Professional Documents

Culture Documents

Stress Calculation

Uploaded by

ognen88Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stress Calculation

Uploaded by

ognen88Copyright:

Available Formats

Stress Analysis on Truck Chassis using Finite Element Analysis

55

Stress Analysis on Truck Chassis Using Finite Element Analysis

S. Prabhu

Senior lecturer, School of Mechanical Engineering, S. R. M. University, Chennai, India

ABSTRACT: In this work a stress analysis of a truck chassis was performed through FEA. The truck chassis was modeled

using PRO/E and the commercial finite element package ANSYS 5.7 was used to solve the problem. The joint area with

the max stress was identified using the above software package. In order to achieve a reduction in the magnitude of stress

near the riveted joints area, local plates were introduced.

Keywords: FEA, Stress analysis, Truck chassis

1. INTRODUCTION

Many engineering structures and machines consist of

components suitably connected through carefully

designed joints. In metallic materials, these joints may

take a number of different forms, as for example welded

joints, bolted joints and riveted joints. In general such

joints are subjected to complex stress states under loading

since the joints are quite complex in nature there would

manifest severe stress discontinuities that cannot be

calculated using closed form solutions it is in such

situations finite element analysis lends itself as an

indispensable tool. Good design of connections is a

mixture of stress analysis and experience of the behavior

of actual joints; this is particularly true of connections

subjected to repeated loads.

Cicek karaoglu, et al. [1] proposed stress analysis of

a truck chassis with riveted joints was performed by

using FEM. The commercial finite element package

ANSYS version 5.3 was used for the solution of the

problem. Determination of the stresses of a truck chassis

before manufacturing is important due to the design

improvement. Naveen Rastogi [2] proposed the detailed

finite element analysis steps illustrated here demonstrate

a method for accurately analyzing and designing an

automotive composite chassis structure. J. Moreno [3]

presents a method to determine the stress intensity factor

in riveted steel beams. The cracked component interacts

with the remaining plates and angles of the beam by

means of the rivets close to the crack, and this interaction

is incorporated into the modeling to compute the stress

intensity factor. P. M. G. P. Moreira, et al., [4] focused on

one geometry, a single-lap splice with three rivets rows

and one rivet column. A three-dimensional stress

analysis using the finite element method was carried out

in order to analyze the load transfer as a function of crack

geometry and length, and to determine the stress

*corresponding author: Prabhume@yahoo.co.in

intensity factors for one or two cracks emanating from

the edge of the hole located at the critical cross section.

1.1 Stress Analysis

Stress analysis is an engineering discipline that

determines the stress and strain in materials and

structures subjected to static or dynamic forces or loads.

The aim of the analysis is usually to determine whether

the element or collection of elements, usually referred to

a structure, can safely withstand the specified forces. This

is achieved when the determined stress from the applied

force(s) is less than the allowable strength, or fatigue

strength the material is known to be able to withstand,

though ordinarily a safety factor is applied in design. A

key part of analysis involves determining the type of

loads acting on a structure, including tension,

compression, shear, torsion, bending, or combinations

thereof such loads. Sometimes the term stress analysis is

applied to mathematical or computational methods

applied to structures that do not yet exist, such as a

proposed aerodynamic structure, or to large structures

such as a building, a machine, a reactor vessel or a piping

system.

A stress analysis can also be made by actually

applying the force(s) to an existing element or structure

and then determining the resulting stress using sensors,

but in this case the process would more properly be

known as testing (destructive or non-destructive). In this

case special equipment, such as a wind tunnel, or various

hydraulic mechanisms, or simply weights is used to

apply the static or dynamic loading. When forces are

applied, or expected to be applied, repeatedly, nearly

all materials will rupture or fail at a lower stress than

they would otherwise. The analysis to determine stresses

under these dynamically forced conditions is termed

fatigue analysis and is most often applied to aerodynamic

structural systems.

