Professional Documents

Culture Documents

Retaining Walls PDF

Retaining Walls PDF

Uploaded by

Suman JainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Retaining Walls PDF

Retaining Walls PDF

Uploaded by

Suman JainCopyright:

Available Formats

MOA Project #10-026

Golden View Drive Intersection & Safety Upgrades

Appropriate transitions can include extending the insulation beyond the roadway

improvements, reducing the insulation thickness, or angling the insulation downward.

Use of a frost tolerant section, an alternative to the insulated section, may be

warranted where subgrade soil has low to moderate frost susceptibility or where

groundwater is relatively deep and subgrade soil is not saturated most of the year. A

frost tolerant section could be considered at the beginning of the project, from

approximate station 508+00 to about station 520+00. Soil borings in this area

encountered shallow weathered rock, between 2.5 feet to 12 feet below ground

surface. A frost tolerant section may also be considered at the north end of the

project, between approximate stations 590+00 to 599+50. General appearance of

the pavement surface suggests that roadway performance in this segment is better

than the remainder of the alignment. A frost tolerant section in these two segments

would consist of approximately 2.25 feet of NFS fill material.

For both an insulated and frost tolerant section, a non-woven geotextile is included

along the base of the structural section to separate the native silty subgrade

materials from the imported subbase fill.

When peat is exposed in the base of the excavation, it is recommended that the peat

be excavated out and replaced with imported fill.

H.

Retaining Walls

Due to the steep adjacent terrain along the project corridor, retaining walls will be

required to reduce the impacts from roadway grading and slopes. Retaining walls

should be installed as needed to minimize impacts to utilities, the environment, and

adjacent properties.

1. Retaining Wall Types

Below is a description of the four basic types of retaining walls along with their

characteristics.

Draft Design Study Report

March 2012

68

MOA Project #10-026

Golden View Drive Intersection & Safety Upgrades

Gravity: Gravity retaining walls rely on the mass of the wall structure for stability.

The wall mass must be sufficient to counteract sliding and overturning forces

from the retained soil. These systems can use stone, concrete or other heavy

material as well as mechanically stabilized earth (MSE) for stability. These are

the most common type of retaining walls and include gabions, bin walls, and

Example rock-gabion retaining wall

Example modular block retaining wall

modular block concrete construction. In most cases the slope behind the wall

needs to be temporarily removed during construction. For mechanically stabilized

earth walls, the reinforcing often extends horizontally into the embankment about

as far as the exposed wall face is tall.

Piling: Piling retaining walls have structures that extend significantly below grade

to provide support to counteract horizontal forces from the retained soils.

Typically two thirds of the structure height is embedded below grade. The

structures are usually steel sheet piles or H beams. Piles are driven into the soil

while H beams can either be driven in or set into drilled holes. Quite often, the

structural face of a piling wall is covered with a facade of concrete blocks or

panels. These are some of the most expensive types of retaining walls but they

do allow construction with very little removal of soil behind the wall.

Cantilever: Cantilever retaining walls have a large effective mass due to the soil

placed over a horizontal section of the wall. These walls are typically constructed

of cast-in-place, reinforced concrete. The horizontal (cantilevered) leg of the

Draft Design Study Report

March 2012

69

MOA Project #10-026

Golden View Drive Intersection & Safety Upgrades

structure can either extend back into the retained soil or out away from the slope.

The slope behind the wall typically needs to be temporarily removed during

construction. Cantilever walls are relatively expensive due to the work required to

build concrete forms, install reinforcing, pour concrete, and provide joints

between pours. The concrete needs ample time to cure before the soil can be

replaced behind the wall.

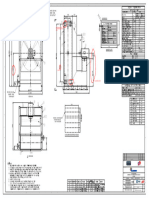

Basic types of retaining walls

Anchored: Anchored (or tieback) retaining walls use cables driven horizontally

into the soil to counteract opposing horizontal forces from the retained soils. The

anchors, which typically pull horizontal plates or sheets against the soil, can be

soil nails, tieback cables, or screw anchors. The soil behind the wall does not

need to be removed during construction. The anchors may need to extend into

Draft Design Study Report

March 2012

70

MOA Project #10-026

Golden View Drive Intersection & Safety Upgrades

the embankment quite a ways, which can impact buried utilities or future

development.

