Professional Documents

Culture Documents

Affinity Laws PDF

Affinity Laws PDF

Uploaded by

Gustavo Baccho Jorge FilhoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Affinity Laws PDF

Affinity Laws PDF

Uploaded by

Gustavo Baccho Jorge FilhoCopyright:

Available Formats

GRUNDFO S

PUMP AFFINITY LAWS FOR

WHITE PAPER

CENTRIFUGAL PUMPS

by Steve Wilson

T he Affinity Laws for centrifugal pumps

describe the impact of changes in speed or

impeller diameter on pump flow, head, and HP.

However, as explained in this White Paper,

care must be taken in their application. Several

watch outs will be discussed.

They are useful tools in predicting pump perfor-

mance changes when speed or impeller diameter THE AFFINITY LAWS

are changed, such as might be experienced when The Affinity Laws state that (1) flow will change

variable speed drives are employed, directly when there is a change in speed or

diameter, (2) heads will change as the square of

impellers are trimmed, and

a change in speed or diameter, and (3) HP will

pump curves, which are plotted at 60 Hz change as the cube of a change in speed or diam-

speeds, are to be used across international eter. As formulae, Affinity Laws are expressed as

borders at 50 Hz speeds (and vice versa). follows in Table 1.

Q1 D1 Q1 N1 Where:

= OR =

Q2 D2 Q2 N2

Q = Flow

D = Impeller Diameter

H1 D1

2

H1 N1

2 N = Speed

= OR = H = Head (TDH)

H2 D2 H2 N2 BHP = Brake Horsepower

3 3

The subscript 1 indicates existing

BHP1 D1 BHP1 N1 conditions; the subscript 2 indicates

= OR =

BHP2 D2 BHP2 N2 new conditions.

Table 1. Formulaic Representation of Affinity Laws

PUMP AFFINITY LAWS FOR CENTRIFUGAL PUMPS GRUNDFOS WHITE PAPER | 2

Using these calculations, we could then predict their use in impeller trim, work better for radial-

the impact a 10 percent drop in speed would vaned impellers (impellers with low specific

have on the performance of a pump that is de- speed) while very poorly for Axial Flow impellers

livering a flow of 100 gpm against a head of 100 (impellers with high specific speeds).

ft., operating at a speed of 3,550 rpm, and having As the specific speed increases, the accuracy of

a BHP requirement of 3.53 (Table 2). This pump Affinity Law decreases. When coupled with the

would now deliver 90 gpm at 81 ft. TDH and impact of increases in shock, recirculation, and

require 2.574 BHP. turbulence, it is recommended that Affinity Laws,

in general, not be used for ascertaining a change

DISCUSSION AND WATCH OUTS in impeller trim unless the manufacturer is con-

The understanding of how centrifugal pumps tacted and approves the use.

work is vitally necessary. Energy is added to the

Superior results will be obtained by using empiri-

fluid in the form of velocity in the impeller. This

cal data that is available from the pump manu-

velocity increases as it travels out the vanes of

facturer for performance at various trims and

the impeller.

interpolating, as required.

As the fluid exits the impeller, the fluid enters the

Regarding changes in speed, great care must

pump body (volute), thereby reducing velocity

also be taken. The Affinity Laws are very useful in

and increasing pressure. The increase in veloc-

small changes to speed, but they have become

ity is directly related to the shape of the impel-

predictive tools for VFD operation where changes

ler vanes, the impeller discharge angle (specific

may be more dramatic. Since BHP is a function of

speed), the diameter of the impeller, and the

the amount of work being done (GPM x TDH) and

speed at which the impeller is rotating.

the efficiency of the pump (3,960 x Eff), it is obvi-

The relationship between the impeller and the vo- ous that changes in efficiency will impact BHP.

lute is important in this conversion to pressure as

At shutoff, the efficiency is zero (0) (power is

recirculation losses, turbulence, shock, and friction

going in, but no work is being done). Using the

inside the pump will detract from the conversion.

logical extreme to illustrate the point, what would

When the shape of the vane inside the impeller happen to the efficiency of a pump designed for

changes, prediction of the impact of impeller trim 1,750 rpm operation with 85 percent efficiency

becomes difficult. The Affinity Laws, in regard to when the speed is reduced to 1 rpm?

