Professional Documents

Culture Documents

RoClean P112 DATASHEET

Uploaded by

ramonmza0 ratings0% found this document useful (0 votes)

71 views1 pageRoClean P112 is a powdered cleaner designed to remove silica scales, organic fouling, and bacterial slime from RO membranes. It offers superior removal of these contaminants compared to generic cleaners. RoClean P112 is compatible with all major membrane brands and is NSF certified for producing drinking water. The instructions describe mixing a 1-2% solution in permeate or DI water heated to 35C and recirculating it through each membrane stage for 60 minutes to clean. The pH should be monitored and more solution added if needed to effectively clean membranes.

Original Description:

xc

Original Title

RoClean_P112_DATASHEET

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRoClean P112 is a powdered cleaner designed to remove silica scales, organic fouling, and bacterial slime from RO membranes. It offers superior removal of these contaminants compared to generic cleaners. RoClean P112 is compatible with all major membrane brands and is NSF certified for producing drinking water. The instructions describe mixing a 1-2% solution in permeate or DI water heated to 35C and recirculating it through each membrane stage for 60 minutes to clean. The pH should be monitored and more solution added if needed to effectively clean membranes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

71 views1 pageRoClean P112 DATASHEET

Uploaded by

ramonmzaRoClean P112 is a powdered cleaner designed to remove silica scales, organic fouling, and bacterial slime from RO membranes. It offers superior removal of these contaminants compared to generic cleaners. RoClean P112 is compatible with all major membrane brands and is NSF certified for producing drinking water. The instructions describe mixing a 1-2% solution in permeate or DI water heated to 35C and recirculating it through each membrane stage for 60 minutes to clean. The pH should be monitored and more solution added if needed to effectively clean membranes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

RoClean P112

High pH RO Membrane Cleaner - Powder

RoClean P112 is a powdered cleaner designed to remove silt and

Performance:

organic foulants such as colloidal silica, clays, organic color and

bacterial slime from spiral wound thinfilm elements.

RoClean P112 offers a variety of

performance benefits:

Extensive field experience and laboratory analyses have shown

Superior results in the removal of RoClean P112 is an effective silica scale cleaner. Use of RoClean P112

silica scales, organic and also avoids the potentially severe safety hazards associated with

colloidal foulants, especially alternative chemicals commonly used in silica scale removal. These

when compared to generic include hydrofluoric acid and ammonium bifluoride solutions.

solutions.

Compatible with the thinfilm Use Instructions:

(polyamide) elements of all Below is a summary of the RoClean P112 cleaning guidelines. For detailed

major membrane manufacturers. procedures, please consult the Avista technical bulletin entitled "Cleaning of Spiral

Wound Membrane Systems".

NSF Certified for off-line use in

systems producing drinking 1. Fill the cleaning tank to the desired volume with RO permeate or DI water. Heat

o

the solution to 35 C as this will dramatically increase the cleaning efficiency. Add

water. sufficient RoClean P112 to create a 2% wt/wt solution if the fouling is

Contains a specialized blend of moderate/severe or 1% if the fouling is mild. Recycle the solution through the

cleaning tank to ensure adequate mixing.

buffers and other components to

dissolve organic foulants and 2. Recirculate the cleaning solution through each RO system stage, one at a time, for

disperse colloidal particles. a minimum of 60 minutes at the flow rate recommended by the membrane

manufacturer. If that rate is not known, use the guidelines listed below:

Highly buffered to resist pH Element Diameter

3

Flowrate per Vessel, gpm (m /hr)

changes during the cleaning 4 10 (2.4)

process. 8 40 (9)

Can be used in conjunction with 3. If the membranes are heavily fouled and the recirculated cleaning solution

becomes discolored or turbid, discard as much as 15% of the solution volume. Heavily

other applicable cleaners as fouled elements may also benefit from a soak period (up to 8 hours).

shown in the Avista cleaner

4. Monitor the pH of the solution during the cleaning process. If the pH remains in

selection guide.

the desired range of 12 and the solution is not turbid, it may be used to clean

Temperature compensated to subsequent stages. In the unlikely event that the pH falls below 11.5, prepare a new

maintain optimum pH over a batch and repeat steps 1-4.

wide temperature range. 5. When the clean is completed, rinse the membranes by recirculating RO permeate

through each pressure vessel. The system can then be returned to service.

