Professional Documents

Culture Documents

Abstract Six Sigma

Uploaded by

Anonymous GGtvR65MR0 ratings0% found this document useful (0 votes)

12 views1 pageAbstract Six Sigma

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAbstract Six Sigma

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 pageAbstract Six Sigma

Uploaded by

Anonymous GGtvR65MRAbstract Six Sigma

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

Abstract

Implementation of Six-Sigma in Motorola

By

Arjun Radhakrishnan 13ME217

Sumukha M Harish 13ME269

Variability and defects in products have been inherent characteristics of production. Variation

can be attributed towards creating inconsistent processes. These inconsistent processes lead to

different experiences for different customers. Experts in the field of quality have been

fighting variation for decades. Defects on the other hand hamper the quality of production.

Quality assurance being the foremost promise of the company to its customers, defects in

production lead to the deterioration of the companys standards and its image in the market.

The Six Sigma philosophy stems from the belief that statistics and numerical facts can be

used to control the quality of manufacturing processes and service organizations. Six Sigma

is a systematic way of thinking to solve quality problems. Six sigma involves use of statistics

to convert raw data into facts about how the processes of the organization are being run. The

thrust is on creating processes which can replicate the same results over and over again with

near 100% predictability. With the implementation of Six Sigma an accuracy of 99.99966%

in production can be obtained corresponding to 3.4 defects per million opportunities.

To beat growing technological and quality demands and to stay in close competition with the

Japanese and Chinese companies, America based company Motorola challenged itself to

improve the performance in the market ten-fold over a period of five years. Mike Harry and

Bill Smith after analysing this situation developed a solution to this problem. Bob Galvin,

CEO of Motorola later launched a long term quality program called Six Sigma Quality

Program. Looking at the success of Motorola, many companies like Texas Instruments and

Allied Signal started using Six Sigma methodology to bring organization-wide

improvements. Today almost every major organization in the world is following Six Sigma

initiatives and making their processes more controlled and more predictable.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Octavia LeafletDocument28 pagesOctavia LeafletAnonymous GGtvR65MRNo ratings yet

- NITK PG R Curriculum 2014-1 2 PDFDocument384 pagesNITK PG R Curriculum 2014-1 2 PDFRamesh BabuNo ratings yet

- Training and Developing EmployeesDocument12 pagesTraining and Developing EmployeesAnonymous GGtvR65MRNo ratings yet

- Refrigeration Cycle Assignment QuestionsDocument3 pagesRefrigeration Cycle Assignment QuestionsAnonymous GGtvR65MRNo ratings yet

- Feedwater Heater - Regeneration Analysis - HandbookDocument19 pagesFeedwater Heater - Regeneration Analysis - HandbookAnonymous wIPMQ5rhNo ratings yet

- Sales TrainingDocument46 pagesSales TrainingArturo GmoraNo ratings yet

- 6th Sem TimetableDocument1 page6th Sem TimetableAnonymous GGtvR65MRNo ratings yet

- Differential Equations NotesDocument7 pagesDifferential Equations NotesAnonymous GGtvR65MRNo ratings yet

- Iterative MethodsDocument9 pagesIterative MethodsArun MahalingamNo ratings yet

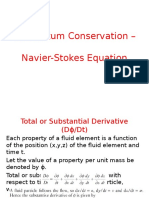

- Momentum ConservationDocument16 pagesMomentum ConservationAnonymous GGtvR65MRNo ratings yet

- 1D Convection-Diffusion Problem PDFDocument13 pages1D Convection-Diffusion Problem PDFAnonymous GGtvR65MRNo ratings yet

- Mass Conservation - Continuity EquationDocument6 pagesMass Conservation - Continuity EquationAnonymous GGtvR65MRNo ratings yet

- Implementing Six Sigma at MotorolaDocument18 pagesImplementing Six Sigma at MotorolaAnonymous GGtvR65MR75% (4)

- Flywheel (SSR)Document4 pagesFlywheel (SSR)Anonymous GGtvR65MRNo ratings yet

- Byte of PythonDocument174 pagesByte of PythonJohnNo ratings yet

- Momentum ConservationDocument16 pagesMomentum ConservationAnonymous GGtvR65MRNo ratings yet

- Jmeter Distributed Testing Step by StepDocument4 pagesJmeter Distributed Testing Step by StepShunSetiyabudiNo ratings yet

- MCQDocument20 pagesMCQPeter Osundwa Kiteki100% (1)

- Reynolds Transport TheoremDocument15 pagesReynolds Transport TheoremAnonymous GGtvR65MR100% (1)

- Godrej About Us - Godrej GroupDocument10 pagesGodrej About Us - Godrej GroupAnonymous GGtvR65MRNo ratings yet

- Metal Casting Processes ChapterDocument31 pagesMetal Casting Processes ChapterAnonymous GGtvR65MRNo ratings yet

- Computer Assisted Part ProgrammingDocument21 pagesComputer Assisted Part ProgrammingSanthan SalaiNo ratings yet

- Slider CrankDocument3 pagesSlider CrankAnonymous GGtvR65MR100% (1)

- Cylindrical CoordinatesDocument53 pagesCylindrical CoordinatesAnonymous GGtvR65MRNo ratings yet

- Engineering Circuit AnalysisDocument37 pagesEngineering Circuit AnalysisAnonymous GGtvR65MRNo ratings yet

- Chetan Bhagat - Three Mistakes of My LifeDocument144 pagesChetan Bhagat - Three Mistakes of My LifeGayathri ParthasarathyNo ratings yet

- 10 1 1 157Document11 pages10 1 1 157Subbu PalletiNo ratings yet

- J K ROWLING - Spells of Harry PotterDocument2 pagesJ K ROWLING - Spells of Harry Pottersarah100% (19)

- M.Tech. (IT) admission and application details at IIIT AllahabadDocument28 pagesM.Tech. (IT) admission and application details at IIIT AllahabadAsheesh PandeyNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)