Professional Documents

Culture Documents

Failure Mechanism - Jingping P - Li

Uploaded by

renos730 ratings0% found this document useful (0 votes)

18 views18 pagesFailure Mechanism of Jingping Hydropower

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFailure Mechanism of Jingping Hydropower

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views18 pagesFailure Mechanism - Jingping P - Li

Uploaded by

renos73Failure Mechanism of Jingping Hydropower

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 18

Rock Mech Rock Eng (2017) 50-1883-1900

DO! 10.1007/s00603-017-1208-0

Mow

ORIGINAL PAPER

Failure Mechanisms and Evolution Assessment of the Excavation

Damaged Zones in a Large-Scale and Deeply Buried Underground

Powerhouse

Haicbo Li" + Ming-chang Liu? - Wan-bo Xing* + Shuai Shao! «Jiaewen Zhou

Received: 10 September 2016/ Accepted: 20 March 2017/ Published online: 25 March 2017

(© Springer-Verlag Wien 2017

Abstract The Finping I underground powerhouse is deeply

buried and is one of the largest underground powerhouses

in China, As a result of high levels of in situ stress, com-

plex geological conditions and the effects of excavation in

‘adjacent caverns, the surrounding rock mass has been

severely deformed and broken, and excavation damaged

zones (EDZs) have become major obstacles to the design

‘of cavern excavation and support. Field investigations and

‘monitoring data indicated that there are two main modes of

failure: high tangential stress induced failure and progres

sive failure, which have occurred on the mountain side and

the river valley side of the Jinping I underground power-

house, These two main modes of failure were due to strong

secondary principal stress forces in the sub-parallel direc-

tions and sub-vertical directions, acting on the axes of the

‘main powerhouse on the mountain side and on the river

valley side, respectively. Deformations and EDZs on the

river valley side were generally larger than those found

along the mountain side, and the distribution of deforma-

tions was consistent with the distribution of EDZs. The

evolution of the EDZ on the river valley side has clearly

been time dependent, especially along the downstream arch

abutment, and the EDZ was considerably enlarged with

further excavation, Additionally, the deformation of the

© Siawen Zhou

jwzhou@seu.eda.en

State Key Laboratory of Hyéraulis and Mountain River

Engineering, Sichuan University, Chengdu 610065, People's

Republic of China

‘Yalong River Hydropower Development Company, LTD.

Chengdu 610051, People’s Republic of China

ower China Chengdu Engineering Corporation Limited,

‘Chengdu 610072, People’s Republic of China

surrounding rock mass was first initiated from the edge of

the excavation area and gradually extended to deeper areas

away from the opening. However, the EDZ on the moun-

tain side was enlarged only during the first two phases of

excavation, The extension of pre-existing cracks and the

creation of new fractures hias mainly occurred in the oldest

EDZ section, and the HDZ has been visibly enlarged,

whereas the EDZ has shown little change in other exca-

vation phases.

Keywords Underground powerhouse - Excavation

damaged zone (EDZ) « Progressive failure » Time

dependent behavior - EDZ evolution

1 Introduction

‘The construction of large underground caverns can result in

stress redistribution and concentration, in unloading

rebounds in surrounding rock mass, and in the initiation

and propagation of micro-cracks, and typically results in

the creation of excavation damaged zones (EDZs) (Kim

et al. 2013), As a result, the deterioration of rock mass

{quality and marked changes in hydrogeological conditions

‘occur in EDZs, thereby decreasing stability levels and

increasing the probability of failure in underground caverns

(Chen et al, 2015). The density and magnitude of induced

fractures and cracks in EDZs should decrease from the

borders of excavation zones to far-field undisturbed areas

(Maxwell et al. 1998; Zhou et al. 2013). EDZs can be sub-

divided into three zones: excavation damaged zone (EDZ),

‘excavation disturbed zone (EdZ) and highly excavation

‘damaged zone (HDZ). An EDZ is defined as a zone that has

significant changes in mechanical behavior and in perme-

ability characteristics, and an EdZ is a zone that has not

D Springer

1884

‘undergone major changes in mechanical behaviors and

permeability characteristics and that has no negative effects

on long-term safety. An HDZ is a zone positioned near the

edge of an excavation area where macro-scale fracturing,

spliting or spalling can occur, in which the surrounding

rock mass is heavily damaged, the mean wave veloc

level is relatively low; such areas represent the section of|

an EDZ that has been highly damaged by excavation

(attahi etal. 2013; Dai et al. 2015).

EDZs significantly influence the overall performance of

underground caverns and have become a Key factor

affecting the design and construction of underground cav-

cms. This problem has been the focus of several studies

‘Atomic Energy of Canada Limited (AECL) has invest-

gated EDZ sizes and characteristics through in situ tests

mainly conducted in underground research laboratories

(URLs) (Hudson et al. 2001; Martino and Chandler 2004)

Previous studies have used displacement monitoring,

acoustic emission and microseismic events, acoustic waves

and a borehole television (TV) technique to analyze EDZs

around several excavation sites (Malmgren et al. 2007;

Kwon et al. 2009; Lu et al. 2013). A simple relationship

between unloading strain and the cumblative opening dis-

placement of cracks has been proposed to quantify the

extent of damage in EDZs according to unloading strain

energy, which is released during the excavation of under-

ground caverns (Wu et al, 2009), The extemt of EDZs and

the quantification of the degree of damage to underground

cavers have been studied using a micromechanies model

according to acoustic emission and microseismie events

(Cai and Kaiser 2005). However, there have been few

studies on EDZ formation, width and evolution at large

scales and in deeply buried and complex excavation project

sites.

