Professional Documents

Culture Documents

Cement Mill O&m Manual 1 of 6

Cement Mill O&m Manual 1 of 6

Uploaded by

Ramsai Chigurupati0 ratings0% found this document useful (0 votes)

8 views177 pagescem

Original Title

Cement Mill o&m Manual 1 of 6

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcem

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

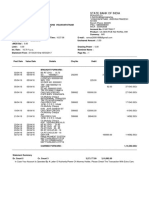

8 views177 pagesCement Mill O&m Manual 1 of 6

Cement Mill O&m Manual 1 of 6

Uploaded by

Ramsai Chigurupaticem

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 177

GEBR. PFEIFFER AG BA200700693-E/D

KAISERSLAUTERN Table of Contents Edition 04.2008

Contents

~ Cover sheet

- Foreword

- Revision list

- Table of contents

1. Process data File 1

14 Rating data

1.2 Process description

Flow sheet

2 Fundamental safety instructions

24 Warnings

22 Basic operation and designated use of the machine

23 Organizational measures

24 Selection and qualification of personnel

25 Safety instructions governing specific operational phases

26 Warning of special dangers

27 Safety instructions for the user

3. Technical description

34 Design and operation

32 Description of the main constructional components

33 Measuring and regulating equipment

4, Transport and erection

44 Transport

444 Storage

4.1.2 Scope of supply

42 Erection

424 General instructions

4.2.2 Erection site - machine

5. Commissioning

51 Measures to be taken before commissioning

514 Erection control

5.1.2 Performance control

52 Commissioning

6. Operation

61 Start-up after operational shut-down

62 Shutdown

63 Start-up after longer downtime periods.

64 Important note

6.41 Operation in the winter

- Water injection system

- Oil lubrication system of mill gearbox

General data

.9e0700693_I.doc page 1/5

GEBR. PFEIFFER AG BA200700693-E/D

KAISERSLAUTERN Table of Contents Edition 04.2008

1 Malfunctions

7A General instructions

744 Comments on indication of malfunctions

72 Table of malfunctions

8. Maintenance

81 General instructions

83

8.3.1

83.2

84

84.1

84.2

84.3

844

8.4.5

8.4.6

847

848

84.8.1

8.4.8.2

8.4.8.3

8.4.8.4

84.8.5

8.4.9

Before machine restart

Inspection and servicing

List of inspection and service works

Description of service works

Seal air pressure — seal air system of vertical roller mill

Lifetime and marking of a hydraulic hose pipe

Oil level monitoring on grinding rollers

Oil change at grinding rollers

‘Check of automatic levelling of grinding rollers

Lubrication of classifier bearing

Lubrication of the roller bearings of the rotary locks DSZ or EWA

Tightening torques for screws

Wear limits

Gap and wear measurement — pressure frame stop

Wear measurement at grinding elements

Lubrication instructions

General hints

Instructions for lubrication of grinding roller bearings

Lubrication plan

Lubrication lists

Lubrication chart

Repair

How to lift the classifier off the grinding plant

Removal and mounting of grinding rollers

Replacement of roller tyres

Replacement of grinding plate segments

Replacement of liner plates

Removal of one hydraulic cylinder of the tensioning system

Repair of the oil pressure piping to go with the tensioning system

Replacement of roller bearings and radial shaft sealing rings

of the grinding rollers

Preparatory work

Removal of radial shaft sealing rings

Fitting of radial shaft sealing rings

Removal of roller bearings

ing of roller bearings

Replacement of pressure yokes

19e0700693_I.doo page 2/5

GEBR. PFEIFFER AG BA200700693-E/D

KAISERSLAUTERN Table of Contents Edition 04.2008

10.

10.1

10.2

10.3

10.4

10.5

Repair of torque support of the pressure frame

Emergency operation with a defective hydraulic buffer

Removal of torque support of the pressure frame

Removal and repair of hydraulic buffer and

the internals of the torque support of the pressure frame

Hard facing of grinding elements

General

Hard facing

Removal of grit cone

Removal of louver

Removal of separating wheel and separating wheel hub

Removal of classifier drive

Removal of classifier bearing

Repair of rotary lock DSZ 160

‘Adjustment of sealing plates

Replacement of sealing plates

Replacement of wear bushing and wear rings

Replacement of roller bearings and sealings

Repair of rotary lock EWA 80

Adjustment of sealing plates

Replacement of sealing plates

Replacement of wear bushing and wear rings

Replacement of roller bearings and sealings

Annex

Auxiliary equipment for removal of ball sockets

Tool box — packing list

Drawings

Spare parts File 2

General instructions

How to use the spare parts lists

Spare parts lists / Spare parts drawing

= Mill

- Classifier

- Rotary lock DSZ 160

- Rotary lock EWA 80

Lists and drawings

List of machines and equipment

List of electric consumers, with

- Flow sheet (see chapter 10.4)

Interlocking diagram

List of measuring points, with

- Flow sheet

Foundation plan

19¢0700693_I.doc page 3/5

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5809)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- German Short Stories: 9 Simple and Captivating Stories For Effective German Learning For BeginnersDocument51 pagesGerman Short Stories: 9 Simple and Captivating Stories For Effective German Learning For BeginnersRamsai ChigurupatiNo ratings yet

- Mechatronics SystemsDocument22 pagesMechatronics SystemsRamsai Chigurupati100% (1)

- Lecture 23Document19 pagesLecture 23Ramsai ChigurupatiNo ratings yet

- Ncrdme Conference Schedule: 27july-2018 (Friday)Document4 pagesNcrdme Conference Schedule: 27july-2018 (Friday)Ramsai ChigurupatiNo ratings yet

- Materials ColoursDocument13 pagesMaterials ColoursRamsai ChigurupatiNo ratings yet

- Screw Conveyor CatalogDocument88 pagesScrew Conveyor Catalogmortensen5100% (4)

- Shimming of Chair PadsDocument5 pagesShimming of Chair PadsRamsai ChigurupatiNo ratings yet

- Screw Conveyor Design123456789Document8 pagesScrew Conveyor Design123456789Ramsai ChigurupatiNo ratings yet

- Tires and Tire ElementsDocument20 pagesTires and Tire ElementsRamsai ChigurupatiNo ratings yet

- Screw Conveyor DesignDocument8 pagesScrew Conveyor DesignRamsai ChigurupatiNo ratings yet

- 01 04 2016 - 18 03 2017 PDFDocument3 pages01 04 2016 - 18 03 2017 PDFRamsai ChigurupatiNo ratings yet

- Shimming of Chair PadsDocument6 pagesShimming of Chair PadsRamsai ChigurupatiNo ratings yet

- Postal: Ese + Gate + PsusDocument3 pagesPostal: Ese + Gate + PsusRamsai ChigurupatiNo ratings yet

- Sprocket Guide123456789Document17 pagesSprocket Guide123456789Ramsai ChigurupatiNo ratings yet