IJME January-June 2013 Volume 6 Issue 1

56

S. Prabhu

1.2 FEA

Finite Element Analysis is a technique to simulate loading

conditions on a design and determine the designs

response to those conditions. The design is modeled

using discrete building blocks called elements. Each

element has exact equations that describe how it responds

to a certain load. The sum of the response of all elements

in the model gives the total response of the design.

The finite element model, which has a finite number

of unknowns, can only approximate the response of the

physical system, which has infinite unknowns. It

depends entirely on what we are simulation and the tools

we use for the simulation. Guidelines are provided

throughout this volume to perform various types of

analysis.

2. TRUCK AND CHASSIS

2.1 Parts of Truck

The different parts of a truck are body, axle, chassis

frame, transmission, engine and Cab.

consisting of side and cross members. The conventional

chassis frame, which is made of pressed steel members,

can be considered structurally as grillages. The chassis

frame includes cross-members located at critical stress

points along the side members. To provide a rigid, boxlike structure, the cross-members secure the two main

rails in a parallel position. The cross-members are usually

attached to the side members by connection plates.

2.1.4. Transmission

Small trucks use the same type of transmission as almost

all cars which have either an automatic transmission or

a manual transmission with synchronizers. Bigger trucks

often use manual transmissions without synchronizers

which are lighter weight although some synchronized

transmissions have been used in larger trucks.

Transmissions without synchronizers require either

double clutching for each shift, (which can lead to

repetitive motion injuries,) or a technique known

colloquially as floating, a method of shifting which

doesnt use the clutch, except for starts and stops.

2.1.5. Engine

2.1.1. Body

Specific body structures such as flatbeds, standard vans,

box vans, dump-truck deep-beds, tankers, concrete

mixers etc. permit the economical and efficient

transportation of a wide variety of goods and materials.

Connection between body and load-bearing chassis

frame is effected in part by means of auxiliary frames.

Truck assemblies

1 Body, 2 Axle, 3 Chassis frame,

4 Transmission, 5 Engine, 6 Cab

An engine is something that produces an effect from a

given input.

2.1.6. Cab

The cab is an enclosed space where the driver is seated.

There are a variety of cab designs available depending

on the vehicle concept. In delivery vehicles and vans,

low, convenient entrances are an advantage, whereas in

long-distance transport space and comfort are more

important. The type of cab configurations are cab-overengine (COE) and cab-behind-engine.

2.2 Functions of Chassis Frame

Fig. 1: Truck Assembly

2.1.2. Axle

An axle is a central shaft for a rotating wheel or gear. In

some cases the axle may be fixed in position with a

bearing or bushing sitting inside the hole in the wheel

or gear to allow the wheel or gear to rotate around the

axle. In other cases the wheel or gear may be fixed to the

axle, with bearings or bushings provided at the mounting

points where the axle is supported.

2.1.3. Chassis Frame

The chassis frame is the commercial vehicles actual load

bearing element. It is designed as a ladder type frame,

IJME January-June 2013 Volume 6 Issue 1

The chassis frame is the commercial vehicles actual load

bearing element. It is designed as a ladder type frame,

consisting of side and cross members. The choice of

profiles decides the level of torsional stiffness.

Torsionally flexible frames are preferred in medium and

heavy duty trucks because they enable the suspension

to comply better with uneven terrain. Torsionally stiff

frames are more suitable for smaller delivery vehicles

and vans. Critical points in the chassis-frame design are

the side-member and the cross-member junctions. Special

gusset plates or pressed cross-member sections form a

broad connection basis. These junctions are riveted,

bolted and welded. The conventional chassis frame,

which is made of pressed steel members, can be

considered structurally as grillages. The chassis frame

includes cross-members located at critical stress points

along the side members. To provide a rigid, box-like

structure, the cross-members secure the two main rails

Stress Analysis on Truck Chassis using Finite Element Analysis

57

in a parallel position. The cross-members are usually

attached to the side members by connection plates. The

joint is riveted or bolted in trucks and is welded in

trailers. When rivets are used, the holes in the chassis

frame are drilled approximately 1/16 in larger than the

diameter of the rivet. The rivets are then heated to an

incandescent red and driven home by hydraulic or air

pressure. The hot rivets conform to the shape of the hole

and tighten upon cooling. An advantage of this

connection is that it increases the chassis flexibility.

