FEBRUARY 2013

The Better Business Publication Serving the Exploration / Drilling / Production Industry

New Process Recovers NGLs From CO2

By Naomi Baker these valuable hydrocarbons from the costs.

CO2 stream either have recovered only Another method frequently employed

HOUSTONProducers have been uti- limited amounts or have been prohibitively is a combination of membranes and amine

lizing carbon dioxide-enhanced oil re- expensive. treating. In these hybrid systems, the high-

covery since the early 1980s in the Permian There have been several methods de- CO2 stream is compressed and then

Basin, Gulf Coast, Rocky Mountains and veloped for recovering the recycled natural processed through a permeable membrane,

elsewhere in the United States. Not only gas liquids, and in some cases also separating where bulk CO2 removal results in a low-

is CO2 being injected today into oil for- the methane and ethane components. pressure CO2 permeate and a higher-pres-

mations in mature fields, but the emergence The most common recovery method is sure, hydrocarbon-rich residual stream that

of residual oil zones beneath the oil/water simple refrigeration. In this case, the CO2 still contains significant CO2. The hydro-

contact in areas such as West Texas and reinjection stream is chilled using propane carbon stream is sent to a traditional amine

Wyoming offers vast potential for CO2 refrigeration. Condensed NGLs are treated system to treat for further CO2 removal,

EOR in the future. for CO2 (and hydrogen sulfide, if present), which then is sent to sales or to an NGL

In a CO2 flood operation, the produced utilizing a liquid-amine treater, and are recovery plant such as a cryogenic unit.

oil and water are separated, and the CO2 sold. Although easy to operate and relatively Costs associated with operating a hy-

is recompressed and reinjected into the inexpensive, this method recovers only brid system include significant pretreating

formation. In many cases, however, the 20-50 percent of the hydrocarbons. of the feed, in some cases including

reinjected CO 2 contains appreciable An economic benefit of refrigeration prechilling, hydrocarbon adsorbents, and

amounts of light hydrocarbonsprimarily systems is that the CO2 reinjection has a dehydration. The CO2-rich permeate and

propanes, butanes and pentanesas well very low pressure drop, eliminating the the amine regeneration still are at low

as some methane, ethane and nitrogen. need for additional recompression, which pressure, and must be recompressed at

In the past, the processes for capturing adds materially to the capital and operating several stages to be used for CO2 rein-

jection. These systems are very expensive

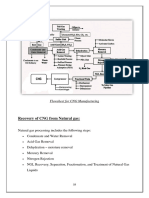

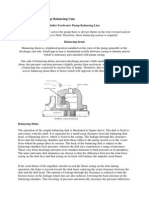

FIGURE 1 to build and operate, and only on rare

occasions will pay out based on hydro-

Refrigerated Fractionation Process carbon recovery.

Pilot Ceritas CO2 LLC A more elaborate CO2 removal process

Dehydration NGL Recovery Liquid Product is a Ryan-Holmes type system, or a vari-

System Treater ation of this process. Depending on the

desired end products (pure methane, pure

CO2, NGL streams, or CO2 and NGLs),

the Ryan-Holmes process can have up to

four distillation columns. The plant uses

From Recycle Compression Auxiliary Systems an additive (lean oil) to break CO2/ethane

Refrigeration for NGL azeotropes. Like the hybrid system, these

Recovery also are very expensive and usually are

Glycol and Amine

Regeneration not economic.

Hot Oil System

Acid Gas Recompressor Refrigerated Fractionation

Utilities

An advanced new solution is available

now that has been developed specifically

Y-Grade Product to to process nontraditional and niche markets

To Recycle Compression Pipeline or Truck Loading in EOR floods. This proprietary technology

was introduced in 2009 to assist companies

Reproduced for Pilot Energy Solutions with permission from The American Oil & Gas Reporter www.aogr.com

�SpecialReport: Enhanced Recovery

of compression.

In the plant, the gas is dehydrated

first, and then fed to a fractionation col-

umn. The column is refluxed through a

refrigerated condenser, and is reboiled

with a heat medium. The overhead contains

essentially all of the original CO2, methane,

ethane, and a portion of the propane. The

NGL bottoms contain nearly all of the

butanes and heavier hydrocarbon products,

the recovered propane, and an equilibrium

amount of CO2 (and H2S, if present).

A patented refrigerated frac- The NGLs then are treated with a stan-

tionation system was devel-

oped to recover natural gas dard amine-liquid system, and are sent to

liquids from the carbon diox- a pipeline or tanks for truck loading and

ide-reinjection streams in ter- ultimate sale. The product is an ethane-

tiary oil recovery operations. free liquid petroleum gas mix with a

The process plants for the new

NGL recovery method typi- vapor pressure well under 200 psi.

cally cost between $500 and In addition to the fractionation, a

$700 an Mcf, depending on lo- tightly integrated system of heat exchang-

cation and gas composition. ers and separators minimizes utilities and

allows propane recovery levels to be cus-

in building and operating processing fa- ating additional revenue from recovered tomized. The dehydrated overhead is de-

cilities to capture recoverable hydrocarbons NGLs, but are not necessarily interested livered back to the producer at 10-15 de-

from the CO2 reinjection streams. in operating plants, and certainly do not grees Fahrenheit cooler and 10-20 psi

Several new projects using this patented want to have production disrupted. lower pressure than it was received at the

process are being implemented to recover The CO2 reinjection stream is com- plant inlet. The amine regeneration over-

NGLs from high-CO2 natural gas streams. pressed through several stages by the head can be compressed and returned to

The objective is to provide third-party, producer, from an inlet of 20-200 psi to a the reinjection stream, if necessary. How-

owner-operated processing services to reinjection pressure of 1,500 psi or higher, ever, because of the very low volumes,

producers, to allow them to enhance the depending on the reservoir. The NGL re- this gas frequently is vented or flared.

value of their EOR fields by increasing covery plant is situated interstage at a Emissions from the plant are limited to

production volumes and cash flows without pressure between 300 and 650 psi. Existing the heat medium heater and volatile or-

incurring any incremental capital costs. compression is not changed; a series of ganic compounds.

