Professional Documents

Culture Documents

Tech Note 10

Uploaded by

nadeesha0 ratings0% found this document useful (0 votes)

10 views16 pagesggd

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentggd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views16 pagesTech Note 10

Uploaded by

nadeeshaggd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 16

UTRACON

ning Systems Using Strands

THE UTRACON GROUP

www.utracon.com

Contents uTRAcon

Page

1. Company Profile i

2. UPS - DSI Post-Tensioning Systems 1

3. Post-Tensioning Works — Site Installation 2

4. Standard Strands 3

5. Corrugated Ducts 4

6. DYWIDAG Multiplane Anchorage MA 5

7. UPS Flat Anchorage FA 6

8 Bond Anchorage 7

9. Ancillary PT Components 8

10. Equipment Overview 9 12

‘subject to modifications: Jan 2014

Company Profile UTRACON

Utracon Group of Companies (Utracon) was established in 1998 with the aim to provide specialist

design and construction services to our clients.

The main activities of Utracon evolve around the application of sound engi

ering concepts in the

DESIGN & CONSTRUCTION of concrete structures.

Utracon has established its name in the region as being one of the few specialists that has the

capabilities of performing the following services:

Utracon has established itself in the following overseas markets

over the last few years:

Through our Singapore's licensee agreement with DYWIDAG

Systems International (DS!), Utracon is the authorised supplier

of DSI patented products:

Sophisticated structural design and construction methods for both building and

civil engineering structures.

Design, supply an installation of boll inlerrl and external prestessing tendons

Design, supply and installation of fiber reinforced plastics (FRP) and other

structural strengthening methods.

Design, fabrication and erection of temporary structures and system formwork (to

uit construction of bridgoe, egg shaped digeetore, elevated wator towore, otc.)

South East Asia

Malaysia / indonesia / Brune

Vietnam / Myanmar / Cambodia / Laos

Sri Lanka

India

Guam

United Arab Emirates

Algeria

DYWIDAG Post-tensioning System

DYWIDAG Prestress Bar

DYWIDAG Geotechnical range of products

DYWIDAG Stay Cable System

subject to modifications: Jan 2014 i

UPS — DSI Post-ten:

g Systems UTRACON

Various PT slab systems

PT flat slab

DYWIDAG Bonded Post-tensioning System is a world renown system which complies to all

international specifications and recommendations. This system is suitable for all applications and is

widely used throughoul the world in bridges and civil engineering structures, e.g. waler lanks, LNG

tanks, stay cable structures, ete.

Through years of experience in the design and construction of post-tensioned buildings, Utracon has

euccesefully embarked on a venture to design and produce ite own UPS flat anchorage eystom.

With bonded post-tensioned slab being the most favoured floor system used in South East Asia,

Utracon has the opportunity to experience the various design and construction requirements of

buildings. where the use of flat anchorages is most predominant.

As a leading post-tensicning specialist in Singapore, Utracon had constructed more than 5 million

square meter of post-ensioned floor since 1998. It has accumulated a great deal of experience and

knowhow in the application of flat anchorages, which helped it to fine-tune the design of its UPS flat

anchorage system,

To-date, Utracon’s UPS system has been used extensively in the construction of buildings and civil

engineering projects in South East Asia, India, Sri Lanka, The Middle East and Africa.

subject to modifications: Jan 2014 1

gy

Post-tensioning — Site Installation Works uTRAcon

a © é

Stressing of beam tendon Mixing of grout for tendon grouting Locking of tendon after grouting

‘subject to modifications: Jan 2014 2

Standard Strands

eZ

Strands are made up of 7 individual

cold-drawn wires; 6 helically wound

outer wires and one centre wire

(king wire) Strands can be supplied

either bare, galvanized or epoxy-

coated without any loss in strength,

Str

Epoxy coated strands

a

Bere strands

Components of an Internal Post-tensioned Tendon

Wedge plate

Grout

= Multiplane Anchor Body

Recess

wim: PE Trumpet

Technical Data

strand Type

ASTM

Code / Specification Aa16

Grede 270

Nominal diameter = mm = 12.7

Ultimate Strength, fa N/mm? 1860

Cross-sectional area. = mm? 98.71

Weight Ke/m 0.775

Ultimate load KN 183.7

Yieldstrength, fos N/mm? 1670"

