Professional Documents

Culture Documents

Angle Globe Check Valve

Uploaded by

okaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Angle Globe Check Valve

Uploaded by

okaCopyright:

Available Formats

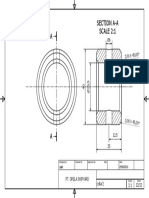

ANGLE GLOBE CHECK VALVE SDNR

DESCRIPTION

VALMATIC Angle Pattern Globe Check Valve provides high

tightness during valve closure. This valve is applicable where the

elbow fitting can be void in certain piping design.

VALMATIC Angle Pattern Globe Check Valve allows as one-way

flow to preventing the pipelines and related equipments against

reverse flow of medium. Additionally function allows stopping the

medium flow. This valve is widely used in process industries such

as Palm Oil and Refinery Plant, Food Industries, Petrochemical,

Heating and Cooling System.

APPLICATION

Suitable for water, steam, oil, gases and non-abrasive media

(Refer to corrosion resistance table for valve materials

selection).

SPECIFICATION

Face To Face Dimension - Series 8 according to DIN EN 558-1

End Connection

- Flanged End to DIN PN16 and PN40

FIG 8A2

MATERIALS

NO. PARTS

1.

Body

2.

Seat Ring

3.

Disc

4.

Gasket

5.

Gland Packing

6.

Gland

7.

Bonnet

8.

Stem

9.

Handwheel

PN16 RATING

PN40 RATING

Cast Iron

EN-GJL-250

Stainless Steel

X20Cr13

Stainless Steel

X20Cr13

Graphite - CrNiSt

Cast Steel

GP240GH

Stainless Steel

X20Cr13

Stainless Steel

X20Cr13

Graphite - CrNiSt

Graphite

Cast Iron

EN-GJL-250

Cast Iron

EN-GLC-250

Stainless Steel

X20Cr13

Cast Iron

EN-GJL-250

Graphite

Forged Steel

C 22.8

Cast Steel

GP240GH

Stainless Steel

X20Cr13

Cast Steel

GP240GH

PRESSURE-TEMPERATURE RATINGS ACC. DIN EN 1092-1/2

TEMPERATURE

PRESSURE RATING

AND MATERIAL

-10C

20C

100C 120C 150C 200C 250C

16 Bar 16 Bar 16 Bar 16 Bar 14 Bar 13 Bar 11 Bar

PN16 - Cast Iron

40 Bar 40 Bar 40 Bar 40 Bar 37 Bar 35 Bar 32 Bar

PN40 - Cast Steel

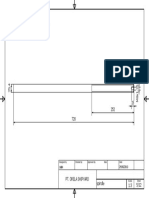

DIMENSIONS (mm) AND WEIGHTS (Kg)

SIZE (mm)

15

20

25

32

40

50

65

80

100

300C

350C

400C

450C

10 Bar

28 Bar

24 Bar

21 Bar

18 bar

125

150

200

250

300

90

95

100

105

115

125

145

155

175

200

225

275

325

375

H -PN16

163

160

173

173

214

211

236

250

301

339

383

455

531

710

H -PN40

170

170

170

240

250

265

290

320

350

390

440

515

575

655

h (Opening)

12

13

16

20

25

32

38

50

62

100

W -PN16

100

100

120

120

160

160

180

200

250

250

320

360

360

500

W -PN40

120

120

120

160

160

160

250

250

320

320

320

400

500

520

Weight PN16

3.1

3.5

4.8

6.6

8.7

11.8

14

20.5

32.2

46

62

106

184

270

Weight PN40

4.1

4.7

4.9

10.6

13.6

16

28

37

48

59.2

75.5

153

188

327

The specification is subject to change without further notice

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Avenged Sevenfold - Dear GodDocument2 pagesAvenged Sevenfold - Dear GodMade Dwiana SwulungganiNo ratings yet

- Amplop Sinar Dunia Bobohoy 1Document1 pageAmplop Sinar Dunia Bobohoy 1okaNo ratings yet

- Tata SuryaDocument1 pageTata SuryaokaNo ratings yet

- Print TariDocument3 pagesPrint TariokaNo ratings yet

- 3 - Interrupt Driven IODocument5 pages3 - Interrupt Driven IOAbhinav MadheshiyaNo ratings yet

- Crew Boat 20 MDocument1 pageCrew Boat 20 MokaNo ratings yet

- 3 - Interrupt Driven IODocument5 pages3 - Interrupt Driven IOAbhinav MadheshiyaNo ratings yet

- Aluminium Material PDFDocument123 pagesAluminium Material PDFokaNo ratings yet

- Kover - Daftar IsiDocument2 pagesKover - Daftar IsiokaNo ratings yet

- 40.4m 3 Generation Crewboat: Technical SpecificationDocument22 pages40.4m 3 Generation Crewboat: Technical SpecificationokaNo ratings yet

- Aluminium Material PDFDocument123 pagesAluminium Material PDFokaNo ratings yet

- Esb 2017 - Lines PlanDocument1 pageEsb 2017 - Lines PlanokaNo ratings yet

- 4.4 Spindle Collar: Designed by Checked by Approved by Date DateDocument1 page4.4 Spindle Collar: Designed by Checked by Approved by Date DateokaNo ratings yet

- 3 - Interrupt Driven IODocument5 pages3 - Interrupt Driven IOAbhinav MadheshiyaNo ratings yet

- 3D Esb 2017Document1 page3D Esb 2017okaNo ratings yet

- 7.4 Baut Whole Bearing: Designed by Checked by Approved by Date DateDocument1 page7.4 Baut Whole Bearing: Designed by Checked by Approved by Date DateokaNo ratings yet

- Section A-A Scale 1: 4 Section B-B Scale 1: 4 A B: Designed by Checked by Approved by Date DateDocument1 pageSection A-A Scale 1: 4 Section B-B Scale 1: 4 A B: Designed by Checked by Approved by Date DateokaNo ratings yet

- Esb 2017 DeckDocument6 pagesEsb 2017 DeckokaNo ratings yet

- Section A-A SCALE 2:1 A: 4.13 COLLAR 2Document1 pageSection A-A SCALE 2:1 A: 4.13 COLLAR 2okaNo ratings yet

- PT. ORELA SHIPYARD BANTALAN BEARING HOUSING DRAWINGDocument1 pagePT. ORELA SHIPYARD BANTALAN BEARING HOUSING DRAWINGokaNo ratings yet

- PT. ORELA SHIPYARD BANTALAN BEARING HOUSING DRAWINGDocument1 pagePT. ORELA SHIPYARD BANTALAN BEARING HOUSING DRAWINGokaNo ratings yet

- Designed by Checked by Approved by Date DateDocument1 pageDesigned by Checked by Approved by Date DateokaNo ratings yet

- Thrust Washer: Designed by Checked by Approved by Date DateDocument1 pageThrust Washer: Designed by Checked by Approved by Date DateokaNo ratings yet

- Split Collar DETAIL PDFDocument1 pageSplit Collar DETAIL PDFokaNo ratings yet

- Assembly Method Windlass PDFDocument1 pageAssembly Method Windlass PDFokaNo ratings yet

- Designed by Checked by Approved by Date DateDocument1 pageDesigned by Checked by Approved by Date DateokaNo ratings yet

- Thrust Washer PDFDocument1 pageThrust Washer PDFokaNo ratings yet

- Inspection Cover Detail PDFDocument1 pageInspection Cover Detail PDFokaNo ratings yet

- Dimensions for welding pipe fittingsDocument1 pageDimensions for welding pipe fittingsokaNo ratings yet