Professional Documents

Culture Documents

Tor - Ond - Hse - Ms Audit - 26-2 To 09-3-2017.final

Tor - Ond - Hse - Ms Audit - 26-2 To 09-3-2017.final

Uploaded by

zam110Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tor - Ond - Hse - Ms Audit - 26-2 To 09-3-2017.final

Tor - Ond - Hse - Ms Audit - 26-2 To 09-3-2017.final

Uploaded by

zam110Copyright:

Available Formats

L1.HSE -2017-7.

3-01 Terms of Reference Level 1 HSE MSOil North Directroate

TERMS OF REFERENCE:

PDO Level 1 HSE MS Audit

Oil North Directorates HSE- MS Audit

Type of Audit Level 1 HSE MS Audit

Sponsor MSEM

Auditee Saadi Khamis OIL DIRECTOR - NORTH OND

Facility Audit

Ismaili, Said HSE Advisor ONS3

coordinator

Health, Safety and Corporate Health, Safety & Environment

Salmani, Mohamed MSEM

Environment Manager Manager

Audit Manager Hinai, Younis Head HSE Corporate Planning MSE5

Lead Auditor Moamary, Said HSE Auditor MSE531

Hassan, Ammar HSE Auditor MSE532

Rawahi Ahmed HSE Auditor MSE533

Audit Team Geafar Elvin Functional Senior CSU Engineer UOP41

Dhuhly Nasser Maintenance Coordinator OSO4B

Harthy, Salim Geomatics Manager XGG

Petrizzo, Jose Senior Industrial Hygienist MCOH1

Maskari, Mohammed HSE Advisor OSSN

Follow Up co-ordinator Ismaili, Said HSE Advisor ONS3

Peer Reviewer Hinai, Younis Head HSE Corporate Planning MSE5

Locations to be

Muscat / Interior. Locations to be finalized 2 weeks prior to audit

covered

Period of Audit 26 February - 09 March 2017

Audit Reference L1.HSE -2017 -7.3 01

Date Issued 01 Dec. 16

Objectives

The objectives of the audit are:

To appraise the completeness of the Oil North Directorate HSE MS against PDO HSE Policies, Objectives,

Standards and Procedures.

To assess the adequacy & effectiveness of the HSE Management System with respect to the Oil North

Directorate

Where weaknesses are identified, to highlight what is expected and needed to demonstrate adherence to

the PDOs HSE Policy and Standards.

Scope

The scope includes all activities, processes and facilities under the operational control of Oil North Directorate HSE

Management and interfaces including other business activities, contractors, sub-contractors & projects.

Not every aspect of each process or facility will be audited, as the audit is risk-based (see methodology

described below). Sample areas will include activities and processes of PDO and Contractor/subcontractor at their

offices and sites.

Specific focus areas have been defined for this HSE-MS audit, although these may not be exhaustive. System

failure issues identified during the audit may necessitate inclusion in an agreed and expanded scope of work:

Level 1 HSE MS Audit Page 1

L1.HSE -2017-7.3-01 Terms of Reference Level 1 HSE MSOil North Directroate

Risk Area Focus points

Common Processes Completeness and effectiveness of the inventory of hazards and controls

(HEMP Process)

Identification of HSE critical activities, roles and responsibilities including

Adequacy of Emergency response plan

Incident investigation

HSE Competency, Training & Awareness

HSE Contractor Management

Personal Safety Permit To Work

Working Safely (Life Saving Rules & Golden Rules)

Working at Height

Scaffolding

Excavation

Transport

Heavy Lifting and Hoisting

Occupational Health & MER Fitness to Work

HRA

Medical Emergency Responses

Assurance HSE Assurance processes

Environment (ISO 14001 Assurance) Environmental Permits, Aspects & Impacts

Borrow pits

Waste Management

Chemicals Managements

Standards

The audit will be carried out against the following standards:

1. Omans laws and regulations.

2. PDOs HSE Commitment and Policy.

3. PDOs HSE Management system, manuals and procedures.

Particular emphasis areas:

(PR-1980, SP-2000, SP-2001, PR-1172, PR-1708, PR-1709, PR-1969, SP-1230, SP-1231, SP-1225,SP-

1013, SP-1257)

Audit Plan

The audit takes place in the period from 26 February to 09 March 2017 and may include the weekends as working

days.

A proposed audit plan containing details on the proposed site fieldwork and interviewees will be sent and agreed

separately. The Auditee will submit the organisational chart and general site processes description to the lead

auditor to allow for the schedule to be made specific to the auditees organisation as detailed in their HSE-MS.