Therefore, high stresses are prevented in critical area.

The side- and cross-members are usually open-sectioned,

because they are cheap and easily attached with rivets.

2.3 Parts of a Truck Chassis Frame

The different parts of a conventional truck chassis frame

are Side members, Cross members and Gusset plates or

connection plates.

Figure 3: Installation of a Riveter

Figure 4: Riveting Operations on a Truck Chassis

Figure 2: Parts of a Truck Chassis Frame

In case of riveting, if its rivet is longer in length or

irregular in hole diameter, the rivet will be fully

expanded in the hole, then the rivet head will be

formed; therefore it makes no looseness in cooling,

sealing or against vibrations.

Caulking is not necessary because no extra tension

is added to the rivet.

2.4 Riveting Operation on Truck Chassis

A monorail shall be provided above the operating places

and the trolley compiled with the balancer shall be hung

down from the monorail. The generator shall be installed

at the place where it will be free from troubles and

operation. The high pressure steel pipe shall be arranged

from the generator to the center upper portion of

operating position, then high pressure hose shall be

connected between the pipe end and riveter the piping

shall be fixed at near by columns or supporting beams,

with clamps for protection against vibration the hose

shall be fixed with spring bands in order to flexure;

however its fixing shall not affect the operation of riveter.

Advantages of Cold Riveting

The heating equipment and its operator

are unnecessary. Handing of rivet is easy,

accordingly.

2.5 Loads on the Chassis Frame

All vehicles are subjected to both static and dynamic

loads. Dynamic loads result from inertia forces arising

from driving on uneven surfaces. Loads acting in the

frame cause bending or twisting of the side and the crossmembers. Symmetric loads acting in the vertical direction

predominantly cause the bending in side members.

Vertical loads additionally arise from lateral forces acting

parallel to the frames plane, e.g. during cornering. Loads

acting in the plane of frame cause bending of the side

members and of the cross-members.

IJME January-June 2013 Volume 6 Issue 1

58

S. Prabhu

Fig 5: Chassis Frame

2.6 Material Data

Table 1

Material Data

Material

HSLA Steel to Ashok Leyland

Standard for ALMDV Models Having

Youngs Modulus (E) 2.6*105 N/mm2

and Poisson Ratio () 0.3.

Chemical Composition

Carbon-0.16% max

Silicon- 0.15-0.35% max

Manganese- 0.8-1.3% max

Phosphorus-0.02-0.05% max

Figure 8: Zoomed View of Applied load

4.2 Stress Distribution at Joint Areas

4.2.1 Stress Distribution Across Joint 1

3. MODELLING AND MESHING OF

TRUCK CHASSIS

3.1 Pro-E Model of the Designed Chassis

Figure. 9: Nominal Loading at Joint 1

Figure 6: Meshed Chassis

4. STRESS ANALYSIS

4.1 Load Applied On the Model

Figure 7: Load Applied

IJME January-June 2013 Volume 6 Issue 1

Figure 10: Stresses at Maximum Load Condition on Joint 1

Stress Analysis on Truck Chassis using Finite Element Analysis

59

4.2.2 Stress Distribution Across Joint 2

Figure 11: Stress Distribution On Nominal loading In Joint 2

Figure 14: Stress Distribution at Joint 3 on Maximum

Load condition

4.2.4 Stress Distribution Across Joint 4

Figure 12: Stress Distribution at Joint 2 on Maximum

Load Condition

Figure 15: Stress Distribution on Nominal loading In Joint 4

4.2.3 Stress Distribution Across Joint 3

Figure 13: Stress Distribution on Nominal loading In Joint 3

Figure 16: Stress Distribution at Joint 4 on Maximum Load

Condition

IJME January-June 2013 Volume 6 Issue 1

60

S. Prabhu

4.2.5 Stress Distribution Across Joint 5

Figure 20: Stress Distribution at Joint 6 on Maximum

Load condition

Figure 17: Stress Distribution on Nominal loading

In Joint 5

5. RESULTS AND DISCUSSION

From the analysis performed the maximum stress was

found to be at joint area 5 the respective graphs shown

below clearly signifies that at the maximum loading

condition the stress was found to be 151.98 N/mm.