DRINKING WATER TREATMENT

Packaging and Storage:

ADDITIVES

NATIONAL

CLASSIFIED BY

SANTATION

Standard regional pack sizes are listed below. Custom packing available on request.

FOUNDATION. TO ANSI/NSF 60 ON Specifications Packaging Formats Americas EMEA

OCTOBER 2007 AS STANDARD

DRINKING WATER TREATMENT Appearance: Cream powder Pails 45 lbs 20 kg

CHEMICAL FOR USE OFF-LINE IN pH (2% solution): 12 12.8 Fibre Carboy 100 lbs -

REVERSE OSMOSIS SYSTEMS.

Density (kg/litre): 1.2+ 0.05 Fibre Drums 350 lbs -

10/08

Avista Technologies, Inc. Avista Technologies (UK) Ltd.

Phone: + 1 760 744 0536 Phone: + 44 131 449 6677

Info@avistatech.com Info@avistatech.co.uk

Visit www.avistatech.com for a list of global offices and distributors.

You might also like

- Drake Family - Work SampleDocument1 pageDrake Family - Work Sampleapi-248366250No ratings yet

- Product Brochure With Industrial ApplicationDocument9 pagesProduct Brochure With Industrial Applicationanon_159986285No ratings yet

- Reverse Osmosis Reverse OsmosisDocument43 pagesReverse Osmosis Reverse OsmosisSagar SbNo ratings yet

- NRA2010 DirectoryDocument19 pagesNRA2010 DirectoryGame_fan1970No ratings yet

- LeadsDocument4 pagesLeadsinshijeNo ratings yet

- Listing of Registered Liquor Products NYSDocument123 pagesListing of Registered Liquor Products NYSLouie_popwhatskiNo ratings yet

- Certain Activated Carbon From ChinaDocument122 pagesCertain Activated Carbon From ChinaHạnhNguyễnNo ratings yet

- Jacobi Aquasorb 2000Document2 pagesJacobi Aquasorb 2000PT Purione MegatamaNo ratings yet

- Poweder Activated Carbon Treatment (Pact)Document10 pagesPoweder Activated Carbon Treatment (Pact)Harish GowdaNo ratings yet

- Thailand Chemexcil Report VF PDFDocument63 pagesThailand Chemexcil Report VF PDFRATHEESH P.KNo ratings yet

- Companies: Complete ListDocument366 pagesCompanies: Complete ListKaviyarasan Singh100% (1)

- RussiaDocument830 pagesRussiaThe Cultural CommitteeNo ratings yet

- MARCH 2020 Surplus Record Machinery & Equipment DirectoryDocument717 pagesMARCH 2020 Surplus Record Machinery & Equipment DirectorySurplus RecordNo ratings yet

- AsiFood Database Companies HEIsDocument8 pagesAsiFood Database Companies HEIstamchau nguyenngocNo ratings yet

- Supplier - Manufacturer of Sewage Treatment Plant - Ahmedabad Surat Rajkot Baroda PDFDocument6 pagesSupplier - Manufacturer of Sewage Treatment Plant - Ahmedabad Surat Rajkot Baroda PDFShubham India - Sewage Treatment PlantNo ratings yet

- Activated Carbon: Material Safety Data SheetDocument7 pagesActivated Carbon: Material Safety Data Sheetirowati17No ratings yet

- Biscuit Industries PDFDocument2 pagesBiscuit Industries PDFanil gautamNo ratings yet

- Showcase Malaysia ExhibitorsDocument13 pagesShowcase Malaysia ExhibitorsnazzishsNo ratings yet

- CropByCompany NOPDocument164 pagesCropByCompany NOPRicardo Noé Montemayor LeosNo ratings yet

