Professional Documents

Culture Documents

MSR 35096E 0 Inspection Procedure

Uploaded by

LautBiru0 ratings0% found this document useful (0 votes)

12 views6 pagesinspection procedure

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentinspection procedure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views6 pagesMSR 35096E 0 Inspection Procedure

Uploaded by

LautBiruinspection procedure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

Doc.No. : MSR-35096E Rev.0 1/3

TO : PT UNITECHNINDO PERKASA

INSPECTION PROCEDURE |

‘TEAM TRAP

0 | 2017.05.16 | A new prepared. Fbbihera.| T Yasuda PA

Rev. . Reviewed

Date Description Approved Prepared

No. (QA)

rN MIYAWAKI INC.

PRODUCTION DEPARTMENT / PRODUCTION CONTROL SECTION

Doc.No. : MSR-35096E Rev.0 2/3

1. Application

‘This procedure covers inspection procedure for commodities highlighted on the cover sheet.

2. Applicable Code, Standard and Specifications

1) Japanese Industrial Standards [JIS]

JIS B8401(1999) : Automatic steam traps

2) American Society of Mechanical Engineers (ASME}

ASME B16.11(2011) : Forged Fittings, Socket-Welding and Threaded

8) American Society for Testing and Materials [ASTM]

ASTM A105/A105M : Carbon Steel Forgings for Piping Applications

4) Customer's project specifications

GGCP-04-L6-DS-001-KE : DATA SHEET FOR STEAM TRAP

3. Material Inspection

1) Material test certificate shall be checked according to requirements specified in the applicable

ASTM standards.

The heat number or lot number on the material shall be identified in the corresponding material

test certificate.

2) Material certificates shall be submitted for body and cover.

3) Material certificates shall be in accordance with EN10204 Type 3.1.

4, Visual Inspection

1) The internal and external surfaces of casting shall be free from harmful defects, such as cracks,

blowholes, burrs, burn-on, scale, sand inclusions and other defects

2) Forging shall be free from harmful defects, such as cracks, fogging, tool marks and other defects.

3) Steel bar and pipe shall be free from harmful defects, such as cracks, scab, roll marks and other

defects,

4) Machined surfaces shall be free from harmful scratches and no irregularities concerning the

finishing.

5) Welds shall be free from harmful defects, such as cracks, undercut, overlap, splatters, pits and

other defects

6) Corners and ends without specified dimensions shall be properly chamfered or rounded.

7) Flow path positioned shall be properly finished and cleaned.

5. Dimensional Inspection

‘The assembled commodities shall be inspected for dimensions specified in approved drawing using

measuring equipment which has been calibrated within required calibration cycle

1) Dimensional tolerance of socket welds shalll be as follow

Size 1/2”, 3/4” V1"

(OD (C)__|Min.: 0, Max.: +2 Min.: 0, Max.: +2.5

TD (B)__|Min.: 0, Max.: +0.4

[Depth (D)

Notes : a) Dimensions are inmm. b) Abbreviation OD : Outside diameter , ID : Inside diameter

2) Dimensional tolerance of face to face length (L), unless otherwise specified in drawing, shall be as

follows. _

L 280 and below | 280.1~600 | 600.1 and above

‘Tolerance 21.5 230 4.0

Note : Dimensions are in mm.

Mh MIYAWAKI INC.

Doc.No. : MSR-35096E Rev.0 3/3

8) Dimensional tolerances of machined parts other than the above, shall follow medium class

(turning process) and coarse class (other processes) in JIS B0405, General Tolerances - Part 1

‘Tolerances for linear and angular dimensions without individual tolerance indications.

4) For approximate dimensions or H dimension shown in drawing, the dimensional tolerance shall

be +10mm.

6. Hydrostatic Inspection

1) Inspection conditions

@ Inspection equipment (Refer to Appendix-1).

Q Test fluid shall be city water.

@ Testing temperature is room temperature.

@ 2 equivalent pressure gauges, which are calibrated every 6 months, shall be used for

measuring the test pressures.

At full scale, the pressure gauge can be used from 1.5 to 8 times of test pressure.

@® The short term shown for hydrostatic test pressure in drawing is “HYDRO'C TEST PRESS”.

@® Minimum holding time for hydrostatic test shall be 3 minutes.

2) Acceptance criteria

‘There shall be neither leakage nor abnormal deformation of pressure parts.

3) Re-inspection

If the test fails, the test product shall be inspected for faults before retesting.

7. Operational Inspection

1) Inspection conditions

@ Inspection equipment (Refer to Appendix-1)

® Test pressure shall be settled 3.88MPaG.

@® Testing temperature is fluid saturated temperature at a pre-determined test pressure.

@ Test product will open and close for at least 3 times at a pre-determined test pressure.

2) Acceptance criteria

‘The steam trap shall be smooth and neither valve seat leak nor other abnormalities found.

3) Re-inspection

If the test fails, the test product shall be inspected for faults before hydrostatic test, follow by

operational test.