Modulus of elasticity N/mm*

Relaxation "after

1000 hr at 0.7 x %

ultimate strength fox

note:

(1) Yield at 1% effective elongation.

bead end anchorage—

Tendon (Duct

with strands) |

Grout tube 1

Anti-burst reinforcement

os"

Bs 5896

Super

12.9

1860

100.00

0.785

186.0

sso"

(2) Yield measured at characteristic 0.1% proof load.

(3) Applicable for relaxation Class 2 according to BS $896 and $8475: or low relaxation complying with ASTM A416,

08" /0.62"

ssa7s (SIM pssen6 5475855896 855896

Ordinary Grade 270 Standard Ordinary Super Super

2715285215287 157

3860 18601860 «1860«1770—1860

98.70 140.00 139,00 139.00 150.00 150.00

O77 | 410211090 1401 4180 1.280

1840 260.7 2580 2530 2650 2730

1530” 1670 ~— asso ~— 1525 1500" —1sg0"

195,000

Max 25

‘subject to medications: Jan 2014

Corrugated Ducts

Metal corrugated ducts are produced from hot-dipped

galvanised stee! sheet on special tubeformer machines.

‘These thin-walled (0.25mm — 0.60mm), ribbed sheet

metal ducts provide high rigidity that can withstand

being embedded in concrete without deformation. The

duct corrugation provides excellent bond behaviour

between the tendon and concrete.

Metal ducts also provide a fair secondary corrosion

protection to the strands. Primary protection is provided

by the alkalinity of grout and concrete.

Dimensions of Corrugated Round Duct

No. of Strands in Duct Duct

Strandtype Strand type Wo. oo,

os" 06"/0.62" (mm) (om)

or 05 50 55

° 07 65 70 6

2 09 75 80 "

15 2 80 8s }

20 15 90 95

a7 19 95 100

31 2 100 105

37 27 110 115

2 31 120 125

7 330 135

Dimensions of Corrugated Fat Duct

No. of Strands in Duct Duet

Strandtype Strand type Width Height

os" 0.6"/0.62" (mm) (om)

3 a 55 23 :

45 4 15 23

- 5 90 23

Dimensions (internal width and height) of

flat ducts: \

subject to modifications: Jan 2014

eZ

DYWIDAG Multiplane Anchorage MA UTRACON

ea —

cf mops

Anti-burst reinforcement

2T10generaly, except

Wedges

routinet |

Mt

3 4 CE erg

= } 1 PE Trumpet Round duct

vege ne em

atin chr bay |

H H 2710 generally, except

THe ove

1

Multiplane Anchorage (MA) & Anti-burst Reinforcement Data

Tae ART

ran res acon

os" 0.6"/0.62" A 0B oC D — OF G H 4 No. of Links

7 5 2 070TH’

° 7 220 17 150 100 100TH’ SDs

29S aca

BB am mo 100TH’ 300s

0 = «S=S80DSD.«9-=«20D««m00SsTtsCSiimOasa

780mm.

no aDSsDS2DsawsCTSSatSas tO

39 40 HDHD

2 a5 «8S_D.«2D:=«sSD.:SCT2O.:C«SOs BOSC

- 7700213535058]

(21) For type 0.6” 0.62", maximum UTS of strand applicable is 279KN.

(2) The above configurations can be substituted with equivalent helical reinforcement.

(3) The above is based on minimum concrete (cube) strength at transfer of 25 N/mm®. For higher concrete strength at

transfer, please refer to Utracon Design Department for details.

