Professional Documents

Culture Documents

The New SW 76 Submachine Gun Small Arms Review PDF

The New SW 76 Submachine Gun Small Arms Review PDF

Uploaded by

TepeRudeboyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The New SW 76 Submachine Gun Small Arms Review PDF

The New SW 76 Submachine Gun Small Arms Review PDF

Uploaded by

TepeRudeboyCopyright:

Available Formats

Visit us on line at: www.smallarmsreview.

com

The SW 76 shown with its

stock in the extended position.

Nearly twenty

years have passed

since former President Ronald Reagan

signed the infamous

McClure-Volkmer

Act into law. Although this piece of

legislation had a few

pro-gun clauses, a

last minute amendment was added that

banned all future

manufacture of machine guns for private ownership. The

law took effect on

May 19, 1986.

This piece of legislation forever fixed

the number of transferable machine

guns in the system.

Since that day prices

have steadily increased as the supply

of transferable guns

has steadily decreased. Today the

cost of a transferable

machine gun can exceed the cost of a

new well-equipped

automobile.

Many Class 2

manufactures were

well aware of the

impending restrictions a few weeks

prior to the enactment of the ban.

Most of the manufacturers worked

night and day to

make and register as

many machine gun

receivers as possible. It was not necessary to assemble

26

complete working guns, but the receivers

had to meet a minimum stage of construction as set forth by the BATF. At midnight

May 18th it was all over.

The firearm-collecting world is always

full of unexpected surprises; often parts or

part sets that are unavailable for years suddenly show up in the warehouses of surplus

dealers. One example is the parts and part

sets for military issue Thompson submachine guns. These parts that were once in a

seemingly inexhaustible abundance were

gone and the prices of the few remaining

parts were increasing daily. Then, recently,

hundreds of mint to like new M1, M1A1

and M1928 Thompson part sets were found.

Who would have ever thought this would

ever occur - sixty year old Thompsons in

new condition!

Every now and then a small quantity of

new, unused registered receiver tubes would

emerge. Most of the remaining tubes were

originally produced to be assembled into

Sten submachine guns, but then just a few

years ago most of the Sten part sets disappeared, shelving the plans to assemble the

tubes into working guns.

More recently, Class 2 manufactures got

creative and have submitted plans to the

BATF Technology Branch to use the remaining registered receiver tubes for assembly into guns other then the Sten. Although

many of the new applications for

the receiver tubes were approved,

there were restrictions placed on

modifications allowed to the receiver tube itself. To date, the BATF has

approved the Sten tubes to be made into

Sterlings, Lanchesters and most recently

clones of the Smith & Wesson Model 76.

Yes, the Model 76.

The original 9mm Smith & Wesson

Model 76 submachine gun was first manufactured in 1968 with production ending in

1974. 6,000 production guns were built

during that period. There were other earlier clones of the S&W 76 made. One was

the MK Arms Company model called the

MK 760 and another was the Global Arms/

Southern Tools M76A1. Production of

these weapons were just starting up as the

machine gun ban was being enacted, limiting production of these submachine guns.

Lack of magazines was always a problem with the Model 76, with originals being scarce and proportionately expensive.

Then, seemingly out of nowhere, the easily

adaptable Suomi M31 magazines appeared

at bargain basement prices. Not only were

the magazines cheap, most of them were in

brand new condition. The magazines could

be altered in seconds with a Dremel Tool to

fit in the Smith Model 76 by simply removing a few thousands of metal from the front

Jim Burgess SW 76, a

copy of the Smith &

Wesson Model 76. The

example shown here

has the standard gray

Parkerized finish.

The Small Arms Review Vol. 9 No. 5 February 2006

Visit us on line at: www.smallarmsreview.com

guide plate. Accordingly, with the magazine problem solved, the asking prices for

the Model 76 began to increase.