The Jinping I underground powerhouse is one of the

largest underground powerhouses in southwestern China

‘Owing to high levels of in stu stress, complex geological

conditions and the effects of adjacent excavation, some

special geological hazards have occurred during the excs-

vation, such as spliting, spalling, bulking, cracking and

deep fracturing of the shoterete layer. The formation of a

large and asymmetric relaxation zone (as deep as 15m) has

been a key problem encountered throughout the construe-

tion of the underground powerhouse of the Jinping 1

Hydropower Station (Wu et al. 2010; Huang etal. 2011; Li

tal 2014), Fortunately, a complete set of monitoring data,

including from rock deformations, acoustic waves, bolt

stress and borehole TV techniques, has been collected to

estimate the stability of the underground powerhouse and

to determine the probability of failure. In this study,

spliting, slabbing and folding characteristics and defor-

mations of surrounding rock masses were analyzed, and

‘mechanisms of stress-induced and progressive failure are

© springer

H.Lieta,

presented. Through the use of acoustic waves, multipoint

‘extensometers and borehole TV techniques, the evolution

of deformations and acoustic wave curves in different areas

‘was studied. Furthermore, through the study of geological

conditions, excavation steps and monitoring data, typical

EDZs around powerhouse cavers were graded (e.g., HDZ,

EDZ and EdZ), and the evolution of EDZs in different

areas throughout the excavation of the underground pow-

cethouse was revealed,

2 Project Background

‘The Jinping I Hydropower Station is located along the lower

reaches of the Yalong River, which is 75 km away from the

city of Xichang in Sichuan Province of southwestern China

(Fig. 1a). The large-scale underground powerhouse is posi-

tioned along a right-flanking mountain at vertical depths of

160-420 m and at horizontal depths of 110-380 m. As

shown in Fig. 1b, the underground powerhouse is mainly

composed of six diversion tunnels, a main powerhouse, six

omnibus bar caves, a main transformer chamber, two cit-

cular tailrace surge chambers and two tailrace tunnels. The

‘main powerhouse and main transformer chamber are

arranged in parallel with a dip direction of N6S*W and cover

excavation areas. of 276.99 m x 28.90 m x 68.80 m

length x width x height) and 197.10 m x 19.30 m x

32.70 m (length x width x height), respectively. The cit-

cular tailrace surge chambers accommodate three turbines

and cover excavation areas of 41,00 m x 80.50 m (diame-

ter x height) on the mountain side and 37.00 m x 79.50 m

(Giameter x height) on the riverside, Rock pillars above the

rock bench and between the main transformer chamber and

‘main powerhouse are 43.75 m thick and those below the

rock bench are approximately 46.00 m thick, The under-

ground powerhouse reflects a typical design with tall side-

walls, a long span and complex construction conditions.

2.1 Geological Conditions

‘The geological conditions in the underground powerhouse

area are complex. As shown in Fig. 2a, rock strata in the

powerhouse area are mainly found in the second to fourth

layers (132,720, and 72%) of Trasic marble. The

second layer (732%) is mainly divided into upper and

lower sub-layers, of which the upper sub-layer mainly

consists of a fairly thin marble layer anda small volume of

fen schist, and the lower sub-layer is mainly composed

of thick breciated marble, The third layer (72%,) is

rnainly composed ofa thick marble layer wth traces of thin

Failure Mechanisms and Evolution Assessment of the Excavation Damaged Zones ina Large-Scale. 1885

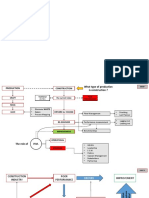

Fig. 1 Location and layout of (fay

the underground powerhouse of

the Jinping Hydropower

Station: a map of the Yalong

River; b layout of the Jinping

underground powerhouse

=

npg

yeropde Se

seen schist The fourth ayer (72) ism

of gray marble and motley breccated marble with traces of

green schist, which forms weak structural planes, The main

Strata area is found in a strike at N3O"-60°E at a dip

direction of NW and a dip angle of 25-40°,

‘The main strctual surfaces of the powerhouse arva

consist of three large-scale, sub-vertically oriented faults

(Fis, Fi4 and Fjg) and a small weakness dike (X). Three

faults le parallel at an angle of approximately 50° to the

axis ofthe main powerhouse with a strike of N6O°-70°E, a

dip direction of SE and a dip angle of 60-80", Fi is

contol fault that extends approximately 700_m and that

passes through the main powerhouse, main transformer

chamber and tailrace surge chamber on the mountain side

cover a fault zone of approximately 0.2-1.0 m that is locally

up t0 35-40 m thick, and itis mainly composed of

breccia. Xs a small dyke of mice-pagioelas lamprophyre

that intrded into the marble at a later stage and covers

fault zone of approximately 1.0-20 m thick and approxi

mately 1000 m long. Additionally, four groups of ertcally

‘ricated joins are found inthe powerhouse area (Jy with a

stike of N30°-6O°E, a dip direction of NW and a dip angle

(0 30-40"; Ja witha stk of NSO*-70°E,a dip direction of

SE and a dip angle of 60-80"; J, with a stke of N2S*—

+#1-6 pressure piping

#1-2 circular tailrce surge chamber

-40°W, a dip direction of NE and a dip angle of 80-90"; and

J, with a strike of N6O°70°W, a dip direction of NE and a

ip angle of 80-90°). J and J2 are the two most fully

developed joints around the main powerhouse and are

spaced 1-2 m apart, whereas Js and J are less developed

and are spaced 0.3 and 5 m apart, respectively. A stereo-

‘graphic projection of the joints presented in Fig. 2b shows

correlations between the faults and underground

powerhouse,

2.2 In Situ Stress

In situ stress in the underground powerhouse area was

‘measured by using the borehole stress relief method at an

early stage before the excavation of the underground

powerhouse (Fig. 3a). As shown in Fig. 3b, field test

results for the powerhouse area show that the in situ stress

distribution had a humped configuration and followed the

typical stress distribution pattern of deep valleys with a

horizontal depth of 100-350 m representing the peak. The

‘underground powerhouse area is located in the high in situ

stress region. An abrupt change of in situ stress was found:

near fault Fy4; on the river valley side, the in situ stress

ficld is controlled by regional tectonic stress, but on the

mountain side, gravity stress is the main form of stress

D Springer

SE ee

1886

Fig. 2 Geological conditions of

the underground powerhouse of

the Jinping I Hydropower

Station: a2 typical geological

section ofthe underground

powerhouse (along the axis of

‘the main powerhouse) and ba

stereographic projection of four

sroups of critically oriented

joins in the underground

powerhouse area

Nosew/

Stereographic projections of in situ stress are presented in

Fig. 3c, d to illustrate detailed spatial characteristics. The

direction of the maximum principal stress force was rela-

tively uniform, and it intersected with axes of the main

powerhouse at a small angle with a dip direction of N30°-

‘7O°W and an average dip angle of 30°. The second prin-

cipal stress force, which was approximately in line with

fault Fs, could be divided into two groups: group I and

group II (Fig. 3a). Group I intersected with axes of the

‘main powerhouse at a small angle (approximately 10°)

toward the mountain side with a stecp dip angle of

approximately 60°, Group II was sub-vertical to axes of the

‘main powerhouse and was oriented toward the mountai

side at a large intersection angle of approximately 60-70°

and a dip angle of 50°. The directions of the minimum

Drincipal stress forces did not follow well-defined rules;

Sorin

2 en et

lof the

smowntaine

Downstream

Upstréam

they intersected with axes of the main powerhouse at

approximately 40-85° and followed a dip angle of

approximately 3-20°,

‘The magnitudes of maximum principal stress (1) were

approximately 20.0-35.7 MPa, The second principal stress

(c2) magnitudes were approximately 10,0-25.0 MPa, and

the minimum principal stress (3) magnitudes were

approximately 4.0-12.0 MPa. The rock mass strength’

stress ratio (RU¢q, where R, is the saturated uniaxial

compressive strength of rock mass in the underground

powerhouse area, and cy, is the maximum level of stress in

surrounding rock mass of the underground powerhouse

during excavation) was approximately 1.5-4.0, and the

underground powerhouse was positioned in the high in situ

stress zone. More detailed parameters of the in situ stress

‘measurements are provided in Table 1

Failure Mechanisms and Evolution Assessment ofthe Excavation Damaged Zones in a Large-Scale... 1887

ig. 3 Typical characteristics

——

of in situ stress at the Jinping I \, Co

yeropowe Staton a tajot of Qe) pesnsarneimees

te neve pao || US a iaeiaks,

‘ns soes in tbe undergron \ ay) 2

Powerhouse region; bvaaons TE} Tse

of in situ stress with horizontal |

depth inthe main powerhouse

a

|

|

|

|Groupll

of maximum principal stress; \ rt.

