Professional Documents

Culture Documents

Redwood Canoe PDF

Redwood Canoe PDF

Uploaded by

Rodrigo Miranda0 ratings0% found this document useful (0 votes)

56 views7 pagesOriginal Title

redwood canoe.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

56 views7 pagesRedwood Canoe PDF

Redwood Canoe PDF

Uploaded by

Rodrigo MirandaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

Se YS

Pree wr ag

you can build

PSeae ie tree (iy

CLL aad

Wou'can build this 74-pound, 16-foot

canoe for $84. For a new canoe, that's a

real bargain. You use redwood strips, an

CTE STi ra Cra nT Come ce et

Plas core ca eN a eee

to tho crosspieces, Nail a strip down the cen-

forte hatd the stems and Yoniplates in positien.

prototspe canoe took abiont three weekends

to build, She's bread of beans and flatbot-

tomed-amidship: Two persons can sit side

by side-in the: center; with one=person at

each end and plenty-of room for gear.

This canoe is formed around plywood

templaies using 3”-by-%” redwood strips,

glued edge to edge, You hiy up the’ strips,

remove. the form, and the canoe’ is cam-

plete, escept for fiberghssing and putting

in the seats.

How to start. First, lay out. the patterss

full size on lange shedts of heavy brown

wrapping popes. Since a éamoe is sym-

metrical front to back and side: to side,

you teed draw full-scale patterns of only

half of each template, forming half of the

cance. The pattems are flopped to draw

the othor half of cach template: duplicate

templates are mede from these for the

othier half of the cance. Draww the template

patterns using a 18” grid as shown in: the

blueprint.

Build the fonn from four two-by-fours.

Make it square, solid, and Jovel; the finished

canoe will be no better than the-form is

made on, If built as shown, it cus be con-

verted into a bench for working on the

canoe ight side up.

Cut the templates from 8” plyword and

sorow them to the building form. Make

sure they are centered and vertical. Put on

templates 1 and 9 fist; then shieteh a

string over the center of these between the

ends. This lets you line up theother tem-

plates, Next, make the caoe’s sterapleces

172 | Poruian soietice

4D) ‘egmood sti ara tacked to the templates,

and edgegiued, Drive brads through into the

templates before putting on fiberglass cloth.

and sétithom in, place om the frame: Glue

theo pieces'of white pine together for each

stem, and trace the Jines from the full-size

drawing on exch, Bevel each plece ta ac-

copt the redwood side strips. ‘Tie together

the stempieces and the tomplates with a

1” -sauuaro strip of wood.

Nex! rip. the longer steaightgrain red

‘wood plonks (see Materials List) into'strips

XY Wide. Yon need about 70 of these

Strips to make the canoe hill,

Tefore phinking the hull, put smacking

tape alone the edge of exch template. to

keep ghie from sticking tot. Start planking

at the gunwales, using 1” No. 18 brads to

5

Reinforcing strips are:put on each stem after

the hull gets: ie fst coat of resin. Hull is

with two layers of glass and resin,

Bevel strips so they mest in front of stem.

A tight fit is not necessary, since the stems

Bre covered with two layers of clot ana resin,

nail each strip to the templates, Place the

strips so thet the 2” width forms the thick-

ness of the hall. Don't nail the strips to the

endpieces yer.

After each strip is nailed in place, put

Elmer's Glue-All along its edge. As you

lay each strip in place, hold it firmly axainst

the strip below aud nail it to each plywood

template.

Do this until you have three or four

strips on each side in place. Then eut cack

strip aff ¥” beyond the stempieces. With

a sharp knife, cut the inside of the strips

to an angle that lets them meet in a point

{See lie-flat Blueprint on the following

Hull is placed in tilted position on the bulld

Ing fornt for easy working of inside. Only one

layer of cloth and resin is needac on inside,

Se ze

‘Clamping jfgs hold the strips in place when you

reach the point where twist gets bad. Scraps

trom the beveled stem make good clamping pads.

heyond the stempieces, Glue them with

resorcinol and nail them with X” copper

nails.

A little ingenuity is needed to clamp the

ends of the strips tight. A large mbber band

{cut from an old inner tube} tightened

with a stick through one end does a good

job.

