Professional Documents

Culture Documents

JIS Z2331, 2003 SS Covered Electrodes

Uploaded by

panji akbar0 ratings0% found this document useful (0 votes)

69 views18 pagesStainless steel covered electrodes

Original Title

JIS Z2331 ,2003 SS Covered Electrodes

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStainless steel covered electrodes

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

69 views18 pagesJIS Z2331, 2003 SS Covered Electrodes

Uploaded by

panji akbarStainless steel covered electrodes

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 18

JIS

JAPANESE

INDUSTRIAL

STANDARD

nslated Published by

Japanese Standards Association

@JIS Z 3221:

(JWES/JSA)

Stainless steel covered electrodes

98

Z 3221 : 2003

Foreword

This translation has been made based on the original Japanese Industrial

Standard revised by the Minister of Economy, Trade and Industry through

deliberations at the Japanese Industrial Standards Committee, as the

result of proposal for revision of Japanese Industrial Standard submit-

ted by The Japan Welding Engineering Society (JWES)/the Japanese

Standards Association (JSA) with the draft being attached, based on the

provision of Article 12 Clause 1 of the Industrial Standardization Law

applicable to the case of revision by the provision of Article 14. Conse-

quently JIS Z 3221 : 2000 is replaced with this Standard.

In this revision, welding consumables for SUS304N2 high strength

stainless steel is added. Further, though a bend test is conventionally

specified as bending performance of deposited metal, it is changed to

longitudinal face bend test in conformity to JIS Z 3323.

Date of Establishment: 1957-01-30

Date of Revision: 2003-01-20

Date of Public Notice in Official Gazette: 2003-01-20

Investigated by: Japanese Industrial Standards Committee

Standards Board

Technical Committee on Welding

JIS Z 3221:2003, First English edition published in 2003-05

Translated and published by: Japanese Standards Association

4-1-24, Akasaka, Minato-ku, Tokyo, 107-8440 JAPAN

In the event of any doubts arising as to the contents,

the original JIS is to be the final authority

© JSA 2003,

“All rights reserved, Unless otherwise specified, no part of this publication may be reproduced or

utilized in any form or by any means, electronic or mechanical, including photocopying and

microfilm, without permission in writing from the publisher.

Printed in Japan

PROTECTED BY COPYRIGHT

4d

42

43

44

45

10

Attached Table 1 Normative references.

7.3221 : 2003

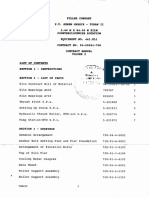

Contents

Scope ..

Normative references ...

Classification al

Quality, 2

Covering 2

Chemical composition 2

Mechanical properties .. : 3

Bending performance .. 5

Corrosion resistance of deposited metal 5

Dimensions and tolerances 5

5

5

Chemical analysis test... 6

Tensile test of deposited metal 6

Bend test of deposited metal .. a

Corrosion test of deposited metal 8

Inspection. : 9

Packaging 9

Designation of products... 9

Marking

12

@

PROTECTED BY COPYRIGHT

JAPANESE INDUSTRIAL STANDARD @ JIS Z 3221 : 2003

Stainless steel covered electrodes

1 Scope This Japanese Industrial Standard specifies the stainless steel covered

electrodes (hereafter referred to as “electrodes”) capable of obtaining the deposited

metal of not less than 11 % in chromium and not more than 22 % in nickel.

2 Normative references The standards listed in Attached Table 1 contain pro-

visions which, through reference in this Standard, constitute provisions of this Standard.

The most recent editions of the standards (including amendments) shall be applied.

8 Classification The electrodes shall be classified as given in Table 1 according

to the chemical composition of the deposited metal and the type of current.

The applicable welding positions are given in Table 1.

