Professional Documents

Culture Documents

Example

Uploaded by

Arif Widyatama0 ratings0% found this document useful (0 votes)

10 views2 pages2nd paragraph

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document2nd paragraph

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pagesExample

Uploaded by

Arif Widyatama2nd paragraph

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

example, Liz and I were working on an asphalt vacuum tower

along the Chickasaw River in Mobile, Alabama.

The primary ejector was making a surging sound, indicating a periodic loss of its

sonic boost. However, I also noted the

following:

The jet's discharge pressure was well below its

design critical discharge pressure.

My client had recently replaced the jet's steam

nozzle, even though the old one was in perfect

condition.

The gas rate to the jet was half of its design value.

The motive steam pressure was at design.

At each surge, the pressure in the vacuum tower jumped

far more than I expected from the loss of the sonic boost. Also,

changing the jet's discharge pressure or its gas rate did not

alter the two minute frequency of the surges.

Liz, who was monitoring the skin temperature of the jet's

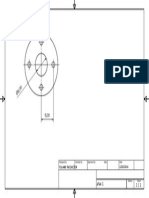

mixing chamber (see Figure 7.1), noted the following:

The vacuum would break every two minutes as

the jet went very, very quiet.

The mixing chamber temperature would drop

from about 70F to exactly 32F.

After remaining quiet and cold for a minute, the

jet would suddenly come to life with a roaring

sound for a minute. It would heat back up and

the vacuum would be briefly restored.

The cycle would be repeated with great regularity

every two minutes no matter what other parameters we varied.

When the front portion of the ejector chilled to precisely

32F (0C), it did not become just quiet, it became silent. This

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Testing in Tccordtnce With The Metsuring Instruments Directive TND OIML R50Document1 pageTesting in Tccordtnce With The Metsuring Instruments Directive TND OIML R50Arif WidyatamaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- MeterDocument2 pagesMeterArif WidyatamaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Linking Words PDFDocument2 pagesLinking Words PDFmanojkhadka23No ratings yet

- 7Document2 pages7Arif WidyatamaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Clas IfiedDocument2 pagesClas IfiedArif WidyatamaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Turbomachinery Design and Theory, Rama S. R. Gorla & Aijaz A. KhanDocument403 pagesTurbomachinery Design and Theory, Rama S. R. Gorla & Aijaz A. KhanWing Hin Chan90% (10)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Aaf SfsfsDocument2 pagesAaf SfsfsArif WidyatamaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- FGHJKLDocument1 pageFGHJKLArif WidyatamaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Latian Writing Task 1 #1Document2 pagesLatian Writing Task 1 #1Arif WidyatamaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 3sdsadas AsaDocument2 pages3sdsadas AsaArif WidyatamaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Example AsDocument1 pageExample AsArif WidyatamaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Photoshop CS5 Read MeDocument11 pagesPhotoshop CS5 Read Meali_mohammed_18No ratings yet

- RandoDocument1 pageRandoArif WidyatamaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- SadasasDocument1 pageSadasasArif WidyatamaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- CompleteDocument1 pageCompleteArif WidyatamaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 26384Document3 pages26384Jayaneela PrawinNo ratings yet

- CV Skills Template SaveTheStudentDocument1 pageCV Skills Template SaveTheStudentsamirsamhouriNo ratings yet

- SadasdadDocument1 pageSadasdadArif WidyatamaNo ratings yet

- P E10 2a IsocyDocument108 pagesP E10 2a IsocyArif WidyatamaNo ratings yet

- Centrifugal Pump Set Failure ModesDocument70 pagesCentrifugal Pump Set Failure ModesArif WidyatamaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- You Are The Doctor 12/02/2014: Designed by Checked by Approved by Date DateDocument1 pageYou Are The Doctor 12/02/2014: Designed by Checked by Approved by Date DateArif WidyatamaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- 2015 Poster UGM S1dsd S2 EmploymentDocument2 pages2015 Poster UGM S1dsd S2 EmploymentArif WidyatamaNo ratings yet

- Digital Catalog: Click The Series Name You Are Looking ForDocument1 pageDigital Catalog: Click The Series Name You Are Looking ForArif WidyatamaNo ratings yet

- Thermaline PHE ManualDocument17 pagesThermaline PHE ManualArif WidyatamaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- SfsfsfsDocument10 pagesSfsfsfsArif WidyatamaNo ratings yet

- List TempatdDocument1 pageList TempatdArif WidyatamaNo ratings yet

- List TempatdDocument1 pageList TempatdArif WidyatamaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Assembly Drawing for Simple Plate Clutch ComponentsDocument1 pageAssembly Drawing for Simple Plate Clutch ComponentsArif WidyatamaNo ratings yet

- Matlab InstallationDocument161 pagesMatlab InstallationEjaz Hussain HNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)