0% found this document useful (0 votes)

302 views1 pageFYP Poster

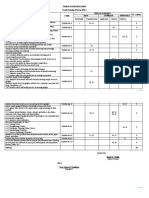

The document discusses the implementation of Total Productive Maintenance (TPM) at a flexographic printing area with a focus on 5S, Environment, Health and Safety (EHS), and Overall Equipment Effectiveness (OEE). TPM aims to minimize failures, defects, and accidents through a comprehensive equipment management approach. 5S and EHS methodologies were applied to improve the working environment, safety, and productivity. Key metrics like OEE, hazards reported, and injuries were tracked before and after the implementation, showing improvements like a 22% increase in OEE and 60% reduction in hazards reported.

Uploaded by

Muhammad HassanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

302 views1 pageFYP Poster

The document discusses the implementation of Total Productive Maintenance (TPM) at a flexographic printing area with a focus on 5S, Environment, Health and Safety (EHS), and Overall Equipment Effectiveness (OEE). TPM aims to minimize failures, defects, and accidents through a comprehensive equipment management approach. 5S and EHS methodologies were applied to improve the working environment, safety, and productivity. Key metrics like OEE, hazards reported, and injuries were tracked before and after the implementation, showing improvements like a 22% increase in OEE and 60% reduction in hazards reported.

Uploaded by

Muhammad HassanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd