Professional Documents

Culture Documents

C Safety Clamp Maintenance Manual

Uploaded by

Imed Hammouda100%(2)100% found this document useful (2 votes)

193 views7 pagesDG

Original Title

c Safety Clamp Maintenance Manual

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDG

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(2)100% found this document useful (2 votes)

193 views7 pagesC Safety Clamp Maintenance Manual

Uploaded by

Imed HammoudaDG

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

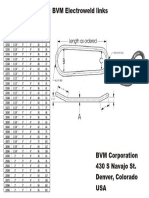

REFERENCE REFERENCE DESCRIPTION

[iype'C Safety Clamp Type‘C Safety Clamp

nem oye {VM Corporation USA

£30South Novo St.

‘Denver Co. 80225 USA

Us Tolfiee

n| SaLesaevwecoRPcom

\wunnavcoRecom,

[DOCUMENT ROWER

ENDOO1 aa

W.BVMCORP.COM —_

~BYM.. Introduction

MA Maintenance Manual

Thank you for purchasing the BVM Type ‘C’ Safety Clamp.

With proper usage and maintenance, your purchased item

could last for years.

The purpose of this manual is to assist the user in the

proper way to maintain the safety clamp. Inspections

and checks should be performed every day by qualified

personnel,

The following sections contain references to the

components of the safety clamp. The part names as well as

the corresponding item numbers can be found using both

FIGURE 1 and TABLE 1 found at the back of this manual

fesnis)

ao Visual Inspection

mn

MEN Maintenance Manual

Vv

Check to make sure that all the cotter pins (items 5 and 8)

are in their correct location and that they are installed properly

(i.e, each end is pulled over to prevent “backing out").

Check to see if the safety chain (item 15) is secured to both

the pin and the end link (item 3).

Check for obvious cracking in all of the components. Should

there be any concerns; dye penetrant testing can assist in

the disposition of the parts in question.

Make sure that all of the “teeth” on the inserts (item 4) are sharp

and intact.

~BYM. Functional Check

ME Maintenance Manual

Vv Open and close the clamp completely several times and check

for binding. The clamp should open and close with little force.

If binding does occur, isolate the area and check links and pins

for excessive wear and/or corrosion, If there is excessive wear,

replace components as necessary with approved BVM parts.

If there is corrosion, disassemble affected areas and clean

corrosion off with an appropriate medium abrasive . Apply a thin

film of grease on parts, reassemble and check for functional

performance.

7 Press down on each insert (item 4). The insert should “bottom

out” in each link and return to the up position each

cycle. If the insert does not return to the up position, check to

ensure that there is grease in the slide area and that the

insert spring (item 6) is functional. Replace components as

necessary with approved BVM parts.

Vv Ensure that the pivot block screws (item 14) are secure.

~BYM. Greasing

om

ME Maintenance Manual

Vv There are 3 components on the Type ‘C’ safety clamp that need

to be checked for and, if necessary, greased on a daily basis

to ensure proper function. These 3 components are as follows:

Item 1, Item 11 and item 12. It is essential that insert (item 4)

and insert spring (item 6) areas have a sufficient amount of

grease in the slide area of link (item 1).

em

~BYM.. Item Numbers

one

MANN Maintenance Manual

a he ;

ge te

y

e a

a @

i

Figure 1

7

mew

DESCRIPTION

csca6oe|

cscos0s|

cse9606|

* lomeosor

* Temsasoa

craasig

(CSAFETY CLAMP - 334" 451

(CSAFETY CLAMP -4 12-551

(CSAFETY CLAMP. 12-6 51

CC SAFETY CLAMP -6 12-7 51

CC SAFETY CLAMP.-7 12-851

CSAFETY CLAMP -6 12-951"

(C SAFETY CLAMP -© 172% 10 5

(C SAFETY CLAMP 10:12 11 5"

CSAFETY CLAMP. 11172

(CMse611 | C SAFETY CLAMP 14 v2 18 5/8" : = x

+ [99601 C SAFETY CLAMP CENTER LINK. z ear es es 16

(C SAFETY CLAMP END LINK, POT

2_| saso0_| stock. atatatatatststartatatatas

3 |~sosa2 —[¢ SAFETY CLAWP -END UNK, SCREW. Se

4 | ~g9606 | C SAFETY CLAMP INSERT 7s fo [ao arte as a4 [a5 [6

| St030.05.0 | COTTER PIN epee fio faa [as |e 5

6 | 90600 ¢ SAFETY CLAWPINSERT SPRING a

CC SAFETY CLAMP INTERMEDIATE LINK

2_| ov6074_| pin’ altaia}s}oelr}s}7}elelwoly

‘8 | 30030-10.0 | COTTER BN, a eo ae a3 ear 09 | 20)