The newest submachine gun on the market is the product of Ohio Class 2 manufacturer, and no stranger to the Class 3 world,

Jim Burgess. Jim was a once a retail dealer

for John Stemples original line of submachine guns, and also manufactured suppressors for them.

Jims new creation has been designated

as the SW 76 (without the &). The SW

76 guns are manufactured from virgin tubes

that were originally registered by John

Stemple in 1986. Jim has enough parts and

receiver tubes to assemble 100 guns. Jim

said that he personally test fires each gun

that he builds to insure proper functioning

before shipping it off to the customer. All

of the parts of the SW 76 will interchange

with an original Smith & Wesson M76 except for the bolt. The bolt is not interchangeable due to the reorientation of the extractor and the Stemple receiver tubes have an

inside diameter that is slightly larger than

that of an original S&W M76, requiring two

sleeves that act as bearing surfaces to be

placed on the bolt to take up the extra space

inside the receiver.

A big question is; where in the world would

you find the part sets from the Smith &

Wesson Model 76? Original spare parts for

the gun just dont exist. The answer; from

semiautomatic copies of the Model 76.

During 2001 the Tactical Weapons Company of Arizona was engaged to manufacture the parts and receivers for a weapon

that would be marketed as the Omega 760

carbine, a semiautomatic-only copy of the

Smith & Wesson Model 76. Initial sales of

the Omega 760 were brisk but quickly

dropped off. The disappointing sales of the

Omega ultimately drove the decision to

cease production and the decision left a

number of parts that were never assembled

into guns. Jim was able to purchase 100 of

the surplus Omega 760 kits and convinced

Special Weapons to produce the full auto

bolts and the other parts he needed. The

company agreed, and the 9mm SW M76

was born. Special Weapons still have a lim-

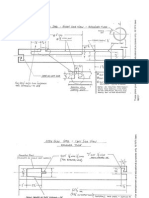

Above: Bottom view of the SW 76 barrel retaining catch. The original Smith

& Wesson design was a straight bar. The redesigned curved catch is much

easier to depress and hold.

Above: Side view of an original Smith & Wesson Model 76 bolt (top) and a

bolt from the SW 76. Note the raised bearing surfaces on the lower bolt, and

the different extractor positions.

Left: Front view of the bolts clearly

shows the different extractor locations. An original Smith & Wesson

bolt is on the right, the SW 76 bolt

on the left. The repositioning of the

extractor increases its service life,

and provides a more positive extraction of spent cases.

The Small Arms Review Vol. 9 No. 5 February 2006

27

Visit us on line at: www.smallarmsreview.com

ited number of new Omega 760 semiautomatic carbines as well as part sets available

for purchase.

One of the weakest areas of the original

Smith & Wesson Model 76 design was its

extractor, which will often fail after several

thousand rounds. One substantial improvement that was implemented into the design

of the SW 76 is the relocation of the extractor from the original 12 oclock position to

a 2 oclock position on the bolt. Relocating the extractor substantially reduces lateral stress on the extractor effectively extending its service life. The extractor was

also beefed-up for additional durability. The

trigger, magazine catch and sear are easily

serviced on SW 76, pivoting on removable

pins that are secured with E-clips. While

the sear on the original M76 is easily removable, the trigger and magazine catch are

semi-permanently riveted in place.

The SW 76 uses the same magazines as

the original Model 76 and, like the original, the plentiful Suomi magazine will fit

and function in the gun with some minor

fitting. The new SW 76 comes with instructions on altering the Suomi magazines.

Jim also has designed a suppressor specifically for his new SW 76. The powder

coated suppressor uses standard 9mm ammunition and is designed to reduce its velocity to subsonic speeds. The suppressor

will also fit and function on the Smith &

Wesson M76, the MK Arms MK760 and

the Southern Tool M76A1 guns.

