sensor voltage 1 (low side)

YES

YES

YES

YES

P0643

Sensor voltage 1 (high side)

YES

YES

YES

YES

P064C

Glow control unit malfunction

YES

YES

YES

YES

P0652

Sensor voltage 2 (low side)

YES

YES

YES

YES

P0653

Sensor voltage 2 (high side)

YES

YES

YES

YES

P0683

Glow control unit communication abnormality

YES

YES

YES

YES

P1203

Low charging

YES

YES

YES

YES

P1204

Overcharging

YES

YES

YES

YES

P1210

Throttle valve opening malfunction

P1272

Pressure limiter valve opening abnormality

YES

YES

YES

YES

P1273

Supply pump single side pumping abnormality

YES

YES

YES

YES

P1274

Supply pump protective fail flag

YES

YES

YES

YES

P1275

Supply pump replace fail flag

YES

YES

YES

YES

P1276

Fuel filter clog abnormality

YES

YES

YES

YES

P1298

Turbo system (positive deviation)

YES

YES

YES

YES

P1299

Turbo system (negative deviation)

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

P1427

P1428

P1474

Exhaust gas temperature sensor 3 abnormality

(low side)

Exhaust gas temperature sensor 3 abnormality

(high side)

Temperature sensor for the Diesel Particulate

Filter (DPF) differential pressure sensor (low side)

YES

YES

YES

Operation Section

1 24

Applicable Engine

DTC

P1475

Detection Item

Temperature sensor for the DPF differential

pressure sensor (high side)

4N13

4N14

Detection

MIL

Detection

MIL

YES

YES

YES

YES

P1496

DOC temperature abnormality

YES

YES

P1497

DOC regeneration time exceeded

YES

YES

YES

YES

P1498

No opportunity for regeneration

YES

YES

YES

YES

P1499

DPF heat loss temperature abnormality

YES

YES

YES

YES

P1546

Exhaust gas temperature abnormality during

YES

regeneration

YES

P1625

QR data abnormality

YES

YES

YES

YES

P1626

QR data failure to write abnormality

YES

YES

YES

YES

P1639

Throttle abnormality during regeneration

P2009

EGR cooler bypass open load/short to ground

P2010

EGR cooler bypass short to battery

P20CF

YES

YES

YES

YES

YES

YES

YES

YES

Exhaust injector stuck open abnormality

YES

YES

P20D0

Exhaust injector stuck closed abnormality

YES

YES

P2118

DC motor overcurrent abnormality

P2122

P2123

P2124

P2127

Accelerator position sensor 1 abnormality

(low side)

Accelerator position sensor 1 abnormality

(high side) final

Accelerator position sensor 1 abnormality

(high side)

Accelerator position sensor 2 abnormality

(low side)

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

Accelerator position sensor 2 abnormality

P2128

YES

YES

YES

(high side)

Accelerator position sensor 2 abnormality

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

ACCP characteristic abnormality

YES

YES

YES

YES

P2146

Common 1 line open circuit

YES

YES

YES

YES

P2147

COM 1 TWV actuation line ground short

YES

YES

YES

YES

P2148

COM 1 TWV actuation line +B short circuit

YES

YES

YES

YES

P2149

Common 2 line open circuit

YES

YES

YES

YES

P2150

COM 2 TWV actuation line ground short

YES

YES

YES

YES

(high side) final

Accelerator position sensor duplicate malfunction

(high side)

P2138

Accelerator position sensor duplicate malfunction

(low side)

Operation Section

1 25

Applicable Engine

DTC

P2151

P2228

P2229

Detection Item

4N13

COM 2 TWV actuation line +B short circuit

Atmospheric pressure sensor abnormality (low

side)

Atmospheric pressure sensor abnormality (high

side)

4N14

Detection

MIL

Detection

MIL

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

P2238

A/F sensor positive (+) terminal (low side)

YES

YES

P2239

A/F sensor positive (+) terminal (high side)

YES

YES

P2252

A/F sensor negative (-) terminal (low side)

YES

YES

P2253

A/F sensor negative (-) terminal (high side)

YES

YES

YES

YES

P2297

Atmospheric

learning

value

abnormality/

malfunction detection

P2413

EGR feedback abnormality

YES

YES

YES

YES

P2426

VSS output (VSV) open load/short to ground

YES

YES

YES

YES

P2427

VSS output (VSV) open load/short to battery

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

P2454

P2455

DPF differential pressure sensor abnormality (low

side)

DPF differential pressure sensor abnormality

(high side)

P2463

Manual regeneration timing abnormality

U0131

Power steering ON malfunction

1 26

Operation Section

9. CONTROL SYSTEM COMPONENTS

9.1 Engine ECU External Wiring Diagrams

(1) LANCER

Operation Section

1 27

1 28

Operation Section

(2) ASX, OUTLANDER

Operation Section

1 29

1 30

Operation Section

9.2 ECU Connector Terminal Layouts

(1) LANCER

Operation Section

(2) ASX, OUTLANDER

1 31

Service Department DENSO CORPORATION

1-1, Showa-cho, Kariya-shi, Aichi-ken, 448-8661, Japan

You might also like

- Mitsubishi L200 Triton Service ManualDocument51 pagesMitsubishi L200 Triton Service Manualloveluna94% (18)