Table 1 Classification of electrodes

Classification | Welding position | Type of current || Classification | Welding position | Type of current

paor-*[i8]| FV, 0,H | Dow past [15] FV,0,H8 | Dom

16 ‘AC or DEM 6 ‘AC or DOCH

‘D308 15] FV, 0,8 | Dow paient [15] Fv, 0,8 | Dow

16 AC or DG 16 ‘AG or DOW)

pst | 15] FV, 0, H | DOM Dsi7 uw] BV,0,8 | Doe

16 [ AG or Dom 6 ‘AC or DOCH

psosn2 [15] F,v,0,H | Dow) foam [a5] Fv, 0,8 | Dom

16 ‘AC or DCC) 16 | ‘AC or DOM)

pao -[as| Fv, 0,8 | Dew pas [is] FV,0,H | Dom

76 | ‘AC or DOCH 16 ‘AG oF DOCH

soot [15] Fv, 0, | DOW pazes1 [15] FV, 0, H | DOM

‘AC or DOCH 16 AC or DOCH

Da0eNb [15] F, V, 0, H | DOW) D347 a[ FV,0,8 | pce |

16 AC or DCG) 16 [AC oF DOH

Dsoenst [18 [ Fv, 0, H | Dem pam [15 Dow

6 ‘AC or DOCH 6 AC or DOH

| Ds00mo [15] Fv, 0, H | Doc aaa Bl RV0H | Dow |

16 ‘AC or DE | AG orDom

Ds0eMoL [15] F, V, 0, H | DOW D410 15| Fv, 0,4 | Dow

16 ‘AC or DOM 16 [AC or DOM

pao [6] FY, 0,8 | Dow pions [15| Fv.0,H | Dom |

16 ‘AC or DOCH 16 [AC or DOM)

psi0Me [15] FV, 0,8 | Dom DA30 15] FV, 0,4 | Dow

16 ‘AC or DOW) a6 | ‘AC or DO)

PROTECTED BY COPYRIGHT

2

2 3221 : 2008

Table 1 (concluded)

Classification | Welding position | Type of current |] Classification | Welding position | ‘Type of current

Daiz 15] FV,0,H | Dow |pasons [a5] Fv, 0,8 | DO®

16 ‘AC or DGG) 16 [Ac erDew

pies2 | 15| FV, 0,H | DOW pes0—«| 35| FV,0,H | DOH

16 [ Acor Dew 16 AC or DO(#)

Daié 5] FV,0,H | Dow LT

16 ‘AG or DGG) [ |

Remarks 1 The symbols used for the welding positions are as follows:

F: Flat, V: Vertical, O: Overhead, H: Horizontal or horizontal

fillet

‘The welding positions shown in Table 1 apply to electrodes of not

more than 4.0 mm in diameter.

2 The symbols used for the type of current are as follows:

AC: Alternating current, DC (+): Direct current (electrode posi-

tive)

4 Quality

4.1 Covering The covering shall be in accordance with 8 of JIS Z 3200.

4.2 Chemical composition The chemical composition of deposited metal shall

comply with the requirements specified in Table 2 when tested in accordance with

the method of 6.2.

PROTECTED BY COPYRIGHT

3

Z 3221 : 2003

Table 2 Chemical composition of deposited metals

Unit: %

Classi ‘Chemical composition

cation ec | si ‘Ma, P s | Ni ce Mo |__Others

[b307 [013 max. ] 0.90 max. | 3.00%8 00) 0.040 max. 0.030 max] 9011.0 |180:21.0 0501.50 =

fo308 [008 max. | 090 max. | 2.50 max. |0.040 max |0.030 max| 9.0%011.0|180%21.0] — -

lb30st | 0.08 max | 0.90 max. | 250 max. |0.040 max.|0.030 max. 9.0120] 180w21.0) — — -

Ipsosn2 | 0.10 max. | 0.90 max. | 1.00%04.00]0.040 max.| 0.030 max.| 7011.0 |200%%25.0| — | No.120030

Ip309 | 015 max. | 0.90 max. | 250 max. |0.040 max 0.030 max|120%140|720025.0) — — -

Ip30o1. | 0.08 max. | 0.90 max. | 250 max. |0.040 max.| 0.030 max.| 120%160|220w250| — — -