Q1 = 100

H1 = 100

N1 = 3,550

BHP1 = 3.53

N2 = (3,550 x .9) = 3,195

Q2 = [100 x (3,195/3,550)] = (100 x .9) = 90

H2 = [100 x (3,195/3,550)2] = [100 x (.9 x .9)] = (100 x .81) = 81

BHP2 = [3.53 x (3,195/3,550)3] = [3.53 x (.9 x .9 x .9)] = (3.53 x .729) = 2.574

Table 2. Performance Impact

PUMP AFFINITY LAWS FOR CENTRIFUGAL PUMPS GRUNDFOS WHITE PAPER | 3

Using the Affinity Laws would allow us to calcu-

late flow, head, and BHP but that calculation

would be based on keeping efficiency constant.

It is apparent that efficiency will not stay at 85

percent and then suddenly become zero (0) with a

1 rpm change in speed.

A prediction cannot be made other than the

pump most likely will not work when there is

not enough energy being added to the fluid. The

Affinity Laws must therefore not be used when

speed change is extreme.

How is extreme determined? One useful tool

provided by most manufacturers is minimum con-

tinuous stable flow. It is plotted on many curves

and represents the manufacturers recommenda-

tions for a stable operating range. Of course, this

will vary by both manufacturer and pump.

If in doubt or when the reduction in speed could

violate MCSF, the manufacturers engineering

department should be contacted to ascertain

suitability. Since most VSDs are being employed

as energy-saving devices, and energy use will be

directly linked to pump efficiency, the efficiency of

the pump at those reduced speeds must be taken

into consideration. Actual BHP should be calculat-

ed from empirical data rather than by using pump

Affinity Laws.

In general, most manufacturers will place a lower

limit on speed reduction to approximately 40 to

50 percent of full speed before considering speed

reduction as extreme, and, beyond that, Affinity

Laws may be used for predictive purposes.

CONCLUSIONS

Affinity Laws are useful tools for the majority of

centrifugal pumps. When properly used, they will

allow prediction of performance when speeds or

impeller trims are employed. Used improperly, Af-

finity Laws may yield false predictions.

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

You might also like

- A Study On An Optimal Approach Temperature Control Strategy of Condensing Water Temperature For Energy SavingDocument8 pagesA Study On An Optimal Approach Temperature Control Strategy of Condensing Water Temperature For Energy SavingjoasobralNo ratings yet

- Pump Armstrong PDFDocument47 pagesPump Armstrong PDFMohamed Sulaiman Ibrahim100% (1)

- Yokogawa SyncDocument40 pagesYokogawa SyncHumberto Galvez100% (1)

- IEC Motor StandardsDocument9 pagesIEC Motor Standardssubramanyanvenkat6185100% (1)

- Practical Task 3 PumpDocument8 pagesPractical Task 3 Pumpshirleyna sara100% (2)

- Chanjot ReportDocument18 pagesChanjot ReportKumud BadoniNo ratings yet

- Air SysDocument11 pagesAir Syspbhat83No ratings yet

- Using Variable Speed Drives VSDs in Pump Applications 1700774456Document36 pagesUsing Variable Speed Drives VSDs in Pump Applications 1700774456hamedNo ratings yet

- Ansi - Ieee STD 352 - 1987Document118 pagesAnsi - Ieee STD 352 - 1987ERICK MARTINEZ AGUIRRENo ratings yet

- 23 09 13.33 - Control ValvesDocument25 pages23 09 13.33 - Control Valvesforevertay2000No ratings yet

- DRAFT IEEE Recommended Practice For Field Testing Electric Submersible Pump CableDocument28 pagesDRAFT IEEE Recommended Practice For Field Testing Electric Submersible Pump CableJairo Jaramillo100% (1)

- Temperature Effects On DC Motor Performance PDFDocument10 pagesTemperature Effects On DC Motor Performance PDFthierry42No ratings yet

- Ieee StandardsDocument176 pagesIeee StandardsVasu IyerNo ratings yet

- Mil R 83248CDocument20 pagesMil R 83248C이형주No ratings yet

- Motor Duty TypesDocument3 pagesMotor Duty TypesVijay KumarNo ratings yet

- Method of Reducing Carry-Over and Reducing Pressure Drop Through Steam Separators, EPRI NP-1607Document367 pagesMethod of Reducing Carry-Over and Reducing Pressure Drop Through Steam Separators, EPRI NP-1607MarioNo ratings yet