The process utilizes a refrigerated automated bypass valves is installed,

fractionation system to remove the re- which allows the reinjection gas to flow Case Studies

coverable NGLs from the CO2 stream, to either the plant or the subsequent stage The first plant to use the new process

rather than removing the CO2 from the

hydrocarbons (Figure 1). Because the re-

frigeration horsepower is the largest op-

erating cost, a careful analysis is conducted

on each potential project to determine

what level of propane recovery will

support the increased costs of refrigeration

compressor and utility usage.

In some cases, the propane recovery

may be slightly lower than what can be

achieved with other processes, but such

analyses frequently show that the incre-

mental per-gallon cost of recovery is not

economical, based on propane prices. In

these cases, the optimum propane recovery

is targeted, rather than maximum propane

recovery.

This NGL recovery process was de-

veloped with an economic perspective

from the beginning. Typically, independ-

entsespecially smaller producersare not The refrigerated fractionation system utilizes a tightly integrated system of heat ex-

interested in processing and prefer to changers and separators to minimize utility costs and allow customized propane recov-

ery levels. The first plant to use the new process was located in Sweetwater County, Wy.,

focus on their core business: producing followed by a plant in Ector County, Tx.

oil and gas. They are interested in gener-

�SpecialReport: Enhanced Recovery

was a 20 million cubic-foot-a-day CO2 cation and gas composition. hydrocarbons that are recycled with the

flood located in Sweetwater County, Wy. Refrigeration systems have lower in- CO2 injection stream, which have not al-

Installed in 2006, the plant has been run- stalled costs than does an NGL recovery ways been economic using older tech-

ning continuously. The CO2 injection plant, but do not offer the NGL recoveries nologies. For producers interested in the

stream has very low hydrocarbon content, available with other technologies. bottom line, this proven process offers

but consistently produces 140-180 barrels A four-column Ryan-Holmes process high recoveries at a low cost. Installations

of natural gas liquids a day. is also extremely expensive, complicated, can be structured to have limited operational

The second plant is located in the San and is rarely built. For sake of analysis, the impact on an EOR flood while adding to

Andres formation in West Texas. This refrigerated fractionation process has been production, reserves and cash flow.

plant, which is located adjacent to Legado compared with a one-column Ryan-Holmes With well developed analytical models

Resources CO2 operations in Ector County, facility using online data collected in 2008. and operational experience, we can quickly

began operations in 2012. Based on analy- According to the report, the Ryan- evaluate the applicability of the process

Holmes one-column plant (RHOC) to any EOR field and provide the specific

ses from Legados early phased develop-

processed 35 MMcf/d of gas with an 86 incremental benefit that can accrue to it,

ment work, the 30 MMcf/d plant will percent CO2 content. The stated production typically at no cost to the producer.

produce more than 800 bbl/d of NGLs. rate was 511 bbl/d of NGLs, using 3,500

An additional stabilizer has been added horsepower of refrigeration.

at this location, which will allow about Using the well-tested models for the

60 percent of the NGL product to be new NGL recovery process, we determined

blended into the companys crude oil that 1,400 hp would provide enough re-

stream, thereby increasing revenue by up- frigeration to produce 848 bbl/d, with a

grading the product, and avoiding trucking, propane recovery of 40 percent, and es-

transportation and fractionation fees. Plans sentially 100 percent recovery of the

include building an additional 50 MMcf/d heavier components. Based on the publicly

train as Legado expands its EOR acreage. available data on the RHOC, including

A mini plant with a 1.2 MMcf/d ca- screen shots of the PLC control panel,

pacity, designed for a one-well CO2 flood, the tower for the new NGL recovery NAOMI

also has been constructed and is operating process has one-third as many trays as BAKER

in West Texas on an older flood owned the RHOC, and uses a hot oil temperature Naomi Baker is director of engi-

by an independent operator. approximately 100 degrees F lower than neering and operations at Pilot Energy

the reported temperature at the RHOC. Solutions LLC. The company was

Cost Comparisons Significantly, at $0.05 a kilowatt-hour, formed in 2009 to build and operate

Generally, amine/membrane hybrids the electricity to operate the RHOC costs facilities to capture hydrocarbons from

are considerably more expensive and $735,000 more than the plant utilizing CO2 reinjection streams, utilizing a

complicated to operate, can require sig- the new NGL recovery method (assuming patented refrigerated fractionation

nificant preconditioning of the gasin- 100 percent utilization year round). The process. Baker has 30 years of expe-

cluding chillingand can cost up to $2,000 report did state that the RHOC was not rience in natural gas processing, proj-

an Mcf to install. The CO2 must be re- operating efficiently at the time, but even ect management and operations with

compressed after permeation, and it usually if the NGL production was equal to the Amoco, Phillips (GPM), and Enbridge

is not cost effective to make the methane new plant design, it would require 2.5 Energy. She is co-holder of two patents.

saleable. The process plants for the new times more refrigeration horsepower and Baker earned a B.S. in chemical en-

NGL recovery method have costs between more heat in the reboiler. gineering from Texas Tech University.

$500 and $700 an Mcf, depending on lo- Many CO2 EOR floods have recoverable