[D309Nb | 0.12 max. | 0.90 max. | 2.50 max. |0.040 max.| 0,030 max.| 12.0 014.0|22.0%025.0| ~ Nb 0.70 t01.00

Ip3ooNbL | 0.04 max. | 0.90 max. | 250 max. }0.040 max |0.030 max|120%140]220«25.0] — | Nb0.70.01.00

Jp309Mo | 0.12 max. | 0.90 max. | 250 max. |0.040 max.|0.030 max.| 120%140]22.0%25.0|2.0003.00 -

Ip3osMot. | 004 max. | 0.90 max. | 20 max. |0.040 max |0.030 max. 12022140 22.0:325.0|.00:03.00 -

lpsio— | 020 max | 0.75 max. | 250 max. |0.030 max.|0.030 max.| 2001522025080] — -

Jp3tomo | 0:12 max. | 0.75 max. | 20 max. |0,030 max.|0.030 max.| 20.220 250:528.0| 2.00:»3.00 -

Jps12 [0.15 max | 0.90 max. | 2.0 max. |0.040 max.|0.030 max.| 80%10.5|280%320] — — -

lpi6-8-2 [0.10 max. | 0.50 max. | 2.50 max. |0,040 max.|0.030 max.| 75% 9.5|145:916.5| 1.00%02.00 -

Jos16 | 008 max. | 0.90 max. | 2.50 max. | 0.040 max.|0.030 max. 11.0140 | 17.0:520.0| 200:02.75 -

Ipsist. | 004 max. | 090 max. | 2.50 max. |0,040 max.|0.030 max. 11.0 916.0 |1.0%20.0| 2.00%02.75 -

lostert | 04 max. | 0.90 max. | 2.0 max. |0,040 max.|0.030 max.| 11.0916. |17.0%20.0| 1.20%2.75 | Cu 1.000250

Jo317 | 008 max. | 090 max. | 250 max. |0.040 max |0,030 max. | 12.1914. |18.0%021.0|3.000400 -

Jpsi7t | 04 max. | 0.90 max. | 2.50 max. |0.040 max.|0.030 max. |12.0%916.0|18.0%21.0|3.00:94.00 -

Josis | 0.08 max. | 0.90 max. | 2.50 max. | 0.040 max.|0,030 max.|1.04014.0 [17.01020.0 | 2.000250 No6XC%toL 00

fo3291 | 0.08 max. | 090 max. | 1.50 max. 0.040 max.|0.030 max.| 60%08.0 |23.0%028.0| 1.00%3.00 -

fo347 | 0.08 max. | 090 max. | 2.50 max. 10.040 max.|0.030max.| 9.0:011.0]18.0%210| | NosxC%uolO0

Jose. } 0.06 max. | 090 max. | 2.50 max. 10.040 max.|0.030max.| 90.110 |18.0.21.0| — | Noaxc%iot00

fo349 J 0.13 max. | 090 max | 2.50 max 0.040 max.|01030max.| 801010.0 | 18.0%21.0|035%0065) W1.25101.75

Nb 07500120

Isto | 0.12 max. | 0.90 max.| 1.00 max. |0.040 max.|0.030 max.) 0.60 max |110%0140] -

Ipaione | 0.12 max. | 0.90 max. | 1.00 max. |0.040 max.|0.030max.|060mex |110%0140] - | Nb0S0%150

}p430— 0.10 max. | 090 max. | 1.00 max. |0.040 max. |0.030 max. | 060 mex. [15.0180] ~ -

Ipazowe | 0.10 max. | 0,90 max. | 1.00 max. |0.040 max.|0.030max.| 0.60max. |15.0%180] — | Nb05001.50

D630 | 0.05 max. | 0.75 max. | 0.25120.75| 0.040 max.| 0.030 max. | 40:05:00] 160 1016.75] 0.78 max. | NbO.15:00:30

| cu3.25 104.00

4.8 Mechanical properties The tensile strength and elongation of deposited metal

shall comply with the requirements specified in Table 3 when tested in accordance

with the method of 6.3

PROTECTED BY COPYRIGHT

4

2.3221 : 2003

Table 3 Mechanical properties of deposited metal

‘Classification ‘Tensile test

“Tensile strength | Elongation

Nira? %

D307 390 min 30 min,

D308 550 min 35 min.

