Professional Documents

Culture Documents

BeschreibungOmniconeCrushersRF5199 1

BeschreibungOmniconeCrushersRF5199 1

Uploaded by

estramilsolution100%(1)100% found this document useful (1 vote)

172 views10 pagesomnicone

Original Title

BeschreibungOmniconeCrushersRF5199-1-

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentomnicone

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

172 views10 pagesBeschreibungOmniconeCrushersRF5199 1

BeschreibungOmniconeCrushersRF5199 1

Uploaded by

estramilsolutionomnicone

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

Cox ae

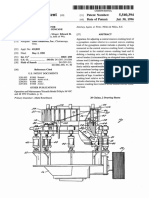

Omnicone

crushers

7-1 OMNICONE CRUSHERS,

EASY TO OPERATE, ADJUST AND MAINTAIN

Hydraulic Control Setting

Omnicone Crushers are equipped with a

fingertip hydraulic control that adjusts the

crusher setting, for optimum performance,

while the crusher is operating under load.

All operator controls are conveniently

mounted on a remote control console to

eliminate the need for an operator to ao-

‘roach the crusher during operation.

Hydraulic Release & Clearing

Each Omnicone features a hydraulic

system that provides a sate and fast way to

lear a jammed cavity. Should the crusher

become plugged, the operator merely

pushes levers on the remote control console

to clear the crusher.

OMNICONE CRUSHERS 7-2

The release cylinders are double acting, They

supply the clamping force to hold the ad-

jusiment ring securely to the frame and also

act as clearing jacks by raising the adjust:

ment ring bow! and hopper.

(Once the clearing stroke has been reached

the crusher can be jogged, if needed, so that

material clogging the cavity falls out.

When the cavity has been cleared, the

operator simply pulls back on the release

control levers to return the crusher back to

the original setting. Omnicone crushers can

be cleared and back in operation within

15 minutes.

7-3 OMNICONE CRUSHERS SPECIFICATIONS

Standard Omni h

nda mnicone crushers.

“cresting | =

Cavities + Feed openings + Product sizes » Capacities | coves open

eGUMEAPED | accommenneonmomncrsermes TT | ae fee pve Cy Te

OPEN CIRCUIT TYPE OF DISCHARGE 8 3 sores samy | fren {49m | (22my | (mm) | 4m |

1352 | Meoium 4 (1¢mmp 64" (162mm) TH" 119%} I |oyas | 1 190 | 220 | 250 | 260 ood

Fine ier 7a fe0omm ‘2am Wo | 200) 20 | 3s | 200 {sermon wrdersze) roca cue at

FEED OPENING WITH MIN. “er (gammy |" (16mm) | Ho (1Gmmy |e P2mm) | 1 (25mm) | 14 |Stmm) | 11" nny | 2" (50mm)

recqumenneo | scconSRO ee, eign Cs tee ctee Le eg Leal ear Final

‘CLOSED CIRCUIT MopeL| CAVITY SETTING A CLOSED Sine OPENSIDE [Rote 1] Note 2| Note 1] Note 2] Note 1 [Note 2|Note {[Note 2] Note 1 [Note 2|Note 1|Note 2] Note 1 [Note 2| Note 1[Note 2

Fine We t16men} 7%" (200mm) 9” (220r0n) | vss | 203) 185 | 280 eo | 240 | 310 | 24s | 25

Short Head Omni h

Cavities « Feed openings « Product sizes « Capacities a Ee a

FEGOMMENDED necommENveDoiscHaRGeserTBGA | | | ge | oge | we | Loy 7

TYPEOF DISCHARGE 8 8 siminy | ¢Geum) | cxGrvoy | ¢s3mm | x6 ram) | (Sem) ee tft

OPEN CIRCUIT movet| CAVITY SETTING A CLOSED SIDE OPEN SIDE

1860 (Smt 4 (202mm) is" (140mm ts | 210 | 260 | 200 rigneg prot pha

FEED OPENING WITH MIN. 7h wm} [| _" {6rmmj [ %" (10mm) | ¥" (1dmm) | wenn) |e tammy Lemmy |

RECOMMENDED RECOMMENDED DISCHARGE SETTING A fre SEOs oar Snr tetra CoS che ON :

‘CLOSED CIRCUIT Fine Pha ( Sma) | Ve" ( Sermmy 2 { Sirm) ss Tao] eof ss] asf rs) wo] 95 10

‘capacities in. 1144 | Medium: "| mm} V's" { 48mm) 3" 4 76mm) | | 80 | 105] 95 330

