Professional Documents

Culture Documents

SR en 13480 2 2003 PDF

SR en 13480 2 2003 PDF

Uploaded by

Anonymous 1hOgJqwZuz100%(1)100% found this document useful (1 vote)

141 views60 pagesOriginal Title

200100232-SR-EN-13480-2-2003 (2).pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

141 views60 pagesSR en 13480 2 2003 PDF

SR en 13480 2 2003 PDF

Uploaded by

Anonymous 1hOgJqwZuzCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 60

ICS 23,040.01

201g WOULSa

SR EN 13480-2

Aprilie 2003,

STANDARD ROMAN Indice de clasificare B14

:

i

CONDUCTE INDUSTRIALE METALICE

Partea 2: Materiale

Metallic industrial piping - Part 2: Materials

Tuyauteries industrielles métalliques - Partie 2: Matériaux

APROBARE ‘Aprobat Directorul General al ASRO la 16 aprilie 2003,

Standardul european EN 13480-2:2002 a fost adoptat prin

metoda confirmarii si are statutul unui standard roman

CORESPONDENTA | Acest standard este identic cu standardul european

EN 13480-2:2002

This standard is identical with the European Standard

EN 13480-2:2002

La présente norme est identique @ la Norme européenne

EN 13480-2:2002

DESCRIPTOR! TIT | Sistem de transport prin conducte, conducte de uz industrial,

material, otel, conditie, conditie tehnica

"ASOCIATIA DE STANDARDIZARE DIN ROMANIA (ASRO),

‘Actosa postal st. Mendlooy 21-25, 7018, Bucrest 1

Direoba Goneral: Te 40 1211.02.06 Fax 401 21008.33

roca Standardizare: Tel, r40 1 310.43.08; +40 1 310.43.09, Fax: M40 1.316 58 70

ASRO —_Reprecucera cau utizareaintogralé sau paral prazentui standard in rice publicati $pin orice procadeu

(electrons, mecari,ttoceper, mirrimare ot este nerisédacd nu ext acordul cis a ASO

Ref.: SREN 13480-2:2003 Edita 4

Preambul national

3

?

:

‘Acest standardul stabileste conditile materialelor pentru sistemele de transport prin conducte metalice

industriale inclusiv a suportior de sustinere ale acestora. Aceste materiale se limiteazé la ofeluri cu

ductitate acceptabils

Acest standard stabileste cerinfe pentru selectarea, inspectia, incercarea si marcarea materialelor metalice

pentru execulia conductelor industrale.

zebeb 09 ‘Lo0zre0st

Corespondenta dintre standardele internationale si europene fa care se face referire si standardele romane

este urmatoarea:

EN 288.3, MOD SR EN 288-3+A1:1999

Spocificafia si caliicarea procedurilor de sudare pentru materiale

metalice. Partea 3: Verificarea procedurii de sudare cu arc electric @

‘ofeluriior

(Corespunde EN 288-3:1992+A1:1997)

EN 764.3,

EN 10288-1 IDT SREN 10028-11996

Produse plate de ofeluri pentru recipiente sub presiune, Partea 1: Condit

generale

(Corespunde EN 10028-1:1992)

EN 10288-2 IDT SR EN 10028-21996

Produse plate de ofeluri pentru recipiente sub presiune. Partea 2: Oteluri

nealiate gi aliate cu caracterstici specificate la temperatur ridicate

(Corespunde EN 10028-2:1992)

EN 10288-3 IDT SREN 10028.3:1996

Produse plate de ofeluri pentru recipionte sub presiune, Partea 3: Ofeluri

sudabile cu granulatie fina, normalizale

(Corespunde EN 10028-3:1992)

EN 10288-4 IOT SREN 10028-4:1996

Produse plate de ofeluri pentru recipiente sub presiune. Partea 4: Ofeluri

aliate cu nichel cu caracteristci specificate la temperatura scazuts

(Corespunde EN 10028-4:1994)

EN 10288-5 IDT SREN 10028-5:2001

Produse plate de otel pentru recipiente sub presiune. Partea 5: Oteluri

‘sudabile cu granulatie find laminate termomecanic

(Corespunde EN 10028-5:1996)

EN 10288-6 IDT SREN 10028-6:2001

Produse plate de ofel pentru recipiente sub presiune, Partea 6: Ojeluri

‘sudabile cu granulatie fing, cite si revenite

(Corespunde EN 10028-6:1996)

EN 1028.7 IOT SREN 10028-7:2001

Produse plate de ojel pentru recipiente sub presiune. Partea 7: Ofeluri

inoxidabile

(Corespunde EN 10028-7:2000)

EN 1045-1 IOT SREN 10045-11993

Materiale metalice. Incercarea de Incovolere prin soc pe epruveta

Charpy. Partea 1: Metoda de incercare

(Corespunde EN 10045-1:1990)

EN 10164

EN 10204

EN 10213-1

EN 10213.2

EN 10213-3

EN 10213-4

EN 10216

EN 102162

EN 102163

EN 10216

EN 102165

EN 10217

EN 102172

EN 102178

EN 102174

EN 10217-5

EN 102176

EN 10217-7

EN 102224

EN 1022.2.

EN 1022-3,

ior

MoD

ior

iT

iT

ior

iT

SR EN 10164:1995

Ofeluri de construct’ cu caracteristici de _deformare imbunatatite pe

directie perpendiculard pe suprafata produsului. Condit tehnice de ivrare:

(Corespunde EN 10164:1993)

SR EN 10204+A1:2000

Produse metalice. Tipuri de documente de inspectie

(Corespunde EN 10204:1991+A1:1995)

SR EN 10213-1:1996

Condit tehnice de livrare pentru piese tumate din ojel utlizate ta

presiune. Partea 1: Generalitat

(Corespunde EN 10213-1:1995)

SR EN 10213-2:1996

Condit tehnice de livrare pentru piese tumate din ojel utiizate la

presiune. Partea 2: Marci de ojel utiizate la temperatura ambianta si fa

temperaturi ridicate

(Corespunde EN 10213-2:1995)

SR EN 10213-3:1996

Condit tehnice de tivrare pentru piese tumate din ojel utlizate a

presiune. Partea 3: Marci de ofelutiizate la temperaturi scazute

(Corespunde EN 10213-3:1995)

SR EN 10213-4:1996

Condit tehnice de livrare pentru piese tumate din olel utlizate la

presiune. Partea 4: Marci de oleluri austenitice 51 austenito-feritice

(Corespunde EN 10213-4:1995)

SR EN 10222-1:2001

Piese forjate din ofel pentru recipiente sub presiune. Partea 1: Prescrpti

‘generale pentru piesele obtinute prin forjare liber

(Corespunde EN 10222-1:1998)

3

?

:

zebeb 09 ‘Lo0zre0st

EN 10222-4

EN 102225

prEN 10253-2

EN 10269

EN 10272

EN 10273,

EN 10274

prEN 13479-1

EN 13480-1

EN 13480-3:2002

EN 13480-4:2002

EN 13480-5:2002

EN ISO 2566-1

EN ISO 2566-1"

RISO 15608

WoT

WoT

wor

ior

SR EN 12480-1:2003

‘Conducte metalice industriale, Partea 1: Generalitati

(Corespunde EN 13480-1:2002)

SR EN 19480-3:2003

Conducte metalice industriale, Partea 3: Proiectare gi calcul

SR EN 13480-4:2003

Conducte metalice industriale, Partea 4: Executie gi instalare

SR EN 13490-5:2003

Conduecte metalice industriale, Partea 5: Inspect $i ineercare

Pentru aplicarea acestul standard se utllzeaza standardele europene respectiv internationale la care se face

referinta (respectv standardele romane identice cu acestea).

Simbolurile gradelor de echivalenta (IDT - identic, MOD - modificat, NEQ - neechivalent),

conform SR 1000-8.

Standardele europene Ia care se face referire gi care nu au fost adoptate ca standarde romane pot f

consultate sau comandate la Asociatia de Standardizare din Romania,

Standardul european EN 13480-2:2002, in limbile englez’, franceza sau germana, poate fi consultat sau

comandat la Asociatia de Standardizare in Roréria,

211d WOMLSd

zebeb 09 ‘Lo0zre0st

(Pagina alba)

Zeb aD ‘Yoozea/st HSIN’ WOULSa

scuyhentb viemie) 2002 2006 A2pO A Elune Sten casa sanen

Standardul european EN 13480-2:2002 a fost acceptat ca standard roman de cétre comitetul

tehnic CT 169, Utila petrolier.

Membrii Comitetului De Lectura care au verificat aceasté fila de confirmare a standardului

‘european EN 13480-2:2002.

dl, Viorel CRISTOCEA Institutul Nalional de

Cercetare - Dezvoltare

pentru Utila) Petrolier —

IPCUP SA — Ploiesti

dl. Florin PANCESCU Institutul_ Nalional de

Cercetare - Dezvoltare

pentru Utila) Petrolier —

IPCUP SA — Ploiesti

dl. Valentin BARDEANU -

Presedinte al _comitetului

tehnic CT 169 - Utilaj

petrolier

Secretar al_comitetului

tehnic CT 169 - Utila)

petrolier

Expert ASRO

Un standard roman nu contine neaparat totaltatea prevederiior necesare pentru contractare. Utilizator

standardului sunt réspunzator de aplicarea corecté a acestuia

Este important ca utlizatori standardelor romne s& se asigure cA sunt in posesia ultimei edit gi a tuturor

modificdrilor

Informatile referitoare la standardele romane sunt publicate in Catalogu! Standardelor Romane gi tn

Buletinul Standardizavi.

Modificari dupa publicare:

‘Amendamentul

Buletinul Standardizarii

Nefan

Punctele modificate

i

i

EUROPEAN STANDARD EN 13480-2

NORME EUROPEENNE

EUROPAISCHE NORM May 2002

211d WOMLSd

(08 23.040.01

:

i

English version

Metallic industrial piping - Part 2: Materials

Tauris insotoes tains Pane 2: Marae etalon Indust Rootungen- Ta 2: Weste

‘This European Standard was approved by GEN on 29 May 2002.

‘CEN member are bound to comply with the GEN.CENELEC intemal Regulations which stipulate the conditions for gving this European

Standard he status of @natona standard without any alteration. Upo-dale els and bbllograplica releences concerning Such nail

‘fandards may be oblainad on appcaios to the Management Cane oro any CEN mamber.

This European Standard exists in thee oficial versions (Engish, French, German). version in any ther anguage made by tatation

undar te responsiby ofa CEN memier itis own language and notied to tho Management Conta has the same slats as the ficial

‘CEN members are he national standards bois of Aust, Belgium, Czech Repub, Denmark, Finland, France, Germany, Geoace,

leeland, land, aly, Luxembourg, Mata, Notas, Noway, Portugal, Spain, Sweden, Switzerland and Led Kingor

Tama

EUROPEAN COMMICTHE FOR STANDARDIZATION

COMITE EUROPEEN DE NORMALISATION

EUROPAISCHES KOMITEE FOR NORMUNG

Management Contre: rue de Stagsart, 966-1050 Brussole

(©2002 CEN Al ight of expltatin in any form and by any means reserved Fel. No. EN 19480-22002 €

‘wos for GEN national Memo.

EN 13480-2:2002 (E)

Issue 1 (2002-05)

Contents

Foreword

1 Scope

Normative references...

Terms, definitions, symbols and units

Requirements for materials to be used for pressure containing parts in industrial piping

Requirements for materials to be used for non-pressure parts

‘Annex A (normative) Metallic materials for industrial piping systems ~ grouping system and European

standardized steels,

Annex B (normative) Requirements for prevention of brittle fracture.

Annex C (normative) Pro

purposes...

jonal technical delivery conditions for clad products for pressure

Annex ZA (formate) Clauses of this European Standard adcessing essential safety requirements oF

‘other provisions of EU directives

i

i

Issue 1 (2002-05)

Foreword

‘This document (EN 13480-2:2002) has been prepared by Technical Committee CEN/TC 26;

pipelines’, the secretariat of which is held by AFNOR,

‘Industrial piping and

‘This European Standard shall be given the status of a national standard, either by publication of an identical text or

by endorsement, at the latest by November 2002, and conflicting national standards shall be withdrawn at the latest

by November 2002.

‘This document has been prepared under a mandate given to CEN by the European Commission and the European

Free Trade Association, and supports essential requirements of EU Directives).

For relationship with EU Directive(s}, se informative annex ZA, which is an integral part of this document

In this standard the Annexes A, B and C are normative

This European Standard EN 13480 for metallic industrial piping consists of seven interdependent and not dissociabie

Paris which are:

— Part 1: Genera

~ Part 2: Materials

— Part a: Design.

— Part 4: Fabrication and instalation.

— Part : Inspection and testing

— Prat 6: Aditional requirements for buried piping.

CEN/TR 19480-7, Guidance on the use of canformity assessment procedures.

According to the CEN/CENELEC Inlemal Regulations, the national standards organizations of the following

Countries are bound io implement this European Standard: Austria, Belgium, Czech Republic, Denmark, Finland,

France, Germany, Greece, Iceland, Ireland, llaly, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain,

‘Sweden, Switzerland and the United Kingdom

3

?

:

zebeb 09 ‘Lo0zre0st

EN 13480-2:2002 (E)

Issue 1 (2002-05)

1 Scope

This Par of this European Standard specifi the requirements for materials (including metalic clad materials) for

industrial pping and supoors covered by EN 13480-1 manufactured from of metalic materials. tis curently imited to

stools with suificient ductity. This Part ofthis European Standard is not applicable to materials in the creep range.

NOTE Other materials will be added later by amendments

It specifies the requirements for the selection, inspection, testing and marking of metallic materials forthe fabrication

of Industal piping.

2 Normative references

This European Standard incorporates by dated or undated reference provisions from other publications. Those

normative references are cited at the appropriate places in the text and the publications are listed hereafter. For dated

references, subsoquent amendments to of revisions of any of these publications apply to this European Standard only

when incorporated in it by amendment or revision. For undated references the latest edition of the publication referred

10 applies (including amendments)

EN 288-8, Specification and approval of welding procedures for metallic material ~ Part 3: Welding procedure tests

for the arc welding of steels.

EN 764-3, Pressure equipment - Terminology Part 3: Defintion of parties involved.

EN 10028-1, Flat products made of steels for pressure purposes ~ Part 1: General requirements,

EN 10028-2, Flat products made of steels for pressure purposes ~ Part 2: Non-alloy and alloy steels with specitiod

elevated temperature properties.

EN 10028:3, Flat products made of steels for pressure purposes ~ Part 3: Weldable fine grain steels, normalized.

EN 10028-4 , Flat products made of steels for pressure purposes ~ Part 4: Nickel alloyed steels with specified low

temperature properies.

EN 10028-5, Flat products made of steels for pressure purposes ~ Part S: Weldable fine grain steels,

thermomechanically rolled.

EN 10028-6, Flat products made of steels for pressure purposes ~ Part 6: Weldable fine grain steels, quenched

and tempered.

EN 1028-7, Flat products made of steels for pressure purposes — Part 7: Stainless steols.

3

?

:

zebeb 09 ‘Lo0zre0st

Issue 1 (2002-05) 3

>

Z

EN 1045-1, Metallic materials ~ Charpy impact test ~ Part 1: Test method.

3

EN 10164, Ste! produets with improved delermation properties perpendicular to the surtace of the product -

Technical delivery conditions. z

EN 10204, Metallic materials ~ Types of inspection documents. =

EN 10213-1, Technical delivery conditions for steel castings lor pressure purposes ~ Part 1: General. 8

EN 10213-2, Technical delivery conditions for steel castings for pressure purposes ~ Part 2: Stool grades for use at

‘oom temperature and elevated temperatures.

EN 10213-3, Technical delivery conditions for steel castings for pressure purposes ~ Part 9: Steel grades for use at

low temperatures.

EN 10213-4, Technical delivery condltions for stee! castings for pressure purposes ~ Part 4: Austenitic and

austenitcfertc steel grades.

EN 10216-1, Seamless stee! tubes for pressure purposes ~ Technical delivery conditions ~ Part 1: Non-alloy steel

tubes with specified room temperature properties.

EN 10216-2, Seamless steo! tubes for pressure purposes ~ Technical delivery conditions ~ Part 2: Non-alloy and

allay steo! wbes with spectid elevated temperature properties.

EN 10216-8, Seamless stee! tubes for pressure purposes ~ Technical delvery condltions ~ Part 3: Alloy ne grain

steel tubes.

EN 10216-4, Seamless stee! tubes for pressure purposes ~ Technical delivery conditions ~ Part 4: Nor-alloy and

alloy steet uibes with specified low temperature properties.

prEN 102165, Seamless stee! tubes for pressure purpases ~ Technical delivery conditions Part 5: Stainless steel

tubes.

EN 10217-1, Wolded stoe! tubes for prossure purposes ~ Technical dolivery conditions ~ Part 1: Nonvalloy stool

tubes with specified room temperature properties.

EN 10217-2, Welded stee! tubes for pressure purposes - Technical delivery conditions ~ Part 2: Electric welded

rnoralloy and alloy steel tubes with specified elevated temperature properties.

EN 10217-3, Welded stoe! tubes for pressure purposes ~ Technical delivery conditions ~ Part 2: Alloy fine grain

steo! tubes.

EN 10217-4, Welded stee! tubes for pressure purposes ~ Technical delivery conditions ~ Part 4: Electric welded

nnorvalloy stael tubes with specified low temperature properties.

prEN 10217-5, Welded stee! tubes for pressure purposes ~ Technical delivery conditions ~ Part 5: Submerged arc

welded non alloy and alley steo! tubes with specified elevated temperature properties.

EN 10217-6 Welded steo! tubes for pressure purposes ~ Technical delivery conditions ~ Part 6: Submerged arc

welted non-alloy steel tubes with specified low temperature properties.

5

EN 13480-2:2002 (E)

Issue 1 (2002-05)

3

?

:

EN 10217-7, Welded steel tubes for pressure purposes ~ Technical delivery conditions ~ Part 7: Stainless steel

tubes. 3

EN 102221, Sto fagings fr pressure purposes Pat: Ganeralequiroment for epon ao egings a

wy ema St :

€ 102289, lor peso papes Patek oo wit secoow emprive poparia

a

£1097, Sines stirs presse uses

£1027 Hood noel brie pees it speci slated enprhe popar

«12074, Wet conus ~ in regions manda, iy ad dion onset

ay Met corse

18025081, S = Comat ann vais at: Cat anova sot 10 28811869

3. Terms, definitions, symbols and units

3.1 Terms and definitions:

°

Issue 1 (2002-05) 3

>

Z

ana i

tninimum metal temperature 3

lowest fmperture determined for any of he folowing conor :

— normal eperatons; 3

— star up and shut down procedures 2

— possible process upset, suchas lashings of fi, which have an atmosphere bong point below 0 °C

— uring prossre or oak tsting

NOTE seealso.12eras19

a2

temperature adjustment term

temperature clevent to ho calculation ofthe design referenoe temperature i and dependent onthe calculated

tensie membrane stress athe appropriate minimum metal tomperatur,

NOTE Vali ortperau auton tr are gn Tale 82.

NOTE2 Fortensle membrane tess eorenc is mateo EN 19480-82008 caus 1

ana

design reference temperature

temperature used for determining the inpac energy requirements ané determined by adding the temperature

dustron foe minimum meta omporatue

ona

impact test emperature

temperature at wnicn the required resistance to impact nergy achieved

NOTE Sota

aa

impact rupture energy

nergy absorbed by 2 sample of mati when subjected to a Chary-V-notch impact test in accordance wih

EN Taos

aa6

Feference thickness

Thelmess of € component to be used to relate the design releronce temperature ve ofthe component wih is

required impact tet temperature ie

NOTES See Tble 82-1 and Figures 8232-110 82825.

NOTE2 the rtrene theless ee, dela Table 8.44, i based on he nominal sks (raiding coasion

‘Mowao), Fort waaed component eps thereon wal icness le component are cage the weld pearson,

7

EN 13480-2:2002 (E)

Issue 1 (2002-05)

3.2 Symbols and ut

For the purposes of this Part of this European Standard, the symbols and units of EN 13480-1 apply tagether with

those given in Table 3.24

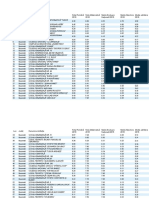

Table 3.2-1 — Symbols and units

‘Symbol Characteristic.

Zeb aD ‘Yoozea/st HSIN’ WOULSa

‘constant =

reference ihickness me

‘shear modulus Nie

Brinel hardness =

Viekers hardness =

maximum perisebie reinforcement of wald

Ww ~ impact rapture envoy

L | length (gauge length)

Pe pressure

parameter according to Larson-Mllor

yield strength

‘ere9p rupture strength Tor Tinh al temperature F

‘original cross section area

= 7

“Traforal Impact test teriperature

design reference temperature

‘temperature adjustment term

Tinear expansion cosffcient K

‘train %

‘minimt

NOTE 1 Nm? =1 MPa

ing parts in industrial

4 Requirements for materials to be used for pressure contai

piping

41 General

4.1.4 Materials to be used for pressure containing parts in industrial piping shall meet the general requirements

of 4.1 and the special provisions of 4.2 if applicable. Materials for pressure containing parts shall be ordered

‘complying with the technical delivery conditions in 4.3.

Marking of materials for pressure containing parts shall be performed in accordance with 4.4.

‘Materials shall be selected in accordance with Annex A.

8

“popne werann drvaphcatiy ctandurs Puna View e) 200.2008 #204 Pe Propet Soe ‘pone leanen

Issue 1 (2002-05) 3

>

Z

Materials shall be selected to be compatible with anticipated fabrication steps and to be suitable for the internal fluid

Shaextomal envvonment Boh nol operaing cations ang tensent condone occuring dug Taoraaton,

anspor sig commision ad daamesaning sal botakon mascot wien sgoctighemaeas.

NOTE 1 The roqamens of 41 and 42 cho le be hited when techie delury condone ave developed for =

Eopcan Sans rma Espo Approval tas of Paes Sopa 8

NOTE 2 When technical delivery conditions for pressure-containing parts are developed, the structure and requirements of 8

EN ed shal bo Swap su be ocala

‘The matoals shal! be grouped in accordance with OR 180 18008 to relate manufacturing anc inspection

recuements ogo tena ipa,

NOTES Wetorle nave teen alcated io hese gus in ascordace wih fe henicalcanpostion and proses in

4:12 _ Materials for pressure conning pats compliant with the requirements of his European Standard shall

te cod on he bask of EN T0208

NOTE Tho coiatin shuld be n accordance wih EN 7885

1.3 The products shal be tee om surface and intemal detects which might impale ther usb.

4.14 The spectied minimum elongation ofthe steal ater rate shal be

214% fo tn transverse droton: and

2 16% forthe longi! dection, or where this he ls eit cecton, the transverse detion

when measured ona gauge length, calcula as follows:

Lo= 56515, (ar

were

So's te orginal ros sectional area within the gauge lena in oder ofl formula 4-4

However, lower elongation values than speed in 4.1 2 9 fo fasteners or casings) may also be app, proved

that appropriate messes sal bo ken by the patios concerned 1 componsate for thse lower value end hat

Complance hth spect equtement ls vetiale.

— application of higher safety actos in design;

— pettornance of eppropat burt tests io drone dct mato behevout

415. When moasured on a gauge length chor than that stated in 4.1.4 tho minimum elongation ator Hactre

Shall be detonined by eonvering the eongaton gen i 44in secovdance wih

— EN 180 2566-1 for carbon and ow alo steels;

— EN 180 2566-2 for austen sees

°

EN 13480-2:2002 (E)

Issue 1 (2002-05)

4.16 — Steels shall have @ specified minimum impact energy measured on a Charpy V-notch impact test

specimen (EN 1046-1) that is

— 227 Jor ferritic and 1,5 % to 5 % Ni alloyed steels;

40 J for steels of material groups 8, 9.3 and 10,

at a test temperature in acoordanoe with Annex B, but not higher than 20 °C, The other requirements of Annex B shall

also apply.

