Professional Documents

Culture Documents

BSL-3 10.02.2016

BSL-3 10.02.2016

Uploaded by

SE EST0 ratings0% found this document useful (0 votes)

7 views3 pagesear

Original Title

BSL-3_10.02.2016

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentear

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views3 pagesBSL-3 10.02.2016

BSL-3 10.02.2016

Uploaded by

SE ESTear

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

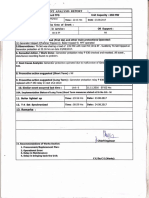

EVENT ANALYSIS REPORT

3_[res:ehusawal Tes: Unit Capacity: 210 MW

[Station Code: TOOL Time= Date- Wo, of days from last sync.

10:32Hrs | 10.02.2016

2, Operating conditions at the time of Event :- The unit was sharing 160 MW load with A,C,D,E,F Coal Misi service without

oil Support.

a ——|

nl

160 ACO.EF

[3. Nature of Event:

[Ta set wiendrawn to attend suspected Boller tube leakage near comer no.

[a, Name of First Up, Main Protections & protection on which GCB tripped:

2. whisting/ puffing sound was noticed near WSB no, 28 13 (at comer no.t)

[5B) Remedial Action/work done

1. SHH 1 to 2 roof tube found pin hole. T-32 found pin hole. pen chew 2 T™3/ = f+ secon

2. SHH 1 to 2 roof tube, T-31,32, damage portion replaced with its fins.

[6: Root Cause Analysis = Five gas erosion.

7. Preventive action suggested (Short Term) ==

1, Regular round of Boller will be taken in every shift to noticed abnormal sound at near by area to avoid secondary damages.

fs: Preventive action suggested (Long Term) = Any minor leakages to be identified during hyraulc test should be get attended for

ong running of units.

9. Simitar event occurred last time:- |U# 3, [Time pate:

[SA. Implementation Status of Long Term/Short Term measures stated at 51 No 9

[10. Boiler lighted up [rime - 18:36 Hrs [pate 12.02.2016

faa. TA Set Synchronized [rime 01.03 Hrs [Date- 13.02.2016

fz. Remark =

“chit Engineer

[i3. Recomendations of Works Section:

4. Procurement/ Replacement Plan:

2. Operational Error:

3. Delay in Maintenance:

4, Delay in bringing back the unit:

5. Training of Staff:

6. Whether remedial action is completed satisfactory & point is closed :

CE/Dy CE (Works)

"HO Code willbe Given by Wares Soi

Nokicipreation No: 3000 6599

EVENT ANANLYSIS REPORT

Unit No :03 TPS :Bhusawal Unit Capacity: 210 MW

1. HO Code: Station Code

Time: 13:32 Hrs Date:10.02.2016 No. of days from last

sync.

2. Operating Conditions at the time of Event:

The unit was sharing 160 MW load with A,C,D,E,F coal mills in service

without oil Support.

Load: 160 MW Coal Cycles In service: A,C,D,£,F Oil support: Nil

3. Nature of Event

TA set withdrawn to attend suspected Boiler tube leakage near corner

no.

4. Name of First Up, Main Protections & protection on which

GCB tripped:

Name of First up- Boiler hand tripped.

Main Protection:~ Boiler hand tripped.

Turbine tripped due to Boiler tripped.

Protection on which GCB tripped:- Low forward Power

SA. Observations

1. DM water consumption increased @ 458 T/Hr.

2. Whistling/ puffing sound was noticed near WSB no. 26 13 (at corner

no.1)

5B. Remedial Action

1. SHH 1 to 2 roof tube found pin hole. T-32 found pin hole.

2. SHH 1 to 2 roof tube, T-31,32 damage portion replaced with its fins.

6. Root Cause Analysis : Flue gas erosion.

7. Preventive Action Suggested Short Term:

1. Regular round of Boiler will be taken in every shift to noticed

abnormal sound at near by area to avoid secondary damages.

8. Preventive Action Suggested Long Term:

Any minor leakages to be identified during hydraulic test should be get

attended for long running of units.

9. Similar event occurred last time

Unit : Date / Time:

9A. Implementation Status of Long Term/Short Term measures

stated at Sr No 9:

10.Boiler Lighted Up

Date: 12.02.2016 eae

Set Synchronized:

A. teas Date

12. Remarks:

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

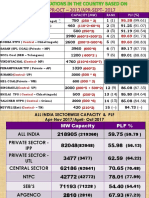

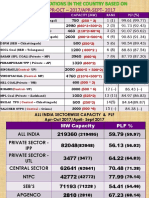

- NTPS - Highlights and Records For FY 2017-18Document2 pagesNTPS - Highlights and Records For FY 2017-18SE ESTNo ratings yet

- BTL Index Nov2017Document4 pagesBTL Index Nov2017SE ESTNo ratings yet

- All India Nov-17Document2 pagesAll India Nov-17SE ESTNo ratings yet

- Sop Chlorine and Ammonia GasesDocument3 pagesSop Chlorine and Ammonia GasesSE ESTNo ratings yet

- Compiled by EST-HO MumbaiDocument47 pagesCompiled by EST-HO MumbaiSE ESTNo ratings yet

- Station Capacity (MW) Rank PLF (%) : Central Central CentralDocument2 pagesStation Capacity (MW) Rank PLF (%) : Central Central CentralSE ESTNo ratings yet

- Event Analysis: TPS: Unit - Date: Operating Coal SeruiceDocument1 pageEvent Analysis: TPS: Unit - Date: Operating Coal SeruiceSE ESTNo ratings yet

- At Of: Eyent Analysis NewlarliDocument1 pageAt Of: Eyent Analysis NewlarliSE ESTNo ratings yet

- Sept 17 New DataDocument8 pagesSept 17 New DataSE ESTNo ratings yet

- PRS-4 16.12.2015Document1 pagePRS-4 16.12.2015SE ESTNo ratings yet

- BTL 500MW U4 Updated 06072017Document1 pageBTL 500MW U4 Updated 06072017SE ESTNo ratings yet