I was able to get a first hand look and an

opportunity to test fire the SW 76 at a recent shoot in Ohio. The SW 76 is indeed a

dead ringer for the original M76. Jim

brought along several of his SW 76 submachine guns to the shoot and all worked perfectly. He also brought along his new suppressor. It, too, was quite impressive and

quiet even when firing standard super-sonic

9mm ammunition.

28

Left side view of

the SW 76. This

weapon has the optional black powder

coat finish.

Magazine markings. Note that the SW 76 logo that lacks

the & between the letters.

As mentioned earlier, the availability of

these guns is limited to 100 pieces , and this

is probably one of the last opportunit ies for

buyers to purchase a brand new design and

newly manufactured machine gun. Jim has

a CD available that has close-up views of

the SW 76 submachine gun, plus live-fire

demonstrations both with and without Jims

new suppressor. The CD even includes

complete assembly and disassembly procedures. The cost of the CD is $10.00 and is

The Small Arms Review Vol. 9 No. 5 February 2006

free to dealers that send in a copy of their

SOT. Dealer prices for the SW 76 and suppressors are available upon request.

For more information, visit Jims website

at; wwww.jmbdistribution.com. Email;

jburges@insight.rr.com

JMB Distribution

4291 Valley Quail S.

Westerville, Ohio 43081

You might also like

- DIY GUNS: Recoil Magazine's Guide to Homebuilt Suppressors, 80 Percent Lowers, Rifle Mods and More!From EverandDIY GUNS: Recoil Magazine's Guide to Homebuilt Suppressors, 80 Percent Lowers, Rifle Mods and More!Rating: 4 out of 5 stars4/5 (4)

- Sten Blueprints Parts Mk2 ADocument22 pagesSten Blueprints Parts Mk2 Aapi-374043498% (43)

- Blowback Firearms Design - Theory & PracticeDocument5 pagesBlowback Firearms Design - Theory & Practiceg29646950% (2)

- Sten Mk.2 ManualDocument9 pagesSten Mk.2 ManualGasMaskBob67% (9)

- Blueprint - Sten MK II, MP-40, Yugo 56, Submachine GunsDocument8 pagesBlueprint - Sten MK II, MP-40, Yugo 56, Submachine GunsNorm80% (10)

- Building The SGN-22 (Single-Shot Rifle Build)Document25 pagesBuilding The SGN-22 (Single-Shot Rifle Build)blowmeasshole191167% (6)

- Sten Building BookletDocument22 pagesSten Building Bookletpamrick100% (1)

- 1859 1863 Statutes at Large 151-350Document201 pages1859 1863 Statutes at Large 151-350ncwazzyNo ratings yet

- BarrelDocument1 pageBarrelNO2NWO100% (2)

- Thompson SMG PlansDocument52 pagesThompson SMG PlansNicholas Jumikis100% (22)

- Semiplans Sten MK2Document4 pagesSemiplans Sten MK2Mike Nichlos69% (13)

- ОружиеСтрелкаГермания9мая PDFDocument11 pagesОружиеСтрелкаГермания9мая PDF482358209596249420204458140058798324454948309300% (1)

- Danish Resistance STEN VersionDocument1 pageDanish Resistance STEN Versionwalther38_12100% (6)

- The Gun Digest Book of the AK & SKS: A Complete Guide to Guns, Gear and AmmunitionFrom EverandThe Gun Digest Book of the AK & SKS: A Complete Guide to Guns, Gear and AmmunitionNo ratings yet

- A History of the Small Arms Made by the Sterling Armament Company: Excellence in AdversityFrom EverandA History of the Small Arms Made by the Sterling Armament Company: Excellence in AdversityRating: 4 out of 5 stars4/5 (1)

- m1911 Blueprints ScansDocument8 pagesm1911 Blueprints Scansbuckshot1967100% (7)

- StenDocument13 pagesStendinosauro007100% (2)

- Custom Pathfinder Character SheetDocument2 pagesCustom Pathfinder Character SheetLordCoSaX100% (2)

