Professional Documents

Culture Documents

BPVC Ix Qw-484a PDF

Uploaded by

Nector MoyanoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BPVC Ix Qw-484a PDF

Uploaded by

Nector MoyanoCopyright:

Available Formats

FORM QW-484A SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONS (WPQ)

(See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)

Welders name Identification no.

Test Description

Identification of WPS followed Test coupon Production weld

Specification and type/grade or UNS Number of base metal(s) Thickness

Testing Variables and Qualification Limits

Welding Variables (QW-350) Actual Values Range Qualified

Welding process(es)

Type (i.e.; manual, semi-automatic) used

Backing (with/without)

Plate Pipe (enter diameter if pipe or tube)

Base metal P-Number to P-Number

Filler metal or electrode specification(s) (SFA) (info. only)

Filler metal or electrode classification(s) (info. only)

FIller metal F-Number(s)

Consumable insert (GTAW or PAW)

Filler Metal Product Form (solid/metal or flux cored/powder) (GTAW or PAW)

Deposit thickness for each process

Process 1 3 layers minimum Yes No

Process 2 3 layers minimum Yes No

Position qualified (2G, 6G, 3F, etc.)

Vertical progression (uphill or downhill)

Type of fuel gas (OFW)

Inert gas backing (GTAW, PAW, GMAW)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN)

RESULTS

Visual examination of completed weld (QW-302.4)

Transverse face and root bends [QW-462.3(a)] Longitudinal bends [QW-462.3(b)] Side bends (QW-462.2)

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)]

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d)]

Pipe specimen, macro test for fusion [QW-462.5(b)] Plate specimen, macro test for fusion [QW-462.5(e)]

Type Result Type Result Type Result

Alternative Volumetric Examination Results (QW-191): RT or UT (check one)

Fillet weld fracture test (QW-181.2) Length and percent of defects

Fillet welds in plate [QW-462.4(b)] Fillet welds in pipe [QW-462.4(c)]

Macro examination (QW-184) Fillet size (in.) Concavity/convexity (in.)

Other tests

Film or specimens evaluated by Company

Mechanical tests conducted by Laboratory test no.

Welding supervised by

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in accordance with the

requirements of Section IX of the ASME BOILER AND PRESSURE VESSEL CODE.

Organization

Date Certified by

(07/13)

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- NuevoDocumento 2019-12-30 10.10.50Document17 pagesNuevoDocumento 2019-12-30 10.10.50Nector MoyanoNo ratings yet

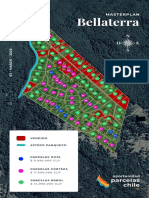

- Masterplan 2019Document1 pageMasterplan 2019Nector MoyanoNo ratings yet

- D 50Document6 pagesD 50Nector MoyanoNo ratings yet

- Multi Lizer 4 PDFDocument1 pageMulti Lizer 4 PDFBridgett AllenNo ratings yet

- Welder Qualification: A G D A G D Qualified DetailsDocument1 pageWelder Qualification: A G D A G D Qualified DetailsNector MoyanoNo ratings yet

- Wps 08-04-2015 - 3Document6 pagesWps 08-04-2015 - 3Nector MoyanoNo ratings yet

- Alineador de PoleasDocument1 pageAlineador de PoleasNector MoyanoNo ratings yet

- Preassembly and Welding FGD: EIM-POS-02-298Document1 pagePreassembly and Welding FGD: EIM-POS-02-298Nector MoyanoNo ratings yet

- Bonsai - Peter ChanDocument160 pagesBonsai - Peter Chanapi-3738310100% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)