Combination: Many retaining walls use a combination of the above types. For

example, many piling walls use anchors to reduce embedment depth and

structure strength.

2. Considerations

Below are important considerations that affect the decision to provide a retaining

wall and which type of wall should be constructed. The decision to construct a

retaining wall can be subjective and must balance the cost of installing a

retaining wall with the overall impacts to utilities, wetlands, the environment, or

adjacent properties. Impacts to wetlands often demand construction of retaining

walls due to permitting requirements to avoid or minimize wetlands impacts if

possible. Exact locations of retaining walls will require further refinement during

the design phase.

Embankment Impacts: Gravity and cantilever retaining walls typically require

some of the soil behind the wall to be temporarily removed during construction. In

some cases the slope can be cut to stand near vertical for short periods of time

to reduce impacts but OSHA embankment guidelines and worker safety must be

accounted for. Piling walls can minimize impacts to adjacent properties and

structures.

Foundation Soils: Gravity and cantilever retaining walls require a solid foundation

to resist the forces of the wall and soil. Where foundation soils are weak, a piling

or anchor wall should be considered or the weak soil replaced. The bedrock

encountered near the south end of the Golden View Drive project provides an

excellent foundation but makes driving sheet piles very difficult (see APPENDIX E

for the geotechnical report).

Groundwater/Drainage: Groundwater needs to be removed from behind the

retaining wall to reduce hydrostatic forces. Many types of wall are inherently

porous while other types, like reinforced concrete, require weep holes to be

integrated into the design to relieve pressure from water behind the wall. In areas

where substantial groundwater and glaciation is expected, a subdrain should be

Draft Design Study Report

March 2012

71

MOA Project #10-026

Golden View Drive Intersection & Safety Upgrades

considered to direct the runoff to drainage ditches or a piped storm drain

collection system.

Utilities: Some types of retaining walls impact a considerable amount of soil

behind the face of the wall. For example, modular block walls and MSE walls rely

on reinforcing geotextile fabric embedded into the soil as part of the structure.

The fabric behind the wall can impact existing utilities or limit future placement of

utilities. Anchor wall cables also extend into surrounding soils and affect utilities.

Aesthetics: Retailing walls are often very noticeable along a roadway corridor

and they should be selected to compliment the landscaping design and blend in

with the surrounding neighborhood. Sometimes retaining walls are chosen to

match existing walls on adjacent properties. Many of the existing retaining walls

along Golden View Drive are large irregular boulders. Although many PM&E

roadway project use concrete modular block retaining walls, gabion walls may be

more appropriate for this project area where residents have expressed a desire

to retain the rural feel. Gabion walls have also been used in other Anchorage

hillside areas including along Birch Road and for South Anchorage High School.

Safety Fence or Handrail: When the vertical face of the retaining wall is more

than

2.5

feet

tall,

fence,

handrail, or guardrail should be

provided for safety.

should

be

discouraged

Moose

from

walking over the wall. Where

space is limited, a fence or

handrail can be placed near the

face of a reinforced concrete

wall.

Most other types of wall

require the fence to be set back

in the soil behind the wall.

Draft Design Study Report

March 2012

72

MOA Project #10-026

Golden View Drive Intersection & Safety Upgrades

Construction Schedule: In some

cases, the amount of time

required to construct a retaining

wall is very important since it

can affect impacts to adjacent

property

owners

environment.

concrete

or

the

Reinforced

headwalls

take

considerable amount of time to

construct. They are typically not

a good option for stream culvert

headwalls that need to be

completed quickly to reduce

Construction of gabion-type retaining wall

environmental impacts.

Maintenance: Retaining walls and associated fences or handrails should be

designed to require little if any maintenance. Concrete surfaces can be provided

with coatings to facilitate removal of spray paint vandalism.

Construction of modular block retaining wall

Draft Design Study Report

March 2012

73

MOA Project #10-026

Golden View Drive Intersection & Safety Upgrades

Cost:

The

installed

estimated

cost

retaining

for

walls

varies

considerably from $45 to

more

than

square

per

of

the

foot

exposed

Some

$200

of

factors

vertical

the

face.

biggest

include

soil

conditions, wall height,

tiebacks,

construction

Example modular block retaining wall with railing

access, type of fence and

the amount of soil to be removed behind the wall for construction. Below is a

summary of order-of-magnitude cost for various types of retaining walls for

comparison purposes. These costs include a chain link fence above the wall.