‘subject to modifications: Jan 2014 5

(Z

UPS Flat Anchorage FA ihton

“ |= Grout inlet/outlet

Tafa

aL -OFHR 1

Flat anchor body Flacauet

concrete surface |

An B - 2710

Wedees '

} aly \ oF

== J tl I

a0 ' ey |

a = t + Flat duct,

miok 1 Wedge plate H

‘Antburst reinforcement Flat anchor body E an0

UPS Flat Anchorage (FA) & Anti-burst Reinforcement Data

{Anti-burst Reinforcement

Type

Tyeos’ gaY, A 8 C dD €& OF

0.6"/0.62" HY we No. of Links

3 2 81 20 «1809350, T30—«S «330200 3

30010 6

4 = 81 203 233-106 330 250

° (200) (133) @)

300710 6

s 4 ams asso 300M aan 80 Qj

350 T10 6

= 5 s 234 300106 350TH, 3030 B

note.

(2) For type 0.6"/0.62", maximum UTS of strand applicable is 2654N.

(2) The above configurations can be substituted with equivalent helical reinforcement.

{3) The above is based on minimum concrete (cube) strength at transfer of 25 N/mm, For higher concrete strength at

transfer, please refer to Utracon Design Department for details.

(4) * For slab thickness <200mm, H = 115mm.

subject to modifications: Jan 2014

Bond Anchorages UTRACON

400

FARE SEE Rove

stands

|

‘9712-50 generally, except

a 7720-50or 0.6"-208 & above

Round duet 1250~ 1350

2710 generally, except

2r16 for 0.6"-205 & above

Dimension

200/or 05-125 /0.6"-9s & below

250 for 0.5"-135 1027s /0.6"-10s to 19s

4400 for 0.5"-28s /06"-20s & above

Typical Dead End Anchorage Type Z for Multistrand Tendon

850~ 950 B

2x2710,L=1000 (Top & Bot)

(Holding bar only. May use

feicting sab dletbution bars)

Flat duet

strands

4T13 or 6T10 generally, except

5113 oF BTID for 0.6"-5s ae

A110 for 0.5°-35 /0.6"-25 200 200

Dimension 8

150200 for 05-3: /0,6"-22

300-350 for 0.S*-48 to Se /0.6"-48

400°450 for 0.555

‘Typical Dead End Anchorage Type Z for Flat Tendon

‘Anti-burst reinforcement only required for slab < 200thk

‘subject to medications: Jan 2014

Ancillary PT Components Ureacon

Coupler P For full range of coupler types,

please refer to DSI catalogue.

Coupler R

aq Anchorage Coupler for Multistrand Tendon

Available for anchorage types:

5s

4s

5s

= 4s

Anchorage Coupler for Flat Tendon

Available for both 0.5" and 0.6"

strand diameters

Strand with Compression Fitting

Note:

+ Full details of the above products will be made available upon request.

‘subject to modifications: Jan 2014 8

Equipment Overview eeeneon

Hydraulic Jacks

CH258DA CHZ006DA ‘CH7008DA

os" oO 07 0 22 15 20

Strand Type

06"/062" 01 05 oy aS ta

Jack

(cH2580A, .

cH200608, eo 8

cH2206/808 eo 8

cH300608, ee

cHao06DA. .

cH7NoRDA eo 8

cHgoo8DA. .

i

D

iN

,

Technical Data

Length, Diameter,D Stroke “Piston Area Capacity Weight*

(ram) (mm) (mm) (om) (kn) (ee)

Jack

cH2S8DA 510 a8 200 33.25 250 4

cH20060A 590 320 150 304.02 2000 220

CH2206/8DA 600 355 150 324.72 2200 290

cH30060A 670 404 150 465.59 3000 350

‘cHag060A 710 457 150 602.40 4000 525

cH70080A 860 630 200 1004.00 7000 1230

ccHoooaDA 1010 700 200 177656 000 680

note

‘Weight with gripping assembly

‘subject to modifications: Jan 2014 a

Equipment Overview Ureacon

Hydraulic Pumps

u60

u70

Jack CH258DA CH2006DA CH2206DA CH3006DA CH4006DA CH7008DA_CHS008DA

Pump

uso .

u70

u77 .