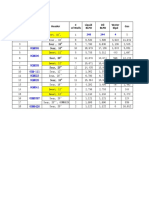

Table 2

Stress Distribution Across the Joints

Joint area number

Figure 18:Stress Distribution at Joint 5 on Maximum Load

condition

4.2.6 Stress Distribution Across Joint 6

Figure 19: Stress Distribution on Nominal loading In Joint 6

IJME January-June 2013 Volume 6 Issue 1

Stress at Nominal

loading (N/mm2)

Stress at Maximum

loading (N/mm2)

41

151

43

133

43

133

40

117

60

152

45

144

The reason for maximum stress in the joint area was

due to the presence of gap found between the gusset plate

(Connecting plate) and the side member as shown below.

Graph 1: Stress Distributions at Nominal Loading

Stress Analysis on Truck Chassis using Finite Element Analysis

61

CONCLUSION

From the stress analysis performed, the maximum stress

acting on the truck chassis was found to be at joint 5

(151N/mm2 ) and local plates can be introduced to reduce

the stress at the joint area. Furthermore, the stress value

of 151N/mm2 was found to be considerably lower than

the allowable stress of the material (288 N/mm2). Thus,

a suitable material can be selected and consequently a

reduction in the overall weight of the chassis can be

achieved.

REFERENCES

Graph 2: Stress Distributions at Maximum loading

[1]

Cicek karaoglu, et al., Stress Analysis of a Truck Chassis

with Riveted Joints, Finite Elements in Analysis and Design,

38(12), (2002), 1115 1130.

[2]

Naveen Rastogi, Stress Analysis and Lay-Up Optimization

of an All-Composite Pick-Up Truck Chassis Structure, SAE

International, 2004.

[3]

J. Moreno, Stress Intensity Factors in Riveted Steel Beams,

Engineering Failure Analysis, 11, (2004), 777787.

[4]

P. M. G. P. Moreira,Stress Intensity Factor and Load

Transfer Analysis of a Cracked Riveted Lap Joint, Materials

and Design, 28, (2007), 12631270.

[5]

Automotive Handbook, BOSCH, 5th Edition, Page 730-736.

[6]

A. H. Chilver, Strength of Materials and Structures, 2nd

Edition, Page 55-91.

Figure 21: Gap at Joint 5

To reduce the stress at the joint area 5 local plates

can be introduced as shown below.

Figure 22: Introduction of Local Plates at Joint 5

IJME January-June 2013 Volume 6 Issue 1

You might also like

- ALS 11ua Optical ScalesDocument1 pageALS 11ua Optical Scalesognen88No ratings yet

- FDocument5 pagesFBandula MahanamaNo ratings yet

- Highly Flexible: Keypad AlarmDocument66 pagesHighly Flexible: Keypad Alarmognen88No ratings yet

- Linear Scales (Encodes) : 1.1. HH: Microcontrol: Cross-Reference ComparisonDocument4 pagesLinear Scales (Encodes) : 1.1. HH: Microcontrol: Cross-Reference Comparisonognen88No ratings yet

- FDocument1 pageFognen88No ratings yet

- Introducing The Phizzyb: by Alan WinstanleyDocument10 pagesIntroducing The Phizzyb: by Alan Winstanleyognen88No ratings yet

- Quad 2-Input NAND Schmitt Trigger: ApplicationsDocument13 pagesQuad 2-Input NAND Schmitt Trigger: Applicationsognen88No ratings yet

- Ian Poole Reports On A New Device That Provides Both Current and Voltage ControlDocument2 pagesIan Poole Reports On A New Device That Provides Both Current and Voltage Controlsuperser123465No ratings yet