The facility/business unit shall finalise and agree the draft schedule 2 weeks prior to the audit. During the

execution of the audit the audit leader may request to modify the schedule to accommodate additional interviews

or sample locations.

Level 1 HSE MS Audit Page 2

L1.HSE -2017-7.3-01 Terms of Reference Level 1 HSE MSOil North Directroate

Interviews shall generally be conducted in the workplace of the interviewee (e.g. offices of management,

workshops of maintenance persons, control rooms of operations persons). Arrangements shall be requested for

detailed inspections of facilities consisting of walk-through of operating areas (to be determined) and including

storage facilities, areas for waste treatment and hazardous waste storage.

The facility shall provide the necessary personal protective equipment (PPE).

The audit plan will include adequate time set aside for the audit team at the facility for clarification and draft

report writing.

Proposed Event Proposed Timing

Audit team brief 1 26/02/2017

Opening Meeting lead auditor, presentation Auditee 1 26/02/2017

Interviews 1-9 26/02 06/03/2017

Field Work/visits 2-9 27/02 06/03/2017

Draft Audit Findings 10 07/03/2017

Independent Review 11 08/03/2017

Review agreed findings with Auditee 12 09/03/2017

Close-Out Meeting 12 09/03/2017

Draft Report Issued to Auditee 19 16/03/2017

Responses from Auditee to be returned to Audit Team 40 06/04/2017

Final Report Issued 47 13/04/2017

Methodology

The audit will be conducted in accordance with the methodology described in this ToR. Findings shall be classified

and the acceptability of Risk Area Controls assessed in accordance with the criteria shown below.

To facilitate the efficient and effective execution of the audit, it is required that the HSE hazard registers,

organisation charts, site & process descriptions and key elements of the current HSE Management System

documentation be submitted to the Audit Team. This will allow a review of the auditees arrangements and enable

set-up of the audit to ensure focus on the areas likely to represent the highest risk to the business.

The methodology will use a risk-based approach and a general auditing approach in line with good industry

practice. Team members will gather information by field observation, through interviews and including checks of

hardware and documentations. Audit evidence will be based upon sampling of the available information and

therefore should not be considered all-inclusive or exhaustive. Conscientious efforts will be made to verify

findings and to confirm the validity of recommended actions. Where judgement is required, the result will be

determined by consensus within the audit team.

Audit Findings Classification

Classification of the audit findings shall be in accordance with the Rating Level table (Table 1).

Weakness Level Definition

The finding is likely to cause a high undesirable effect on the achievement of

Serious (S) the entitys objectives and / or is likely to have a notable impact on other PDO

entities, therefore warranting immediate reporting to senior management.

The finding is likely to cause a high undesirable effect on the achievement of

High (H) one of the entitys objectives, warranting reporting to the auditees

management.

Level 1 HSE MS Audit Page 3

L1.HSE -2017-7.3-01 Terms of Reference Level 1 HSE MSOil North Directroate

The finding is likely to cause a measurable undesirable effect on the

Medium (M)

achievement of one of the entitys objectives.

The weakness is unlikely to have a measurable impact on the entitys

Low (L)

objectives, but its correction would enhance the risk based control framework.

Non-compliance to specific external legal or other regulations applicable to the

Non-Compliance (C)

entity.

Table 1 Rating Level table

All findings are to be classified based upon the professional judgment of the audit team. The primary criterion for

rating each finding is the adequacy of the control for the risk as defined in the Assets relevant Hazard register.

Overall Assessment of HSE Risk Controls and Audit Rating

No audit opinion will be provided. Assessments of the HSE Risk Controls areas will be indicated by reference to

three possible categories:

Controls Acceptable

None, or a few Low and/or Medium rated findings are reported which indicate that a once-off rather

than process or system structural weaknesses is present or that general enhancement of the controls,

process or system framework is not needed.

Controls Need Improvement

Some Medium and / or one or more High rated findings are reported which indicate a weakness in key

controls / barriers or in a part of the process or system structural framework.

Controls Need Major Improvement

Three or more High and/or one or more Serious rated findings are reported indicating failures in key

controls / barriers or across a significant part of the process or system structural framework.

A qualitative description will be provided as part of the Summary and Conclusions, to summarize the overall

outcome and highlighting the control areas where findings are identified. This is in the form of a table that depicts

a reference to each finding and the Control Acceptability assessment for each Risk Area with control acceptability

assessments for those HSSE-MS element areas only where systemic issues are identified and observed across

multiple risk management areas, as per below example.