® CC SAFETY CLAMP HAN soleas ear legalegaleg 2 2

10 CC SAFETY CLAMP HANDLE LINK PIN, 2lapa papa ta 4 4

1 CC SAFETY CLAMP-SCREW el eee en [ae 1 4

2 (CSAFETY CLAM NUT ce H +|

CSAFETY Clamp -pwOTSLOcK + tt ft ttt 4 4

CSAFETY CLAMP. PIVOT BLocKSGREW | 2 [2 | 2 | 2 [2 | 2 2 2

CSAFETY CLAMP-ENDLINKPINWGHAN | 1) [ 1 [+ [414 1 1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- CMSXL Casing Slips Maintenance ManualDocument7 pagesCMSXL Casing Slips Maintenance ManualImed HammoudaNo ratings yet

- Service Manual 200/250 Ton Elevator/SpiderDocument46 pagesService Manual 200/250 Ton Elevator/SpiderImed HammoudaNo ratings yet

- Electroweld Links SpecificationsDocument1 pageElectroweld Links SpecificationsImed HammoudaNo ratings yet

- 500 Ton 24 in Service ManualDocument23 pages500 Ton 24 in Service ManualImed HammoudaNo ratings yet

- 250 Ton Spider Elevator Maintenance ManualDocument46 pages250 Ton Spider Elevator Maintenance ManualImed HammoudaNo ratings yet

- Slips Catalog PDFDocument194 pagesSlips Catalog PDFDaniel Alencar100% (1)

- Astm e 125 - 63Document3 pagesAstm e 125 - 63Humberto EspirituNo ratings yet

- Drift 005Document4 pagesDrift 005tofa01100% (1)

- B Tong Maintenance ManualDocument4 pagesB Tong Maintenance ManualImed HammoudaNo ratings yet

- ndt2 PDFDocument24 pagesndt2 PDFrajivanaaNo ratings yet

- B+V ELEVATOR LSJ SJS Collar Type VS05 PDFDocument2 pagesB+V ELEVATOR LSJ SJS Collar Type VS05 PDFImed HammoudaNo ratings yet

- Yoke Light Kit PDFDocument2 pagesYoke Light Kit PDFImed HammoudaNo ratings yet

- Dcs Drill Collar Slips Maintenance ManualDocument7 pagesDcs Drill Collar Slips Maintenance ManualImed HammoudaNo ratings yet

- 611520-Y-BC-D Rev 009 - B+V Manual CL 150-1000Document56 pages611520-Y-BC-D Rev 009 - B+V Manual CL 150-1000Imed Hammouda100% (2)

- LOT String Book 2015Document123 pagesLOT String Book 2015Imed HammoudaNo ratings yet

- Tenaris Hydril Running ManualDocument151 pagesTenaris Hydril Running ManualHKHKBOOKS70% (10)

- Nuevo Catalogo 2015 Endchile/magnafluxDocument79 pagesNuevo Catalogo 2015 Endchile/magnafluxEric Figueroa UribeNo ratings yet

- Usa Octg CatalogDocument124 pagesUsa Octg Catalognikhil_barshettiwatNo ratings yet

- Freebie Read MeDocument1 pageFreebie Read MeImed HammoudaNo ratings yet

- Casing Tables 2015Document64 pagesCasing Tables 2015JOSENo ratings yet

- LOT String Book 2015Document123 pagesLOT String Book 2015Imed HammoudaNo ratings yet

- LOT String Book 2015Document123 pagesLOT String Book 2015Imed HammoudaNo ratings yet

- SJH Horizontal Pickup Elevator : FeaturesDocument1 pageSJH Horizontal Pickup Elevator : FeaturesImed HammoudaNo ratings yet

- Casing Tables 2015Document64 pagesCasing Tables 2015JOSENo ratings yet

- Blue-3.5in 9.2ppf L80Document1 pageBlue-3.5in 9.2ppf L80Imed HammoudaNo ratings yet

- SJH Horizontal Pickup Elevator : FeaturesDocument1 pageSJH Horizontal Pickup Elevator : FeaturesImed HammoudaNo ratings yet

- SJX Single Joint ElevatorDocument1 pageSJX Single Joint ElevatorImed HammoudaNo ratings yet

- SJX Single Joint ElevatorDocument1 pageSJX Single Joint ElevatorImed HammoudaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)