‘tons (2000 tb.) per hour Coarse 38° (10mm) 2%" ( 60mm) Sw" 80mm) a5 | 15 | 105 150 | 190 | 190 | 150 | 195,

Coarse AY {9mm 6" _{i5emm) 796" [Bare | 135 | 205 | 185 250 | 240 | 320 | 260] 350

OMNICONE CRUSHERS 7-4

LINER SELECTION

uonoeyes soul]

O9sl , wot

Yn wee wus

ANOOINWO ym m

L. A / Z J GHVANVIS

wwangeat —/ wna ances, /

's

[7 6

a = =

yo

Li NOLLWOrdd¥

ey 4

wy / SY 7 x Qv3H 1YOHS

ww7st & 09 wwZ0l Ue

aSuvOO wniasw EINE]

LINER SELECTION

7-5 OMNICONE CRUSHERS

uonoejes J0ul}

cSEL

ANOSINWO

wig 2 8

&

wUEE sie

asuvoo

wniaaw

»,

wwe

[> swess A Hi

/ J]

/} wusiidve N

/ eN/ GHYVONVIS

JOLLVONdd¥

NOILWONdd¥

GV3H LYOHS

OMNICONE CRUSHERS 7-6

LINER SELECTION

uondejes seul]

brie

SNOSINWO

.

WU LL 9

v

asuvoo

~

wut 81

wniaaw

&

J

umse Ke //

v4

opnuew

aNIS

jmoq

NOLLWONddY

GYVONVLS:

NOLLWONdd¥

V3H LHOHS

7-7 OMNICONE CRUSHERS WEIGHTS

WEIGHTS

Model 1144 Model 1352 Model 1560

Kg. Lbs. Kg Lbs. Kg. Lbs.

Crusher Complete

14330 [ 31530 [ 22600 [ 49720 [ 29350 | 64,570

Main Frame, Adjustment Ring, Tramp Release, Eocentric, Socket, Countershaft

and Crusher Sheave

8,295 18,250 14,080 30,980 | 16900 | 37,180

Main Frame, Adjustment Ring and Tramp Release

7,045 15,500 11,535 25,380 | 13.780 | 30,320

Main Frame, Including Mainshaft and Main Frame Liner

3,070 6750 5.110 11240 [6,050 7710

Bowl, Bow! Liner and Hopper

3,635 8,000 5,560 12,230 [7,820 17,200

Head, Mantle and Locking Nut and Collar

2,180 4800 2,690 5,920 4330 9.530

Countershaft and Crusher Sheave

400 880 730 1,610 900 1,980

Eccentric

700 1540 1,640 3610 | 1,970 4330

Socket

150 330 175 385 250 550

Mantle

525) 1.160 810 1,780 1,340 2,950

Bow! Liner

865 1.900 1.220 2,680 7870 4,110

Feed Platform

220 480 [270 590 300 660

Since various assembly combinations are available in each crusher size, and because of manufacturing

variations, the weights shown above are approximate,

All weights can vary + 5%.

DIMENSIONS OMNICONE CRUSHERS 7-8

CLEARNACE DIMENSIONS

iitdal hb 1144 1352

tim ih am im

‘A_[_MainFrame Flange | 910 | 2-11%" | 1,080 1,225

bi MainFrame Flange | 910 | 2-11¥" | 1080 1215

[& [7 MainFrame Flange [910 [ 2-117" | 1,060 1,225

o Main Frame

Hub Diameter 450_| rsx" | 500 580 _| 1-107"

E | To Bottom of Main

Frame Hub 60 | o-2m | 160_| one” | 140 | 0-52"

F To Bottom of

011 Piping 195 | o-7xe" | 315 | tm" | 300

& [To Tap of Dust Collar

(Hydraulic) 1445, 1575 | 5-2" | 1,795

H | Adjustment Ring

Maximum Diameter | 2340 | 7-8%" | 2580 | 8-5%" | 2.900

T | Clearance Requires

for Removing Counter-

shaft Assembly 1900 | 62%" | 2500 | a-2%" | 3.045 | o-11%"

To End of Countershatt | 1290 [| 4-2%" [1525 | S-w" | 1640 | 5.4%”

T | Maximum Height to

Top of Feed Hooper | 1,790 | 5-10" | 1,960 | 6-5%" | 2200 | 7-25"

W | _ Inside Diameter of

Feed Hopper 1148_| s-9m" | 1.334 | 4-6" | 1586 | 5-21"

N | ToTopofFeedPiate [ 1290 | 4.2%" [| 1a20 [| 4-8" | 1710 | 5.7%"

0 To Top of Feed

Platlorm: 1940 | 6-49" | eta | reve | 2425 | 711"

P| Overall Height of Bow

Assembly (Lo, Std

Liner Protages

Below Bowl) goo | sea" | 1,035 | aaa” | 1.060 | 35%"

a Adjustment Cap

Maximum Oiameter

(Hydrauitc) 1990 | e-6%" | 2180 | 71%" | 2976 | 79%"

R_ | Clearance Required

for Removing Bow!