During the audit the audit team may come across weaknesses in risk control areas, which have already been

identified by the Auditee. In some of these cases the Auditee may be able to claim work-in-progress (WIP) when

the following criteria have been met:

Relevant issues and actions are identified and documented prior to the start of the audit.

For these issues and actions an implementation plan was already in place prior to the start of the audit

with milestones set and resources allocated together with evidence of implementation having begun.

During the audit, the follow-up process was found to be satisfactory, taking into account the track record

of the business in closing out action items.

Interim mitigations to control the risk area are in place, and deemed effective by the audit team.

Where testing by the audit team proves that the above criteria can be met, reliance can be placed on the existing

process. No specific findings shall be raised for these issues in the audit report, however, due reference will be

made in the executive summary of the audit report as to the degree of reliance that was placed on the process

and highlighted in the control acceptability matrix (example CAM, table 2). Such issues will also not have major

impacts on the opinion. Where one of the above criteria has not been met, reliance cannot be placed on the

Level 1 HSE MS Audit Page 4

L1.HSE -2017-7.3-01 Terms of Reference Level 1 HSE MSOil North Directroate

process. Another finding will therefore be raised to ensure that relevant actions are taken. The audit opinion will

take such audit findings into account.

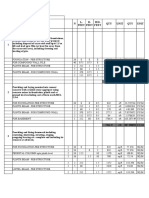

Table 2: Control Example of Acceptability Matrix (CAM)

Report

The draft Audit Report will undergo a peer review prior to the discussion with the Auditee.

The team will present the audit results to the Auditee and their management at the conclusion of the audit. This

closing meeting or presentation shall be conducted at the end of the audit or as pre-arranged between the

Auditee and the Lead Auditor. The purpose of this meeting is to formally communicate the findings and the

assessment of the acceptability of controls to the Auditee and the management team and to ensure clarity of

understanding. The findings, associated classifications, and acceptability of controls shall be considered frozen

and only editorial changes allowed may be considered. The Audit Leader may also be asked by the Auditee to

present the audit results to wider audience.

Within 7 calendar days of the audit conclusion, the Lead Auditor shall send a Draft for Review copy of the Audit

Report to the Auditee. The Auditee will work with his/her organisation to identify underlying causes of the

findings where these are required, and develop suitable means to address the findings, including assigning action

parties and planned completion date.

For Legal (C), Serious (S) and High (H) findings, the Auditee shall have 21 calendar days to perform root cause

investigation into underlying causes, and complete the Underlying Cause, Action, Action Party and Due

Date fields for each of the findings.

For Medium (M) and Low (L) findings, the Auditee shall have 21 calendar days to identify appropriate actions and

complete the Action, Action Party and Due Date fields for each of the findings.

The lead auditor will review the actions and timings proposed by the site and will request clarification if required

to ensure that actions do address the underlying action resulting from the audit findings. When substantial

agreement has been reached on the contents of the report, the report will become Final.

Where agreement on findings or appropriate actions to address findings and/or recommendations cannot be

reached, the Lead Auditor may discuss with the next level of management of the Auditees business and agree a

forward plan to resolve the issue. In cases where resolution between the auditor and Auditee / auditees line

management cannot be reached, they shall be escalated to the Audit Sponsor. If the disputed area cannot be

resolved, the Lead Auditor view will prevail although the Auditee will have the right to insert a management

comment to provide his/her point of view, (on the appropriateness of actions only).

Once the report is completed, it shall be distributed as agreed with the Auditee as shown in these Terms of

Reference. Actions will be uploaded into the PDO Incident Management System (PIM).

Level 1 HSE MS Audit Page 5

L1.HSE -2017-7.3-01 Terms of Reference Level 1 HSE MSOil North Directroate

Report-Distribution

The final report distribution will be as shown in appendix A below.

Logistics and coordination

The audit coordinator must ensure the provision of:

An opening presentation detailing the operations provides, and indicating how MSE is managed

within the function

Coordination and setting up of meetings in MAF

Flights, pickups and accommodation on site.

Travel and guides on site.

Specialized personal protective equipment (PPE). (Excludes coveralls and boots)

IT authorization for audit team to access local data files

A lockable office with sufficient space, desk/table area, and chairs for the audit team and flipcharts

Flip chart holder with paper, ink markers

Computer connection to electronic system where documents are stored (e.g., local intranet, shared

folders)

Computer projector (beamer)

Permission and permit (including gas testing as required) to take photographs on site.

HSE-MS Documentation Request

Documentation including, but not limited to the following may be requested during the audit planning and

implementation process.