308. 510 min 35 min.

D308N2 690 min. 25 min

D309 550 min, 30 min,

D309L, 510 min 30 min.

D309Nb 550 min. 30 min,

D309NBL 510 min, 30 min,

D309Mo 350 min. 30 min.

D309MoL. 510 min. 30 min

D310 350 min. 30 min,

D310Mo 350 min, 30 min,

312 660 min 22 min

D16-8-2 550 min, 35 min

36 550 min, 30 min

p3i6L. 510 min, 35 min

DsieniL, 510 min, 35 min,

D3i7 550 min, 30 min,

DSITL 510 min, 30 min,

pais 350 min, 25 min,

32941 590 min. 18 ain,

D347 550 min 30 min,

D347L, 310 min. 30 min

p39 690 min, 25 min,

D410’) 40min | 20 min

DAIONb() 450 min 20 min

D430) 480 min 20 min

D430NbC*) 480 min, 20 min

630°) 930 min. 7 min.

Notes () After heating at 730 °C to 760 °C

for 1 h before processing the test

pieces, furnace-cool to 315°C at

a cooling rate of within 55 °C per

hh, and thereafter air-cool.

(@) After heating at 760°C to 785 °C

for 2 h before processing the test

pieces, furnace-cool to 590 °C at

a cooling rate of within 55°C per

h, and thereafter air-cool.

(°) After heating at 1025 °C to

1050 °C for 1 h before processing

the test pieces, air-cool to room

temperature. In succession, heat

at 610°C to 630 °C for 4h and

then air-cool.

PROTECTED BY COPYRIGHT

5

23221 : 2003

44 Bending performance The bend test of deposited metal shall apply espe-

cially when designated by the purchaser and when tested by the method of 6.4, there

shall be no crack exceeding 3.0 mm in length in any direction nor any defects detri-

mental to use on the bent outer surface of test piece.

4.5 Corrosion resistance of deposited metal The copper sulphate-sulphuric

acid test (hereafter referred to as “corrosion test”) of the deposited metal shall apply

only to the classification shown in Table 4 when particularly designated by the pur-

chaser and when tested by the method of 6.5, the bent outside surface of the test

piece shall be free from intergranular corrosion cracks.

Table 4 Classification of electrodes to be applied to

corrosion test

Classification

‘DSOBL, D316L, DBiGIIL, D31TL, D318, D347, D347L.

5 Dimensions and tolerances The dimensions and tolerances of electrodes shall

be in accordance with 2 of JIS Z 8200. The representative dimensions are shown in

Table 5.

Table 5 Representative dimensions of electrodes

Unit: mm

Diameter Length

16 | 200 250

20 | 200 250 ~ |

| 26 250 300 350

32 300950 400

40 350 400 450 500

50 350 400 450 500

[60 350 400450 500

6 Tests

6.1 General

6.1.1 Test plates The test plates shall be as follows:

a) The test plates to be used for chemical analysis test, tensile test, bend test and

corrosion test of the deposited metal shall be the plates of the same composi-

tion as the chemical components of the deposited metal specified in JIS G 4304

or JIS G 4305.

PROTECTED BY COPYRIGHT

6

2.3221 : 2003

b) For the test plates to be used for chemical analysis test, tensile test and corro-

sion test of the deposited metal, $8400 of JIS G 3101 or SM400 A to C or SM490

A to C of JIS G 8106 may be used. In this case, uttering shall be carried out

in accordance with the method specified in 6.1.2.

c) For the test plates for the bend test of deposited metal, SUS304 specified in

JIS G 4304 or JIS G 4805 may be used.

