Professional Documents

Culture Documents

KPKD-4 04.12.2015

KPKD-4 04.12.2015

Uploaded by

SE EST0 ratings0% found this document useful (0 votes)

4 views1 pageear

Original Title

KPKD-4_04.12.2015

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentear

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageKPKD-4 04.12.2015

KPKD-4 04.12.2015

Uploaded by

SE ESTear

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

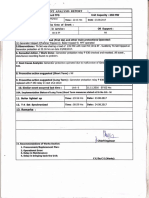

EVENT ANALYSIS REPORT

| PST Waperifaia WS ‘alt cap NW

| Station Code Time Date - No. of days from last sync. :

| Too3 21:35 HI 04/12/2015 6 days

1.*HO Code:

Operating conditions at the time of Event i= oe ae =

I Load 7 Coal Cycles in service Oi Support

98 MW B,C&D NIL

3. Nature of Event: Unit withdrawn to replace gland box sheared-off bolts at LPT.

4. Name of First Up , Main Protections & Protection on which GCB tripped :

Hand Tripped (First Up), MFT Operated, Turbine Tripped, Trip Gear Operated.

'BA) Observations: - At 21:00 hrs on date 04/12/2015, unit was on load at 146 MW with 5 Coal cycles (A, B, C, D & E)

in service. The load was started reducing by withdrawing coal cycles one by one in order to withdraw the unit for

replacing sheared off bolts of LPT gland box. Set hand Tripped at 21:35 hrs on date 04/12/2015 when load was 98

MW with coal cycles B, C & D in service. _

3B) Remedial Action/work done: - LPT gland box centering done and all the holding bolts LPT gland box (Total 08

Nos) replaced with new ones. : |

6. Root Cause Analysis:- LPT rear gland box bolts damaged due to high vibrations of turbine shaft & bearings.

Atabout 21:00 hrs on dt. 04/12/2015,

Shaft vibrations (microns) : Xz = 147, Y2= 60, X= 84, Ys=129

| _ Bearing vibrations (microns) :Xs=28, Ys=42

“7. Preventive action suggested (Short Term) :

_ 8. Preventive action suggested (Long Term) :

9, Similar event occurred last time:- UnitNo#4, 210MW | Time: 22:15 Hrs Date: 26/11/2015

Event: Unit withdrawn to replace gland box sheared-off bolts at LPT.

Remedial Actions: - LPT gland box centering done and all the holding bolts of LPT gland box (08 Nos) replaced with

new ones

9A. Implementation Status of Long Term /Short Term measures stated at Sr No 7&8

“10. Boiler lighted up Time 04:07 Hrs | Date- 06/12/2015

“A Set Synchronized Time - 07:38 Hrs Date- 06/12/2015

Remark:- At 13:00 hrs. on dt. 06/12/15 turbine bearing and shaft vibrations recorded at 150MW and are

as follows:

Shaft vibrations (microns): X2= 138, ¥2= 49, Xs=76, Y«=119

Bearing vibrations (microns) : X+= 25, Ys=37

| 13, Recommendations of Works Section

Procurement/Replacement Plan;

2. Operational Error: |

3. Delay in Maintenanc -

4, Delay in bringing back the Unit:

Training of Staff:

6. Whether remedial action is completed si

factory & point is closed:

__CE/DyCE (Works)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

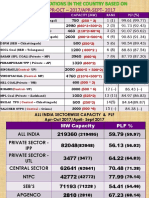

- NTPS - Highlights and Records For FY 2017-18Document2 pagesNTPS - Highlights and Records For FY 2017-18SE ESTNo ratings yet

- BTL Index Nov2017Document4 pagesBTL Index Nov2017SE ESTNo ratings yet

- Sop Chlorine and Ammonia GasesDocument3 pagesSop Chlorine and Ammonia GasesSE ESTNo ratings yet

- All India Nov-17Document2 pagesAll India Nov-17SE ESTNo ratings yet

- Compiled by EST-HO MumbaiDocument47 pagesCompiled by EST-HO MumbaiSE ESTNo ratings yet

- Station Capacity (MW) Rank PLF (%) : Central Central CentralDocument2 pagesStation Capacity (MW) Rank PLF (%) : Central Central CentralSE ESTNo ratings yet

- Event Analysis: TPS: Unit - Date: Operating Coal SeruiceDocument1 pageEvent Analysis: TPS: Unit - Date: Operating Coal SeruiceSE ESTNo ratings yet

- Sept 17 New DataDocument8 pagesSept 17 New DataSE ESTNo ratings yet

- At Of: Eyent Analysis NewlarliDocument1 pageAt Of: Eyent Analysis NewlarliSE ESTNo ratings yet

- BTL 500MW U4 Updated 06072017Document1 pageBTL 500MW U4 Updated 06072017SE ESTNo ratings yet

- PRS-4 16.12.2015Document1 pagePRS-4 16.12.2015SE ESTNo ratings yet