Professional Documents

Culture Documents

Irc 34 1970 Recommendations For Road Construction in Waterlogged Areas

Uploaded by

Sarada Dalai0 ratings0% found this document useful (0 votes)

115 views8 pagesRoad Construction in Waterlogged Areas

Original Title

Irc 34 1970 Recommendations for Road Construction in Waterlogged Areas

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRoad Construction in Waterlogged Areas

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

115 views8 pagesIrc 34 1970 Recommendations For Road Construction in Waterlogged Areas

Uploaded by

Sarada DalaiRoad Construction in Waterlogged Areas

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

RECOMMENDATIONS

FOR

ROAD CONSTRUCTION

IRC 134-1970

IN

WATERLOGGED AREAS

THE INDIAN ROADS CONGRESS

1996

IRC : 34.1970

RECOMMENDATIONS

FOR

ROAD CONSTRUCTION

IN

WATERLOGGED AREAS

Published by

‘THE INDIAN ROADS CONGERSS

‘Jamnagar House, Shabjaban Road,

0011

Price Rs. 24.00

(Plus Packing & Postage)

IRC : 34.1970

First Published : January, 1970

Reprinted May, 1974

Reprinted: May, 1980

Reprinted —: August, 1996

[Rights of Publication and of Translation are reserved)

Printed at Sagar Printers and Publishers, New Delhi-110003,

(1000 copies)

IRC: 34.1970

RECOMMENDATIONS FOR ROAD CONSTRUCTION

IN WATERLOGGED AREAS

1. INTRODUCTION

‘A Panel Discussion* on the subject of construction of roads in

waterlogged areas was held during the Hyderabad session of the

Indian Roads Congress in January 1959. As a result of this discussion,

the Soil Research Commitee (personnel given below) took: upon

‘sell the task of framing recommendations for road construction in

these areas

B.D Mathur Convenor

Dr. HLL. Uppal Member-Secretary

MEMBERS

N. Amanullah 3.8. Marya

K. Basanna Prof. S.R. Mehra

Lt, Col. Harish Chandra HLV. Mirchandani

S.N. Gupta, A Muthukumaraswamy

Dr. RK. Katti ‘ALR. Satyanarayana Rao

Kewal Krishan SAN. Sinha

Mababir Prasad JM. Trehan.

H.C. Malhotra Dr. LS. Uppat

MAR. Malya

Ditsctor General (Road Development) &

‘adi. S20y 0 the Government of Inde

(Ex-Officio)

The recomendations drafted by the Committee were subsequ-

ently reviewed by the Specifications and Standards Committee (per

sonnel given on inside front cover) and after approval of the Council

at theit 72nd meeting held on the 4th October, 1969 are now sugges-

ted for general adoption in the country.

2. SCOPE,

‘The recommendations deal with the problem of road construc-

tion in waterlogged areas, including those subject in addition to

flooding and/or infested with detrimental salts like the sulphates and

carbonates. The recommendations relate both to the construction of

new roads and to the remedial measures to be adopted in the case

of existing construction:

“The background note for the Panel Discussion i published in the Jouraal

ofthe Indian Roads Congress, Volume XXIll-part 2 and discussion inthe

Volume XXtiipart 4

IRC: 341970

For the purpose of these recommendations, waterlogged arcas

are considered to be those where the level of ‘subsoil or standing

water is such that for prolonged periods the subgrade immediately

below the pavement, is well within the capillary fringe of the water-

table, ie., within aBout 1.5 metres.

3, THE PROBLEM

3.1, Due to Waterlogging

As a result of migration of water by cayillarity from the high

water-table, the soil immediately below the pavement gets more and

more wet and this leads to a gradual loss in its bearing value,

3.2, Due to Flooding

Where flooding for continuously long periods also takes place

side by side with waterlogging, the progressive deformation of the

subgrade, as well as of the pavement, is accentuated by ingress of

water from the top of the wearing surface comprising usually of a

thin bituminous treatment. The already inadequate waterproofness

of the surface is impaired further by stripping of the binder due to

prolonged contact with water. Infiltration of flood waters through

the shoulders is another factor aggravating the situation.

3.3. Due to Presence of Detrimental Salts

The problem is made still more complicated if in addition to

waterlogging, and/or flooding, injurious sats like sulphates of sodium,

calcium or magnesium and sodium carbonate are present either in

the subgrade s ‘the ground water. Damage to crust from

injurious salts can be in two ways—due to physical effect or

chemical.

3.3.1, Physical effect of the injurious salts: In waterlogged

areas infested with detrimental salts, the salts keep on moving up

with capillary moisture. During subsequent evaporation of the

salt-laden water the salts are left behind and they get concentrated

in the surface layers. The salts increase many times in volume upon

hydration under suitable humidity and. temperature conditions*.

Alternate hydration and dehydration results in repeated formation

of salt crystals occupying much more volume than the amorphous

salts lodged in the voids. In due course these repeated volume

changes break up the structure of the pavement, working from the

top downwards.

As a result of research carried out in India, i has been demonstrated

that crystallisation of sodium sulphate takes place ‘when temperatures below

S2C and relative humidity’ above 80 per cent. In. northen parts. of the

‘ouacry these conditions exist generally during the period of winter rains,

2

IRC: 34.1910

3.3.2. Chemical effect of the injurious salts: The damage due

to chemical action is mainly on account af sulphates of calcium,

‘magnesium and sodium. Constructions specially vulnerable to this

type of attack are those containing cement like the cement concrete

pavements and soil-cement base/sub-base course,

Cement concrete

The sulphates present in the subsoil which migrate to the top

by capillarity react with the free lime liberated from cement resull-

ing in the formation of gypsum. This reaction is accompanied by a

considerable increase in the volume of the solids which is known to

lead to the destruction of the hydrated cement matrix. After gyp-

sum hasbeen formed, ot if calcium sulphate itself is found in the

soil or ground water, tricalcium aluminate in the hydrated cement

‘combines with gypsum to form needle-shaped crystals of double salts

Hike calcium sulpho-aluminate_ which give rse to further expansion

of volume and damage. Apart from the formation of gypsum and

calcium sulpho-aluminate, the decomposition of hydrated calcium

silicate by sulphate solution is an additional factor affecting the

durability of concrete. However, this would occur normally only in

the case of magnesium sulphate solution which is found generally in

waterlogged areas near the sea.

Dissolved carbon’ dioxide and bicarbonate salts. present ia

certain marshy and rice growing areas also take part in the leaching

of lime liberated from cement and slowly attacking the cementitious

calcium silicate hydrates formed. Such solutions are characterised

by pH value in the acidic range, usually below 5.

Concrete is not directly attacked by solid sulphate salts, but

only by their solutions in water, so that it is the amount of salts

dissolved in the ground water that determines the rate of attack. As

a result of chemical action of sulphates, the cement concrete pave-

ments suffer internal disintegration and gradual. spalling from the

underside. The process described is, however, slow.

Soil cement

Presence of sulphates in waterlogged areas has a detrimentsl

effect on soil cement mixtures akin to that in the case of cement

concrete pavements.

Bituminous constructions

It does not appear that these salts, in the concentration they

normally occur in Soil, ground water or sea-water, have any detri

‘mental chemical effect on bituminous constructions.

3

IRC: 34-1970

Water-bound macadam

Salts do not directly affect unsurfaced water-bound macadam

constructions provided the filler material used in them is inert and

free of injurious constituents.

4. RECOMMENDATIONS ON METHODS OF ROAD

CONSTRUCTION IN WATERLOGGED AREAS

4.1. The recommendations are ‘divided into the following

three groups:

(a). Road construction in areas where the problem is one of

waterlogging alone and is not tied up with flooding or salt

infestation.

(b) Road construction’ in areas where in addition to water-

lagging flooding for prolonged periods is also expected.