and d stereographic projection

of secondary principal sess {

'Yalong

River)

L

(b) 40

Underground

jowerkivee =]

| 0 50 100 150 200 250 300 350 400 450 S00 ss0

i Morlzontal aepibon)

1888

Hliea,

‘Table 1 Field measurements of in stu suess around the underground powerhouse (linping Hydropower Station)

No Measuring Horizontal Verieal ay o

am serihim) dep) Vane a) FO) Va a PO)

ara) Pa)

1 ey-t 8 307 1613 1509 51694524926 418368 TW

2 o-1 180 24 2127 1841-296 9473269 2S 3

3 on 2 385 523 253231931796 20S BLL a9

4 o-1 233 299 357 BHO

5 ay-3 40 180 1542 128 26 961 1S 46 2037 184

6 en-4 MO 280 17431507 907-735-3457 SRA 6224987

7 oar-1 310 360 21981264 46.794 M7365 GOL 2391 0

8 on-S 150 210 2321784051767 3509471105948

9 on-2 368 403 2 B74 29 2382-1339 23094

10 ose—1 270 330 182 156) 741923 27365304 RG

HN ama-2 20 310 3039-198 2871847778259 98H

2 o@-3 280 330 2863 3S 2198S 2 OTS OG

13 owt 380 320 2872 167322092280. 6S 79610932

4 am-1 200 270 3565 1323-89 «S83 459 GR 241109

15 cer-2 400 20 1787 136.1 321166236 4761398243248

‘is the dip direction ofthe principal stress and isthe ip angle ofthe principal sess

2.3 Failure Characteristics of the Surrounding Rock

Mass

‘The rock masses in the Jinping underground powerhouse

‘area are mostly fine grained. The roughness of the sur-

rounding rock surface is low, and the half-cast factor

reached 90% afler excavation blasting. However, a

number of stress-induced breakages (¢.g., splitting, spal-

ling and peel off) occurred hours after excavation. Fig-

lure 4 shows some typical failure phenomena occurring

around the underground powerhouse during the excava-

tion and supporting process. As shown in Fig. 4a, b, the

rock mass was split, and the shoterete layer bulked and

cracked considerably along the downstream arch abut-

‘ment between sections KO + 35 m and KO + 65 m of the

‘main powerhouse. The split rock mass was mainly lake-

like, fragmented and weak, and the reinforcement mesh

‘was extruded and heavily bent, thus indicating the pres-

ence of a high level of tangent stress concentrated along

the downstream arch abutment. The surrounding rock

mass in the downstream arch foot between sections

KO + 165 m and KO + 185m was extruded and then

folded and bellied, and some even broke off (Fig. 4c). As

shown in Fig. 44, the surrounding rock mass rebounded

and deformed toward the free face, and slabbing fre-

quently occurred along the downstream arch abutment

between sections KO + 95m and KO + 145 m of the

‘main powerhouse, Slabbing cracks had opened and were

nearly parallel to the critically oriented joint J. Because

of unloading and relaxation, surrounding rock masses

© springer

around the high sidewalls were deformed toward the free

face with relatively large values, thus causing tension

‘cracks to open and leading to considerable dislocations of

the remaining blast holes (Fig. 4c).

Monitoring data show that deformations along the

downstream sidewall of the main powerhouse became

more pronounced as the number of excavation steps

increased, and deformation rates evidently did not

decrease, even during the suspension of excavation from

May to October of 2009, owing to the rheology of sur-

rounding rock mass subjected to high levels of tangential

stress. Deformations exceeding 50 mm occurred at 14.5%

{in the monitoring points in the main powerhouse. Addi-

tional protrusion occurred in the deep relaxation zone

around the main powerhouse, especially on the river valley

side, where the deepest relaxation zone reached 15 m (in

section KO + 126.8 m of the downstream arch abutment).

‘The depth of the relaxation zone (1-15 m) exceeded the

expected depth for similar scales and geological conditions

of underground powerhouses built in China (1-9 m for the

main powerhouse of the Houziyan Hydropower Station).

3 Large Deformations and Excavation Damaged

Zones

‘The underground powerhouse was excavated using a bench

method involving conventional drilling and blasting. As

shown in Fig. 5, the construction of the main powerhouse

‘occurred from May 2006 to April 2010 over 11 main

(nS

Failure Mechanisms and Evolution Assessment of the Excavation Damaged Zones in « Large Scale

Fig. 4 Failure problems

encountered around the

Underground powerhouse during

‘constuction: a bulking and

cracking ofthe shoterete layer;

1b extrusion and bending of the

reinforcement mesh; e folding,

telling and breaking off;

4 stabbing; and e tension cracks

and dislocation of remaining

blast holes along the tall,

sidewall

Moss]

Misis

vinon , DYheanszo O

TE avai0r-0 | 16300 8

E 100 1620.0 &

é a

2 so 16100

00 1600.0

08/05/27 08/11/23 09/08/22 0/11/18 10/08/17 10/11/18

Time(yysmmda)

©

or Orifice-4m—4— 4m-7m—6= 7m-15m—e=15m-30m a

30.0 16545, aa

Faso e

ibe 1650.0 &

F200} :

= 1685.08

Eso

fo 1610.08

é sot § 1633.9} 1635.0

0.0 hecho cc ED 16200

08/08/27 08/12/28 09/07/01 lo/oa/i7

Time(yy-mm-dd)

D Springer

Failure Mechanisms and Evolution Assessment ofthe Excavation Damaged Zones in a Large-Sc

surrounding rock mass in the deeper area gradually

deformed as excavation proceeded. Figure 6b, ¢ shows

relative deformations at various depths of surrounding rock

‘masses in section KO + 31.7 mand section KO + 126.8 m

of downstream arch abutments of the main powerhouse

(elevation 1659 m), respectively. Deformation character-

istics between section KO+31.7m and section

KO + 126.8 m of the downstream arch abutments were

significantly different. The surrounding rock mass in see-

tion KO + 31.7 m of the downstream arch abutment

showed rapid deformation in the first two excavation steps

(step IV and step V) and deformed less in the remaining

excavation steps. The surrounding rock mass at the surface

(from the orifice to 8 m) experienced the majority of

deformation effects, and only a limited amount of elastic

deformation occurred in the deeper area and was induced

by stress adjustments during excavation. Although the

surrounding rock mass in section KO + 126.8 m of the

downstream arch abutment underwent gradual deformation

as excavation proceeded, relatively significant deformation

‘occurred, even in the deeper area (between 15 m and

30 m). Additionally, the surrounding rock mass in section

KO + 126.8 m of the downstream arch abutment clearly

exhibited time-dependent deformation, particularly

between 4m and 7m, within which the deformation

increased rapidly during the suspension of excavation

between step VI and step VI (from May to October 2008).

The evolution of deformation in section KO + 126.8 m of

the downstream arch abutment initiated from the edge of

the excavation zone and gradually propagated to deeper

areas away from the opening as excavation proceeded,

‘The monitored deformations in the surrounding rock

sass in section KO + 31.7 m and section KO + 126.8 m

of the underground powerhouse are shown in Fig. 7. The

deformations in section KO + 1268 m were generally

larger than those in section KO + 31.7 m, especially along

the downstream sidewall of the main transformer chamber

‘where there was a large fault Fy and an intrusive weakness

dike X, the maximum deformation level reaches 236.7 mm

(in September of 2010). The quality of the surrounding

rock mass in section KO + 126.8 m of the upstream side-

wall was poor and was influenced by fault F4; the defor-

mation magnitude was roughly 30-60 mm, and the heavily

deformed layer was approximately 4-6 m. However,

deformation in section KO + 31.7 m of the upstream

sidewall reached approximately 10-25 mm, and the heavy

deformed layer was shallower (1-3 m). The surrounding

Tock masses in section KO-+ 31.7 m and section

KO + 126.8 mof the downstream sidewalls exhibited clear

time dependence with large deformations of approximately

50-70 mm as a result of the complex excavation of

‘omnibus bar caves and thin rock pillars (46 m), whereas

the heavily deformed layer in section KO + 126.8 m of the

1891

downstream sidewall was as deep as 6-12 m, extending

‘deeper than section KO + 31.7 m, which reached approx-

imately 3-6 m. Deformations at the arch crowns were

smaller (less than 10 mm), except at downstream arch

abutments of the main powerhouse, where a large defor-

‘mation with a thick, heavily deformed layer formed in

section KO + 126.8 m; the heavily deformed layer in

section KO + 31.7 m was much thinner.

3.2 EDZs Detected by Acoustic Waves

Our acoustic wave test was based on the theory of elastic

‘wave propagation in solid media. The test is used to ana-

lyze the physical and mechanical properties of the sur-

rounding rock mass. By launching sound waves at @

distance through a medium with a manval shaking method

and receiving the modulated sound waves, including their

physical characteristics, the EDZs can be confirmed after

observation and analysis of the speed along the test bore-

holes (Barton 2007). The wave velocity decreases with

increasing acoustic impedance and fracture development,

and it increases with increasing rock mass stress and den-

sity (Deng et al. 2001). It is typically assumed that the

release of radial stress and the formation of new cracks are

the two major causes of velocity (and modulus) reductions

in the EDZs. Confinement reduction causes stress release

and redistribution and leads to the opening of original

closed cracks (assuming that no new cracks are induced), to

the expansion of pores and to minor changes in rock mass

density, thus eventually resulting in the reduction of wave

velocity. Induced fracturing in the EDZs, owing to either

the extension of pre-existing cracks or the creation of new

fractures, would result in decreased clastic moduli and

wave velocity, and as the magnitude of the wave velocity

decreases, more damage would be caused (Suzuki et al

2004; Li et al. 2013). Confinement reduction and stress

release have considerable effects on wave velocity, but this

relationship is very complex, and it is difficult to monitor

the stress response of surrounding rock masses during the

construction of an underground powerhouse (Wepfer and

Christensen 1991; Barton 2007). Therefore, wave velocity

changes in rock masses as a result of stress-induced frac-

turing and confinement reduction have not been distin

guished to assess the EDZs during excavation via the

acoustic wave test, thus satisfying engineering

requirements

Figure 8 shows typical test results for acoustic wave

ccurves recorded during excavation in section KO + 31.7 m

and section KO + 126.8 m of arch abutments in the main

powerhouse, As shown in Fig. 8a, b, the wave velocity in

section KO + 31.7 m of the downstream arch abutment

decreased considerably within a certain distance from the

borders of the excavation zone, and the wave velocity in

D springer

1392 HLietal

100m Deformation ——— wm

a — mz

fuels dz

and excavation damaged zones (EDZs) detected by monitoring the underground powerhouse after excavation: « around

section KO 431.7 m and b around section KO + 126.8 m

2 springer

Failure Mechanisms and olution Assessment ofthe Excavation Damaged Zones in Large Seale 1893

Fig. 8 Typical test resus of @r0 wo

acoustic wave curves measured $60 rr meen, 260 i JST Faye,

in the main powerhouse daring 350 WO gs0 :

‘excavation: ain section 240 pes ooo jan-2008 |

KO4 317 mot the x1) Ab mse: 200 S40] MJ ‘svg 2008

‘downstream arch abutment, bin oe —Apr2009 7) care

section KO + 126.8 m of the

downstream arch abutment, ein

section KO + 31.7 m ofthe

upstream arch abutment and

02 4 6 & to ip ia 16 18 20

Depth ian

in section KO + 1268'm of wea ppnow

the upsream ach abutment f

May-2008 May-2008

e208, —Sepr2008

4 == Apr2009 agre2009

O29 6% toiisiere a0 027 6 § tor teieie a0

Depth (m) Deptnim)

section KO + 126.8 m of the downstream arch abutment (@)75 ~<~Osiee 2a-te2-4m--:6m—E-6im-M-f.20m

fluctuated considerably during excavation. In contrast, the

wave velocity in section KO + 31.7 m of the upstream arch

abutment showed strong fluctuations, and the wave veloc-

ity in section KO + 126.8 m of the upstream arch abutment

decreased considerably during excavation but only along

the surface (0-4 m) of the surrounding rock mass (as

shown in Fig. 8c, d). These wave velocity patterns showed

4 time effect, especially in section KO + 31.7 m of the

upstream arch abutments and in section KO + 126.8 m of

the downstream arch abutments, and EDZs were visibly

enlarged during excavation,

Figure 9 shows the mean wave velocity versus time at

various depths of the surrounding rock mass in section

KO 431.7 m and section KO + 126.8 m of the down-

stream arch abutments. As shown in Fig. 9a, the mean

wave velocity in section KO + 31.7 m of the downstream

arch abutment decreased the most 30 days after excavation

by blasting, and this decrease decelerated over time. The

mean wave velocity showed a sharp change, decreasing

considerably along the surface of the surrounding rock

‘mass (0-6 m) and decreasing less in deeper areas.

Although the mean wave velocity in section KO + 126.8 m

of the downstream arch abutment showed no obvious jump

point, the decrease in wave velocity was initiated from the

edge of the excavation zone and gradually propagated to

deeper areas away from the opening as excavation pro-

ceeded (Fig. 9b). The strong decrease observed in the mean

wave velocity zone in section KO + 1268m of the

downstream arch abutment was deeper than that in section

KO + 31.7 m of the downstream arch abutment.