Retaining Wall Type

Summary of Unit Costs

Cost per

Square foot of

wall face,

installed

Excavation

Modular block (Keystone),

without tiebacks

$45

full excavation behind blocks,

limited to 4' height

Modular block (Keystone),

geogrid tiebacks

$60

full excavation behind geogrid

Mechanically Stabilized

Earth (MSE)

$75

with concrete face, full excavation

behind wall and tieback

Gabion Basket

$75

full excavation behind wall

Reinforced concrete,

cast-in-place

$120

full excavation behind base of

structure

Soldier pile, without

tiebacks

$130

with block facade, minimal

excavation behind wall

Soldier pile, with tiebacks

$190

with block facade, minimal

excavation behind wall

Sheet pile, without tiebacks

$180

with block facade, no excavation

behind wall

Sheet pile, with tiebacks

$210

with block facade, no excavation

behind wall

Draft Design Study Report

March 2012

74

MOA Project #10-026

Golden View Drive Intersection & Safety Upgrades

3. Estimated Project Cost

The conceptual drawings located in APPENDIX B indicate where retaining walls

should be considered to limit impacts to utilities, the environment or adjacent

property. The potential areas for retaining walls for the preferred alternative

(Alternative 1) are summarized below in TABLE 7. Note: this summary does not

include stream culvert headwalls.

Table 7 Summary of Retaining Walls (preferred alternative)

Purpose

Street

Approx.

Start

Station

Offset

Ave

Height

(ft)

Length

(ft)

Area

(sf)

Golden View

528+75

Left

4.9

181

887

Golden View

531+27

Right

3.5

108

378

Golden View

535+34

Right

5.2

28

146

Golden View

541+27

Right

6.4

285

1,824

Golden View

543+88

Left

2.5

65

163

Golden View

544+69

Left

2.0

107

214

Golden View

546+45

Left

3.0

296

888

Golden View

549+72

Right

4.0

667

2,668

Golden View

568+81

Right

3.4

116

394

Golden View

570+69

Left

3.5

572

2,002

Golden View

577+45

Left

2.5

542

1,355

Golden View

584+65

Left

4.5

530

2,385

Romania

200+78

Left

4.1

38

156

Utility

Environment

Property

X

X

X

X

X

A modular block or gabion basket type retaining wall can be used in nearly all of

the areas identified above. Assuming a unit cost from $60 to $75 for modular

block and gabion basket wall types respectively, this represents an approximate

cost of $880 thousand to $1.01 million for the recommended Alternative 1.

I. Traffic Calming

Based on speed studies and comments from local residents, speeding is a concern.

Various methods for traffic calming were investigated, including:

Vertical traffic calming measures (ex. speed hump)

Horizontal traffic calming measures (ex. neckdowns)

Draft Design Study Report

March 2012

75

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- UDSM Admissions 2016 - 2017 Round 1 PDFDocument397 pagesUDSM Admissions 2016 - 2017 Round 1 PDFkhalfan saidNo ratings yet

- LED Lights Coding On Non LED Equipped Vehicles OBDeleven PDFDocument18 pagesLED Lights Coding On Non LED Equipped Vehicles OBDeleven PDFLaborer72No ratings yet

- Section Adequacy:: For Solid Section: For Hollow SectionDocument1 pageSection Adequacy:: For Solid Section: For Hollow SectionAmmar A. AliNo ratings yet

- Prof. Connor Section 5: Non-Linear Analysis of Members 5.1 Deformation AnalysisDocument17 pagesProf. Connor Section 5: Non-Linear Analysis of Members 5.1 Deformation AnalysisAmmar A. AliNo ratings yet

- 08 Plasticity 01 Introduction PDFDocument11 pages08 Plasticity 01 Introduction PDFAmmar A. AliNo ratings yet

- 1 s2.0 S1877705816327643 MainDocument7 pages1 s2.0 S1877705816327643 MainAmmar A. AliNo ratings yet