Key elements of the current HSE Management System documentation

Organisation Charts

A general description of operations undertaken & an overview of the processes (See presentation above)

HSE Hazard Register

Health Risk Assessments

HSE Plans (Own & contractors)

HSE Audit Programme and Schedule. (Own & contractors)

Reports of recent HSE related audits and reviews (Own & contractors)

Follow up records for past audits (Own & contractors)

Accident and incident reports (Own & contractors)

HSE performance indicators and statistics for the last year and year to date (Own & contractors)

HSE Plans, both plans specific to the facility/business unit and plans at business level related to the

facility/business, for last year and year to date

HSE Targets and Objectives, both plans specific to the facility/business unit and plans at business level

related to the facility/business, for last year and year to date

Contractor details, services supplied and related contractor HSE documentation

Note: Relevant Contract specific documentation and records may be requested during the audit planning and

implementation process.

Level 1 HSE MS Audit Page 6

L1.HSE -2017-7.3-01 Terms of Reference Level 1 HSE MSOil North Directroate

Distribution list

Saadi Khamis OIL DIRECTOR - NORTH OND

Farsi Salah HSE Team Lead ONS

Salmani, Mohamed Corporate Health, Safety & Environment Manager MSEM

Hinai, Younis Head HSE Corporate Planning MSE5

Moamary, Said HSE Auditor MSE531

Hassan, Ammar HSE Auditor MSE532

Rawahi, Ahmed HSE Auditor MSE533

Geafar Elvin Functional Senior CSU Engineer UOP41

Dhuhly Nasser Maintenance Coordinator OSO4B

Harthy, Salim Geomatics Manager XGG

Petrizzo, Jose Senior Industrial Hygienist MCOH1

Maskari, Mohammed HSE Advisor OSSN

Level 1 HSE MS Audit Page 7

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ERP PepsicoDocument24 pagesERP PepsicoPreeti Dhillon100% (20)

- Line of FireDocument1 pageLine of Firezam110No ratings yet

- Procedure For Lifting Operations Over Live Process Are AsDocument11 pagesProcedure For Lifting Operations Over Live Process Are Aszam110No ratings yet

- Supply Chain Performance Measurement ApproachesDocument273 pagesSupply Chain Performance Measurement ApproachesErik Van0% (1)

- BS 7385Document16 pagesBS 7385ClaudioSantosNo ratings yet

- Landing Gear Mid Block Test ADocument9 pagesLanding Gear Mid Block Test AYuriShibuya1993No ratings yet

- PDO Incident First Alert: Main Contractor Name - LTI# - Date of IncidentDocument1 pagePDO Incident First Alert: Main Contractor Name - LTI# - Date of Incidentzam110No ratings yet

- Severe Weather Preparation Checklist: Key Focus AreasDocument2 pagesSevere Weather Preparation Checklist: Key Focus Areaszam110No ratings yet

- PDO Incident First Alert: Main Contractor Name - LTI# - Date of IncidentDocument1 pagePDO Incident First Alert: Main Contractor Name - LTI# - Date of Incidentzam110No ratings yet

- SOP For Plant & Equipment RepairDocument1 pageSOP For Plant & Equipment Repairzam110No ratings yet

- Reporting of HSE Incidents - Flow ChartDocument2 pagesReporting of HSE Incidents - Flow Chartzam110No ratings yet

- 2017 2018Document116 pages2017 2018zam110No ratings yet

- The Sayings and Wisdom of Imam Ali (As)Document145 pagesThe Sayings and Wisdom of Imam Ali (As)zam110No ratings yet

- BuildingDocument370 pagesBuildingzam110No ratings yet

- Timeline Free PowerPoint Template WDDocument6 pagesTimeline Free PowerPoint Template WDzam110100% (1)

- Methodology For Classifying and Remediating Incidents and BreachesDocument9 pagesMethodology For Classifying and Remediating Incidents and Breacheszam110No ratings yet

- Line of Fire Incident Prevention: Compiled by Rudi NieuwoudtDocument3 pagesLine of Fire Incident Prevention: Compiled by Rudi Nieuwoudtzam110No ratings yet

- Off-Plot Delivery Contract - C31/603: Az-HsemDocument1 pageOff-Plot Delivery Contract - C31/603: Az-Hsemzam110No ratings yet

- PDO Incident First Alert: Main Contractor Name - LTI# - Date of IncidentDocument1 pagePDO Incident First Alert: Main Contractor Name - LTI# - Date of Incidentzam110No ratings yet

- 88-0000-S-90-04-O-0015-00-E Appendix 1Document2 pages88-0000-S-90-04-O-0015-00-E Appendix 1zam110No ratings yet

- Tool Box Talk Procedure: Hazardous Activities Standard Rev 04Document6 pagesTool Box Talk Procedure: Hazardous Activities Standard Rev 04zam110No ratings yet