‘As shown in Fig. 10, sufficient data indicated that

acoustic wave curves of rock mass surrounding the Jinping

1 underground powerhouse could be classified into the

following four categories: type J, type Il, type III and type

IV. For type I, the acoustic wave curve could be divided

into three parts: a “lower wave velocity” section near the

ge” ‘.

gas

© ss oiptatcocrmaN

287 ir Ti Vv Vv VI

Excavation steps

~+~Oriee-2m-@+2-4m

466m 6-4 8-20

Originalrock mast >

vi

Excavation steps

Fig. 9 Mean wave velocity versus time at various surrounding rock

mass depths: a in section KO + 31.7 m of the downstream arch

abutments and b in seetion KO + 126.8 m of the downstream arch

sutments

boundaries of the excavation site zone where the rock mass

is heavily damaged (HDZ); a “rises with fluctuation wave

velocity” section where multiple parallel fresh cracks are

initiated by stress redistribution after excavation and where

the wave velocity is lower near cracks and relatively high

in the rock bridge (EDZ); and a “high wave velocity with

‘minor fluctuations” section in the deeper zone where rock

is disturbed but not damaged (EdZ). For type II, which

mainly occurred in the high stress concentration-induced

failure area, the acoustic wave curve could be divided into

two parts, and it differed from type I in that “rises with

fluctuation wave velocity” sections were not present or

‘were very small. For this type, the surrounding rock mass

‘was heavily damaged in the area along the borders of the

excavation site but was not as affected in deeper areas. For

D springer

1894 H Lita,

Fig. 10 Four categories of 240) eh)

acoustic wave eames ofthe ¢ Highvelosity with — igh velocity with

Surrounding rock mass ine é Eiecvit, “smligyomidon’ all dugtucton

underground powerhouse ofthe & | Lower Seytion, S| tower

Sinping 1 Hydropower Satin: 3 | vetogtty i FI velocity

farypel, b type Il, type I and z Vppz | EZ | eee, Raz

aitype IV 2[mpz i i eLHpz |

Depihtm Depihimy

FAO gicewih Hisdvelociyy win — ZA @

i Aerie womimagunton BT gcc ig, — lahyelacy with

8 omer veri E] Risewitn “Slt goctunion

2 | witsjpwrie z|

z 3

4 | _HDZ Baz

2 3|_naznz

Depihm)

Wave velocity (Km,

Depih(ay

Depth(m)

Fig. 11 Two typical acoustic wave curves ofthe same test borehole measured during excavation and unloading: a pattern I, which occured

‘mainly in the progressive failure area and b pattem Il, which occurred mainly inthe high tangential stress

type II, which was mainly found during stress regulation

after excavation, the acoustic wave curve could also be

separated into three parts. It differed from type T in that

lower wave velocities near the edge of the excavation site

rose slowly. For type IV, which was mainly found during

the lining stage after excavation when the EDZs were

emerging and expanding, the acoustic wave curve could be

divided into two parts: a “rise of wave velocity with

fluctuation” part and a “high wave velocity with minor

fluctuations” part (Zhang et al. 2011)

Figure 11 presents two typical evolution paths of

acoustic wave curves in the same test borehole during

excavation and unloading. As shown in Fig. 11a, the

undisturbed rock mass occupied a triaxial compressive

stress state (axial stress, radial and tangential stress), and

the wave velocity reached up to 6000-6300 m/s along the

centite test borehole. After excavation blasting, the wave

velocity near the edge of the excavation site decreased, and

acoustic wave curve shapes in type IV of the rock mass

were damaged by blast vibrations. The radial stress was

relieved, and the rock mass entered an unstable high biaxial

stress state, thus causing the surrounding rock mass to

deform by gradually rebounding toward the free face, The

EDZs were enlarged because of micro-crack initiation,

2 springer

vduced failure area

propagation and coalescence due to unloading and defor:

mation. Then, with an increase in excavation steps, cracks

and EDZs gradually expanded into deeper ground layers

because of excavation disturbances and increasing sidewall

heights. Cracks and EDZs expanding from the edges of the

excavation site to deep ground layers resulted in the evo-

lution of acoustic wave curves from type IV to type III ©

type I (eg. Fig. 8b, c). However, as shown in Fig. 11b,

when cracks and EDZs mainly formed near the edges of the

excavation site and did not extend to deeper areas, the

acoustic wave curve evolved from type IV to type Ill 10

type II (@g., Fig. 8a, d).

Construction findings have shown that the densities and

‘magnitudes of induced fractures and cracks in EDZs should

decrease from the boundaries of an excavation site to a far

field undisturbed state. In contrast, the wave velocity

increases gradually. On the basis of the acoustic wave test

and borehole TV images, Fig. 12 shows a typical measured

result for EDZs in the main powerhouse of the Jinping I

Hydropower Station. The figure shows that the mean wave

velocity near the boundaries of the excavation site was

relatively low (below 4000 mis). The rock mass was

heavily damaged with densely distributed extrusion cracks

accompanied by shear cracks, which showed clear signs of

ag

Failure Mechanisms and Evolution Assessment of the Excavation Damaged Zones in a Large Scale. 1895

Fig. 12 Excavation damaged @ Lower

‘zones (EDZs) along the depth of. velocia

the rock mass surrounding the

Finping main powerhouse: a a

typical account ofthe acoustic a

wave velocity inthe G60 A

poe % /

tppical account of» borehole e507 fh |

‘TV of fractures in the Zao t

surrounding rock mass and a \

€ classicaton of EDZs along sof]

Rise with

uct

High velocity with

|

i

I

I

Mow we

/

|

y

the depth ofthe rock mass

surrounding the Jinping min

powerhouse OW

)

Densely distributed

HDZ

splitting and spalling induced by blasting vibrations and

siress concentrations. This zone is called the HDZ. (Cater

and Booker 1990; Zhou et al. 2012). Next to the HDZ,

Where the EDZ was located, the wave velocity fluctuated

between 4000 and 5500 mis. Fresh cracks formed, and

rupture surfaces were fairly steep and nearly parallel to the

‘excavation surface. The response characteristics of wave

velocity changes varied with crack formation. Inthe deeper

zone, the mean wave velocity reached up to 5500-6300 m/

' with minor fluctuations occurring near the EDZ because

of the presence of sparsely distributed closing cracks. The

rock mass was disturbed but was not damaged (EdZ).

The distribution of EDZs was analyzed by applying

acoustic waves to the surrounding rock mass of section

KO + 31.7 m and section KO + 126.8 m of the under-

‘ground powerhouse. The corresponding results are shown

in Fig. 7. The EDZs in section KO + 126.8 m are rela-

tively large and asymmetric, especially for the EDZ. that

reached 15 mat the downstream arch abutment of the main

powerhouse. The depths of the EDZ in section

KO + 126.8 m of the downstream arch abutment and of

sidewalls of the main powerhouse were much greater than

the depth of the HIDZ in the same area, and the depth of the

[BDZ in section KO + 31.7 m was not significantly greater

than the depth of the HZ in the same area, particularly at

the downstream arch abutment. The HDZ in section

Depth (m)

Sparsely distributed

losing cracks

Deep tension

‘cracks

EZ

KO + 126.8 m of the arch crown and upstream arch

abutment was fairly small, as is the EDZ, but a large EDZ

‘was found in section KO + 31.7 m of the upstream abut-

ment of the main powerhouse. EDZs in sections

KO + 31.7 m and KO + 126.8 m of tall sidewalls in the

‘main powerhouse were relatively large, whereas they were

generally small around the main transformer chambers,

‘except in section KO + 126.8 m of the downstream side-

wall, where there was a large deformation. The EDZs

around section KO + 31.7 m and section KO + 126.8 m of

the underground powerhouse were relatively large and

were positioned much deeper than 20 m (the scope of the

acoustic wave test) in many areas. These findings were

determined mainly on the basis of deformations, though

such resulls are not very accurate. Furthermore, the dis-

tribution of EDZs agreed well with the distribution of

deformations.

