Professional Documents

Culture Documents

2720 (Part-III, Section-1) PDF

2720 (Part-III, Section-1) PDF

Uploaded by

Soundar PachiappanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2720 (Part-III, Section-1) PDF

2720 (Part-III, Section-1) PDF

Uploaded by

Soundar PachiappanCopyright:

Available Formats

f$ I 2720 ( Part III/k

( Reaffirmed 1997 )

i ) - 1980

Indian Standard

METHODS OF TEST FOR SOILS

PART

III

DETERMINATION

Section 1

(

OF SPECIFIC GRAVITY

Fine Grained Soils

First Revision )

First Reprint APRIL

UDC

624.131.431.1

@ Copyright

BUREAU

hlANAK

Gr 2

OF

BHAVAN,

1989

INDIAN

1980

STANDARDS

9 BAHADUR

SHAH

NEW DELHI 110002

ZAFAR

MARG

Decernhrr 1YSO

t8:2720(hdIl/Secl)-h80

Indian Standard

METHODS OF TEST FOR SOILS

PART

III

DETERMINATION

OF SPECIFIC GRAVITY

Section 1 Fine Gralned Soils

(

Soil Engineering

First Revision)

and Rock Mechanics

Sectional Committee,

Repremlfing

Chainnan

University

DB JAODIBHNAMIN

ADDITIONAL

ADDITIONAL DI~WTO~ REEEABOE

( F. E. ), RDSO

DEPUTY DIREOTO~ ~~E~BOR

1, RDSO ( Alh+

CAL AVTA~ SINGE

LT-COL V. K. KANITXAB (

Da A. BANERJEE

SHRI S. GUPTA ( Ahmale )

DR R. K. BHANDARI

CHIEF ENWNEEB ( B&R )

of Roorkee,

Roorkee

Irrigation

Department,

Patna

Ministry of Railways

DIBIOTOB, IRI

PBor ~;-B&H

BDC 23

Government

Ahnuts )

Cemindia

Co Ltd,

Headquarters

Bombay

Central Building Research Instittite, Roorkea

Irrigation

Department,

Government

of Punjab,

Chandigarh

The Concrete

In

Association

of India,

Bombay

personal

capacitv

(5 H&I rr ad

Hunbwfwd Strut, Colcut~aRX&/,

eotechnical

Society, New Delhi

Indian

Irrigation

Department,

Government

Pradesh, Roorkee

DR G. S. DHILLON

DIREOTOR, IRI

@ Cow+

BUREAU

Bihar,

Unlve-rsity of Jodhpur, Jodhpur

Engineer-in-Chiefs

Branch, Army

Da G. S. Dhillon ( AlternaIe )

SHRI M. G. DANDAVATB

SHBI N. C. DUWUL ( Ahnuts

SERI A. G. DASTIDAB

of

OF

INDIAN

Courr, 12/l

of

Uttar

1980

STANDARDS

This publication

is protected

under the Indian Cobrig& Act ( XIV of 1957 ) and

reproduction

in whole or in part by any means except with written permission

of the

publisher shall be deemed to be an infringement

of copyright under the said Act.

IS 8 2720 ( Part III/Set 1) - 1980

( Contiwdfrom

pa&y

1)

Rqmwnting

Mambers

Asia

SERI A. H. DIVANJI

SHRI A. N. JANQLE ( Ahmate

Pnos GOPALRANJAN

Pnov GOPAL RANJAN

Da SHASHI K. GULAATI

DR G. B. RAO ( Altcrnntc )

San1 0. P. MALHOTBA

Foundations

Bombay

&

Construction

(P)

Ltd,

)

University of Roorkee, Roorkee

Institution of Engineers ( India ), Calcutta

Indian Institute of Technology, New Delhi

Public Works Department, Chandigarh Administration, Chandigarh

Central Road Research Institute, New Delhi

SERI T. K. NATBAJAN

All India Instrument Manufacturers & Dealers

PRESIDENT( IMDA )

Association, Bombay

DEPUTY SECRETARY( AIIMDA ) ( Altcrnatc )

Central Water Commission, New Delhi

SH~I R. V. RANTHIDEVAN

DEPUTY DIRECTOR( CSMRS ) ( Ahmate 1

Public Works Department, Government of Punjab,

RE&AI~CH OBBICER( B&RRL )

Chandiqarh

Public Works Department, Government of Andhra

SHRI K. R. SAXENA

Pradesh, Hyderabad

Central Board of Irrigation & Power, New Delhi

SECRETARY

DEPUTY SECRETARY( Ahmate )

