Professional Documents

Culture Documents

Uk London

Uploaded by

raamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uk London

Uploaded by

raamCopyright:

Available Formats

BC

Coursework

Module Name:

Module No:

Coursework Mark:

Submission deadline:

Advanced Manufacturing Engineering and Management Practice

PDE 4221

35%

Friday 19 December 2008

Problem:

Affordable Automation Ltd, based in Manchester, has been commissioned to supply an electro-mechanical

handling system. The machine is to have two axes, X and Z, and will be used to carry sink tap units in

preparation for painting or plating. Z-axis will be mounted on a fixed beam section travelling along the XAxis, and will have a suitable area for loading a batch of 10 taps. The overall mass of the Z-axis is estimated

to be 28 kg. The taps are made from brass and will be required to be cleaned and dried prior to being plated.

The taps are to be supplied to Ideal Standard Limited for their Affinity range (P/N E7834AA), catalogue

number 9:4:1A. The gross mass of the unassembled taps is 1.5 kg (body and spout). The lever handles of the

taps will be cleaned using another carrier and is not part of this task.

The frame is to be built by another company, Machine Building Systems (MBS) based in Derby, using

aluminium alloy extrusions manufactured by a German company, Item. A proposed configuration of the

system is provided by MBS with some overall dimensional details in Figure 1.

The vertical axis is a telescopic construction and offers an effective area of 300 mm x 300 mm to mount a

suitable tap carrier (body and spout). The company would like to have the taps pre-loaded onto these carriers

and then loaded onto the gantry. The depth of each station is 0.9 m (cleaning, rinsing and drying). Once

carrier is loaded, there should be no free movement other than the natural flexing of the structure.

It is worth noting that each end of the cross slide beam will be mounted onto a pair of linear bearing blocks.

Z-axis is to be mounted at midpoint along the cross slide.

Task:

1- Specify a suitable section for the Z-Axis and its associated components using the Item catalogue. You can

obtain an electronic version of their catalogue at www.mbsitem.co.uk and www.iteminternational.com/en/.

2- Design a suitable carrier for the tabs specified and the necessary interface with the gantry system.

3- Use Solidworks/Cosmos to test the structure to determine:

a) Maximum vertical displacement of the cross beam carrying the z-axis

b) First five natural frequencies of the cross slide and the associated mode shapes.

4- State any assumption you make in your calculations.

5- Provide a report to detail your solution including the necessary CAD images/drawings in a PDF format

6- Submit your report using Oasisplus.

IDEAL

S TA N D A R D

CI/SfB

January 2007

(74)

Uniclass L721

brassware

affinity

Distinctively designed quarter turn

kitchen brassware.

Valves incorporate ceramic disc

cartridges and are supplied complete

with matching chromium plated brass

lever handles.

Suitable for low or high pressure

systems. Balanced or unbalanced

supplies.

Distinctive design

Quarter turn for ease of use

Ceramic disc cartridge

Available in two finishes

Illustrated

E7834AA Affinity CD

1/2 in ceramic disc bridge

mixer, twin flow swivel

spout with lever

handles, chromium

plated

Options

E7834GN Affinity CD

1/2 in ceramic disc bridge

mixer, twin flow swivel

spout with lever handles,

satin chromium finish

Special notes

Inlets screwed 1/2in BSP

male, bored and coned

for 15mm copper.

Minimum 0.3 bar

pressure required

170

305

190

48

180

brassware

kitchen

115

Tel: 0870 122 8822 Fax: 0870 122 8282

email: info@thebluebook.co.uk

9 : 4 : 1A

Visit www.thebluebook.co.uk

online for search, specify & CAD facilities

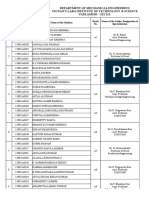

Figure 1: Proposed Gantry Structure

Figure 2: Proposed Gantry Structure suggested beam profiles

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Lecture - 1 Nptel FormingDocument12 pagesLecture - 1 Nptel Formingaghosh704No ratings yet

- VTU Notes, Question Papers, News and ResultsDocument21 pagesVTU Notes, Question Papers, News and Resultsraam100% (1)

- Vignan's Lara Institute Mechanical Engineering Project Review 2016-17Document2 pagesVignan's Lara Institute Mechanical Engineering Project Review 2016-17raamNo ratings yet

- 13 - Projects Titles (Master Copy)Document10 pages13 - Projects Titles (Master Copy)raamNo ratings yet

- Metal Forming ProcessesDocument40 pagesMetal Forming ProcessesRyat AtmadjaNo ratings yet

- ASRS Storage LocationDocument23 pagesASRS Storage LocationraamNo ratings yet

- Ch11Document20 pagesCh11raamNo ratings yet

- Inventory Management Sample ChapterDocument33 pagesInventory Management Sample ChapterraamNo ratings yet

- Production Planning ControlDocument31 pagesProduction Planning ControlvesgacarlosNo ratings yet

- CE Structural Analysis Classical Methods Deflection DeterminationDocument22 pagesCE Structural Analysis Classical Methods Deflection DeterminationNaveen Sundarrajan0% (1)

- PPC Notes PDFDocument36 pagesPPC Notes PDFIbrahim UjjainwalaNo ratings yet

- Linear Programming PDFDocument13 pagesLinear Programming PDFraamNo ratings yet

- Adilakshmi Nallabirudu: Career ObjectiveDocument3 pagesAdilakshmi Nallabirudu: Career ObjectiveraamNo ratings yet