8, Marking Inspection

‘The commodity shall be marked on body or name plate for the following items;

1) Manufacture's name

2) Model name

3) Size

4) Maximum working pressure, Maximum working temperature

5) Arrow of flow direction

6) Material’s name, heat or lot number

7) S.No. (manufacturing date)

9. Inspection Document

Refer to Appendix 2-3 for details of documents provided.

"A MIYAWAKI INC.

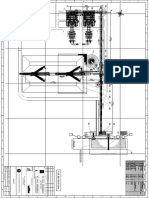

APPENDIX-1

Pressure

gauge

Qe

Hyrule

Sy |oylinder

Valve

Hydrostatic inspection apparatus kU i

Test plece

Accurpulater

=

Pressurized Valve

water ly pet ok ke

x OX

Water t

Operation inspection apparatus (Steam trap)

Reducing Pressure : more than 1MPaG

valve

seen Sep oh

~~ | Valve rately |

Spsite

Pressure valve

at KC)

APPENDIX-2

aoteueyt yoaulg Aaenp “ONT DYMIVAIN Aa panes,

auva

871229722 RE EAI CHORT TT

“uausmsp0 apm soumioo0 pnoanypuw psn PUTNAM AA op 8 AICO A984 OM

BemRH

d= ALVOISILNO TWRESLV wrskeaBee

Soa

i

Lip

=

Je]

or eRe

aaa il gas 4 a de d nev

: aod. Je J, |i de ay a

zowE SE Ss wif SE clo wld oct dig |e |. |e

Se ge gM 9 gy ge “1 Se ge sf eB gi ol wer

8 3? 4 8 a? | a: 4 BC Tle 1 4 oma

war Tm a sear waar

Tare Tar

OF SOE-VORVE TOSS ZOEO-OOTAL

soc BL ZIRE AEMOMY. 1z00-Ze8

N¥¥P1200-288'V1VS0 HVIAYOOGOA VADIVAYO¥L 08-1-2

7 ae

+Ga= rome VW ‘wasn

“ONT DIVMWAIN or)

wanoisno

sRene

‘ON aLVOILLYIO

#8 w Ee

SLVOIILYAO NOLLOAdSNI

APPENDIX-3

ar ASS

Ben ea

scon 1a a wots zo ae

=e tea aa Ti soe -ane “10 RG

‘syre1@p AsoA2 ut avo pue any axe synsax eaoge ayy Tey palzze Aqaroy St 3] ‘$2163 22 ea a ORT

T

z ZF ponent

eo “Cen DHOE

vl oss ssz Les

€ sa on

=| eam | eae ‘v0 (07 if

Sie) "wo | steno mi |

sea as) PE See | SE we | a

Be XA OOLL romunean weg

feooy CORRE Sem] wet i sak i Bs

adesoy mg S| i, i i i ita EY

Hivs :

wa | AGOm I 01070 [ozo-o | e-0 $0°0 49S

7 a

ge PRY ag o“ vu on _ = e y gee “eon

eee or a | he

= — sy a,

8 os

$002 “Tor ‘10 a's eIsos ( £002) IzIs9 sir on

Nun SRivand Gnokoee 5 yi

ye a 7 i

L100. ONVOWN ssory YW Brant GRY

rH ELCEDRBBRRBY BX ny wasn

€ 09 ye

KE HSE me +a FY

—f0o=10 oN us Sal TWRALVN AO LYOdaY

OLI-9 Nese SWE MW th

©

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- CPI Pressure-Relief Systems ExplainedDocument6 pagesCPI Pressure-Relief Systems Explainedahsan8880% (1)

- Mechanical Calculation Sheet Design of a Feed HopperDocument5 pagesMechanical Calculation Sheet Design of a Feed HopperLautBiruNo ratings yet

- Mon Mar 06 10:59:33 2017 Case: F:/Project Osbl/Simulasi Hysys/Comment Review/Osbl Steam Simulation - Rev1.Hsc Flowsheet: Case (Main)Document1 pageMon Mar 06 10:59:33 2017 Case: F:/Project Osbl/Simulasi Hysys/Comment Review/Osbl Steam Simulation - Rev1.Hsc Flowsheet: Case (Main)LautBiruNo ratings yet

- 1 11 030 17Document18 pages1 11 030 17LautBiruNo ratings yet

- Lay Out LombokDocument1 pageLay Out LombokLautBiruNo ratings yet

- Feeding Hopper ArrangementDocument1 pageFeeding Hopper ArrangementLautBiruNo ratings yet

- 274921 (110) Pt Unitechnindo保証書Document1 page274921 (110) Pt Unitechnindo保証書LautBiruNo ratings yet

- TIASA - Thermal Insulation HandbookDocument58 pagesTIASA - Thermal Insulation HandbookSirGawain99No ratings yet

- Cal Sil Data SheetDocument1 pageCal Sil Data SheetLautBiruNo ratings yet

- Preparasi Dan KarakterisasiDocument16 pagesPreparasi Dan KarakterisasiCahyo NugrohoNo ratings yet

- Readme File For Renesas' USB3.0 Host Controller Driver (V1.0B)Document5 pagesReadme File For Renesas' USB3.0 Host Controller Driver (V1.0B)LautBiruNo ratings yet