Roads Wing, Ministry of Shipping 8t Transport

SHBI

N. SIVAQURU

SHRI D. V. SlxxA (Altmats)

National Buildings Organization, New Delhi

SH~I K. S. SRINIVASAN

SHRI SUNIL BEHRY ( Aftmats )

SUPERINTENDINGE N Q I N E E R Public Works Department, Government of Tamil

Nadu, Madras

(P&D)

EXECUTIVEENGINEER( SMRD ) ( Alternate )

All India Instrument Manufacturers & Dealers

SHRI H. C. VEBMA

Association, Bombay

SHBI H. K. GUIZIA ( Altmuk)

Public Works Department, Government of Uttar

Ssar S. D. VIDYARTHI

Pradesh, Lucknow

DR B. L. DHAWAN ( Al&ma& )

Director General, IS1 ( J&-o@& Muakr )

SBRI G. RAYAN,

Director (Civ Engg )

SEEI K. M. MATHW

Deputy Director ( Civ Engg ), IS1

(Conhwdonpogr8)

IS I 2720 ( Part III/&x

1) - 1980

Indian Standard

METHODS OF TEST FOR SOILS

PART III

DETERMINATION

Section 1

OF SPECIFIC

GRAVITY

Fine Grained Soils

( First Revision)

0.

FOREWORD

0.1 This Indian Standard ( Part III/Set 1 ) ( First Revision ) was adopted

by the Indian Standards Institution on 3 October 1980, after the draft

finalized by the Soil and Rock Mechanics Sectional Committee had been

approved by the Civil Engineering Division Council.

0.2 With a view to establishing uniform procedures for the determination

of different characteristics of soils and also for facilitating a comparative

study of the results, the Indian Standards Institution is bringing out a

series of standards on methods of test for soils ( IS : 2720 ). This standard

( Part III ) deals with the method of test for determination of specific

gravity of soils which finds application in finding out the degree of

saturation and unit weight of moist soils. The unit weights are needed

This

in pressure, settlement and stability problems in soil engineering.

standard was published in the year 1964. In view of the further work done

in this field in this, as well as in other countries, the revision has been prepared so as to give the latest method of test which has separate provision

for fine grained and coarse soils. The revision is being prepared in two

sections : Section 1, dealing with the method for fine grained soil which is

a basically laboratory method and Section 2 for fine, medium and coarse

grained soils which is field method.

0.3 In reporting the result of a test or analysis made in accordance with

this standard, if the final value, observed or calculated, is to be rounded

off, it shall be done in accordance with IS : 2-1960*.

*Rules for rounding off numerical values ( r&red).

3

IS I 2720 ( Part III/kc

1) - 1980

1. SCOPE

1.1 This standard

( Part III/Set

1 ) lays down the methods of test for the

determination

of the ,specific gravity of soil particle of fine grained soils

( see Note ) .

NOTE

the coarse

The method may also he used for medium and coarse grained

parttcles are grained to pass 4*75-mm IS sieve before using.

soils

if

2. TERMINOLOGY

2.1 For the purpose

of this

in IS : 2809-1972* shall apply.

3. APPARATUS

3.1 The following

apparatus

standard,

the

definition

of terms

given

is required:

50 ml

4 Two density bottles ( pyknometers ) of approximately

capacity with stoppers.

b) A water-bath maintained at a constant temperature to within

f 02C.

( If standard

density bottles are used this constant temperature is 27C. )

Cl A vacuum desiccator ( a convenient size is one about 200 mm to

250 mm in diameter

).

A

desiccator

(

a

convenient

size is one about 200 mm to 250 mm

4

in diameter

) containing

anhydrous

silica gel.

A thermostatically

controlled

drying oven, capable

ing a temperature

of 105 to 110C.

f 1 A balance readable and accurate to O*OOl g.

of maintain-

.!a A

4

j)

k)

source of vacuum,

such as a good filter pump or a vacuum

pump.

A spatula ( a convenient

size is one having a blade 150 mm long

and 3 mm wide; the blade has to be small enough to go through

the neck of the density bottle ), or a piece of glass rod about

150 mm long and 3 mm diameter.

A wash bottle, preferably

made of plastics, containing

air-free

distilled water ( see Note ).

A sample divider of the multiple slot type ( S%le box ) with 7 mm

width of opening.

A length

of rubber

tubing to fit the vacuum

pump and the

desiccator.