4.1.7 The chemical composition of steels intended for welding or forming shall not exceed the values given in

Table 4.1-1. Exceptions shall be technically justified,

Table 4.1-1 — Maximum carbon, phosphorus and sulphur content for steel intended for

‘welding or forming

Material group Maximum content of cast analysis

{according to Table A.1) %C %P %S

Steel | 7

(ite 6and 9) 0.29) 0.035 0,025

Feri sainess ss 5.08 040 0018

Martensitestaitess steals 5

oy 0,040 0,015

‘Austonilic stainless steels ss

ei) 0.045 0015

‘Austenitic stainless steals 010 0085 0018

(62)

‘Austeniic-eriiie stainless steals 3

(io 0,080 0,085 0.015

> Maximum content of pout anal 025%

© For preciso machined a contol suphur cortent of 015 440 0.90 is pamited by agreement

proud he esitence fo consion said fhe tendad PupISe

4.2 Special provisions

4.2.4 Special properties

4.2.1.1 General

Where the betiaviour of a material can be affected by manufacturing processes or operating conditions, to an

extent that would adversely affect the safety or service life of the piping system, this shall be taken into

consideration when specifying the materia

10

3

?

:

zebeb 09 ‘Lo0zre0st

Issue 1 (2002-05) 3

>

Z

Adverse effects can arise from:

z

— manufacturing processes: 6.9. degree of cold forming, heat treatment; 8

= operating conditions: e.g. hydrogen embrittlement, corrosion, scaling, ageing behaviour after cold forming, 8

4.2.1.2 Lamellar tearing 8

\Where lamellar tearing due tothe joint design and loading needs to be addressed (soe EN 13460-3:2002, 7.2.3.3),

steels shall be used which have improved delormation properties perpencicular fo the surface shall be speciied and

vertied in zocordance with EN 10168.

NOTE For guidance see prEN 1011-2

4.2.2 Design temperature above 20°C

422.1 A material shall only be used for pressure parts within the range of temperatures for which the material

properties required by EN 13420-3 are defined in the technical specication for the material fhe technical delivery

Corkition does not contain the speciic material values required for the design temperature i, the values requted in

EN 1940-3 for the design shall be determined by linear interpolation between the two adjacent values. Values shall

not be rounded up.

For other than austenitic and austenitioferrio stainless steels, the specified value of Aus (Riaz) at room

temperature may be used for temperatures less than or equal to 50 °C. Interpolation for design temperatures

between 50 °C and 100°C shall be performed with the values of Ry, at room temperature and at 100 °C, and using

20 °C. as tho starting point for interpolation. Above 100°C linear interpolation shall be performed between the

tabulated valves given inthe appropriate material stands

In the case of croop rupture strength values or strength values for plastic strain in a given time, finear intorpotation

shall be permissiie only i the diflerence between the two temperatures serving as starting points forthe interpolation

is equal to or less than 10 °C.

42.2.2. Materials in the creep range shall not be used unless the creep rupture strength values or stength values for

plastic strain needed for design are speciied in the base material specication. The manufacturer ofthe piping system

installation shall be assured by the material supplier thatthe material supplied is capable of complying with spectied

properties (within the normal scatter band) by a statement that the manufacturing processes have remained

equivalent to those forthe steel for which the test sults were obtained

4.23 Prevention of brittle fracture

“The requirements given in Annex B shal aply.

4.2.4 Specific requirements for fasteners

Fasteners includes bolts, studs and nus.

Free cutting steel shall not bo used. Fastoners made of carbon steel or low alloyed forte steol with > 9,5 % nickel

shall not be used above 300 °C.

The specified minimum tensile strength of bar material of ferric and martensitic steel for bolts shall not

‘exceed 1000 Nimm*, The minimum elongation after fracture of bar material shall be at least 14%.

"

You might also like

- Calendar Concursuri Bucuresti 2017 2018 1Document21 pagesCalendar Concursuri Bucuresti 2017 2018 1Anonymous 1hOgJqwZuzNo ratings yet

- Subiect Si Barem Matematica EtapaN ClasaV 10-11 PDFDocument5 pagesSubiect Si Barem Matematica EtapaN ClasaV 10-11 PDFAnonymous 1hOgJqwZuzNo ratings yet

- Top Scoli BucurestiDocument7 pagesTop Scoli BucurestiAnonymous 1hOgJqwZuzNo ratings yet

- Formular Aplicatie CAER 2017Document4 pagesFormular Aplicatie CAER 2017Anonymous 1hOgJqwZuzNo ratings yet

- Cele Mai Populare Metode de Tortura Din Evul Mediu FOTODocument11 pagesCele Mai Populare Metode de Tortura Din Evul Mediu FOTOAnonymous 1hOgJqwZuzNo ratings yet