6.1.2 Buttering of test plate In the case where $8400 of JIS G 8101 or SM400

‘A to C or SM490 A to C of JIS G 8106 is used as the test plate for tensile test and

corrosion test of the deposited metal, the groove face shall be applied with buttering

of two or three layers by using the same kind of electrode as the test electrode as

shown in Fig. 1.

Unit: mm

Buttering

14

a T: Plate thickness

Approx. 25, a: Root gap

Fig. 1 Buttering of test plate

6.1.3 Welding position and diameter of electrodes All welding shall be car-

ried out in flat position.

The chemical analysis test shall be carried out on all diameters, and the tensile

test, bend test and corrosion test shall be carried out on a diameter of 3.2 mm or

4.0 mm as a representative of all the diameters. However, for D312, D329J1, D410,

D410Nb, D430, D430Nb and D630, the bend test is not carried out.

6.2 Chemical analysis test The method of preparing deposited metal pad and

samples for chemical analysis shall be in accordance with JIS Z 3184.

a) For the analysis sample of the deposited metal, a residual material of a paral-

lel portion of the tensile test piece after rupture by the test of 6.8 may be sampled

by cutting.

b) The method for chemical analysis of the deposited metal shall be in accordance

with any one of the following standards:

JIS G 1201, JIS G 1204, JIS G 1211, JIS G 1212, JIS G 1213, JIS G 1214,

JIS G 1215, JIS G 1216, JIS G 1217, JIS G 1218, JIS G 1219, JIS G 1220,

JIS G 1237, JIS G 1253, JIS G 1256, JIS G 1257, JIS Z 2611, JIS Z 2615

6.3 Tensile test of deposited metal The tensile test of deposited metal shall

be carried out in accordance with JIS Z $111.

PROTECTED BY COPYRIGHT

a)

b)

e)

@)

e)

6.4

7

Z 3221 : 2003

The welding current shall be 70 % to 90 % of the maximum value in the current

range recommended by the manufacturer.

For D410, D410Nb, D430 and D430Nb, the preheating and interpass tempera-

ture shall be 150 °C to 250°C, and for other classifications the welding of each

pass shall be started at a temperature of 15 °C to 150°C. However, when the

temperature of the test plate has exceeded the interpass temperature at the

start of welding for each pass, the test plate shall be air-cooled.

‘The heat treatment of D410, D410Nb, D430, D430Nb and D630 shall be carried

out under the conditions shown in Notes of Table 3 prior to processing the test

piece, and for other classifications as-welded condition shall be applied

‘The type of test pieces shall be No. A2 for 3.2 mm diameter, and No. Al for 4.0 mm

diameter.

‘The test temperature shall be room temperature.

Bend test of deposited metal The bend test of deposited metal shall be carried

out as follows:

a)

b)

c)

a)

‘The bend test shall be a longitudinal face bend test.

The test plate shall either be restrained previously or be given preset distor-

tion so that the angular deformation after completion of welding does not ex-

ceed 5 degrees.

‘The welding of the first pass shall be carried out at room temperature, the interpass

temperature shall be 15°C to 150°C, and the number of layers shall not be

less than 3. The treatment of stress relieving shall not be applied to the test

material and the test pieces.

A piece of test piece shall be sampled in accordance with Fig. 2, and be pre-

pared as shown in Fig. 3.

PROTECTED BY COPYRIGHT

8

Z 3221 : 2003

Unit: mm Unit: mm

Approx. 160,

T T 7

| |

| | 3

| | 8) r

| | 3 3

i \ 8

a |

i

| | ~

| fol

Test pects ss ney sf

60" Reinforcement S|

gy 2 {otra ‘3 max.

=| 3 Fig. 3 Dimensions of

i Sf bend test piece

e)

f)

Not more than electrode

covering diameter ro

4to6

Fig. 2. Dimensions of test material for

bend test and sampling positions

of test piece

Cutting of test piece shall be carried out by machine cut or thermal cutting.