- Fertilizer Directory OF PakistanDocument9 pagesFertilizer Directory OF Pakistankapil_rahtiNo ratings yet

- Chwmeg MembersDocument4 pagesChwmeg MembersJudea EstradaNo ratings yet

- List of Licences (Manufacturers, Importers & Distributors) Valid Up To 04-08-2020Document247 pagesList of Licences (Manufacturers, Importers & Distributors) Valid Up To 04-08-2020Muhammad Boota ZahidNo ratings yet

- Directory of Petrochemicals Units 2014-15 - 1 PDFDocument31 pagesDirectory of Petrochemicals Units 2014-15 - 1 PDFSatyanNo ratings yet

- Jordan 100Document51 pagesJordan 100seherucarNo ratings yet

- List of LaboratoriesDocument4 pagesList of LaboratoriesMark Yu0% (1)

- List of VN To Korea 5 2017Document126 pagesList of VN To Korea 5 2017Ngan PhamNo ratings yet

- AquaDocument3 pagesAquaRavishankar ShankarNo ratings yet

- !'JIII, All.,.. - , - , - , - : InvoiceDocument5 pages!'JIII, All.,.. - , - , - , - : InvoiceLouie SyNo ratings yet

- Thuc Pham Va Do Uong PDFDocument9 pagesThuc Pham Va Do Uong PDFPriska MalvinNo ratings yet

- Tootpaste Ingredient by Pharma ClasssesDocument1 pageTootpaste Ingredient by Pharma ClasssesSahil ChagtiNo ratings yet

- B I1ding Be Haphil IarkDocument7 pagesB I1ding Be Haphil IarkTanya Marie ArgameNo ratings yet

- List of Chemical Companies in Jeddah - AZ ChemistryDocument6 pagesList of Chemical Companies in Jeddah - AZ ChemistryAfshan NaikNo ratings yet

- Datasheet EFPE 1003ANDocument1 pageDatasheet EFPE 1003ANAhyoria ZapataNo ratings yet

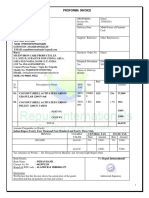

- I 009g - Proforma Invoice For Pellet & Granular Activated Carbon - Environ CareDocument2 pagesI 009g - Proforma Invoice For Pellet & Granular Activated Carbon - Environ CareBin DevassyNo ratings yet

- Fertilizer-companies-in-Sri-lanka 2Document1 pageFertilizer-companies-in-Sri-lanka 2Senthil KumarNo ratings yet

- Licensed-Importer - 20150428 - Contact-No. - Edit (Done Excel, Done CC)Document32 pagesLicensed-Importer - 20150428 - Contact-No. - Edit (Done Excel, Done CC)CK AngNo ratings yet

- Directory of Biodiesel Producers 9.2.11Document8 pagesDirectory of Biodiesel Producers 9.2.11Aneesch PreethaNo ratings yet

- List CompanyDocument6 pagesList CompanyAmir Al-AimanNo ratings yet

- O & M Client ListDocument2 pagesO & M Client ListKasiv72No ratings yet

- Beva SiliconsDocument3 pagesBeva SiliconsvgvpplNo ratings yet

- German Cosmetic CompaniesDocument2 pagesGerman Cosmetic CompaniesDonna Delector100% (1)

- Poultry Feed Mills in PunjabDocument21 pagesPoultry Feed Mills in PunjabKazimNo ratings yet

- DetergentsDocument29 pagesDetergentsMike TysonNo ratings yet

- 2020 Spices DraftDocument18 pages2020 Spices DraftJohn Eric AngatNo ratings yet

- Tamil Nadu 2015Document22 pagesTamil Nadu 2015rohitindiaNo ratings yet

- The Bleaching of Palm Oil Using Activated CharcoalDocument5 pagesThe Bleaching of Palm Oil Using Activated CharcoalRevivalist Ekele StephenNo ratings yet

- Silicone SealantDocument8 pagesSilicone SealantSaurabh RungtaNo ratings yet

- 2 Spice SHDocument149 pages2 Spice SHSusi UmifarahNo ratings yet

- Chem IndustriesDocument20 pagesChem IndustriesDhrumil GandhiNo ratings yet

- ContactsDocument2 pagesContactsDipesh PuriNo ratings yet

- India - Seafood NRIDocument81 pagesIndia - Seafood NRISiraj KuvakkattayilNo ratings yet

- Awareness About The RO Water PurifierDocument7 pagesAwareness About The RO Water PurifiervikaskamaljnuNo ratings yet

- Data Sheet EMPE 5316Document1 pageData Sheet EMPE 5316quangga10091986No ratings yet

- Brazil Food Community Directory PDFDocument32 pagesBrazil Food Community Directory PDFTushar SavaliyaNo ratings yet

- Offer STP Abhishek SirDocument6 pagesOffer STP Abhishek SirA8304008005No ratings yet

- Case Study - ZLD Plant at SABMiller, Aurangabad PDFDocument2 pagesCase Study - ZLD Plant at SABMiller, Aurangabad PDFmarysarkerNo ratings yet

- Adhesive MarketDocument12 pagesAdhesive Marketkhushboo chandaniNo ratings yet

- Address ShipperDocument81 pagesAddress ShipperBintang Manies100% (1)

- Product Information and Data SheetDocument2 pagesProduct Information and Data SheethelenNo ratings yet

- RoClean-P111 DATASHEETDocument1 pageRoClean-P111 DATASHEETramonmzaNo ratings yet

- RoClean L811 DATASHEET PDFDocument1 pageRoClean L811 DATASHEET PDFramonmzaNo ratings yet

- WS1 5ciDocument2 pagesWS1 5ciramonmzaNo ratings yet

- Roclean P112: Safety Data Sheet Safety Data SheetDocument11 pagesRoclean P112: Safety Data Sheet Safety Data SheetramonmzaNo ratings yet

- Roclean P112: Safety Data Sheet Safety Data SheetDocument11 pagesRoclean P112: Safety Data Sheet Safety Data SheetramonmzaNo ratings yet

- Roclean P111: Safety Data Sheet Safety Data SheetDocument11 pagesRoclean P111: Safety Data Sheet Safety Data SheetramonmzaNo ratings yet

- Genesys GPFDocument1 pageGenesys GPFramonmzaNo ratings yet

- RoClean Selection GuideDocument2 pagesRoClean Selection GuideramonmzaNo ratings yet

- Roclean P111: Safety Data Sheet Safety Data SheetDocument11 pagesRoclean P111: Safety Data Sheet Safety Data SheetramonmzaNo ratings yet

- RoClean-P111 DATASHEETDocument1 pageRoClean-P111 DATASHEETramonmzaNo ratings yet

- RoClean L811 DATASHEET PDFDocument1 pageRoClean L811 DATASHEET PDFramonmzaNo ratings yet

- RoClean L811 DATASHEET PDFDocument1 pageRoClean L811 DATASHEET PDFramonmzaNo ratings yet

- LG163Document4 pagesLG163ramonmzaNo ratings yet

- US UK Avista PDS RoQuest 4000 FinalDocument1 pageUS UK Avista PDS RoQuest 4000 FinalramonmzaNo ratings yet

- US UK Avista PDS RoQuest 6000 FinalDocument1 pageUS UK Avista PDS RoQuest 6000 FinalramonmzaNo ratings yet

- MINUZA Laptop Scheme Programs ThyDocument9 pagesMINUZA Laptop Scheme Programs Thyanualithe kamalizaNo ratings yet

- Bee Keeping-KVK MorenaDocument6 pagesBee Keeping-KVK MorenaAsh1Scribd100% (1)

- Lesson 4: Health and Fitness AdvertisingDocument4 pagesLesson 4: Health and Fitness AdvertisingCatherineNo ratings yet

- Ergo 1 - Workshop 3Document3 pagesErgo 1 - Workshop 3Mugar GeillaNo ratings yet