- "Tiptronic" Style: Gear IndicatorDocument65 pages"Tiptronic" Style: Gear Indicatorognen88No ratings yet

- Why The United Kingdom Should Join The Eurozone: DebateDocument14 pagesWhy The United Kingdom Should Join The Eurozone: Debateognen88No ratings yet

- Easy-PC For Windows 95: by Robert PenfoldDocument6 pagesEasy-PC For Windows 95: by Robert Penfoldsuperser123465No ratings yet

- Pic Tape Measure: Microcontrolled Ultrasonic Distance Calculator With Data Recording and Foreground MaskingDocument9 pagesPic Tape Measure: Microcontrolled Ultrasonic Distance Calculator With Data Recording and Foreground Maskingognen88No ratings yet

- Dijagnostika Fanuc 400 GreskaDocument1 pageDijagnostika Fanuc 400 Greskaognen88No ratings yet

- 1198d PDFDocument3 pages1198d PDFsuperser123465No ratings yet

- Methods To Determine Torsional Stiffness in A Semi-Trailer Chassis FrameDocument9 pagesMethods To Determine Torsional Stiffness in A Semi-Trailer Chassis Frameognen88No ratings yet

- 15-02319erik OlofssonRapportDocument64 pages15-02319erik OlofssonRapportMohamed MansourNo ratings yet

- Construction Equipment Lifting and TransportingDocument54 pagesConstruction Equipment Lifting and Transportingognen88No ratings yet

- Tar 35 5 2 1105 29Document8 pagesTar 35 5 2 1105 29ognen88No ratings yet

- Dijagnostika Fanuc 400 GreskaDocument1 pageDijagnostika Fanuc 400 Greskaognen88No ratings yet

- Fanuc 0M 0T C Alarm 401Document3 pagesFanuc 0M 0T C Alarm 401ognen8875% (4)

- AgieCharmile SP1UDocument20 pagesAgieCharmile SP1URezza KudoNo ratings yet

- Revised Conservation TillageDocument42 pagesRevised Conservation Tillageognen88No ratings yet

- Fanuc 0M 0T C Alarm 401Document3 pagesFanuc 0M 0T C Alarm 401ognen8875% (4)

- Modelling Vertical and Lateral Seed Bank Movements During Mouldboard PloughingDocument14 pagesModelling Vertical and Lateral Seed Bank Movements During Mouldboard Ploughingognen88No ratings yet

- RucinsDocument11 pagesRucinsognen88No ratings yet

- Tabla 137 C1830Document7 pagesTabla 137 C1830ognen88No ratings yet

- 03 IJAT 2012 8 (5) Javad Computer Agricultural Engineering TDocument9 pages03 IJAT 2012 8 (5) Javad Computer Agricultural Engineering Tognen88No ratings yet

- Ha Moldboard Plow PartsDocument18 pagesHa Moldboard Plow Partsognen88No ratings yet

- Draught Requirements of Enamel Coated Animal Drawn Mouldboard PloughDocument7 pagesDraught Requirements of Enamel Coated Animal Drawn Mouldboard Ploughognen88No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Bulletin Oct Dec 2011Document64 pagesBulletin Oct Dec 2011Abhijeeth NagarajNo ratings yet

- Gsas Check ListDocument10 pagesGsas Check ListΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Piled Raft Foundations: Examples of the Petronas Towers & Burj KhalifaDocument3 pagesPiled Raft Foundations: Examples of the Petronas Towers & Burj Khalifasuryakantame100% (1)

- Steel Design Problem SetxzDocument35 pagesSteel Design Problem SetxzMiah N. PascualNo ratings yet

- QM 05. Line PipesDocument2 pagesQM 05. Line Pipesmohamed elmasryNo ratings yet

- SERIES 5 QuestionsDocument6 pagesSERIES 5 QuestionsTon Ton BondaNo ratings yet

- Pendel Bearing Replacement at A9 Kessock Bridge, Scotland 2007Document9 pagesPendel Bearing Replacement at A9 Kessock Bridge, Scotland 2007정주호No ratings yet