- Australian F1 SUBMACHINE GUNDocument4 pagesAustralian F1 SUBMACHINE GUNCaprikorn100% (4)

- Lorica Segmentata Newstead Type Armor PDFDocument4 pagesLorica Segmentata Newstead Type Armor PDFwienslaw5804No ratings yet

- Nangant Pistol HistoryDocument67 pagesNangant Pistol Historygorlan100% (1)

- Practical Guide to the Use of the SEMI-AUTO PPS-43C Pistol/SBRFrom EverandPractical Guide to the Use of the SEMI-AUTO PPS-43C Pistol/SBRNo ratings yet

- Practical Guide to the Operational Use of the M79 Grenade LauncherFrom EverandPractical Guide to the Operational Use of the M79 Grenade LauncherNo ratings yet

- Building or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsFrom EverandBuilding or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsNo ratings yet

- The English Sten Sub Machine Gun ExplainedDocument11 pagesThe English Sten Sub Machine Gun Explainedknockelflies100% (3)

- SPD ManualDocument696 pagesSPD Manual:Zaphenath:Suneagle:Anoo-ELNo ratings yet

- American Shooting Journal - August 2020Document104 pagesAmerican Shooting Journal - August 2020LipeNo ratings yet

- Instruction Manual For I.O. Inc S Semi-Automatic Pistol Caliber 7.62X25 TokarevDocument20 pagesInstruction Manual For I.O. Inc S Semi-Automatic Pistol Caliber 7.62X25 TokarevRobert L Buettner80% (5)

- Practical Guide to the Operational Use of the PPS-43 Submachine GunFrom EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunNo ratings yet

- M 11 NineDocument26 pagesM 11 NineAntanas Bybis100% (1)

- MAX1045 ManualDocument13 pagesMAX1045 Manualbrowar444100% (1)

- Blueprints PPSH41 Yugo49-57 American180 Browning1919Document7 pagesBlueprints PPSH41 Yugo49-57 American180 Browning1919Mika100% (2)

- Ruger 10-22 Receiver BlueprintDocument2 pagesRuger 10-22 Receiver Blueprintelvergonzalez1100% (1)

- Practical Guide to the Operational Use of the UZI Submachine GunFrom EverandPractical Guide to the Operational Use of the UZI Submachine GunNo ratings yet

- Uniformology - Flags and Uniforms of The French Infantry Under Louis XIV 1688-1714Document260 pagesUniformology - Flags and Uniforms of The French Infantry Under Louis XIV 1688-1714NickiedeposieNo ratings yet

- MP44 BlueprintsDocument90 pagesMP44 BlueprintsNorm100% (8)

- High Mobility Multi-Purpose Wheeled Vehicle: Section 6 .7 PEO LS ProgramDocument6 pagesHigh Mobility Multi-Purpose Wheeled Vehicle: Section 6 .7 PEO LS ProgramAlexandra GanăNo ratings yet

- Practical Guide to the Operational Use of the HK69A1 Grenade LauncherFrom EverandPractical Guide to the Operational Use of the HK69A1 Grenade LauncherNo ratings yet

- The Gun Digest Book of Firearms Assembly/Disassembly Part IV - Centerfire RiflesFrom EverandThe Gun Digest Book of Firearms Assembly/Disassembly Part IV - Centerfire RiflesNo ratings yet

- Practical Guide to the Operational Use of the RPD Machine GunFrom EverandPractical Guide to the Operational Use of the RPD Machine GunNo ratings yet

- MC InitiatorDocument16 pagesMC InitiatorAiden MacleodNo ratings yet

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- The Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsFrom EverandThe Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsRating: 5 out of 5 stars5/5 (3)

- Flight: Head To HeadDocument68 pagesFlight: Head To HeadSaleh1fNo ratings yet

- Practical Guide to the Operational Use of the PPSh-41 Submachine GunFrom EverandPractical Guide to the Operational Use of the PPSh-41 Submachine GunRating: 5 out of 5 stars5/5 (2)