- CAD ME2155 Lab ManualDocument18 pagesCAD ME2155 Lab ManualDilli BabuNo ratings yet

- Auto Cad Lab ManualDocument37 pagesAuto Cad Lab ManualMahipal ReddyNo ratings yet

- FEA Plane Stress AnalysisDocument17 pagesFEA Plane Stress AnalysisraamNo ratings yet

- Automobile Engineering in Brakes Lecture NotesDocument3 pagesAutomobile Engineering in Brakes Lecture NotesraamNo ratings yet

- Flexible Manufacturing SystemsDocument18 pagesFlexible Manufacturing Systemsgreenbelt86% (7)

- Design of Machine Members - I NotesDocument495 pagesDesign of Machine Members - I NotesNaveen SuryaNo ratings yet

- Design of Machine Members - I NotesDocument495 pagesDesign of Machine Members - I NotesNaveen SuryaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SAND ProductionDocument18 pagesSAND Productionali100% (1)

- Metu NCC Fall Semester (2017-1) PHY 105 General Physics I (3580105) Course SyllabusDocument3 pagesMetu NCC Fall Semester (2017-1) PHY 105 General Physics I (3580105) Course SyllabusErgin ÖzdikicioğluNo ratings yet

- Check Valves: Check Valve and Pre - LL Valve Type FDocument2 pagesCheck Valves: Check Valve and Pre - LL Valve Type FSaeid MirNo ratings yet

- DIY Balancing.: © Tony Foale 2008Document6 pagesDIY Balancing.: © Tony Foale 2008Factory PerformanceNo ratings yet

- Specification Chart of Pipes - Stainless Steel - Seamless Pipe - Mild Steel - Hollow SteelDocument3 pagesSpecification Chart of Pipes - Stainless Steel - Seamless Pipe - Mild Steel - Hollow SteelSunitha KumariNo ratings yet

- Tractor Operator AgricultureDocument9 pagesTractor Operator AgricultureConstantin CarpenNo ratings yet

- New Holland - Grader 156-7Document16 pagesNew Holland - Grader 156-7Cristian Cernega100% (1)

- Don3.0 Software - Proper Assembly of Flange JointDocument3 pagesDon3.0 Software - Proper Assembly of Flange JointJoshua HobsonNo ratings yet

- Memoria Muro Mamposteria Escalera QuickMasonryDocument7 pagesMemoria Muro Mamposteria Escalera QuickMasonryJulio Marcial Ramos QuinteroNo ratings yet

- 2014 Miteebite Catalog WebDocument40 pages2014 Miteebite Catalog WebDonald NeislerNo ratings yet

- EmDocument6 pagesEmGonzalo Antonio Mamani PayeNo ratings yet

- 2016 3 1 4 ClucasDocument18 pages2016 3 1 4 ClucasAhmed S. El DenNo ratings yet

- Lab 2 Torsion Lab Instruction SpringDocument7 pagesLab 2 Torsion Lab Instruction SpringYong JinNo ratings yet

- FAGOR Innovation 8kgDocument22 pagesFAGOR Innovation 8kgmenloparckNo ratings yet

- Shubham Gaikwad 163014 Seminar ReportDocument21 pagesShubham Gaikwad 163014 Seminar ReportShubham GaikwadNo ratings yet

- Sheet Metal OperationsDocument27 pagesSheet Metal OperationsbmvinayNo ratings yet

- INSTRUMENTED PILE LOAD TEST REPORTDocument24 pagesINSTRUMENTED PILE LOAD TEST REPORTsandrock92No ratings yet

- Concrete Mixer Truck Chassis CB318Document256 pagesConcrete Mixer Truck Chassis CB318Rendy fahleviNo ratings yet

- ANSYS Stress Analysis of Impeller Blade at Various RPMDocument13 pagesANSYS Stress Analysis of Impeller Blade at Various RPMcena3135No ratings yet

- Thermal Relief Valves: From The Automation List Department..Document1 pageThermal Relief Valves: From The Automation List Department..Sofyan HadiNo ratings yet

- Peake and Tobak 3D SeparationDocument25 pagesPeake and Tobak 3D SeparationPablitox84No ratings yet

- Wind Loading CalculationDocument2 pagesWind Loading CalculationMallesh NenkatNo ratings yet

- SN043a-EN-EU Design of Fixed Column Base JointsDocument23 pagesSN043a-EN-EU Design of Fixed Column Base JointsCenascenascenascenasNo ratings yet

- Bagatelle Showroom Structural AnalysisDocument15 pagesBagatelle Showroom Structural AnalysisDhiraj BeechooNo ratings yet

- Ade 12 Physics Exercise 6 Page 135 144Document48 pagesAde 12 Physics Exercise 6 Page 135 144Hope AlforqueNo ratings yet

- HP Valve PDFDocument48 pagesHP Valve PDFTuanTu NguyenTranNo ratings yet

- Sae As 81819 2001 (En) PDFDocument35 pagesSae As 81819 2001 (En) PDFWilliam LooNo ratings yet

- Exercises Marine Engineer + Internal Combustion EnginesDocument3 pagesExercises Marine Engineer + Internal Combustion EnginesGeorge GaneaNo ratings yet

- EJOT ASYST Component System Flyer 10.17Document5 pagesEJOT ASYST Component System Flyer 10.17Eren GülayNo ratings yet