- Proper gas appliance installation instructionsDocument35 pagesProper gas appliance installation instructionsMark NelsonNo ratings yet

- Progress and Invoice Calculation For General - ACTUAL PROGRESSDocument9 pagesProgress and Invoice Calculation For General - ACTUAL PROGRESSheri_prasetyadiNo ratings yet

- BOQ - OnlineDocument23 pagesBOQ - OnlinevenkateswararaoNo ratings yet

- Gulf Precast GRCDocument12 pagesGulf Precast GRCmujeebscribdNo ratings yet

- Appendix A Examples of Pavement DesignsDocument7 pagesAppendix A Examples of Pavement DesignsEdmund de LunaNo ratings yet

- Granular Sub Base-GsbDocument4 pagesGranular Sub Base-GsbCheng EngiNo ratings yet

- RefresherDocument3 pagesRefresherPrince Q Chan100% (1)

- BEAM 5m ACI-318-11Document1 pageBEAM 5m ACI-318-11AWOUNANGNo ratings yet

- Newtonian and Non-Newtonian Fluids: Velocity Profiles, Viscosity Data, and Laminar Flow Friction Factor Equations For Flow in A Circular DuctDocument9 pagesNewtonian and Non-Newtonian Fluids: Velocity Profiles, Viscosity Data, and Laminar Flow Friction Factor Equations For Flow in A Circular DuctAhmad JobNo ratings yet

- A Refined Model For Predicting Concrete-Related Failure Load of Tension Loaded Cast-in-Place Headed Anchors in Uncracked ConcreteDocument25 pagesA Refined Model For Predicting Concrete-Related Failure Load of Tension Loaded Cast-in-Place Headed Anchors in Uncracked ConcreteEng TrNo ratings yet

- GCE 4145 Foundry Engineering Lecture: Key Pattern Allowances for Casting DesignDocument18 pagesGCE 4145 Foundry Engineering Lecture: Key Pattern Allowances for Casting DesignAbdullah SubbirNo ratings yet

- Architectural DrawingsDocument33 pagesArchitectural DrawingserniE抖音 AI Mobile Phone Based MovieNo ratings yet

- Railway Engineering PDFDocument4 pagesRailway Engineering PDFmani67% (3)

- EBGEO Reinforced Wall DesignDocument34 pagesEBGEO Reinforced Wall DesignNizeyimana Jean BoscoNo ratings yet

- HFY-OGMs CapacityDocument47 pagesHFY-OGMs CapacityVignesh PanchabakesanNo ratings yet

- Wold Life-Safety Reports On Center Cass School District 66 SchoolsDocument8 pagesWold Life-Safety Reports On Center Cass School District 66 SchoolsDavid GiulianiNo ratings yet

- Labor Rates ProductivityDocument9 pagesLabor Rates ProductivityBienvenida Ycoy MontenegroNo ratings yet

- Sai Collapse Building Case StudyDocument7 pagesSai Collapse Building Case StudyRica Faye Nicole Miraflores100% (3)

- Axialsystemsincompressionandtensionincludingsap2000 160304165516Document446 pagesAxialsystemsincompressionandtensionincludingsap2000 160304165516Sara RamliNo ratings yet

- ASTAKEDocument27 pagesASTAKEcimpstazNo ratings yet

- Experiment #3: Energy Loss in Pipe FittingsDocument6 pagesExperiment #3: Energy Loss in Pipe FittingsMustafa AltarhoniNo ratings yet

- NFPA 14 2013 Update PDFDocument12 pagesNFPA 14 2013 Update PDFAnonymous qabSVjzrA100% (1)

- Diked & Spill Protection: Dike Protection Fixed Mount Low Level Foam MakersDocument5 pagesDiked & Spill Protection: Dike Protection Fixed Mount Low Level Foam MakersNattapong NattNo ratings yet