Professional Documents

Culture Documents

' / - , - /' (Initial Layer)

Uploaded by

Anonymous H7nHUOGUs0 ratings0% found this document useful (0 votes)

2 views1 pageBack Grouting

Original Title

Back Grouting

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBack Grouting

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views1 page' / - , - /' (Initial Layer)

Uploaded by

Anonymous H7nHUOGUsBack Grouting

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

" P \

\' _

- \

\ ' \_

I \

.

\ "'~_,

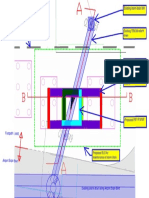

,. Sprayed Concrete layer no.1

, - /

'

(initial layer)

\ 1'.

u \

\ "' .\ .__

\ I

Q \

\ I.

0 \

_

Edge board fixed on rebar -~e__\

to form Corbel shape

T S _

. \

\

\

.

R10-300 Rebar

Bottom reinforcement layer P"

Rebar bended to suit

sprayed concrete layers

3.1.7

~

.

\\

0

1

-/ '

'\

.\\-.

.\~

\.

\\

for OHVD slab

lProfile anchors

\' '~ i.

1" _

0

'

'

ti

I\

n |

I\ ' ' _ -

Membrane

Back-grouting

Back-grouting will be filled up after 28-day and the magnitude of grouting pressure will be

0.5 bar maintain for 2 minutes to ensure the full of grout. The process will be in accordance

with manufactures recommendation.

The back-grouting procedures and method will be fully described under a separate method

statement submission.

3.1.8

Access to the crown

A mobile access platform / gantry will be used to provide safe access to the entire perimeter

surface of the tunnels for installation of membrane, fixing steel reinforcement and spraying

concrete by hand-spraying method. The platform will be certified by a competent person

and issued Form 5. The access platform /gantry shall be designed, erected and dismantled

by competent & trained operatives.

Access Gantry Elevated Workinq Platform for Tunnel Type A, B1, B2

Copyright Leighton. 2011

Page 12 of 28

904-MDS-LJH-TUN-117-04; 24 August 2013

You might also like

- Bridge Design Eurocodes Worked ExamplesDocument438 pagesBridge Design Eurocodes Worked Examplespradeepjoshi007100% (4)

- Interaction DiagramDocument15 pagesInteraction DiagramjungzkiNo ratings yet

- 2014 Tennis Catalogue P24 27 FootwearDocument2 pages2014 Tennis Catalogue P24 27 FootwearAnonymous H7nHUOGUsNo ratings yet

- Less $240 Less $140 $70 $220: Ref:Okas04Document1 pageLess $240 Less $140 $70 $220: Ref:Okas04Anonymous H7nHUOGUsNo ratings yet

- CFD HK CP 2013Document56 pagesCFD HK CP 2013Anonymous H7nHUOGUsNo ratings yet

- PreviewDocument2 pagesPreviewAnonymous H7nHUOGUsNo ratings yet

- Fitness Class - 4th QTR 2017Document2 pagesFitness Class - 4th QTR 2017Anonymous H7nHUOGUsNo ratings yet

- PersonalCoaching NewerDocument1 pagePersonalCoaching NewerAnonymous H7nHUOGUsNo ratings yet

- Introduction To The Institution PDFDocument9 pagesIntroduction To The Institution PDFAnonymous H7nHUOGUsNo ratings yet

- Publication Guide DayHikesInTheBanffArea LOWRES 2014Document2 pagesPublication Guide DayHikesInTheBanffArea LOWRES 2014Anonymous H7nHUOGUsNo ratings yet

- Herzog ShimmiDocument1 pageHerzog ShimmiAnonymous H7nHUOGUsNo ratings yet

- HKIE Seminar 20140320 - FinalDocument71 pagesHKIE Seminar 20140320 - FinalAnonymous H7nHUOGUsNo ratings yet

- 10 Year HDP - FinalDocument70 pages10 Year HDP - FinalAnonymous H7nHUOGUsNo ratings yet

- Ductile Iron Multi Span Covers - 713 MSF PYC PD 000364 102Document23 pagesDuctile Iron Multi Span Covers - 713 MSF PYC PD 000364 102Anonymous H7nHUOGUsNo ratings yet

- 9 SE 5B Default 000Document1 page9 SE 5B Default 000Anonymous H7nHUOGUsNo ratings yet

- Oi HKKLDocument311 pagesOi HKKLAnonymous H7nHUOGUsNo ratings yet

- Storm Drain Page 2Document1 pageStorm Drain Page 2Anonymous H7nHUOGUsNo ratings yet

- Check of Pile OverlapDocument1 pageCheck of Pile OverlapAnonymous H7nHUOGUsNo ratings yet

- Foundation Code 2004Document64 pagesFoundation Code 2004Patie Zheng100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)