6.4

RIL

112

5 H H

&

A $+

Technical Data t “

‘Operating Capacity* Effective Weight Dimension

recat venta) (onameore LW

(a1) Wein) w (ks) (mm)

ump

uso 700 re 5 50 asaxzennars

u7 700 16 “a 1486003104350

un 700 30 10 50 420x380 480

vs4 700 ea 70 310 1400x700 x1100

man2an2 550 112/224 170 615 2000%800.1000

ote

* Capacity of flow rate at 500 bar working pressure

‘subject to modifications: Jan 2014 10

Equipment Overview UTRACON

Grouting Equipment

SD6503

Combined Mixer

Mx6503

Colloidal Mixer

Model Function MUx Rietion MBE. Wing Dimersion

(Bar) (min) (kg) (rm)

SD5503 Mher®&Pump 3520S 3008006203680

wwessoa Mier = =) 300 150055303680

-d mixer functions as a mixer, an agitator and @ pump. Itis capable of producing

a homogenous grout that satisfy requirements of most grout specifications.

* The colloidal mixer is purely a mixer and needs to pair up with a combined mixer or a piston

pump for pumping purposes. The colloidal mixer’s motor operates at very high revolutions

and its able to produce a high quality grout that can comply with the most stringent

requirements. Together with a combined mixer It can supply grout for continuous pumping,

without intervals,

‘subject to modifications: Jan 2014 1

Equipment Overview Ureacon

Ancillary PT Equipment

‘S6/M60SP

‘Strand Pusher

Power Weight Dimension: Lx Wx H

(1?) (ke) (eum)

Pusher

s6/me0sP 30 3210 1800 x 900 x 2000

583 3 70 720 x50 x 440

Compression Fitting Bulb End Former

Machine

Note

+ Full details of the above products will be made available upon request.

subject to modifications: Jan 2014 2

HEAD OFFICE

Utracon Corporation Pte Ltd

5 Joo Koon Way, Singapore 628944

Tol +65 6415 3078

Fax: +05 6863 1928

malt utracon@utracon com

REGIONAL OFFICES

SINGAPORE OVERSEAS PROJECTS SRILANKA

Utracon Structural Systoms Pte Ltd Utracon Oversoas Pte Ltd Utracon Overseas Pte Ltd

5 Joo Koon Way, Singapore 628944 5 Joo Koon Way, Singapore 628944 (Sri Lanka Branch)

Tol: 4856815 3078,

Fax. :+85.6863 1928

Email: utracon@uiracon.com

MALAYSIA

Utracon Structural Systems Sdn Bhd

Kuala Lumpur Office:

Suite 11-03, 118 Flor Lobby 1 Block A

Wisma Damansara Intan,

No. 1 Jalan $820027,

447400 Petaling Jaya,

Selangor, Malaysia

Tol: +809 7710 8816

Fax +803 7118 2983

Email: uaconmsia@utracon.com

tiraconk@utracon.com

Johor Bahru Office:

Nu. 51-01 &51-02, Jatan Molek 18,

‘Taran Molek, 81100 Johor Batru,

Johor, Malaysia

Tol: #607 355 9799

Fax: 1607 354 8799

[Emait ursconmeia@utvacon.com

Tol: 455 6416 3078,

Fax +85 6563 1928

mal : utracon@uracon.com

VIETNAM

Utracon Vietnam Co,, Ltd.