3.3 Mechanism Analyses

As shown in Figs. 3a and 13a, in situ stress on the moun-

lain side (such as section KO + 31.7 m) was classified as

‘group I. Although both the maximum and second principal

stress intersected with axes of the main powerhouse at a

small angle of approximately 10-15°, which favors the

stability of the main powerhouse, the second principal

2 springer

1896

HLieal,

Fig. 13. Main fafure

mechanisms ofthe rock mass

surrounding the Jinping 1

“underground powerhouse during

excavation: a high tangential

stress-induced failure and

D unloading and propresive

failure

a)

SNe @

\ ee mle

ee fo; Ne

\ NG

stress reached large values of approximately 10-25 MPa

and dipped downstream at a steep dip angle of approxi-

mately 60°. As a consequence, significant tangential stress

(c,) was applied on the downstream arch abutment of the

main powerhouse. During excavation, radial stress (o,),

which was approximately parallel to the minimum pri

pal stress with small values, was relieved, and tangential

stress near the edge of the downstream arch abutment

concentrated and inereased as a result of stress adjustments

‘The extensive initiation, propagation and coalescence of

‘micto-cracks occurred, and high levels of tangential stress

confined the rock mass in such a way that caused cracks to

develop only in the direction parallel to the boundaries of

the excavation site (Cai 2008). The existence of a critically

oriented joint J; (one of the most developed oriented joints

in the main powerhouse) aggravated cracking, and the rock

D springer

mass was damaged considerably. As shown in Figs. 6b and

8a, the effects of blasting vibrations and tangential stress

concentrations weakened with depth, and when the heavily

deformed layer was quite shallow, the lower wave velocity

‘area was also shallow. As a result, the HDZ. in section

KO + 31.7 m of the downstream arch abutment was rela-

tively large, whereas the EDZ was not much larger than the

HDZ (Fig. 7a)

‘As shown in Figs. 3a and 13b, in situ stress on the river

valley side (such as section KO + 126.8 m) was classified

as group Il. The second principal stress was relatively

large, at approximately 10-25 MPa, and it was sub-vertical

to the axis of the main powerhouse, dipping upstream at a

large intersection angle of approximately 60-70" and a dip

angle of 50°. AS a result, the radial stress (¢,), which was

approximately parallel 10 the second principal stress, was

a

Failure Mechanisms and Evolution Assessment of the Excavation Damaged Zones in a Large-Seae.

markedly increased, though the tangential stress (o;) was

not as large as that found in the group T area. During

sudden excavation blasting and unloading, the radial stress

(@,) quickly decreased to near zero, and the rock mass

rebounded and deformed toward the free face, thus in turn

leading to the concentration of tension stress tthe tips of

pre-existing micro-eracks, AS @ result, tension cracks

expanded along the critically oriented joint Jy and differ-

‘ences between rebound levels, the relatively high tangen-

tial stress value and the intersection of joint J led to

slabbing, folding, bellying and even breakages near the

edge of the downstream arch abutment (Fig. 4c, d).

‘Simultaneously, stress redistributed, and cracks gradually

extended into deeper areas as excavation continued. As

shown in Figs. 6¢ and 8b, the rock mass near the edges of

the downstream arch abutment was damaged considerably

by blasting vibrations and tangential stress concentrations,

and cracks induced by excavation extended into a

remarkably deep area with clear time-dependent behavior.

{As a consequence, the EDZ. in section KO + 126.8 m of

the downstream arch abutment was much larger than the

HDZ (Fig. 7b.

4 Discussion

EDZs distribution characteristics around Jinping power-

house caverns correlated with cavern sizes, in situ stress,

mechanical parameters of the rock mass, structural planes,

the control of blasting vibrations, the influence of adjacent

excavations and the excavation process. As shown in

Fig. 7a, the HDZ in section KO + 31.7 m of the down-

stream arch abutment was relatively large because tan-

gential stress was concentrated near the edges of the

downstream arch abutment after sudden excavation and

‘unloading. An extensive initiation, propagation, and coa-

lescence of micro-cracks occurred along the boundaries of

the excavation site. The rock mass along the surface was

split considerably, the shotcrete layer was notably bulked

and cracked, and even the reinforcement mesh was extru-

ded and highly bent (Fig. 4a, 6). The wave velocity in this

area is decreased considerably within a certain distance

from the boundaries of the excavation site (Figs. 8a, 9a).

Extensive deformation occurred along the surface of this

area, and the heavily deformed layer was quite thick. The

acoustic wave curve evolved from type IV to type Il to

type II (Fig. 11b), thus showing that the rock mass was

heavily damaged near the boundaries of the excavation

site, whereas the influences of blasting vibrations and

tangential stress concentrations decline with depth, and the

EDZ is not much larger than the HDZ. There were rela-

tively large EDZs around the tall sidewalls of section

KO + 31.7 m as a result of sudden excavation unloading

1897

and large deformations, but EDZs around the transformer

chamber were quite small because of the relatively small

size and high quality of surrounding rock mass.

‘As shown in Fig. 7b, both the HDZ and EDZ in section

KO + 126.8 m of the downstream arch abutment were

extraordinarily large, and especially for the EDZ, which

reached a depth of 15 m. Owing to the existence of rela-

tively high second principal stress foree with a direction

sub-vertical to the axis of the main powerhouse, the radial

sttess(¢,), which was approximately parallel tothe second

principal stress, was markedly increased. During sudden

excavation blasting and unloading, the radial stress (c,)

quickly decreased to near zero, and the rock mass

rebounded and deformed toward the free face. Slabbing,

folding, bellying and breaking frequently occurred near the

edges of the downstream arch abutment because of rela-

tively high levels of tangential stress and the intersection of

joints J, and J>, thus causing eracks to open and become

‘oriented nearly parallel to the critically oriented joint Jy

(Fig. 4e, d), As shown in Figs. 80 and 12, the wave

velocity near the boundaries of the excavation site was

extremely low, and the rock mass was heavily damaged

(HDZ) with densely distributed extrusion cracks accom:

panied by shear cracks. The stress redistributed, and cracks

‘radually extended into a deep area with clear time-de-

pendent behavior. The rock mass was damaged (EDZ) in

this area, Fresh cracks developed or were induced and were

spaced apart by less than 0.4 m, and rupture surfaces were

fairly steep and nearly parallel to joint J;. The wave

velocity clearly fluctuated, and changes varied with erack

evelopment. The surrounding rock mass in this area

showed visible time-dependent deformations (Fig. 6c). The

mean wave velocity graduslly decreased as excavation

proceeded (Fig. 9b), and the acoustic wave curve evolved

from type IV to type Ito type I (Fg. 11b). As a result, the

depth of the EDZ was much greater than the depth of the

HDZ, Additionally, in the downstream arch abutments, the

EDZ in section KO + 1268 m was generally larger than

that in seetion KO + 31.7 m, especially around the tall

sidewall, because of fault Fy, which decreased the quality

of the surrounding rock mass along the upstream sidewall

AA relatively large second principal stress force that was

sub-vertical to the axis of the main powerhouse led to the

formation of a much larger radial stress force (¢,) and more

severe rebound unloading deformation during excavation.