However, in the case of sampling by thermal cutting, the heat-affected zone

generated thereby shall be removed. The weld reinforcement and backing metal

shall be removed to the base metal surface and the test surface shall be cut by

1.5 mm from the face bend side and the test piece shall be finished to 10 mm in

thickness.

‘The bend test method of test piece shall be carried out in accordance with JIS

Z 8122. The radius of bend shall be 20 mm and the test temperature shall be

room temperature.

6.5 Corrosion test of deposited metal The corrosion test of deposited metal

shall be carried out as follows:

a)

b)

c)

‘The test material shall be as shown in Fig. 4, and prepared by groove weld of

the test plates.

‘The welding of the first pass shall be carried out at room temperature and the

interpass temperature shall be 15 °C to 150°C.

‘Two corrosion test pieces having not more than 5 mm in thickness, not more

than 10 mm in width and 30 mm to 70 mm in length shall be sampled from the

test material shown in Fig. 4

PROTECTED BY COPYRIGHT

9

73221 : 2003

d) The corrosion test method of test pieces shall be in accordance with JIS G 0575.

Unit: mm

4 :

atm

a iil

a ||

~ oh Z|

gq MT &

a til

4 uf

45 Test pieves |

oJ | ql

Ey

1

ig

Approx.120_ Approx.25| “1 Approx.120

Fig. 4 Dimensions of test material for corrosion test

and sampling position of test pieces

7 Inspection The inspection shalll be carried out as follows:

a) For electrode, covering, dimensions, and the results of chemical analysis test,

tensile test, bend test and corrosion test shall comply with the specifications of

4 and 5.

b) The tensile test, bend test and corrosion test for electrodes of not more than

2.6 mm and not less than 5.0 mm in diameter shalll be judged from the test results

of electrode of 3.2 mm or 4.0 mm in diameter of the same classification.

©) In case where any one of the chemical analysis test, tensile test, bend test and

corrosion test fails to meet the requirements, a retest on the relevant item may

be carried out only once, and the result shall comply with the requirements.

8 Packaging The packaging shall be in accordance with 5 of JIS Z 8200.

9 Designation of produets The products shall be designated by classification,

diameter and length of the electrodes.

Example: D316-15 — 3.2 — 350

Classification Diameter Length

PROTECTED BY COPYRIGHT

10

2.3221 : 2003

10 Marking ‘he marking shall be in accordance with 4 of JIS Z 3200. The clas-

sification of electrodes shall be applied with colour for identification specified in Table 6

on the end face or both the end face and side face as shown in Fig. 5 or be curved-

surface printed with classification at the position shown in Fig. 6.

End face

ee Side face colour

Fig. 5 Colouring position

Unit: mm

65 max.

Curved-surface printing

Fig. 6 Position of curved-surface printing

PROTECTED BY COPYRIGHT

uu

7.3221 : 2003

Table 6 Marking colour of electrodes

Classification | End face colour | Side face colour

D307 Purplish red 5

D308 Yellow -

sos Red =

D308N2 Yellow e

D308 Black 7

Da09L Yellowish green -

D309Nb Black C

Da09NbL, Black C

Ds09Mo Silver =

D309MoL Silver *

D310 Pink -

Ds10Mo Pink e

paiz Green .

Di6-8-2 White G

psi6 White -

Dsi6L Green =

Dai6s1L Gray ES

pai7 Brown -

Dsi7L Chestnut colour

pais Green .

D291 Red e

D347 Blue |

Dsart, Blue v

p49 Yellow .

410 Purple =

D410Nb Purple *

4so Light brown =

D430Nb Light brown | te

eso Orange |

Remarks: The electrodes corresponding to * mark

shall be coloured on the side face, pro-

vided that the kind of colour is not speci-

fied.

PROTECTED BY COPYRIGHT

12.

