Professional Documents

Culture Documents

H 1915 1962 Fo

H 1915 1962 Fo

Uploaded by

Arjun Prajapati0 ratings0% found this document useful (0 votes)

9 views1 pageH-1915-1962-FO

Original Title

H-1915-1962-FO

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentH-1915-1962-FO

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pageH 1915 1962 Fo

H 1915 1962 Fo

Uploaded by

Arjun PrajapatiH-1915-1962-FO

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

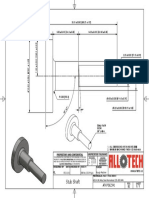

TECHNICAL PURCHASE SPECIFICATION

ANUP [REANUPENGGLTD.. annexure to P.O.No.

AHMEDABAD

lz)

3)

4)

5)

a)

)

8)

a)

»)

°)

®

®)

9)

hy)

\7)

8)

a)

b)

19)

Carbon Stee! Forging

Material Specification: SA260GR'4

Material supplied to this spectication shel confirmed to applicable

requirements of SA 788.

Goveming Code ASME Secall, Part A, £D.2013

Size and Quantity ‘As per Purchase Order.

Delivery Condition Normalised and tempered (Tempering temp. 665 Deg.C minimum)

Gasket Face Finish :

‘Smooth finish to 63 AARH for Double Metal Jacketed Gasket

‘Smooth finish to 125 ARH for Spiral Wound Gasket

‘Additional requirements:

Material shall be of fully killed quality, and produced to fine grain practice.

Grain Size shall be § or higher and also reported in MTR.

BC <= 0.23%

All forgings shall be 100% UT tested as per SA 988. Acceptance criteria shall be as per clause 3.3.4 of

‘ASME Seo. Vill Div.2

All forgings shall be MT/PT examined on entire surface after final machining.

All forgings shall be free from injurious defects. No weld repairs are permitted.

Hardness shall be less than 187 BHN.

‘When the component thickness exceeds 2 inches (50mm), specimens for mechanical testing shall be taken

at 1/2 the thickness (1/27).

Material shell meet the requirement of NACE MR 0103 and NACE SP 0472.

Marking 2 All forgings shall be stamped (low stress) as per section 11 of SA 266 and

must be co-related with manufacturer's test certificate.

Material Test Report (MTR) Required :

Material Test Report shall comply with all requirements as per section 10 of SA 266.

MTC shall be to BS EN 10204 type 3.2

Material shall be procured from EIL approved vendors only.

Zdee

Py ATS

0

7E-0S-20TT |[esued For'11016-62 (CS Non Sta, Flanges)| Panka] Patel _| Rahul Nerkar | Dipak KC Bhavsar

REV

DATE, ‘DESCRIPTION OF REVISION ‘Asst, Manager | Manager| Head - Engineering]

es No ENGG/FORM/O1

0

‘TPS NO.H1915-1962 FO. | REV.NO.

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- BU Motors and Generators: Prepared Separate Part List Title ScaleDocument1 pageBU Motors and Generators: Prepared Separate Part List Title ScaleArjun PrajapatiNo ratings yet

- ATKP362341 Revb1 111116Document1 pageATKP362341 Revb1 111116Arjun PrajapatiNo ratings yet

- Stub Shaft Forging: ATKP362340/ATKP302958Document1 pageStub Shaft Forging: ATKP362340/ATKP302958Arjun PrajapatiNo ratings yet

- QS MS 117Document5 pagesQS MS 117Arjun PrajapatiNo ratings yet

- Ty 14 1 2982 80 Part 1Document5 pagesTy 14 1 2982 80 Part 1Arjun PrajapatiNo ratings yet

- ATKP362339 Revb1 111116Document1 pageATKP362339 Revb1 111116Arjun PrajapatiNo ratings yet

- Integrated: Rough Machine Intermediate Flange Large Bore Shear 7 1/16"-5000 MWPDocument1 pageIntegrated: Rough Machine Intermediate Flange Large Bore Shear 7 1/16"-5000 MWPArjun PrajapatiNo ratings yet

- Forged Plate: Proprietary and Confidential Unspecified ToleranceDocument1 pageForged Plate: Proprietary and Confidential Unspecified ToleranceArjun PrajapatiNo ratings yet

- Forged Donut: Proprietary and Confidential Unspecified ToleranceDocument1 pageForged Donut: Proprietary and Confidential Unspecified ToleranceArjun PrajapatiNo ratings yet

- Specification For Plates and Forgings PDFDocument2 pagesSpecification For Plates and Forgings PDFArjun PrajapatiNo ratings yet

- Bearing Housing: Proprietary and Confidential Unspecified ToleranceDocument1 pageBearing Housing: Proprietary and Confidential Unspecified ToleranceArjun PrajapatiNo ratings yet

- T3 0209 04 SPC - T3RevF PDFDocument4 pagesT3 0209 04 SPC - T3RevF PDFArjun PrajapatiNo ratings yet