NOTE - Obtain the air-free distilled water for at least 30 minute in a container

that can be sealed from the atmosphere

during cooling.

Take care to see that the

container

is strong enough

to resist the reduction

in pressure inside it during

cooling.

*Glossary

of terms and symbols

relating

to soil engineering

.( JirJl n&ion

).

1s I 2720 ( Part III/Set

1 ) - 1980

4. PROCEDURE

4.1 The complete density bottle with stopper, shall be dried at 105 to

1 lOC, cooled in the desiccator and weighed to the nearest 0.001 g ( ml )

( Je Note 1 ).

4.2 The 50 g sample obtained as described in the procedure

for the preparation of-disturbed

samples for testing ( see 1.5 ) shall if necessary

be

ground to pass a 2-mm IS test sieve.

A 5 to 10 g subsample

shall be

obtained by riffling, and oven dried at 105 to 110C ( see Note 2 ). This

sample shall be transferred

to the density bottle direct from the desiccator

in which it has been cooled.

The bottle and contents

together with the

stopper shall be weighed to the nearest 0.001 g ( ma).

4.3 Sufficient air-free distilled water ( see Note 3 ) shall be added so that

The bottle containing

the soil and

the soil in the bottle is just covered.

liquid, but without the stopper, shall be placed in the vacuum desiccator,

The pressure shall be reduced

which shall then be evacuated

gradually.

to about 20 mmHg.

When using a water pump, because of variation

in

mains pressure, care shall be taken to ensure that the required

vacuum is

maintained.

Care shall be taken during this operation to see that the air

trapped in the soil does not bubble too violently,

so as to prevent small

drops of the suspension being lost through the mouth of the bottle.

The

bottle shall be allowed to remain in the desiccator for at least 1 hour until

no further loss of air is apparent.

4.4 The vacuum shall be released and the

The soil in the bottle shall be stirred

Before removing

the

the bottle vibrated.

particles of soil adhering

to the blade shall

of air-free liquid. The lid of the desiccator

desiccator evacuaied

again.

lid of the

carefully

spatula

be washed

shall then

desiccator

removed.

with the spatula,

or

from the bottle the

off with a few drops

be replaced and the

4.5 The procedure

outlined in 4.3 and 4.4 shall be repeated

air is evolved from the soil ( see Note 4 ).

4.5.1 Alternately,

ing the pyknometer

the entrapped

air can be removed

placed on a water-bath

or sand-bath.

until no more

by getting

heat-

4.6 The bottle and cohtents shall then be removed

from the desiccator

and further air-free liquid added until the bottle is full. The stopper shall

The stoppered bottle shall be immersed up to the neck

then be inserted.

in the constant-temperature

bath for approximately

1 hour or until it has

attained the constant temperature

of the bath ( see Note 5 ).

If there is an apparent

decrease in volume of the liquid the stopper

shall be removed

and further

liquid added to fill the bottle and the

stopper.replaced.

The bottle shall then be returned

to the bath and suficient time shall be allowed to elapse after this operation to ensure that the

IS : 2720 ( Part III/SW 1 ) - 1980

bottle and its contents again attain the constant temperature of the bath.

If the bottle is still not completely full this process shall be repeated.

4.7 The stoppered bottle shall then be taken out of the bath, wiped dry

and the whole weighed to the nearest O*OOlg (ma).

4.8 The bottle shall then be cleaned out and filled completely with airfree liquid, the stopper inserted and then the whole immersed in the

constant temperature bath for 1 hour or until it has attained the constant

If there is an apparent decrease in the volume

temperature of the bath.

of the liquid, the stopper shall be removed and further liquid added to

The stoppered bottle shall then

fill the bottle and the stopper replaced.

be returned to the batch and sufficient time shall be allowed to elapse

after this operation to ensure that the bottle and its contents again attain

the constant temperature.

If the bottle is still not completely full this

The bottle shall then be taken out of the bath,

process shall be repeated.

wiped dry and the whole weighed to the nearest OS001 g (md)

( see Note 6 ).

4.9 Two determinations of the specific gravity of the same soils sample

shall be made ( see Notes 7 and 8 ).

NOTE 1 - S!andord Density Bolllcr - If a density bottle is used then in order to

avoid distortion it should not bc dried by placing it in an oven. It may be dried by

rinsing with acetone or an alcohol-ether

mixture and then blowing warm air

through it.

If there

NOTE 2 - Oven drying of the soil has been specified for convenience.

is any reason to believe that this will change the specific gravity due to loss of water

of hydration the soil should be dried at not more than 80C.