Assembly 2485 | 91%" | 2660 | 8-8%" | 2905

5 Overall Height of

Head Assembly 30 | a-ew | 915 | sew" | 1.226 | 4m"

T Head or Mantle

Maximum Diameter | 1,150 | 9-9%" | 1345 | 4-5" | 1560_| 51%

U | Glearance Required

for Removing Head

Assembly 2a30_| 77%" | 2540 | ea" | 3070 | 10-1"

v Tramp Release

Across Corners 2is0_| 7-4" | 2570 | 8-54" | 2900

W | Additional Upwarc

Travel Ove to

Clearing Stroke 76

x ‘Mounting Holes 660

a3 fo-sw' | t20__| o-a%

a2 | 28%" | 83 | 2-10%

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Compavtadora AsfaltadoraDocument224 pagesCompavtadora AsfaltadoraestramilsolutionNo ratings yet

- World Famous Tiles Recycled in World Famous VSI - MetsoDocument4 pagesWorld Famous Tiles Recycled in World Famous VSI - MetsoestramilsolutionNo ratings yet

- 973-0014-1 ALLIS-CHALMERS 3500 MK2 Engine Drive & Optional Equipment Parts Manual (09-1974)Document44 pages973-0014-1 ALLIS-CHALMERS 3500 MK2 Engine Drive & Optional Equipment Parts Manual (09-1974)estramilsolutionNo ratings yet

- CSD Rise Ultra Wrap ManualDocument36 pagesCSD Rise Ultra Wrap ManualestramilsolutionNo ratings yet

- VSI Crushers-2010-HistoryBuildup PhotosDocument76 pagesVSI Crushers-2010-HistoryBuildup PhotosestramilsolutionNo ratings yet

- Terex Simplicity Vibrating Feeders: Terex Minerals Processing SystemsDocument6 pagesTerex Simplicity Vibrating Feeders: Terex Minerals Processing SystemsestramilsolutionNo ratings yet

- Conceptual Flow Sheets Development For Coal Conversion Plant Coal Handling-Preparation and Ash/Slag Removal OperationsDocument221 pagesConceptual Flow Sheets Development For Coal Conversion Plant Coal Handling-Preparation and Ash/Slag Removal OperationsestramilsolutionNo ratings yet

- Metal Detectors MA 3000Document4 pagesMetal Detectors MA 3000estramilsolution100% (1)

- NEW ConesGyraRollDocument4 pagesNEW ConesGyraRollestramilsolutionNo ratings yet

- ExtraDocument1 pageExtraestramilsolutionNo ratings yet

- Chapter1 10 PDFDocument84 pagesChapter1 10 PDFestramilsolutionNo ratings yet

- ManganesDocument118 pagesManganesestramilsolutionNo ratings yet

- Vltraflo Vibrating Feeders & ScreenDocument4 pagesVltraflo Vibrating Feeders & ScreenestramilsolutionNo ratings yet

- Alimentateur PDFDocument4 pagesAlimentateur PDFestramilsolutionNo ratings yet

- Rotex Brochure PDFDocument4 pagesRotex Brochure PDFestramilsolutionNo ratings yet

- Chapter1 10 PDFDocument84 pagesChapter1 10 PDFestramilsolutionNo ratings yet

- Us 5540394Document10 pagesUs 5540394estramilsolutionNo ratings yet

- Principles of Screening and Sizing PDFDocument63 pagesPrinciples of Screening and Sizing PDFestramilsolutionNo ratings yet

- Biobaler LP 2014Document124 pagesBiobaler LP 2014estramilsolutionNo ratings yet

- 39 ConeCrushersDocument8 pages39 ConeCrushersestramilsolutionNo ratings yet

- LT3387 Loctite Nordback Backing MaterialsDocument4 pagesLT3387 Loctite Nordback Backing MaterialsestramilsolutionNo ratings yet