- M-45 Armorers Manual Swedish KDocument61 pagesM-45 Armorers Manual Swedish Klobosolitariobe100% (4)

- Nato Glossary of Medical Terms and DefinitionsDocument48 pagesNato Glossary of Medical Terms and DefinitionsAbrar100% (1)

- F1 SMG 9mm Repair Parts ScaleDocument36 pagesF1 SMG 9mm Repair Parts ScaleCaprikorn100% (4)

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.From EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Rating: 5 out of 5 stars5/5 (1)

- Puma M1887 Lever Shotgun ManualDocument24 pagesPuma M1887 Lever Shotgun Manualesporadico123100% (1)

- Micro Uzi DimensionsDocument1 pageMicro Uzi DimensionsRennie Raines50% (2)

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationFrom EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationNo ratings yet

- Gvtsy NipkytxtsxssnDocument285 pagesGvtsy NipkytxtsxssnEdgar Chávez GarcíaNo ratings yet

- Anthony P. Maingot Social Structure, Social Status and Civil Military ColombiaDocument31 pagesAnthony P. Maingot Social Structure, Social Status and Civil Military ColombiajorconcaldNo ratings yet

- Authorized Distributor'S DirectoryDocument9 pagesAuthorized Distributor'S DirectoryAffordableCebuClassifiedsNo ratings yet

- Elegant and Professional Company Business Proposal PresentationDocument15 pagesElegant and Professional Company Business Proposal Presentationtriharyanto cmkNo ratings yet

- Tamil Historical NovelsDocument39 pagesTamil Historical Novelsrbalajieee1234100% (2)

- English 6 DLP D1Document8 pagesEnglish 6 DLP D1PRESTENENo ratings yet

- FEAR GEAR Camouflage - Raider MagazineDocument1 pageFEAR GEAR Camouflage - Raider MagazineJesse SmithNo ratings yet

- About AngonoDocument10 pagesAbout AngonoPatrick FernandezNo ratings yet

- Japanese OccupationDocument5 pagesJapanese OccupationJo RinzNo ratings yet

- U N RESOLUTION On Jammu Kashmir by Asif RajaDocument3 pagesU N RESOLUTION On Jammu Kashmir by Asif RajaAsif Masood Raja100% (1)

- GP320B Operator's Manual B2 1-13-11Document20 pagesGP320B Operator's Manual B2 1-13-11Mario FerreiraNo ratings yet

- The Blue Hackle - Edition 7Document20 pagesThe Blue Hackle - Edition 7TheHighlandersNo ratings yet

- Proposed ProjectDocument25 pagesProposed ProjectNone None NoneNo ratings yet

- 01 Terrorism or Liberation Towards A Distinction A Case Study by Muttukrishna SarvananthanDocument18 pages01 Terrorism or Liberation Towards A Distinction A Case Study by Muttukrishna SarvananthanPisica ȘtefanNo ratings yet

- De Thi Tieng Anh Lop 3 Hoc Ki 1 Global SuccessDocument3 pagesDe Thi Tieng Anh Lop 3 Hoc Ki 1 Global SuccessLinh PhanNo ratings yet

- SP2022 SP2022 M SP2022: Owners Manual: Handling & Safety InstructionsDocument60 pagesSP2022 SP2022 M SP2022: Owners Manual: Handling & Safety InstructionslaurNo ratings yet

- Reflections of A TechnocratDocument394 pagesReflections of A TechnocratWorldwar RadarNo ratings yet

- 01 IntroductionDocument9 pages01 IntroductionSam JhaNo ratings yet

- ShipsDocument7 pagesShipskineticgangstaNo ratings yet

- Lotf Vocabulary With DefinitionsDocument1 pageLotf Vocabulary With Definitionsbẹjamin hoàngNo ratings yet