- Improving Energy Efficiency of Centrifugal Pumps EU Commision-1Document70 pagesImproving Energy Efficiency of Centrifugal Pumps EU Commision-1Abdulrahman AlkhowaiterNo ratings yet

- Pump InstallationDocument9 pagesPump InstallationYe tun KyawNo ratings yet

- IIT-Intake and Exhaust Manifold DesignDocument28 pagesIIT-Intake and Exhaust Manifold DesignVasudev GuptaNo ratings yet

- Metallurgical Factors Influencing The Machinability of Inconel 718 - SchirraDocument12 pagesMetallurgical Factors Influencing The Machinability of Inconel 718 - SchirraAntonioNo ratings yet

- BOILER PrestigeDocument2 pagesBOILER PrestigeJaime Rodri Millapan AlianteNo ratings yet

- Understanding Pump Curves: Taco Radiant Made Easy Application Guide Technical DocumentsDocument4 pagesUnderstanding Pump Curves: Taco Radiant Made Easy Application Guide Technical DocumentsmohdnazirNo ratings yet

- Philippines Climate DataDocument1 pagePhilippines Climate DataJk Pascii100% (2)

- Radial - Flow: (Centrifugal Pump)Document17 pagesRadial - Flow: (Centrifugal Pump)John A. CenizaNo ratings yet

- Fans and BlowerDocument45 pagesFans and BlowerMad MaxNo ratings yet

- Hydraulic ProfilingDocument104 pagesHydraulic ProfilingiJordanScribdNo ratings yet

- A New Method For Calculating The Busemann Head Coefficients For Radial ImpellersDocument7 pagesA New Method For Calculating The Busemann Head Coefficients For Radial ImpellersIvan RaulNo ratings yet

- Pump Performance Four Quadrante - Pumping Thru ESPDocument8 pagesPump Performance Four Quadrante - Pumping Thru ESPTarcísio PortoNo ratings yet

- Edoc 001864Document52 pagesEdoc 001864leesger7No ratings yet

- Project ReportDocument36 pagesProject Reportvishi89No ratings yet

- Bell & Gossett-Parallel and Series Pump Application PDFDocument18 pagesBell & Gossett-Parallel and Series Pump Application PDFrenoyaboNo ratings yet

- Bearing Current in VFD Fed MotorDocument24 pagesBearing Current in VFD Fed Motormarn-in2501No ratings yet

- Regenerative Liquid Ring Pumps Review and Advances On Design and PerformanceDocument20 pagesRegenerative Liquid Ring Pumps Review and Advances On Design and PerformanceBla BlaNo ratings yet

- JY7903 Series Oil-Resistant Sealing GreaseDocument2 pagesJY7903 Series Oil-Resistant Sealing GreaseilkerkozturkNo ratings yet

- Vosa Equilibrium Float ValveDocument2 pagesVosa Equilibrium Float ValveDota NgNo ratings yet

- Governing of Turbine HydraulicDocument3 pagesGoverning of Turbine HydraulicMike100% (2)

- Motor Nameplate InformationDocument29 pagesMotor Nameplate InformationJaishankar PrabhakaranNo ratings yet

- Armstrong PumpDocument8 pagesArmstrong PumpRohith RavindranathNo ratings yet

- Gasket Application and Material Selection GuideDocument10 pagesGasket Application and Material Selection GuideTieu KakaNo ratings yet

- PID Control of Heat Exchanger SystemDocument6 pagesPID Control of Heat Exchanger SystemTuấn Anh Nguyễn100% (1)

- Pufferspeicher 500-5000 240 810-5 EnglDocument6 pagesPufferspeicher 500-5000 240 810-5 Englpatrutionel99No ratings yet

- Radial ImpellerDocument10 pagesRadial ImpellernikitaNo ratings yet

- Boosting The Reliability of Power System Models: Dong-Hyeon (DH) KimDocument4 pagesBoosting The Reliability of Power System Models: Dong-Hyeon (DH) Kimleorese100% (1)

- Center Pivot Irrigation DesignDocument55 pagesCenter Pivot Irrigation DesignSCERVANTESLUIS100% (1)