- Supplemented Companies As: Memo To Designers APRIL 1989 17-130Document3 pagesSupplemented Companies As: Memo To Designers APRIL 1989 17-130Ammar A. AliNo ratings yet

- Prediction of Short and Long-Term Deflections of Two-Way Edge-Supported Reinforced Concrete Slabs Using Artificial Neural NetworkDocument10 pagesPrediction of Short and Long-Term Deflections of Two-Way Edge-Supported Reinforced Concrete Slabs Using Artificial Neural NetworkAmmar A. AliNo ratings yet

- Kick GuiDocument6 pagesKick GuiPR1CE AlexandreNo ratings yet

- Evolution of Quality ManagementDocument12 pagesEvolution of Quality ManagementOmair Aziz RabbaniNo ratings yet

- 2008 f250f350f450Document80 pages2008 f250f350f450perkinsaustinw50% (4)

- Yamaha-KX-380 480 580 Owner's Manual enDocument19 pagesYamaha-KX-380 480 580 Owner's Manual enkilol00% (1)

- Coro CleanDocument18 pagesCoro Cleanlaminar ersNo ratings yet

- Documen en BI SAPDocument115 pagesDocumen en BI SAPNeil Alarcon QuispeNo ratings yet

- DeskView Client 6 45 enDocument166 pagesDeskView Client 6 45 enRazvan22081997No ratings yet

- Demonstration Rating SheetDocument3 pagesDemonstration Rating SheetJay Mark ReponteNo ratings yet

- Ringo Gate Globe Check ValvesDocument28 pagesRingo Gate Globe Check ValvesRIGOBERTO PONCENo ratings yet

- Raspberry Pi CertificationDocument6 pagesRaspberry Pi CertificationVskills CertificationNo ratings yet

- Oil Cooler - As Built-ModelDocument1 pageOil Cooler - As Built-ModelbasvkaranNo ratings yet

- Title: AuthorsDocument14 pagesTitle: AuthorsKrishnadas GopalakrishnanNo ratings yet

- Fiber Optic TutorialDocument22 pagesFiber Optic TutorialimquantumNo ratings yet

- Manage Your Bookings PDFDocument2 pagesManage Your Bookings PDFdimas bawazierNo ratings yet

- Alcatel-Lucent 1870 Transport Tera Switch (TTS) : Addressing The Exaflood ChallengeDocument8 pagesAlcatel-Lucent 1870 Transport Tera Switch (TTS) : Addressing The Exaflood ChallengeMarco SurcaNo ratings yet

- Udyam Registration CertificateDocument1 pageUdyam Registration Certificatesabir hussainNo ratings yet

- BAib12017-02 Guideline On Conceptual Design and Engineering Requirements For CSSU PDFDocument76 pagesBAib12017-02 Guideline On Conceptual Design and Engineering Requirements For CSSU PDFfispl100% (1)

- WhatDocument4 pagesWhatMichael HutagalungNo ratings yet

- Mazda 626 1994Document58 pagesMazda 626 1994PEDRO CAIPANo ratings yet

- B&W 6l16-24 Combustian Air System 15Document15 pagesB&W 6l16-24 Combustian Air System 15wilson0% (1)

- 103 Blast Nozzle GaugeDocument1 page103 Blast Nozzle GaugeThiti SoonthornvatinNo ratings yet

- The Effectiveness of Data Processors in Correlation To GDPRDocument12 pagesThe Effectiveness of Data Processors in Correlation To GDPROliver SmithNo ratings yet

- Remote Approach For Effective Task Executin and Data Accessing ToolDocument48 pagesRemote Approach For Effective Task Executin and Data Accessing ToolWong Kai WeiNo ratings yet

- MassRoots Corporate Overview Deck July 2017Document16 pagesMassRoots Corporate Overview Deck July 2017Isaac DietrichNo ratings yet

- Governing of Pelton WheelDocument3 pagesGoverning of Pelton WheelErica100% (1)

- Basic ElectronicsDocument10 pagesBasic ElectronicsKENZO LAREDONo ratings yet

- Shumatt Popular Common Rail Diesel Parts 202304Document7 pagesShumatt Popular Common Rail Diesel Parts 202304idris.ballouNo ratings yet

- Animation Opengl ProgramDocument3 pagesAnimation Opengl Program3BR20CS400 Alisha SNo ratings yet