- 4Ja1-Tc & 4Jh1-Tc Engine: Engine Management System Operation & DiagnosisDocument91 pages4Ja1-Tc & 4Jh1-Tc Engine: Engine Management System Operation & DiagnosisNguyễn ĐángNo ratings yet

- Mitsubishi Pajero 4m41 EngineDocument42 pagesMitsubishi Pajero 4m41 Engineesyjam100% (14)

- Mazda 3 6 MZR-CD2.2 EngineDocument46 pagesMazda 3 6 MZR-CD2.2 EnginejorgeNo ratings yet

- 4JH1 Gestión ElectrónicaDocument79 pages4JH1 Gestión ElectrónicaAna Lorca89% (19)

- Fuel Sistem D4EB 2.2 PDFDocument544 pagesFuel Sistem D4EB 2.2 PDFcarnori100% (1)

- Hino j05d Turbo VNTDocument58 pagesHino j05d Turbo VNTEric Porter91% (32)

- Nissan XtrailThrottle and Idle RelearnDocument4 pagesNissan XtrailThrottle and Idle RelearnRa Aranzaso100% (1)

- Crdi System 1 Hyundai H1Document2 pagesCrdi System 1 Hyundai H1Ra Aranzaso100% (6)

- Dokumen - Tips Isuzu 07tf Immobilizer Training Ver1Document50 pagesDokumen - Tips Isuzu 07tf Immobilizer Training Ver1Chamila tharanga madushanNo ratings yet

- Toyota Hilux Kijyang Innova 1kd 2kd PDFDocument68 pagesToyota Hilux Kijyang Innova 1kd 2kd PDFpalaboy88892% (13)

- Denso Mitsubishi L200 Common Rail PDFDocument53 pagesDenso Mitsubishi L200 Common Rail PDFAlex Renne Chambi100% (10)

- DENSO Common Rail Mitsubishi L200 Triton 4D56 4M41 Service Manual PagesDocument11 pagesDENSO Common Rail Mitsubishi L200 Triton 4D56 4M41 Service Manual PagesJB0109198275% (16)

- Transfer D22Document38 pagesTransfer D22Jose FigueroaNo ratings yet

- Preparation 2zr-Fe Engine Mechanical SST PDFDocument3 pagesPreparation 2zr-Fe Engine Mechanical SST PDFAlbert BriceñoNo ratings yet

- Nissan Patrol Y61 Series 1 Brake SystemDocument10 pagesNissan Patrol Y61 Series 1 Brake SystemKofetoNo ratings yet

- Removing Mitsubishi Pajero ECUDocument2 pagesRemoving Mitsubishi Pajero ECUJose GilmerNo ratings yet

- Common Rail Hino - ToyotaDocument41 pagesCommon Rail Hino - Toyota0808833892% (24)

- Honda Civic EK Wiring Diagram Engine Controls 2 of 3Document1 pageHonda Civic EK Wiring Diagram Engine Controls 2 of 3Ra Aranzaso100% (1)

- Nissan Xtrail DTC P0335Document6 pagesNissan Xtrail DTC P0335Ra Aranzaso67% (3)

- Engine Controls Except HX 1 of 3Document1 pageEngine Controls Except HX 1 of 3Ra AranzasoNo ratings yet

- Motorul D4DDocument185 pagesMotorul D4Ddoruk1964100% (5)

- Enviando Denso Mitsubishi l200 Common RailDocument55 pagesEnviando Denso Mitsubishi l200 Common Railisrael machicado calle100% (4)

- Service Manual: Common Rail System For NISSAN YD1-K2 Type EngineDocument40 pagesService Manual: Common Rail System For NISSAN YD1-K2 Type EngineBryan Edu Curay ZavalaNo ratings yet

- Dmax Mux PDFDocument102 pagesDmax Mux PDFibnu malkanNo ratings yet

- DTC P0200-97 Injector Circuit - Open PDFDocument9 pagesDTC P0200-97 Injector Circuit - Open PDFMortada AlsonniNo ratings yet

- Denso - Ecd IIDocument26 pagesDenso - Ecd IIVASEK100% (4)

- Common Rail System (CRS) SERVICE MANUAL: Operation: YD2K3 EngineDocument44 pagesCommon Rail System (CRS) SERVICE MANUAL: Operation: YD2K3 EngineAntony ColonnaNo ratings yet

- Transfer: Workshop ManualDocument92 pagesTransfer: Workshop ManualmailforspamNo ratings yet

- Auto-Tech EncyclopediaDocument2 pagesAuto-Tech Encyclopediajhonathan hernandezNo ratings yet

- Toyota 14Document76 pagesToyota 14Dadang Lukmanul HakimNo ratings yet

- Taller New Actyon Sport Motor D20DTRDocument260 pagesTaller New Actyon Sport Motor D20DTRFernando MorenoNo ratings yet

- TFBRK We 0871 BrakesDocument216 pagesTFBRK We 0871 Brakessoenge100% (5)