- Advantages of High Speed Balancing - ToshibaDocument3 pagesAdvantages of High Speed Balancing - ToshibaJessica SandersNo ratings yet

- Geothermal BrineDocument6 pagesGeothermal BrineAchmad HermansyahNo ratings yet

- Control Valves: Fluid Jet Energy Criterion ForDocument4 pagesControl Valves: Fluid Jet Energy Criterion ForjosethompsonNo ratings yet

- API 692 GuidelinesDocument84 pagesAPI 692 Guidelinessiva prasadNo ratings yet

- Attachment 4 - 630kW 380V 4pole 50Hz Electric Motor Data SheetDocument2 pagesAttachment 4 - 630kW 380V 4pole 50Hz Electric Motor Data Sheetachmadj1405100% (1)

- Mechanical Engineering Department ME 47 (ME Final Year Project Study 1)Document20 pagesMechanical Engineering Department ME 47 (ME Final Year Project Study 1)Roy RagotNo ratings yet

- Armstrong PDFDocument8 pagesArmstrong PDFSanthosh ThekkethottiyilNo ratings yet

- Performance Characteristics of Axial FansDocument4 pagesPerformance Characteristics of Axial Fanskutts76No ratings yet

- Concrete Volute PumpsDocument8 pagesConcrete Volute PumpsvijayunityNo ratings yet

- Induction and Synchronous Motor FundamentalsDocument10 pagesInduction and Synchronous Motor Fundamentalshozipek5599100% (1)

- Ieee 1018-04Document38 pagesIeee 1018-04Jose Antonio EstofaneroNo ratings yet

- Is 7332-2 (1993)Document9 pagesIs 7332-2 (1993)slamienkaNo ratings yet

- Energy Conservationi N Pumps: M.V.Pande Dy - Director NPTI, NagpurDocument37 pagesEnergy Conservationi N Pumps: M.V.Pande Dy - Director NPTI, NagpurmvpngpNo ratings yet

- ISA AW 2012 Control Valve Vs Variable Speed Drive PDFDocument10 pagesISA AW 2012 Control Valve Vs Variable Speed Drive PDFDavid Omar Torres GutierrezNo ratings yet

- Pump Tech 5 Affinity LawsDocument14 pagesPump Tech 5 Affinity LawsGAMUCHIRAI MUGADZANo ratings yet

- Piping Excel SheetDocument52 pagesPiping Excel SheetSubrata Mukherjee100% (2)

- Centrifugal PumpDocument13 pagesCentrifugal Pumpafr5364No ratings yet

- M 389 ContentDocument52 pagesM 389 ContentokahertaberNo ratings yet

- 94 890 NativeBACnet IVS 102 Operating Instructions MG14C102Document32 pages94 890 NativeBACnet IVS 102 Operating Instructions MG14C102subramanyanvenkat6185No ratings yet

- 101 82 - DE - 4300 4380 - VIL - withIVSDrive - IO PDFDocument48 pages101 82 - DE - 4300 4380 - VIL - withIVSDrive - IO PDFsubramanyanvenkat6185No ratings yet

- Pump Vibration Monitoring InstrumentsDocument4 pagesPump Vibration Monitoring Instrumentssubramanyanvenkat6185No ratings yet

- Danfoss Pressure SwitchesDocument2 pagesDanfoss Pressure Switchessubramanyanvenkat6185No ratings yet

- Basic Preventive Maintenance Check List For ReciprocatingDocument4 pagesBasic Preventive Maintenance Check List For Reciprocatingsubramanyanvenkat6185100% (1)

- Motor Wiring DiagramDocument1 pageMotor Wiring Diagramsubramanyanvenkat6185No ratings yet

- Motor ProtectionDocument58 pagesMotor ProtectionVenkat Subramanyam.CNo ratings yet

- Hydraulic Machines MR Raman GahlautDocument44 pagesHydraulic Machines MR Raman GahlautEyob AdNo ratings yet

- 40 - Southern Cross - Iso Pump - 125 X 100 - 250 - 1200 3000 RPMDocument1 page40 - Southern Cross - Iso Pump - 125 X 100 - 250 - 1200 3000 RPMJAZZ KING PROJECTNo ratings yet