- Chemical Management StandardDocument26 pagesChemical Management Standardzam110No ratings yet

- 8-Occupational Health and Hygiene Standard Appendix 3 - International Requirements For Health and HygieneDocument13 pages8-Occupational Health and Hygiene Standard Appendix 3 - International Requirements For Health and Hygienezam110No ratings yet

- ESReDA Training Toolkit Investigation Learning 2015-May-Final-1Document52 pagesESReDA Training Toolkit Investigation Learning 2015-May-Final-1zam110No ratings yet

- Hand Arm Vibration Syndrome HAVSDocument12 pagesHand Arm Vibration Syndrome HAVSzam110No ratings yet

- Unit 8: Part 2 - Mechanical Handling: NEBOSH Health & Safety CertificateDocument12 pagesUnit 8: Part 2 - Mechanical Handling: NEBOSH Health & Safety Certificatezam110No ratings yet

- Traffic Light ChartDocument2 pagesTraffic Light Chartzam110No ratings yet

- Retrofitting A Telematics Control Unit With Bluetooth Technology TCU B841405 E9xDocument6 pagesRetrofitting A Telematics Control Unit With Bluetooth Technology TCU B841405 E9xnmaiorNo ratings yet

- For UploadDocument17 pagesFor UploadPradeepaNo ratings yet

- TPM Conference With Peter WillmottDocument1 pageTPM Conference With Peter WillmottAniko AntalNo ratings yet

- FeasibDocument36 pagesFeasibDandy Salvadora0% (1)

- Module 17.3 Propeller Pitch ControlDocument56 pagesModule 17.3 Propeller Pitch ControlSulaimanNo ratings yet

- Dr. Mikel Harry - 1.5 Sigma Shift ExplanationDocument1 pageDr. Mikel Harry - 1.5 Sigma Shift Explanationanjo0225No ratings yet

- Inventories 2Document1 pageInventories 2Vel JuneNo ratings yet

- GSK Part 1 Oct 2010 - Compressed - PPT Auto Saved)Document88 pagesGSK Part 1 Oct 2010 - Compressed - PPT Auto Saved)Agbor Joseph100% (1)

- PHD Thesis On Big Data in Official Stati PDFDocument134 pagesPHD Thesis On Big Data in Official Stati PDFJoel Yury Vargas SotoNo ratings yet

- Model Aircraft 2016-11Document76 pagesModel Aircraft 2016-11Ajay Kumar89% (9)

- Novac System Inspection, Test and Maintenance: InspectionsDocument8 pagesNovac System Inspection, Test and Maintenance: InspectionsMohamed AshikNo ratings yet

- Work Cell (Layout Design Concept)Document27 pagesWork Cell (Layout Design Concept)ankurume1984No ratings yet

- Multibrain CFU008-12 MembraneDocument2 pagesMultibrain CFU008-12 MembraneJack SongNo ratings yet

- Indian Electrical Motors LimitedDocument12 pagesIndian Electrical Motors LimitedPrashant PuriNo ratings yet

- Dst-Water Technology Initiative Programme (Wti) - GuidelinesDocument26 pagesDst-Water Technology Initiative Programme (Wti) - GuidelinesJegan ParamasivamNo ratings yet

- Hot Rolled Structural Shapes Manufactured From Steel Scrap.: Environmental Product DeclarationDocument25 pagesHot Rolled Structural Shapes Manufactured From Steel Scrap.: Environmental Product DeclarationmariaNo ratings yet

- Fim - Noor Hanira Mahidin (cd8992)Document24 pagesFim - Noor Hanira Mahidin (cd8992)Anastasia BujujanNo ratings yet

- Iphone SFIDocument30 pagesIphone SFIankitsanganeriaNo ratings yet

- Midspan Conductor JointDocument11 pagesMidspan Conductor JointHarry Gusti NugrohoNo ratings yet

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96No ratings yet

- Admin GuideDocument216 pagesAdmin GuideNicolas InfanteNo ratings yet

- Ericsson Businessphone PDFDocument2 pagesEricsson Businessphone PDFJamesNo ratings yet

- Forklift CatalogDocument29 pagesForklift CatalogAndrew Black100% (2)

- Elysian Presentation (White)Document62 pagesElysian Presentation (White)Idzhar TianNo ratings yet

- Final Estimation For Rate PreparationDocument5 pagesFinal Estimation For Rate PreparationmanojNo ratings yet

- Ata 71 Power PlantDocument38 pagesAta 71 Power PlantAlejandroNo ratings yet