‘The EDZs around section KO + 126.8 m were asymmetsic

because of the presence of thin rock pillars and the influ-

‘ence of adjacent caverns (such as omnibus bar caves and

the main transformer chamber), and EDZs along the

downstream high sidewall were much larger than those

along the upstream high sidewall. Rebounding and

unloading deformation was so substantial that it caused the

opening of tension cracks and the dislocation of remaining

© springer

ae eee eee

1998 Hise

Fig. 14 Evouion of EDzs (a)

tnd he main poweinse 1

thring excavation minvecton = 1 4 a

somal vinosion nok TT

ween

+12 ut a om IV

WV \v. Vv

v. yy

vt MI VE a

vi vit Vi VII

vin spy vu VIII

1x 1x re

ebe bz, (

blast holes along the tall sidewall of the main powerhouse

Fig. 4(@)..

‘The evolution of the EDZ in section KO + 31.7 m and

section KO + 126.8 m of the main powerhouse throughout

excavation is presented in Fig. 14. EDZ characteristics

between section KO + 31.7 m and section KO + 126.8 m

‘were significantly different. The EDZ in section

KO +1268 m was relatively large and asymmetric,

especially along the downstream arch abutment, and the

EDZ reached a depth of 15m, The EDZ in section

KO + 126.8 m of the downstream arch abutment exhibited

clear time dependence and was considerably enlarged with

‘an increase in the number of excavation steps, particularly

the first five excavation steps. The evolution of deformation

initiated at the boundaries of the excavation site and

‘gradually propagated to deeper areas away from the

‘opening (Fig. 6c), thus revealing significantly progressive

failures resulting from stress adjustments and tension

cracks gradually spreading into deeper areas of surrounding

rock mass with a low strengtb/stress ratio during exeava-

tion, In contrast, the EDZ in section KO + 31.7 m was

relatively symmetric, The EDZ in the downstream arch

abutment was enlarged only during the frst two excavation

steps (step TI and step III) and did not substantially increase

during the remainder of the excavation period, The mean

wave velocity of the early EDZ considerably decreased

during remaining excavation steps (Fig. 9b), thus indicat-

ing that the extension of pre-existing cracks and the cre-

ation of new fractures mainly occurred in the early EDZ.

‘The HDZ was visibly enlarged, although the EDZ changed

little during the remaining excavation steps. We also note

that, interestingly, the EDZ in section KO + 31.7 m of the

upstream arch abutment was much larger than that in

section KO + 126.8 m of the upstream arch abutment and

D springer

\ 1p 20m

exhibited time-dependent behavior, because the stress state

in section KO + 31.7 m of the upstream arch abutment

(Fig. 13a) was similar to that in section KO + 126.8 m of

the downstream arch abutment, although the rebound

unloading deformation was not as severe as that in section

KO + 126.8 m of the downstream arch abutment and the

critically oriented joint J> was not as developed as joint J.

‘The EDZ around the tall sidewalls was visibly enlarged as

@ result of sudden excavation unloading and large

deformation.

5 Conclusions

Failure mechanisms of rock mass surrounding the Jinping T

underground powerhouse were analyzed, and the evolution

of EDZs around the underground powerhouse was dis-

‘cussed and assessed. The following can be concluded:

1. High levels of tangential stress-induced failures such

as splitting, severe bulking and cracking of the

shotcrete layer along the downstream arch abutment

of the main powerhouse on the mountain side. The

failure weakened with depth, and the depth of the EDZ

was not substantially greater than the depth of the

HDZ. However, progressive failures, such as deep

fractures and large deformations, mainly occurred

along the downstream arch abutment on the river

valley side with clear time dependence, and the depth

of the EDZ was much greater than the depth of the

HZ.

2. High second principal stress levels traveling sub-

vertical and sub-parallel to the axes of the main

powerhouse on the river valley side and the mountain

side, respectively, as well as critically oriented joints,

[coe RRR

Failure Mechanisms and Evolution Assessment ofthe Excavation Damaged Zones in ¢ Large-Seale. 1899)

were the main forces underlying the high tangential

stress-induced and progressive failure in different areas,

of the main powerhouse.

3. Acoustic wave curves of rock mass surrounding the

Tinping 1 underground powerhouse could be classified

into four categories. The evolution of acoustic wave

curves at the same test borehole during excavation

could be classified into two types: high tangential

stress-induced failure and progressive failure areas,

4, Deformations and EDZs on the river valley side were

‘generally larger than those on the mountain side. The

distribution of deformations was consistent with the

distribution of EDZs.

5. The evolution of the EDZ along the downstream arch

abutment on the river valley side exhibited time

dependence that increased considerably with excava-

tion. The deformation of surrounding rock mass

initiated from the boundaries of the excavation site

and gradually propagated to deeper areas away from

the opening. However, the EDZ at the downstream

arch abutment on the mountain side was enlarged only

during the first two excavation steps. The extension of

pre-existing cracks and the creation of new fractures

occurred mainly in the early EDZ, and the HDZ was

visibly enlarged, although the EDZ changed little in

remaining excavation phases.

Acknowledgements We gratefully acknowledge the support of the

Seience Foundation for Excellent Youth Scholars of Sichuan

University (2013SCUO4A07). Critical comments by the anonymous

reviewers greatly improved the initial manuscript,

References

Baton N (2007) Rock quality, seismic velocity, atenuation and

anisotropy. Taylor & Francis, Londen

Birjak KF, Petkoviek B (2004) Displacement analysis of tunnel

support in soft rock around a shallow highway tunnel at Golovec

Eng Geo! 75(1):89-106

(Cai M (2008) Influence of intermediate principal stess on rock

fracturing and strength near excavation boundares—insight from

numerical modeling. Int J Rock Mech Min Sci 45(5):763-772

(Cai M, Kaiser PK (2005) Assessment of excavation damaged zone

using a micromechanics model. Tunn Undergr Space Technol

2044):301-310

Carter IP, Booker JR (1990) Sudden excavation of « long circular

tunnel in elastic ground. Int J Rock Mech Min Sci Geomech

Abstr 27(2):129-132

‘Chen YF, Zheng HK. Wang M, Hong JM, Zhou CB (2015)

Excavation-induced relaxation effects and hydraulic conductiv-

ity variations in the surrounding rocks of a large-scale under-

‘ground powerhouse cave system, Tunn Undergr Space

‘Technol 49:253-267

Dai F, Li B, Xu RW, Zhu YG, Sha C, Xiso PW (2015) Excavation

damaged zones characteristics analysis in éeep-bured under

ground powerhouse of Houziyan Hydropower Staion. Chin J

Rock Mechan Eng 34(4):735-746

Deng JH, Lee CF, Ge XR (2001) Characterization of the disturbed

"one in large rock excavation for the Thee Gorges Project.