- Government College of Technology, Coimbatore - 13 Department of Mechanical Engineering - Ug Course: Semester: Subject: Assignment: 03Document2 pagesGovernment College of Technology, Coimbatore - 13 Department of Mechanical Engineering - Ug Course: Semester: Subject: Assignment: 03SakthiNo ratings yet

- PUMPS ReviewerDocument63 pagesPUMPS ReviewerMark Santos100% (1)

- Harga - 1Document137 pagesHarga - 1Admin Pembelian Barang 85No ratings yet

- Paradeep Refinery Project: A Sunrise Project For A Sunshine FutureDocument54 pagesParadeep Refinery Project: A Sunrise Project For A Sunshine FuturekishoreprithikaNo ratings yet

- Pump HM100 C5 Performance Curve: 300 300 Full Closed 5 30 Metal MetalDocument1 pagePump HM100 C5 Performance Curve: 300 300 Full Closed 5 30 Metal MetalPaulo RobertoNo ratings yet

- Waterco Ps Pumps0 PDFDocument16 pagesWaterco Ps Pumps0 PDFEmanuel MurilloNo ratings yet

- Problems On Axial TurbinesDocument2 pagesProblems On Axial TurbinesSridhar KrishNo ratings yet

- Exercise Lec-05 PDFDocument5 pagesExercise Lec-05 PDFaustin00012No ratings yet

- Mid - 1 Atd-2Document1 pageMid - 1 Atd-2Bhlp RajuNo ratings yet

- How Does Francis Turbine Work - Learn EngineeringDocument4 pagesHow Does Francis Turbine Work - Learn EngineeringedpsousaNo ratings yet

- Problemario Maquinas Hidráulicas Segundo ParcialDocument8 pagesProblemario Maquinas Hidráulicas Segundo ParcialenriqueduvoisNo ratings yet

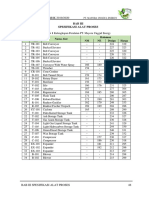

- Perpab6-Spesifikasi AlatDocument38 pagesPerpab6-Spesifikasi AlatardiNo ratings yet

- Propulsion Lect 11 Axial TurbinesDocument28 pagesPropulsion Lect 11 Axial TurbinessanjayNo ratings yet

- Turbine Engine Design and ConstructionDocument4 pagesTurbine Engine Design and ConstructionWanda Aulia SukmaNo ratings yet

- Compressor SurgeDocument3 pagesCompressor SurgeajaysapruNo ratings yet

- Wilo 448622Document16 pagesWilo 448622giovanny jimenezNo ratings yet

- Shlyakhin - Theory and Design of Steam TurbinesDocument239 pagesShlyakhin - Theory and Design of Steam Turbinesjoatanmelo6775100% (2)

- Me0302 Assn Tutorial QDocument4 pagesMe0302 Assn Tutorial QVijay Pal Singh0% (1)

- 1-22SVF 6 June11 EdC PDFDocument20 pages1-22SVF 6 June11 EdC PDFTalin Williams100% (1)

- Meturbo Presen 2009Document37 pagesMeturbo Presen 2009Ronaldo FarinhasNo ratings yet

- Pump Data Sheet: Ronak Pumps and Valves PVT - LTDDocument1 pagePump Data Sheet: Ronak Pumps and Valves PVT - LTDAtul AmgaonkarNo ratings yet

- 2 - Turbopump TypesDocument28 pages2 - Turbopump Typesمصطفى أشرفNo ratings yet

- Katalog MKS Mei 2010Document22 pagesKatalog MKS Mei 2010Maulia SabrinaNo ratings yet

- Task 1: - A) It's Required To Describe With A Schematic Representation The Main Turbomachines Classifications According To: - 1) Energy TransferDocument14 pagesTask 1: - A) It's Required To Describe With A Schematic Representation The Main Turbomachines Classifications According To: - 1) Energy TransferAbd El-Rahman NasserNo ratings yet

- Brosur Gnatus Syncrus HLX Multimedia KitDocument3 pagesBrosur Gnatus Syncrus HLX Multimedia KitBulfendri DoniNo ratings yet

- 5th SemDocument9 pages5th SemKeshav VaradarajuNo ratings yet

- Types of Gasturbine Engine: Prepared By: Engr. Jan Lester V. MagbagDocument24 pagesTypes of Gasturbine Engine: Prepared By: Engr. Jan Lester V. MagbagJohn Kane Mariano100% (1)