This fact should be

rep&ted.

NOTR 3 - Alternative Liquidsfor .Speci/icGrad/y Defcrminufion- With certain soils,

for c*x;~rnpl~~those containing 5oluble salts, kerosene ( paraffin oil ) or white spirit

may 1)~ prcft*rrt*(l. If one of these is used, record the fact and carry ollt a separate

oxp(arinlcn! to d<,tc:rmine the specific gravity of the liquid at the room tempt*rature

of the! tt,st. Ihc equation for the specific gravity of the soil particles, G. given in 5.1

thcan becomes:

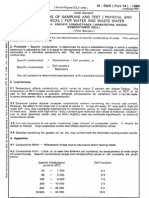

where

CL = specific gravity

of the liquid used, at the constant

temperature;

m, = mass of density bottle in g;

ms = mass of bottle and dry soil in g;

m3 = mass of bottle, soil and liquid in g; and

mg = mass of bottle when f@ll of liquid only in g.

Nom 4Experience has shown that the largest source of error in the test is

To

due to the diflicllltv in ensurine the comnlete removal of air from the sample.

obtain reliable results the soil should be left under vacuum for scvrral hours, preferably overnight.

Shaking the bottle in hand once or twice intcruppting the

vacuum gives quicker results.

I

fS : 2720 ( Part IfI/&c 1 ) - 1930

room or cabinet

NOTE 5 - If a constant temperature

cedure need not be carried out in a water-bath.

is available

then

thir PIO=

NOTE 6 - If method

given in 4.8 is used to find the volume of the density

bottle then the test may be carried out at any temperature

provided

it is constant

throughout

the test.

NOTE 7 - Many soils have a substantial proportion of heavier or lighter particles.

Such soils will give erratic values for the specific gravity even with the

greatest care in testing and a number of repeated tests may be needed to obtain

a good average value.

NOTE 8 - Clean quartz and flint sands generally

have a specific

2.65; low values would suggest the presence of organic matter.

gravity

close to

5. CALCULATION

5.1 The specific gravity of the soil particles G shall be measured

temperature

If water has been psed as the air-free liquid,

following equation shall be used:

G-

(m4-ml)

ms -

where

at ioom

then the

ml

(m8-4 ?.

ml = mass of density bottle in g;

ms =i mass of bottle and dry soil in g;

ms - mass of bottle, soil and water in g; and

m, = mass of bottle

If some other air-free

to Note 3.

when. full of water only in g.

liquid has been used reference

5.2 The specific gravity shall be calculated

rature is different than 27C, the following

at 27OC.

correction

should

be made

If the room tempe

shall be done:

G -KG

where

G x

6. REPORTING

Corrected specific gravity at 27OC, and

Relative density of water at room temperature

Relative density of water at 27%.

OF RESULTS

6.1 The average of the values obtained

shall be taken as the rpcci6c

gravity of the soil particles and shall be reported to the nearest 0.01.

If

the two results differ by more than 0.03 the teats shall be repeated.

1%: 2720 ( Part lff/Sec

Soil Testing

1) - 1986

Procedures

and Equipment

Convcnsr

Pros

ALAM

Subcommittee,

BDC 23:3

Represenfing

University

SINQE

of Jodhpur,

Jodhpur

Members

SIIRI

AMAR- SINGI~

_

~RPUTY

UIIIECTOIZ

RESEA~CII

Central Building Research

Ministry of Railways

Institute,

Roorkee

(FE-II ), RDSO

DEPUTY DIRECTOR RESEA~CII

( SM-III ), RDSO ( Alternafc )

Central Water Commission,

New Delhi

Druncron

( CSMRS )

DEPUTY DIIIEC~OR( CSMRS ) ( a4lfnnafc)

University

of Roorkee, Roorkee

PI~OFGOPAL RANJAN

Dn S. C. HANI~A ( Al&mare )

Indian Institute of Technology,

New Delhi

DB SIIAEIII K. GULHAYI

Sunx H. K. GUIIA

Geologists Syndicate Pvt Ltd, Calcutta

&RI H. N. BIIATTACIIAHAYA ( Altemnfe )

Public Works Department,

Chandigarh

AdminisSam 0. P. MALHOTRA

I tration

Associated Instruments

Manufacturers

( I ) Pvt

SH~I M. D. NAIR

Ltd, New Delhi

Pnos T. S. NA~ARAJ ( Alfe~dc )

