Professional Documents

Culture Documents

KPKD-4 10.07.2017

KPKD-4 10.07.2017

Uploaded by

SE EST0 ratings0% found this document useful (0 votes)

12 views1 pageear

Original Title

KPKD-4_10.07.2017

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentear

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 pageKPKD-4 10.07.2017

KPKD-4 10.07.2017

Uploaded by

SE ESTear

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

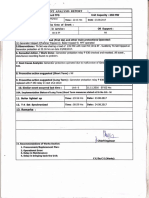

EVENT ANALYSIS REPORT

UNITNO : 04 [ TPS: Khaperkheda TPS Unit Capacity : 210 MW

. Station Code: Time- | Date- | No.of days fromlast syne:

ee’ | coos o3:19Hrs | 10/07/2017 _| 4 days

2. Operating conditions at the time of Event =

Load Coal Cycles in service Oil Support

soMW, B&C NIL

3. Nature of Event: TA set withdrawn due to boiler tube leakage in economiser zone.

4. Name of First Up , Main Protections & Protection on which GCB tripped :

Hand Trip (First Up), MFT Operated, Turbine Tripped, Trip gear Operated.

5A) Observations: On dt. 10/07/2017 at 03:00 hrs, set was on load at 140MW with five coal mills in service(F-S/by)

and no Oil support. As DM water make up increased to 80 TPH also Boiler tube leakage sound observed at 38.5,

mtr. level near LRSB No.79 RHS. So one by one mills are withdrawn, unit hand tripped and finally, set withdrawn

at 03:19 hrs.

5B) Remedial Action/work done : 7 7

Primary Failure ~ Economiser upper bank coil no. 128 tube no, 03 found fish mouth opening punctured.

Secondary failure - Economizer upper bank coil no.134 tube no.03 found punctured.

Economizer upper bank coil no.127 tube no.3 found eroded.

Work carried out: Economizer upper bank coil no.127,128,131 &134 attended by welding hemispherical spool at

‘economizer Intermediate and economizer Inlet header (Total No, of HP weld Joints = 08 Nos.)

6. Root Cause Analysis : localized flue gas erosion of tube no.3 upper bank coil no 128 is the root cause failure.

7. Preventive action suggested (Short Term) :

8, Preventive action suggested (Long Term) :

1) Replacement of complete economizer coil during forth coming AOH of Unit 4.

2) Normalization of plugged economizer coil no.127, 128, 131 & 134 will be carried fourth coming AOH of unit no.

\ilar event occurred last time : Unit No # 4,210 MW Time : 10: Zour | Date : 26/06/2017

Event: T. A. set forced withdrawn (hand tripped) due to boiler tube leakage at economizer coils

Remedial Actions Primary Failure - Economiser upper bank coll no. 144 tube no. 16 found fish mouth opening

punctured.

1) SCW inlet header SHH 4A connecting RHS offset bend no.1 &2 found punctured and bend no.3 found eroded.

2) Economizer upper bank coil no. 145 tube no.17 found puncture.

1) Economizer upper bank coil 144 & 145 attended by welding hemispherical spool at economizer Intermediate and

economizer Inlet header.

2)_ Replacement of SCW inlet header SHH 5 to SHH 4A connecting RHS offset no.1, 2&3.

__(Total no of HP joints =13)

9A, Implementation Status of Long Term/Short Term measures stated at Sr No 7 & 8 =

10.Boiler lighted up [Time - 03:45 Hrs Date- 11/07/2017

11.T-A Set Synchronized | Time - 07:56Hrs [Date - 11/07/2017

12. Remark: wy.

eee |

13. Recommendations of Works Section :

1. Procurement/Replacement Plan:

2, Operational Error:

3. Delay in Maintenance:

4. Delay in bringing back the Unit:

5. Training of Staff

is completed satisfactory & point is closed:

CE/Dy CE (Works),

Ki

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

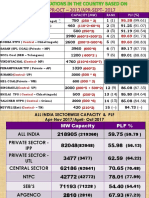

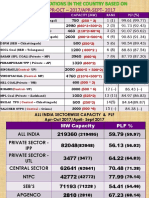

- NTPS - Highlights and Records For FY 2017-18Document2 pagesNTPS - Highlights and Records For FY 2017-18SE ESTNo ratings yet

- BTL Index Nov2017Document4 pagesBTL Index Nov2017SE ESTNo ratings yet

- All India Nov-17Document2 pagesAll India Nov-17SE ESTNo ratings yet

- Sop Chlorine and Ammonia GasesDocument3 pagesSop Chlorine and Ammonia GasesSE ESTNo ratings yet

- Compiled by EST-HO MumbaiDocument47 pagesCompiled by EST-HO MumbaiSE ESTNo ratings yet

- Station Capacity (MW) Rank PLF (%) : Central Central CentralDocument2 pagesStation Capacity (MW) Rank PLF (%) : Central Central CentralSE ESTNo ratings yet

- Event Analysis: TPS: Unit - Date: Operating Coal SeruiceDocument1 pageEvent Analysis: TPS: Unit - Date: Operating Coal SeruiceSE ESTNo ratings yet

- At Of: Eyent Analysis NewlarliDocument1 pageAt Of: Eyent Analysis NewlarliSE ESTNo ratings yet

- Sept 17 New DataDocument8 pagesSept 17 New DataSE ESTNo ratings yet

- PRS-4 16.12.2015Document1 pagePRS-4 16.12.2015SE ESTNo ratings yet

- BTL 500MW U4 Updated 06072017Document1 pageBTL 500MW U4 Updated 06072017SE ESTNo ratings yet