(©) Road construction in areas where in addition, to. water-

Jogging injurious salts are present in the suboil or ground

water.

4.2. Different treatments are suggested under each group,

Some of these can be made use of only on new constructions, and

others on old, while some hold good for both. Broad guidance about

these is provided at the beginning of each section.

RECOMMENDATIONS FOR ROAD CONSTRUCTION

IN-AREAS WHERE THE PROBLEM IS ONE OF

WATERLOGGING ALONE ANDIS NOT TIED

UP WITH FLOODING OR SALT INFESTATION

‘The remedial measures recommended under paras 5.1, 5.2 and

54 could be utilised both on new constructions and existing roads,

However, the capillary cutoff technique described under para 5.3 will

be found economical only on new roads.

5.1. Depressing the Level of Subsoil Water by Drainage

Measures

Satisfactory results could be achieved by providing 5 to 6 ft deep

drainage channels as close to the road bank as possible and connect-

{ng these by suitable outfalls to either channels of irigation system

cor natural drainage. Alternatively, buried drains of suitable design

Such as French. drains. could be provided at the edges of the pave-

‘ent forthe lowering of water-table. Either of these measures will help

4

IRC: 34.1970

in keeping the top of the subgrade above the capillary fringe.

The method of drainage is applicable to all types of road

construction (whether rigid or flexible), and should b: preferred

wherever economically feasible,

5.2. Raising of the Embankment

Where it is too expensive to provide deep drainage channels as

specified in para 5.1, it is recommended that subject to a careful

examination of the economics of the case, an embankment, of such

height may be provided that the bottom of the pavement remains at

east 1.5 metres above the highest water-table.

5.3. Capillary Cutoff

‘As_an_ alternative to the recommendations contained in paras

5.1 and 5.2, a capillary cutoff could be provided to arrest the capil-

lary rise of water. Provision of capillary cutoffs could, however,

fe. and may be justified only in special circum:

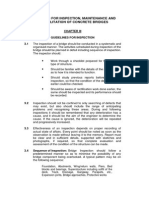

The cutoff should be placed at least 15 em above the ground

level or the standing water level, whichever be higher, as illustrated

in figure on page 6, But in no case should it be positioned higher

than 60cm below the top of the subgrade. Wnen provided, the

cutoff medium should extend under the berms as well.

Suitable types of capillary cutoffs are listed under Section 8.

When the cutoff medium selected is of the type bituminous primer,

tar felt or polythene envelope, it will be advisable to cover it with a

10 to 15 em thick layer of granular material like sand for the dual

purpose of acting as a drainage course for water infiltrating from the

top and of protecting the envelope during construction against rup-

ture by sharp particles in the fill material.

5.4, Providing Sufficient Thickness of the Pavement to be

Adequate for Saturated Subgrade Conditions

In case neither drains nor sufficiently high embankment nor

capillary cutoff can be provided on an existing road, the thickness of

the pavement should be determined on the basis of strength of the

subgrade soil at saturation and strengthening carried out accordingly.

This measure can be- adopted in the case of new constructions

fas well, In that event, at least 10 cm thickness of sub-base should

be made up of such material as stabilised soil, which will be stable

when wet, 30 that it is not possible for the soft subgrade soil in satu

rated condition to work up into the voids.

3

IRC: 34-1970

[THE WiGHEST POSITION OF

[THE CAPLLARY CUTOFF

‘ZONE OF CAPILLARY

‘SATURATION

15 em THICK SAND/ORANULAR

MATERIAL CUSHION WHEN THE

CAPILLARY CUTOFF 13 8

JSITUMINOUS PRIMER, TAR

FELT OR POLYTHENE SHEET

THe mignest rosiTioN of]

THE CAPILLARY CUTOFF

SussRAve

ZONE OF CAPILLARY

SATURATION

(b)

1 LUSTRATING DESIRED POSITION

Of THE CAPILLARY CUTOFF FOR PREVENTING.

‘THE RISE OF CAPILLARY MOISTURE.

ARC : 34-1970

6, RECOMMENDATIONS FOR ROAD CONSTRUCTION IN, AREAS

WHERE IN ADDITION TO WATERLOGGING FLOODING FOR

PROLONGED PERIODS IS ALSO EXPECTED

In the case of roads subject to flooding in addition to water

logging, the following measures may have to be taken over and

ahove those recommended in Section 5 against waterlogging. |The

three treatments suggested could be applied equally on new construc

tions as well as old.

6.1. Raising of the Embankment

In areas subject to frequent floods where the highest flood level

js not too much above the natural ground level, it is recommended

that the embankment should be raised so that the top of the sub-

grade is at least 30 em above the highest recorded flood level.

6.2. Provision of Cement) Asphaltic Conerete Surfacing

Where for any reason whatsoever it is considered inevitable to

let flood ‘waters pass over the road, and also traffic is heavy and

flooding expected for prolonged periods, cement/asphaltic concrete

surfacing of appropriate thickness should be provided for at least

two lanes of traffic. The cement concrete pavement, when provided,

should have a cementjlime soil base 15 em thick underneath the slab

and permanent stakes on the carriageway edges for demarcating the

travelled way. When asphaltic concrete is selected as the surfacing,

the mix should be dense graded and resistant to flood conditions.

Where formation level of the road is well above the surround

ing ground level, side drop walls and guide uprights must, also_ be

provided. In addition, the banks should be protected against

erosion.

6.3. Provision of a Thin Bituminous Surfacing with Seal Coat

Where traffic is very light and the provision of a cement/asphal-

tic conerete surface is considered unjustified on economic grounds, a

tolerable solution will be to provide a thin bituminous surfacing with

Seal coat over at least two lane width, using suitable anti-stripping

agents and. supplemented by guide uprights and side drop walls as

necessary.

J. RECOMMENDATIONS FOR ROAD CONSTRUCTION IN AREAS

BESQMMN’RODITION TO, WATERLOGGING DETRIMENTAL

SHES \RE PRESENT. IN THE SUBSOIL OR GROUND WATER

The following recommendations apply generally to construc-

tion of new roads. On existing roads, measures outlined in paras 5.1

5.2 and 5.4 may be adopted for relief.

1

IRC: 34.1970

7.1. No special measures are considered necessary from the

standpoint of physical/chemical action of injurious salts exeept those

stated in Sections 5 and 6 if the concentration of sulphates in the

subgrade soil is below 0.2 per cent (as sulphut trioxide) while. also

below 0.03 per cent (as sulphur trioxide) in ground water. Similarly,

sodium ‘carbonate concentrations of upto 0.2 per cent in subgrade

soil and 0.02 per cent in the ground water are considered Unharsnful,

Salt concentrations may be determined in accordance with the pro

cedure laid dowa in relevant I.S.I. Standards—IS : 2720, part XXII

G1966 “Methods of Test for’ Soils : Determination of Calcium

Carbonate”, and. IS : 2720, part XXVII—"Methods of Test for

Soils : Determination of Total Sulphate”.

No damage is expected from dissolved carbon dioxide or bicar-

bonate salt solutions (met with in certain marshy areas) provided

‘the pH value of the solutions is higher than 5.

Where the concentration of these salts is in excess of the safe

limits specified above, special measures as indicated below are

Fecommended as a guide for road construction. ‘These measures are

in addition to those recommended in Section 5.

7.2. Flexible Pavements

7.2.1. Water-bound macadam roads with or without bituminous

surfacing: Even if concentration of salts in the subgrade or ground

water is higher than the safe limits prescribed in para 7.1, no special

measures other than those set forth in Section 5 are considered

necessary for water-bound macadam roads with or without bituminous

surfacing except that the filler used in water-bound macadam and

soling should be inert and free from injurious salts.

7.2.2. Stabilised Soit Constructions:

(a) Mechanical stabilisation

(b) Cement and lime stal

(©) Bituminous stabilisation

If the above constructions are contemplated in waterlogged

areas infested with salts, the soil used for stabilisation should not

contain more than 0.2 ‘per cent of total soluble sulphates and

carbonates.

Besides this, to prevent the injurious salts in the'subgrade or

aground water from coming into contact with stabilised soil ourses, «

Suitable capillary cutoff out of those described in Section 8 should be

provided underneath the pavement extending across the full ‘width

Of the roadway, treating it as an essential measure.

ation

8

IRC: 34-1970

7.3. Rigid Pavements

When sulphates are in excess of the safe limits prescribed in.

para 7, the following additional measures are recomtended during

the construction of cement concrete. pavements over and above the

provisions of paras S.1 and 5.2,

1.3.1. ll ty of concrete, irrespective of the type of

cemesi used, are more fanerable to sal stack during the ial

petiod of hardening than when. fly Set, its of importance to pre-

ent contact between the ground water and concrete io the early

Sages. For this purpose, applying 1 ligt cost of bitumen to the

underside of precast units, protecting cast-in-sta concrete by a thin

bituminised” coating on the base just below the slab, or provision oF

one of the capillary cutoffs mentioned in Section 8, are some of the

measures. recommended for: adoption under retalively mild condi

tions of exposures to sulphate attack, viz, when sulphate concentta-

tion in soil upto about 0.5 pet cent,

Under more severe conditions, i.e. when sulphates are in excess

of 0.5 per cent, the bituminous coatings used should be thicker* as,

they are known to possess higher durability.

7.3.2. Furthermore, the following measures are suggested as

suitable for minimising adverse chemical effect of the sulphates on

concrete:

(H Designing a dense, well-compacted, high quality concrete

which will have’ low permeability aginst ingress of

sulphate solution. (This is recommended even when SOs

in water is above 0.02 per cent).

i) Use of special sulphate resistant cement, puzzolanie

© Saoat oF sipersapated thee tureace seg comen

ependiog on availabilty and economy (when sulphats

content is more than 0.3 per cent in sllcand more than

0108 per cent in ground water).

3 Ia areas where theres danger of damage fom disolved

carbon” done or carbonate asa cigenced by pi value of

below 5, the provision of a waterproof layer below the concrete

pavemest ud ns heavy dy buninsed paper or polythene sheet,

and use of a dense, well-compacted, high quality concrete are the

masites recommended for adoption,

9

IRC: 34.1970

8, SUITABLE CAPILLARY CUTOFFS

8.1. Provision of Sand Blanket

Sand blanket of adequate thickness over the full width of

embankment is recommended as an effective capillary cutoff. The

thickness of the sand blanket needed to intercept capillarity depends

‘on the particle size of the sand and may be determined from the

following formula*:

sy

t= &

where f = thickness of sand layer in cm

a a thxde

di + dy

mean particle diameter in mm

a aperture size of sieve (mm) through which

the fraction passes

d= aperture size of sieve (mm) on which the

fraction is retained.

‘The sand shall be compacted after adding suiicient moisture to

permit easy rolling. Alternatively, it might be compacted dry if

the facility of vibratory roller was available.

8.2, Some of the Other Capillary Cutoffs**

8.2.1. Bituminous impregnation using primer treatment: 50 per

cent straight-run bitumen (80-100) with 50 per cent high speed

diesel oil or its equivalent in two applications of 10 kg per 10m?

each, allowing the first application to penetrate before applying the

second one.

8.2.2. Heavy duty tar felt: Providing an envelope with heavy

duty tar felt.

8.2.3. Polythene envelope: Providing an envelope with

polythene sheets of at least 400 gauge.

8.2.4. Bituminous stabilised soil: Providing bituminous.

stabilised soil in a thickness of at least 4 cm.

This formula

roposed initially by the Public Roads Administration

and is published in ‘High

a

way Research Board Proceedings, Vol. 2, 1901, page

s*Experience on the successful performance'of capillary cutoffs suggested

in para 82%, however, limited. ™ .