HEMC Office:

Src Fir, LA 03-08, Lexinglon Bld, 67

Mai Chi Tho Street

[An Phu Ward, Distt 2,

Ho Chi Minh City, Vietnam

Tol: +84 08 2253 9588

Fax: 484 08 2253 0560

mal: uraconvn@utracon.com

He

3 Floor, CT Van Khe Buling,

‘Van Khe Urban Area,

Ha Dong Oistnct,

Hanoi, Vietnam

Tol: +86 04 6325 2182

Fax 86 04 6325 2187

Mobile: +84 9 8338 6859

mal: urasonvn@utracon.com

(eZ

UTRACON

TA.N. J. V. Cooray Mawatha,

Rejagitiya, Sri Lanka

Tol #94 1126 77446

Fax : +94 1128 77442

Mobile: +96 7141 65551

mal :utraconk@utracon.com

MYANMAR

Utracon Myanmar Co.,Ltd.

No, 13344, Yadanar Road, Ward No, 13,

South Okkalapa Tonnship,

“Yangon, Myanmar

“TolFax : +951 8551480

Mobie’: +959 2505 12089

Email: utraconmm@utracon.com

Utracon Structural Systems Pvt Ltd

New No. 31, First Floor, Besant Avenue,

‘Adyar, Chennai-600 200, Inia

Tol: +91 44 2446 a001/2/3,

Fax +91 44 2446 8004

mal: uraconindia@utracon.com

www.utracon.com

Prestressing . Design & Construction of Concrete Structures . Desian & Erection of Precast Concrete Components

Viaduct Construction . Lifting & Launching . Structural Strengthening . FRP Reinforcement . Formwork & Falsework

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Ca Ususin: WCQ G (Document115 pagesCa Ususin: WCQ G (nadeeshaNo ratings yet

- End BlockDocument1 pageEnd BlocknadeeshaNo ratings yet

- Construction $6rvices: Neering, LaboratoryDocument2 pagesConstruction $6rvices: Neering, LaboratorynadeeshaNo ratings yet

- Guyons End BlockDocument71 pagesGuyons End BlockMakesh Kumar80% (5)

- DP ExamplesDocument37 pagesDP ExamplesnadeeshaNo ratings yet

- Ovm PrestressingDocument68 pagesOvm Prestressingnadeesha100% (1)

- Barra Emulsion 57DDocument2 pagesBarra Emulsion 57Dnadeesha100% (2)

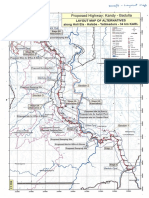

- Badulla New Rajamawatha PlanDocument1 pageBadulla New Rajamawatha PlannadeeshaNo ratings yet

- 3000.submission of Amended Design Report and Drawings of Approach Slab For Abutment (R01)Document12 pages3000.submission of Amended Design Report and Drawings of Approach Slab For Abutment (R01)nadeeshaNo ratings yet

- JL 84 January February 6Document46 pagesJL 84 January February 6nadeeshaNo ratings yet

- Aashto Catalog PDFDocument16 pagesAashto Catalog PDFnadeeshaNo ratings yet

- Design of Anchorage ZonesDocument34 pagesDesign of Anchorage ZonesTan Duy LeNo ratings yet

- Ms For Super Structure Construction-2017.01.25Document58 pagesMs For Super Structure Construction-2017.01.25nadeeshaNo ratings yet

- Ms For Super Structure Construction-2017.01.25Document58 pagesMs For Super Structure Construction-2017.01.25nadeeshaNo ratings yet

- Ms For Super Structure Construction-2017.01.25Document58 pagesMs For Super Structure Construction-2017.01.25nadeeshaNo ratings yet

- Ms For Super Structure Construction-2017.01.25Document58 pagesMs For Super Structure Construction-2017.01.25nadeeshaNo ratings yet

- State Development & Construction Corporation (Established Under The State Industrial Corporation Act No. 49 of 1957) Pre-Cast Yard MinipeDocument1 pageState Development & Construction Corporation (Established Under The State Industrial Corporation Act No. 49 of 1957) Pre-Cast Yard MinipenadeeshaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)