Can Geotech J 38(1):95-105

Fata H, Shojace 8, Farsangl MAE, Mansouri H (2013) Hybrid

Monte Carlo simulation and ANFIS-subtactive clustering

method for reliability analysis ofthe excavation damaged zone

in underground spaces. Comput Geotech $4:210-221

Huang RQ, Huang D, Duan SH, Wa Q (2011) Geomechanics

‘mechanism and characterises of surounding rock mass defor-

ration failure in construction phase for underground power

house of Jinping I Hydropower Station. Chin J Rock Mechan

Eng 30(1)23

Hodson JA, Stephansson 0, Andersson J, Tsang CF, Jing L (2001)

(Coupled T-HLM issues relating 1 radioactive waste repository

design and performance. Im J Rock Mech Min Sei

38(1):143-161

‘Kim HM, RutgvistJ, Jeong JH, Choi BH, Rye DW, Song WK (2013)

(Characterizing excavation damaged zone and stability of pres

surized lined rock caverns for underground compressed sir

energy storage. Rock Mech Rock Eng 46(5) 1113-1124

‘Kwon $, Lee CS, Cho SJ, Jeon SW, Cho WI (2008) An investigation

fof the excavation damaged zone at the KAERI underground

research tunnel. Tuna Underge Space Technol 241):1-13

Lis, Yo H, Liu Y, Wa F (2008) Resalts fom in sitw monitoring of

‘isplacement, bolt load, and disturbed zone of a powerhouse

caver during excavation process Int J Rock Mech Min Sci

45(8):1519-1525

Li SJ, Feng XT, Wang CY, Hudson JA (2013) ISRM suggested

‘method for rock fractures observations using @ borehole digital

‘optical televiewer. Rock Mech Rock Eng 46(3):635-644

Li ¥, Zhu W, Fu J, Goo Y, Qi Y (2014) A damage rheology model

applied to analysis of spliting failure in underground caverns of

Jinping I Hydropower Station. Int J Rock Mech Min Sei

71224-2346

‘Lu WB, Hu YG, Yang JH, Chen M, Yan P (2013) Spatial distibation

‘of excavation induced damage zone of high rock slope. Int J

Rock Mech Min Sei 64:181-191

Malmgren L, Saiang D, Téyri J, Bodare A (2007) The excavation

disturbed zone (EDZ) at Kiirunavaara. mine, Sweden—by

Scismie measurements. J Appl Geophys 61(1):1-15

‘Martino JB, Chandler NA. (2004) Exeavation-nduced damage studies

‘at the underground research laboratory Int J Rock Mech Min Sci

41@):1413-1426

Maxwell SC, Young RP, Read RS (1998) A micro-velocity tool to

assess the excavation damaged zone, Int} Rock Mech Min Sci

35(2):235-247

Sonuki K, Nakata E, Minami M, Hibino E, Tani T, Sakakibara 3,

Yamada N (2004) Estimation of the zone ‘of excavation

listurbance around tunnels, using resistivity and acoustic

tomography. Explor Geophys 35(1):62-69

‘Wepfer WW, Christensen NI (1991) A seismic velocity-confining

pressure relation, with applications, Int J Rock Mech Min Sei

2R(5):451-156

Wo F, Liv J, Liu T, Zhuang H, Yan C (2009) A method for

assessment of excavation damaged zone (EDZ) of a rack mass

and its application to a dam foundation case, Eng. Geol

104(3):254-262

Wu F, Hu X, Gong M, Liu J, Ren A (2010) Unloading deformation

ring layered excavation for the underground powerhouse of

Sinping 1 Hydropower Station, southwest China, Bull Eng Geo!

Env 6913):343-351

‘Zhang JH, Hu ZX, Yang YT, Wen JB, Deng JH (2011) Acoustic

velocity iting and monitoring feedback, Chin J Rock Mechan

Eng 30(6):1191-1197 (in Chinese)

‘Zhou IW, Yang XG, Li HT, Zhou HW, Hu W (2012) Analysis of

‘excavation damaged zone of auxiliary tunnel based on field Wave

syringe

2) Hi. Lietal

|

| velocity test at the Jinping Hydropower Station. In: Proceeding symposium and 9h Asian regional conference of IABG,

| of the 2nd ISRM intemational young scholars’ symposium on ‘September 2013. Beijing, pp 337-343

rock mechanics, October 2012. Beijing, pp 65-71 Zhu W, Yang W, Li X, Xiang L, Yu D (2014) Study on splitting

Zhow IW, Yang XG, Hu W, Duan RJ, Hu XW (2013) Deformation failure in rock masses by simulation test, site monitoring and

{ and failure characteristics of large underground cavems energy model. Tunn Undergr Space Technol 41:152-164

influenced by the favlts. In: Proceeding of the international

© Springer

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Numerical Modelling of Shallow TunnelsDocument16 pagesNumerical Modelling of Shallow Tunnelsrenos73No ratings yet

- Structures Data SheetDocument1 pageStructures Data Sheetkrimchand1825No ratings yet

- Jacksonville, FL - Case ReportDocument14 pagesJacksonville, FL - Case Reportrenos73No ratings yet

- Hoefer Millen Development Geol Model FullPaper R2Document7 pagesHoefer Millen Development Geol Model FullPaper R2renos73No ratings yet

- Plastic Frame Analysis JC PDFDocument17 pagesPlastic Frame Analysis JC PDFrenos73No ratings yet

- Linea de CedenciaDocument175 pagesLinea de CedenciaKatherine Prado100% (1)

- RQD Time To Rest in Peace - BieniawskiDocument18 pagesRQD Time To Rest in Peace - Bieniawskirenos73No ratings yet

- HDC Tunnel Geological ModelDocument22 pagesHDC Tunnel Geological Modelrenos73No ratings yet

- Comparison of Tunnel Blast Design Models PDFDocument9 pagesComparison of Tunnel Blast Design Models PDFandresNo ratings yet

- Bordehore - Q-Slope - JordaDocument11 pagesBordehore - Q-Slope - Jordarenos73No ratings yet

- TBMs take center stage in underground hydro projectsDocument1 pageTBMs take center stage in underground hydro projectsrenos73No ratings yet

- Destructive Probe Drilling Application To Nahakkai TunnelDocument7 pagesDestructive Probe Drilling Application To Nahakkai Tunnelrenos73No ratings yet

- 77 Palmstrom On Block Size and RQDDocument20 pages77 Palmstrom On Block Size and RQDcondorblancoNo ratings yet

- Project Management: Strategic IssuesDocument14 pagesProject Management: Strategic Issuesrenos73No ratings yet

- 77 Palmstrom On Block Size and RQDDocument20 pages77 Palmstrom On Block Size and RQDcondorblancoNo ratings yet

- Theory Behind High Pressure Grouting - BartonDocument6 pagesTheory Behind High Pressure Grouting - Bartonrenos73No ratings yet

- Horizontal Directional Drilling - AGS HKDocument4 pagesHorizontal Directional Drilling - AGS HKrenos73No ratings yet

- Numerical Limit Analysis Solutions For The Bearing Capacity Factor N GammaDocument24 pagesNumerical Limit Analysis Solutions For The Bearing Capacity Factor N Gammarenos73No ratings yet

- HK Poly '10 NB4, Pre-Grouting - BartonDocument79 pagesHK Poly '10 NB4, Pre-Grouting - Bartonrenos73No ratings yet

- AGS Technical Seminar On HDC - CuninghamDocument22 pagesAGS Technical Seminar On HDC - Cuninghamrenos73No ratings yet

- 77 Palmstrom On Block Size and RQDDocument20 pages77 Palmstrom On Block Size and RQDcondorblancoNo ratings yet