10

You might also like

- RDSO Guidelines - Bs 112 - Planning of Road Over BridgesDocument9 pagesRDSO Guidelines - Bs 112 - Planning of Road Over BridgesAnkur MundraNo ratings yet

- Tips & Tricks PDFDocument47 pagesTips & Tricks PDFSarada DalaiNo ratings yet

- GCC OF Indian Railways PDFDocument67 pagesGCC OF Indian Railways PDFSarada DalaiNo ratings yet

- InspectionDocument2 pagesInspectionSarada DalaiNo ratings yet

- Bridge InspectionDocument15 pagesBridge InspectionDevela AvinashNo ratings yet

- BS 111 - Revision 6 - Final-01.05.2019 - 2Document35 pagesBS 111 - Revision 6 - Final-01.05.2019 - 2Vishnu Vandana33% (3)

- RDSO Guidelines - Bs 112 - Planning of Road Over BridgesDocument9 pagesRDSO Guidelines - Bs 112 - Planning of Road Over BridgesAnkur MundraNo ratings yet

- Form 10 DDocument6 pagesForm 10 DilyaskureshiNo ratings yet

- New Microsoft Office PowerPoint PresentationDocument15 pagesNew Microsoft Office PowerPoint PresentationSarada DalaiNo ratings yet

- New Microsoft Office PowerPoint PresentationDocument15 pagesNew Microsoft Office PowerPoint PresentationSarada DalaiNo ratings yet

- GCC OF Indian Railways PDFDocument67 pagesGCC OF Indian Railways PDFSarada DalaiNo ratings yet

- Ballast Spec Nov 2014Document39 pagesBallast Spec Nov 2014Sarada DalaiNo ratings yet

- New Microsoft Office PowerPoint PresentationDocument15 pagesNew Microsoft Office PowerPoint PresentationSarada DalaiNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Interest Rates On Domestic DepositsDocument3 pagesInterest Rates On Domestic Depositsvijay chNo ratings yet

- NALCO Contract Manual-2013Document104 pagesNALCO Contract Manual-2013Sarada DalaiNo ratings yet

- Bs ConcreteDocument61 pagesBs ConcreteSarada DalaiNo ratings yet

- GST Migration AdvisoryDocument2 pagesGST Migration AdvisorySarada DalaiNo ratings yet

- Mix Design Procedure For Self Compacting ConcreteDocument9 pagesMix Design Procedure For Self Compacting ConcretesaxraviNo ratings yet

- 1265 12-Sep-2017 Bid Doc Pahari Zone4Document473 pages1265 12-Sep-2017 Bid Doc Pahari Zone4Sarada DalaiNo ratings yet

- Design of FalseworkDocument15 pagesDesign of FalseworkSarada DalaiNo ratings yet

- Acceptance of Com Pres I OnDocument4 pagesAcceptance of Com Pres I OnmrlobboNo ratings yet

- CGST ActDocument103 pagesCGST Actdkgupta28No ratings yet

- Literature On Self Compacted ConcreteDocument3 pagesLiterature On Self Compacted ConcreteSarada DalaiNo ratings yet

- Analysis For Strength in Different Types of Cement Available in ChhattisgarhDocument6 pagesAnalysis For Strength in Different Types of Cement Available in ChhattisgarhSarada DalaiNo ratings yet

- Self-Compacting Concrete - Procedure For Mix DesignDocument10 pagesSelf-Compacting Concrete - Procedure For Mix DesignM HAFEEZ RAJA100% (1)

- Guidesteelworkssupervision PDFDocument78 pagesGuidesteelworkssupervision PDFPhạm Văn ĐảngNo ratings yet

- Regulations - TAMA Development Authority - Planning and Building Standards Regulations - Part IDocument40 pagesRegulations - TAMA Development Authority - Planning and Building Standards Regulations - Part ISarada DalaiNo ratings yet

- Issue 3 Mar-Apr 11 SpotlightDocument16 pagesIssue 3 Mar-Apr 11 SpotlightSarada DalaiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)