- Fuel Inspection (4JJ1 Without DPD)Document157 pagesFuel Inspection (4JJ1 Without DPD)Patricio ValenciaNo ratings yet

- Toaz - Info Nissan Tb45e Engine Controlpdf PRDocument7 pagesToaz - Info Nissan Tb45e Engine Controlpdf PRAfshin GhafooriNo ratings yet

- Transfer Control Unit Isuzu D-Max UbicacionDocument1 pageTransfer Control Unit Isuzu D-Max UbicacionEltiezo EcheverriaNo ratings yet

- 2018 D 2.5 TCI-A2 Schematic Diagrams Engine Electrical System Engine Control System (With Euro6) Schematic DiagramsDocument1 page2018 D 2.5 TCI-A2 Schematic Diagrams Engine Electrical System Engine Control System (With Euro6) Schematic DiagramsANH LÊNo ratings yet

- Diagrama ABS Toyota HiluxDocument2 pagesDiagrama ABS Toyota HiluxMário Oliveira100% (1)

- Engine 4JG2 PDFDocument233 pagesEngine 4JG2 PDFАлексNo ratings yet

- Group 37 SteeringDocument71 pagesGroup 37 SteeringNeoGaraNo ratings yet

- Actyon FuelSystem D20DTRDocument24 pagesActyon FuelSystem D20DTRAnonymous 7t2BOJbNo ratings yet

- 2018 D 2.5 TCI-A2 Schematic Diagrams Engine Electrical System Engine Control System (With Euro6) Schematic DiagramsDocument1 page2018 D 2.5 TCI-A2 Schematic Diagrams Engine Electrical System Engine Control System (With Euro6) Schematic DiagramsANH LÊNo ratings yet

- Engine ControlDocument15 pagesEngine ControlMichael Porter100% (4)

- 1GD-FTV Engine Control Ecm ComponentsDocument3 pages1GD-FTV Engine Control Ecm ComponentsDaniel rodriguez alayo100% (5)

- Motor 4M41 MitsubishiDocument105 pagesMotor 4M41 MitsubishiMario Rogers100% (13)

- 6hkeed We 0325arDocument274 pages6hkeed We 0325arhumberto100% (5)

- w58 RebuildDocument49 pagesw58 RebuildtfphoenixNo ratings yet

- 1KD EduDocument5 pages1KD EduMakokha Mumelo100% (1)

- ECD-V4 OutlineDocument4 pagesECD-V4 OutlineВячеслав ГлушакNo ratings yet

- Connection of The STAG-300Document1 pageConnection of The STAG-300Anonymous IkfTLYBNo ratings yet

- Cylinder Head Bolt Tightening SequenceDocument2 pagesCylinder Head Bolt Tightening Sequenceອູ່ ໄຊ ອິນເຕີNo ratings yet

- Denso Fuel Injection Pump HP3 5 - L200 - 2.5DI-D MitsubishiDocument51 pagesDenso Fuel Injection Pump HP3 5 - L200 - 2.5DI-D MitsubishiJohnny Chia91% (11)

- DENSO Common Rail Hino E13C Service Manual PagesDocument11 pagesDENSO Common Rail Hino E13C Service Manual PagesYohanor Saputera88% (26)

- Avensis2 0cr-ServmanualDocument46 pagesAvensis2 0cr-ServmanualAmadeus De La CruzNo ratings yet

- Service Manual: Common Rail System (HP3) For Mitsubishi L200/Triton 4D56/4M41Engine (All The Destinations)Document53 pagesService Manual: Common Rail System (HP3) For Mitsubishi L200/Triton 4D56/4M41Engine (All The Destinations)Pizarro Andres100% (3)

- Toyot Common Rail System-2AD Denso For Avensis Service Manual PDFDocument32 pagesToyot Common Rail System-2AD Denso For Avensis Service Manual PDFNery CastellanosNo ratings yet

- Service Manual NissanDocument39 pagesService Manual NissanSky TripNo ratings yet

- Fuso 6m60Document20 pagesFuso 6m60Dowane Charles94% (31)

- Common Rail System For NISSANDocument40 pagesCommon Rail System For NISSANAntonio Ramos Vazquez90% (10)

- VECTOR 8500: Operation & Service ManualDocument74 pagesVECTOR 8500: Operation & Service ManualDM Truck100% (1)

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- Microprocessor Programming and Applications for Scientists and EngineersFrom EverandMicroprocessor Programming and Applications for Scientists and EngineersNo ratings yet

- Toyota Hilux ECM TerminalsDocument2 pagesToyota Hilux ECM TerminalsRa Aranzaso100% (2)

- 1kz-Te Pedal TroubleshootDocument6 pages1kz-Te Pedal TroubleshootLance Ramai100% (9)

- 99 Civic EK Engine Controls Wiring 3 of 3Document1 page99 Civic EK Engine Controls Wiring 3 of 3Ra AranzasoNo ratings yet

- MAX1 Conventional 19nov2010Document2 pagesMAX1 Conventional 19nov2010Ra AranzasoNo ratings yet