Z 3221 : 2003

JIS G 0575

JIS G 1201

JIS G 1204

JIS G 1211

JIS G 1212

JIS G 1213

JIS G 1214

JIS G 1215

JIS G 1216

JIS G 1217

JIS G 1218

JIS G 1219

JIS G 1220

JIS G 1237

JIS G 1258

JIS G 1256

JIS G 1257

JIS G 3101

JIS G 3106

JIS G 4304

JIS G 4305

JIS Z 2611

JIS Z 2615

JIS Z 8111

JIS Z 8122

JIS Z 3184

JIS Z 8200

Attached Table 1 Normative references

Method of copper sulfate-sulfuric acid test for stainless steels

Iron and steel—General rules for analytical methods

General rules for fluorescent X-ray analysis of iron and steel

Iron and steel—Methods for determination of carbon content

Iron and steel—Methods for determination of silicon content

Iron and steel—Methods for determination of manganese con-

tent

Iron and steel—Methods for determination of phosphorus con-

tent

Iron and steel—Methods for determination of sulfur content

Tron and steel—Methods for determination of nickel content

Methods for determination of chromium in iron and steel

Iron and steel—Methods for determination of molybdenum content

Iron and steel—Methods for determination of copper content

Iron and steel—Methods for determination of tungsten content

Iron and steel—Methods for determination of niobium content

Iron and steel—Method for spark discharge atomic emission spec-

trometric analysis

Iron and steel—Method for X-ray fluorescence spectrometric analy-

sis

Iron and steel—Methods for atomic absorption spectrometric

analysis

Rolled steels for general structure

Rolled steels for welded structure

Hot rolled stainless steel plates, sheets and strip

Cold rolled stainless steel plates, sheets and strip

General rules for photoelectric emission spectrochemical analy-

sis of metal materials

General rules for determination of carbon in metallic materi-

als

Methods of tension and impact tests for deposited metal

Methods of bend test for butt welded joint

Method of preparing deposited metal pad and samples for chemi-

cal analysis

Welding consumables—Technical delivery conditions for weld-

ing filler metals—Type of product, dimensions, tolerances and

marking

PROTECTED BY COPYRIGHT

Errata for JIS (English edition) are printed in Standardization Journal, published monthly

by the Japanese Standards Association, and also provided to subscribers of JIS English

edition) in Monthly Information.

Errata will be provided upon request, please contact:

‘Standardization Promotion Department, Japanese Standards Association

41-24, Akasaka, Minato-ku, Tokyo, 107-8440 JAPAN

TEL. 03-3583-8002 FAX. 03-3583-0462

100% Recycled paper

PROTECTED BY COPYRIGHT

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HARDNESS TEST METHODSDocument13 pagesHARDNESS TEST METHODShaizum_adamNo ratings yet

- Sigmacover 410Document5 pagesSigmacover 410panji akbarNo ratings yet

- Zinc Silicate Primer Product Data SheetDocument6 pagesZinc Silicate Primer Product Data Sheetgst ajahNo ratings yet

- Overview of Steel Surface Preparation: H. William HitzrotDocument5 pagesOverview of Steel Surface Preparation: H. William Hitzrotpanji akbarNo ratings yet

- INSPECTION of Galvanize Product PDFDocument24 pagesINSPECTION of Galvanize Product PDFNasikhatul AmanahNo ratings yet

- General5 PDFDocument18 pagesGeneral5 PDFrifqimaterialNo ratings yet

- Malaysia Standart IncomingDocument21 pagesMalaysia Standart Incomingpanji akbarNo ratings yet

- Manual For Cyclic Triaxial TestDocument49 pagesManual For Cyclic Triaxial Testpanji akbarNo ratings yet

- 05 RecrystallizationsDocument26 pages05 Recrystallizationspanji akbarNo ratings yet

- Counteracting Ring Formation in Rotary Kilns: Research Open AccessDocument19 pagesCounteracting Ring Formation in Rotary Kilns: Research Open Accesspanji akbarNo ratings yet

- Kiln PDFDocument134 pagesKiln PDFpanji akbarNo ratings yet