- J. Bleger ArtDocument10 pagesJ. Bleger Artivancristina42No ratings yet

- GeoSS Event Seminar 12 July 2012 - SlidesDocument15 pagesGeoSS Event Seminar 12 July 2012 - SlidesNurmanda RamadhaniNo ratings yet

- The Human Body: An Orientation: Part ADocument10 pagesThe Human Body: An Orientation: Part ARoi Christoffer Jocson PeraltaNo ratings yet

- BDC 6566Document6 pagesBDC 6566jack.simpson.changNo ratings yet

- OphthalmoplegiaDocument5 pagesOphthalmoplegiaPatricia Feliani SitohangNo ratings yet

- The Effect OfAdditional Nanoparticles Supplementation of Indonesian Bay Leaf (SyzigiumPolyanthum) On Blood Pressure in Pregnancy HypertensionDocument4 pagesThe Effect OfAdditional Nanoparticles Supplementation of Indonesian Bay Leaf (SyzigiumPolyanthum) On Blood Pressure in Pregnancy HypertensionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Method of Toxicity Test 1Document59 pagesMethod of Toxicity Test 1Widya AnggrainiNo ratings yet

- Transformers: Z Z Z S S Z S SDocument17 pagesTransformers: Z Z Z S S Z S SSreenivasaraoDharmavarapu100% (1)

- Low Voltage Fixed and Automatic Power Factor Correction SystemsDocument6 pagesLow Voltage Fixed and Automatic Power Factor Correction Systemszabiruddin786No ratings yet

- Microbes in Human Welfare PDFDocument2 pagesMicrobes in Human Welfare PDFshodhan shettyNo ratings yet

- Dual Laminate Piping HandbookDocument46 pagesDual Laminate Piping HandbookA.Subin DasNo ratings yet

- Occlusal Appliance TherapyDocument14 pagesOcclusal Appliance TherapyNam BuiNo ratings yet

- Plastic As Soil StabilizerDocument28 pagesPlastic As Soil StabilizerKhald Adel KhaldNo ratings yet

- Tryout Consent Form - 2014 - Sign and ReturnDocument2 pagesTryout Consent Form - 2014 - Sign and ReturnSanjeevan BaraNo ratings yet

- ESR 2538 ChemofastDocument14 pagesESR 2538 ChemofastEduardo Antonio Duran SepulvedaNo ratings yet

- Clinical Features, Evaluation, and Diagnosis of Sepsis in Term and Late Preterm Infants - UpToDateDocument42 pagesClinical Features, Evaluation, and Diagnosis of Sepsis in Term and Late Preterm Infants - UpToDatedocjime9004No ratings yet

- Hiperparatiroidism SarcinaDocument7 pagesHiperparatiroidism SarcinaClaudia IrimieNo ratings yet

- Plyometric Training: Sports Med 2Document9 pagesPlyometric Training: Sports Med 2Viren ManiyarNo ratings yet

- 7 LevelDocument5 pages7 LevelACHREF RIHANINo ratings yet

- Oral Rehydration SolutionDocument22 pagesOral Rehydration SolutionAlkaNo ratings yet

- T W H O Q L (Whoqol) - Bref: Skrócona Wersja Ankiety Oceniającej Jakość ŻyciaDocument6 pagesT W H O Q L (Whoqol) - Bref: Skrócona Wersja Ankiety Oceniającej Jakość ŻyciaPiotrNo ratings yet

- DET Tronics: Unitized UV/IR Flame Detector U7652Document2 pagesDET Tronics: Unitized UV/IR Flame Detector U7652Julio Andres Garcia PabolaNo ratings yet

- Child Case History FDocument6 pagesChild Case History FSubhas RoyNo ratings yet

- Theories of Learning and Learning MetaphorsDocument4 pagesTheories of Learning and Learning MetaphorsTrisha Mei Nagal50% (2)

- Silly VersesDocument29 pagesSilly Verseskevin daleNo ratings yet