When you have added about 19 strips on

each side, the twist at each end gets pretty

bad. Clamps, shown in photos, hold them,

When about 25 are on, the strips meet

along the keel. Gut them to meet in a

staggered line along the keel

two pager. Test continued an page 200]

Finishing touches inchide adding gunwales,

inmates, seats, yoke, and breast plates. You

weave seats with webbing ss shown in blueprint.

Wp duanes? * prot foe

: 8

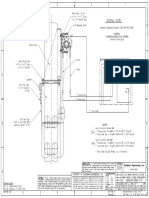

J FRAMES

tal aNNWOED

stem Sa%s@ snip

SUPFROWLNND (TEMPORARY)

pas Ie ae x

EY

‘gies mL BA |

Wiese

aD"

wooo

change

byte ott

AuMiNuM

ot

Wheu all strips are in place, sand. the

hull and give the outside ‘a af poly

ester or epoxy resin. When this has. set,

thin-point nail set and punch all

sch strip through, into the farm,

‘over the outside with glass cloth and

another coat of resin, Start at the center

and work the cloth toward each ead, A

few staples hold it while you apply the resin.

Use inexpensive painthrashes to apply

the resin, Wear rubber gloves, and use a

squeegee to work the resin through fiber-

After the voat of resin, fit an

“stip of fiberglass ut éach end to over-

lap about 2” on each side.

‘When the resin is set, sand the rough

spats amd apply the secund coal. Two coats

of cloth and resin should be enongh.

Removing the templates. After the out-

side is finished, take out the sevews that

hold the templates to the form, and care-

fully remove the templates. ‘To de this,

push them toward the larger part of the

hull. ‘Turn die canoe right side up on the

Intiding form to work on the inside,

Sand the inside. and coat it with re

Shape and attach the keel before glass

ng

and finishing the ititerior, The blueprint

shows how to change the building form to

hold the caine at an angle; it makes work-

ing inside easier.

Cover only: half of the inside at a time.

‘This lets you overlap the glass-at the center

for more strength, Before putting. in the

fulllength glass cloth, work some left-over

pieves in at the stems.

You can cut GO”-vide cloth in half

and staple Ue _selv about 8” over the

center ling so that the keel, serews are: cov

ered. Work it up the sides and toward

cach end. A few staples may be needed

slong the top edge unlil the resin is on;

they may then be pulled ont. Que liyer of

resin and cloth ds enough inside.

When the resin is set, trim off the excess

glass cloth, Attach fhe gumwales and in-

wales with cither serews or bolts

Build-and varnish the seats, breast plates,

12 yoke. und fasten them in place.

These phinis [et you build x 13° canoe,

too, You build it the same way, but you

oliminate templates {-and 5, making tem-

plate G the center of the hull. Nothing else

necd be changed. De

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cablebolting in Underground Mines PDFDocument210 pagesCablebolting in Underground Mines PDFCarlos A. Espinoza MNo ratings yet

- Mechanistic Insights Into The Durability of Ancient Roman ConcreteDocument13 pagesMechanistic Insights Into The Durability of Ancient Roman ConcretePaulaNo ratings yet

- Modular C5 FloatsDocument2 pagesModular C5 FloatsPaulaNo ratings yet

- Technical Bulletin No. 1: Basic Formulas of Static StabilityDocument8 pagesTechnical Bulletin No. 1: Basic Formulas of Static StabilityPaulaNo ratings yet

- Stability Publications FlexiFloatDocument19 pagesStability Publications FlexiFloatPaulaNo ratings yet

- S70 - FlexiboatDocument1 pageS70 - FlexiboatPaulaNo ratings yet

- Deck Cleat Working DrawingDocument1 pageDeck Cleat Working DrawingPaulaNo ratings yet

- Enciclopedia SismicaDocument3,996 pagesEnciclopedia SismicaPaula100% (2)

- Linux Editores de Texto - IntroducciónDocument7 pagesLinux Editores de Texto - IntroducciónPaulaNo ratings yet

- Us Forest Service: Engineered SolutionsDocument1 pageUs Forest Service: Engineered SolutionsPaulaNo ratings yet

- Gouge On Brothers On Boat ConstructionDocument412 pagesGouge On Brothers On Boat ConstructionNilson Olympio100% (1)