Delhi College of Engineering,

Delhi

Snnr N. M. PATEL

Central Road Research Institute, New Delhi

SI~ICIP. JAOANATIIA RAO

Engineer-in-Chiefs

Branch, Army Hcadquartcrs

COL AVTAR Sr~o~r

LT-COL V. K. KANIT~AB ( Alfernatc )

Public Works Department,

Government

of Uttar

Snap S. D. VIDYAI~TIII

Pradesh, Lucknow

DR B. L. D~AWAN ( Alkmute )

BUREAU OF

INDIAN STANDARDS

Headquatiers :

Manak Bhavan, 9 Bahadur

Telephones

Shah Zafar Marg, NEW DELHI 110002

: 3 31 01 31,3

Telegrams : Manaksanstha

( Common to all Offices )

31 13 75

Telephone

Regional Offices :

*Western

; Manakalaya,

Northern

: SC0 445-446,

CHANDIGARH

Southern

: C. I. T. Campus, MADRAS

E9 MIDC, Marol, Andheri ( East ). 6 32 92 95

BOMBAY 400093

TEastern : l/l4

C. I. T. Scheme VII M, V. I. P. Road,

36 24 99

Maniktola, CALCUTTA 700054

Sector 35-C

160036

{ :1:::

41 24 42

l 41 25 19

141 29 16

600113

Branch Offices :

Pushpak, Nurmohamed Shaikh Marg, Khanpur,

4HMADABAD

380001

F Block, Unity Bldg, Narasimharaja Square,

BANGALORE 560002

Gangotri Complex, 5th Floor, Bhadbhada Road, T. T. Nagar.

BHOPAL 462003

Plot No. 82/83, Lewis Road, BHUBANESHWAR 751002

5315 Ward No. 29, R. G. Barua Road.

5th Byelane. GUWAHATI 781003

5-8-56C L N. Gupta Marg. (Nampally Station Road),

HYDERABAD 500001

R14 Yudhister Marg, C Scheme, JAIPUR 302005

11714188

Sarvodaya

Nagar

6 27 l6

5 36 27

22 10 83

KANPUR 208005

6 23 05

52 27

Patliputra Industrial Estate, PATNA 800013

Hantex Bldg ( 2nd Floor ). Rly Station Road,

TRIVANDRUM 695001

inspection Office ( With Sale Point ):

Institution

of Engineers

PUNE 410005

2 63 48

C 2 63 49

22 48 05

( India)

Building,

1332 Shivaji

Nagar, 5 24 35

*Sales Office in Bombay is st Novelty Chambers, Grant Road,

Bombay 400007

t.Sales Office in Calcutta is at 5 Chowringhee Approach, P. 0. Princrp

Street. Calcutta 700072

09 65 28

27 68 00

Reprography Unit, BIS, New Delhi, India

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hyundai Heavy Industries: With Tier 4 Interim Engine InstalledDocument24 pagesHyundai Heavy Industries: With Tier 4 Interim Engine InstalledSoban ReddyNo ratings yet

- LEFOO Pressure Switch PDFDocument1 pageLEFOO Pressure Switch PDFDwightFerrerNo ratings yet

- Hot Water Circulation - Designers Guide PDFDocument3 pagesHot Water Circulation - Designers Guide PDFAntonio LebrunNo ratings yet

- Concrete Centre SamplingDocument1 pageConcrete Centre SamplingEmir MuslićNo ratings yet

- Is 1077 - 1992 Common Burnt Clay Buil. Bricks Spec.Document6 pagesIs 1077 - 1992 Common Burnt Clay Buil. Bricks Spec.rambinodNo ratings yet

- 811Document31 pages811rambinodNo ratings yet

- SP16-Design Aid For RC To IS456-1978Document252 pagesSP16-Design Aid For RC To IS456-1978sateeshsingh90% (20)

- 460 (Part-1)Document15 pages460 (Part-1)rambinod67% (3)

- 460 (Part-2)Document16 pages460 (Part-2)rambinod0% (1)

- 460 (Part-3)Document10 pages460 (Part-3)rambinod100% (1)

- Is 455Document10 pagesIs 455Ravi ChandranNo ratings yet

- IS 3370 Part 3Document15 pagesIS 3370 Part 3SourabhAdikeNo ratings yet

- Hume Pipe Is 458-2003Document33 pagesHume Pipe Is 458-2003Bishwanath Sanfui100% (4)

- 3025 44Document6 pages3025 44rambinodNo ratings yet

- 3025 51Document8 pages3025 51rambinodNo ratings yet

- 3025 20Document1 page3025 20rambinodNo ratings yet

- Mlvss & Mlss Is-3025 - 18Document2 pagesMlvss & Mlss Is-3025 - 18Anuraj20No ratings yet

- UDC IS: 3025 (Part 14) - 1984,: Reprint JULY 1998) (IDocument4 pagesUDC IS: 3025 (Part 14) - 1984,: Reprint JULY 1998) (IrambinodNo ratings yet

- 3025 16Document2 pages3025 16rambinodNo ratings yet

- Volvo Penta MD6AMD7A Workshop ManualDocument44 pagesVolvo Penta MD6AMD7A Workshop ManualIslam AttiaNo ratings yet

- Design and Engineering Manual - Application of Technicals.Document26 pagesDesign and Engineering Manual - Application of Technicals.dauodNo ratings yet

- (已压缩)ESP Catalog.en.GX.2018Document31 pages(已压缩)ESP Catalog.en.GX.2018Setyadi PudjantoroNo ratings yet

- New Burner RG 2Document17 pagesNew Burner RG 2winkyaw333No ratings yet

- Assess Performance Failure Modes PDFDocument41 pagesAssess Performance Failure Modes PDFayaz hasanNo ratings yet

- BredelDocument49 pagesBredelrodolfocv92359No ratings yet

- Application of Quality Function Deployment inDocument8 pagesApplication of Quality Function Deployment indianNo ratings yet

- FittingsDocument7 pagesFittingsMdpn. SalvadorNo ratings yet

- Bucket Hydraulic SystemDocument4 pagesBucket Hydraulic SystemNay SoeNo ratings yet

- Rating 5.4 m3h - 120m - MV 5-24 - 3.7kW-2900rpm-380V-3Ph-50Hz PDFDocument3 pagesRating 5.4 m3h - 120m - MV 5-24 - 3.7kW-2900rpm-380V-3Ph-50Hz PDFTrung TrịnhNo ratings yet

- Method Statement For Post Fixed Rebar Drill & Fix With Chemical AnchorDocument14 pagesMethod Statement For Post Fixed Rebar Drill & Fix With Chemical Anchormohsin.meizaNo ratings yet

- Building LawsDocument32 pagesBuilding LawsJayvee Latosa DividinaNo ratings yet

- Booster Pump 80 LPM @43mDocument3 pagesBooster Pump 80 LPM @43mAndreas B KresnawanNo ratings yet

- Grundfos CR Series InstructionsDocument20 pagesGrundfos CR Series Instructionsbedilu77No ratings yet

- John Deere PowerTech Diesel Engines (DSWT01)Document12 pagesJohn Deere PowerTech Diesel Engines (DSWT01)huskerchamps75% (4)

- 2011 Catalog Rescue EquipmentDocument40 pages2011 Catalog Rescue EquipmentErica Lindsey100% (1)

- Operating Conditions: Technical Data SheetDocument1 pageOperating Conditions: Technical Data SheetImad QsnNo ratings yet

- Nam FDocument12 pagesNam FMohamad JammalNo ratings yet

- Kirloskar Brothers Limited: A Kirloskar Group Company Established 1888Document2 pagesKirloskar Brothers Limited: A Kirloskar Group Company Established 1888keeprocking9777No ratings yet

- Hydraulic SystemDocument203 pagesHydraulic SystemSagarNo ratings yet

- BA DUO 008 02 16 EN DUODOS 15 EN - Part9Document2 pagesBA DUO 008 02 16 EN DUODOS 15 EN - Part9alang_businessNo ratings yet

- Terex TH19-55 Service ManualDocument100 pagesTerex TH19-55 Service ManualMichael Belodon0% (1)

- 1 Arun KumarDocument23 pages1 Arun KumarrafieeNo ratings yet

- Corod SWR High Strength 29feb12Document3 pagesCorod SWR High Strength 29feb12Ronald LlerenaNo ratings yet

- Costing of Pipelines - 1 - PIPING GUIDEDocument7 pagesCosting of Pipelines - 1 - PIPING GUIDEfdsaeh67No ratings yet

- Instruction Manual FOR Rolls-Royce Steering GearDocument58 pagesInstruction Manual FOR Rolls-Royce Steering GearElena Baju100% (1)

- VDU Technical Description: Chemex Modular, LLCDocument4 pagesVDU Technical Description: Chemex Modular, LLCmigelNo ratings yet